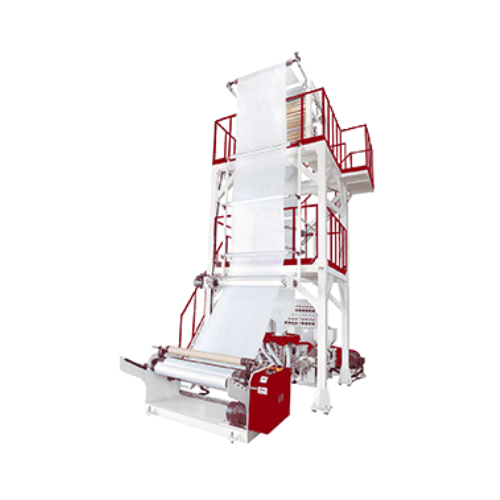

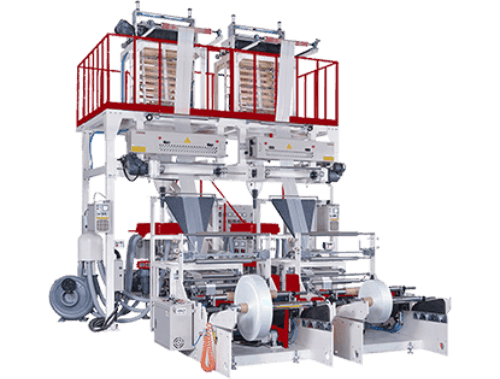

Back to Back Blown Film Winder is constitute with two stations that back to each other. Typically, it combines two winding stations with familiar machine functions into a complete set. With the various function, it produces both single layer and two-layers film. Besides, the machine is available to divide into two bodies for independent working according to the requirements of customer as well. By then tension of machine, it makes the film collecting flatly without uneven edges. For the different use of film, customers are available to equip with Slitting Device and Side Open Device on Back to Back Blown Film Winder.

After the processing of Take-Up Unit, the film becomes extremely flat and reaches the first step of Extrusion Blown Film Winder. The main function is to collect the film perfectly without uneven edges on the collecting roll. A high precision Blown Film Winder is to maintain the average air content value between each layer of film to avoid uneven and unregularly positions. On the process of Blown Film Winder, the film first passes Surface Winding which made of rubber and steel bars. By the interaction of these two bars, it stretches the film to maintain its tension. Next, the film sticks on the rotating roll which called on-line Roller to collect it. Leading the plastic film to follow its direction in order to winding it. Then, when the on-line roller reaching the required meters or wound-up diameters, the Shifting Forks replace the position of Standby Roller for the next winding. At this time, we usually use Knifes to cut the well-wrapped roll down. Besides, for the different use of film, Extrusion Film Winder will equip with Slitting Knife and Side Open Knife to cut. Side Open Knife splits the film into two parts for the products such as cling wrap, shrink film, etc. And Slitting Knife cuts the film into strips for the different demand of size. Further, with the option of automatic system, it increases the higher efficacy for Winding Unit.

- Apply for various kinds of roll materials

- Install inverter to control tension of film

- Simple appearance and invisible circuit

- Apply for various materials

- Automatic cutting

- Auto roll alternation /Auto roll rewinding