3 in 1 Plastic Recycling Machine has become dominant among series of plastic recycling machine in recent years. Compared to hopper feeding and side feeding recycling machine, 3 in 1 plastic recycling machine makes higher efficiency of production and obvious reduction in labor cost.

The buyer is packaging film products manufacturer. There is a need to recycle all scrap films and edge-trimmed materials from production and packaging in respond to global market trend, public awareness of environmental concerns and also saving the cost of raw materials prominently.

What’s more, our customer matters the quality of final plastic pellets which can be reused for future application. Genius’ cutter compactor plastic recycling machine features high value of plastic pellets and product durability. That’s why our buyer relies on us. This is the first success in California, U.S.A. We firmly believe that this is a good start in the west and expect to embrace more opportunities of Genius’ machine installations.

Country: United States

Related Machines: Cutter Compactor Plastic Recycling Machine

What KRIEGER SERIES bring to our Indonesian buyer?

Providing well-organized recycling solution for customers! Our cutter compactor plastic recycling machine is designed to process in-house film waste. What the customer needs is to recycle and reprocess post-industrial waste, i.e., LDPE and HDPE.

Making high standard final plastic pellets is our core value. A good and long-term international industrial cooperation involves product quality, production efficiency and company reputation. The buyer is doing a commercial project with Japanese enterprise. Fine product quality and high output are the primary concern for the customer.

Normally, three meshes is basic equipment for a cutter compactor plastic recycling machine. In this case, it has four sieves with fine and large meshes and the largest mesh is #150. The customized filter design greatly removes the impurities from the recycled waste.

What’s more, the machine is equipped with the latest pelletizing device. As a result, the quality of the final product outweighs the rest. More importantly, the overall output achieves 500kg/hr.

Fine plastic pellets help our customer enjoy good reputation for quality and maintain stable business relationship with the Japanese company.

Country: Indonesia

Related Machines: Cutter Compactor Plastic Recycling Machine

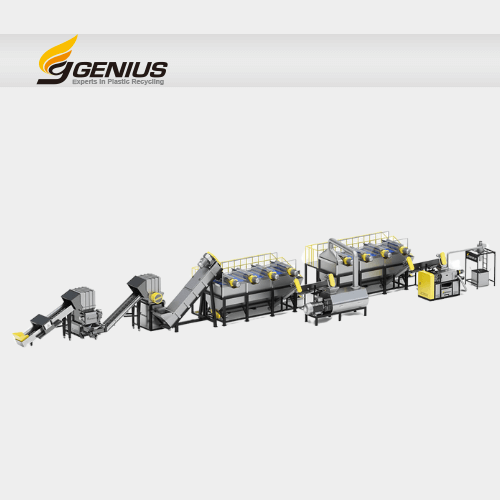

This client is regarded as the biggest plastic bag making company in Southeast Asia which has five divisions and the place is around 300 hectare. The production line has 400 blow film machines running synchronously and the main product is LDPE plastic bag.

After KRIEGER’s installment in Vietnam, the daily productivity is around 13 tons equal to more than 500 KG per hour.

The Vietnamese client says: KRIEGER can process our redundant material to re-pelletize and the quality of pellets is excellent which can be used for the purpose of blow film. The advantages are saving costs, automatic design, and labor-saving. We just need to assign two people to take care of the machine then it will be fine.

The client placed a repeated order for the same machine due to KRIEGER’s extraordinary performance. The second machine installed in Vietnam on the estimated date of May, 2017.

Country: Vietnam

Related Machines: Cutter Compactor Plastic Recycling Machine

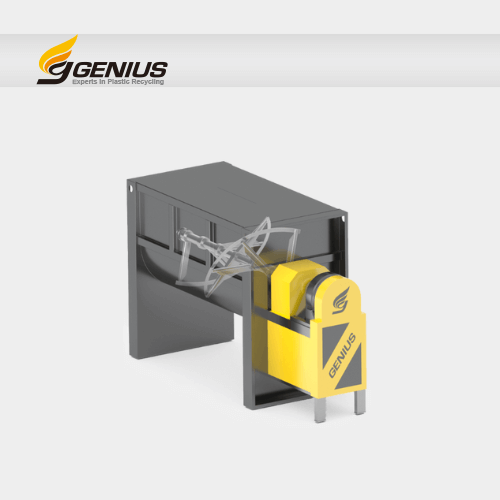

KRIEGER-Z-125i

After 90 days of systematic and careful production, 7 days of shipping, and 4 days of installation, KRIEGER-Z-125i has finally been installed successfully in Daegu, Korea.

