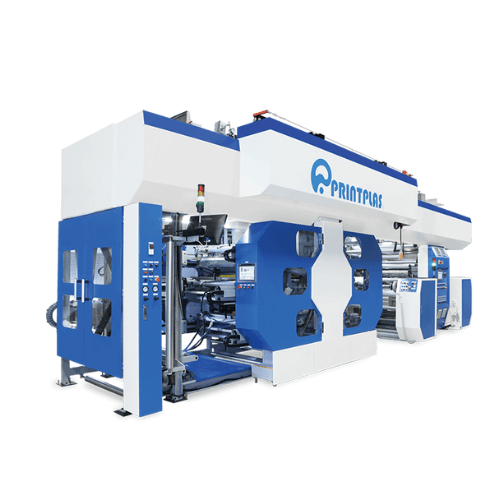

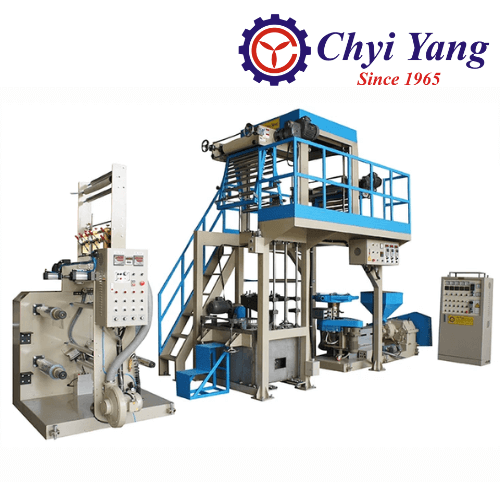

4/6 COLOR CI HIGH-SPEED FLEXOGRAPHIC PRINTING MACHINE PKF-6CI SERIES

Categories : Flexographic Printing Machines

Equipped with internet accessible control system for remote diagnoses of programming and electronic components. CI Flexoprinting Mahcine Flexographic Printing Machine FLEXOGRAPHIC PRINTING MACHINE FLEXO PRINTING MACHINE FLEXO STACK PRESS FLEXO PRINTING PRESS CI PRINTING PRESS CI PRINTING MACHINE PAPER PRINTING MACHINE PAPER PREPRINT PRINTING MACHINE OFF LINE PRINTING MACHINE

Low Pressure Proportional Regulator(0-8bar)

Categories : Indicators and Sensors

Product Serial: QKL-B1T.B2T/QKL-B3-1.B3-2/QKL-B3-1A This series is a complete closed loop servo system consisting of two solenoid valves, an internal pressuretransducer, and electronic controls. Based on analog signal, the pressure is controlled by two solenoidvalves to maintain precise pressure; one valve functions as inlet control, the other as exhaust. The pressureoutput is measured by an internal or an external feedback pressure transducer that provides a feedbacksignal to the electronic controls. The regulator is suitable for industries that require precise pressurechanges at any time and monitor pressure values. Available