The new model of two-stage extruder: Z type

In the two-stage extruder we had seen in the market in the past, during the propelling of material from the main to the sub extruder - if the rotation and speed aren’t in sync - they get stuck in the hopper. And this sometimes leads to an overflow of material.

Furthermore, since the material goes into an open-type hopper, it discharges smoke and bad smell - burnt plastic smell.

In this brand new Z Type two-stage extruder, the main and sub extruders are already joined. Therefore preventing the material from getting stuck. Also the gas/smoke it releases is much less. NO MORE POLLUTION!

In addition, this setup effectively saves space and manpower! You’ll NEED ONLY 2 TO 3 WORKERS to operate the whole machine/plant.

This machine is now in full operation in Korea and is already processing PE foam and the productivity is up to 400 kg per hour.

Country: South Korea

Related Machines: Cutter Compactor Plastic Recycling Machine

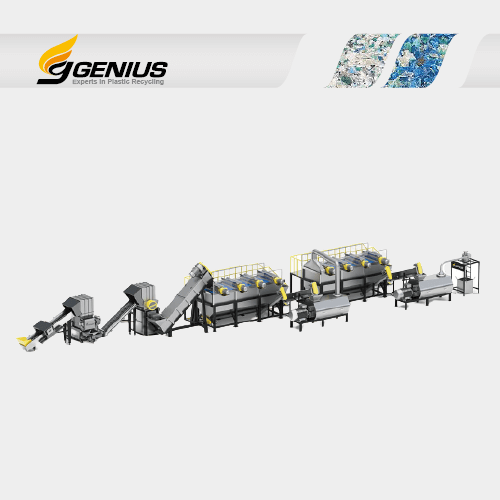

Genius Machinery Co., Ltd. specializes in plant integration planning for plastic recycling machinery. It provides one-stop production line services, which include a whole series of plastic washing plants, plastic recycling machines, plastic squeeze dryers, plastic crushers and plastic shredders. Genius’ equipment offer excellent performance and the ability to produce high-quality pellets. For this reason, that Genius’ recycling system is prominent in the global plastic recycling market.

To satisfy the needs of the ever-expanding market, a PE recycling giant based in Taoyuan, Taiwan; invested a new plant in Changhua 2017. They purchased 3 squeeze dryers from Genius Machinery Co., Ltd. and installed 3 new production lines (2 of which, were pelletizing production lines). In addition, they plan to expand the fourth production line in 2020. The integration of the new plant with the existing Taoyuan plant has allowed the company’s operation scale to soar, while production capacity increases by many folds.

This Taiwanese PE recycling giant has worked in collaboration with Genius Machinery Co., Ltd. for over 30 years. Working side by side, the two companies have helped each other grow and succeed. As Genius’ client, the PE recycling giant continuously provides Genius with user feedback, enabling Genius to constantly enhance their recycling technology. In return, Genius Machinery Co., Ltd. became a strong pillar and foundation, which allowed the PE recycling company to expand from their initial HDPE chemical barrel business, to include LDPE, LLDPE industrial film recycling.

Having acquired impressive results, the PE recycling company stated: “Genius’ astounding plant integration planning makes production lines smoother and the production efficiency has since, greatly improved.” Recalling the initial stages of their collaboration with Genius, the company also stated: “Genius really put themselves in our shoes and proposed improvement plans that accounted for production capacity, quality, and production costs. That is why more than 80% of the present production equipment in our plants came from Genius.”

Genius states, that through the introduction of their plastic recycling machines, universal knife holders and the continuous improvement of machine structure, not only have manual operation errors been effectively reduced, but production capacity and the quality of plastic pellets have also increased; granting the user improved competitiveness. As an illustrative example, the introduction of Genius’ system into a product line increases production capacity from 300 kg/hour to 700 kg/hour under the identical conditions. Genius is taking the market by storm with the excellent performance that its plastic recycling systems deliver.

Country: Taiwan

Related Machines: Film Washing Line

In the beginning of 2019, GENIUS installed a new Plastic Recycling machine in Korea.

The customer used to own a Korean machine with strand pelletizing system. However, its capacity only 300kg/hr. Year by year, the labor cost is becoming much higher. Due to above reasons, the customer decided to improve the efficiency of his production line.

Generally, PP pellets were never been made by hot die cutting device in Korea. The customer thought it’s impossible. Therefore, the GENIUS team developed the special designed die face cutter which can pelletize sticky material.

The key point of cutting PP pellets is adjustment of cutter, but it is not easy to achieve.

Country: South Korea

Related Machines: Cutter Compactor Plastic Recycling Machine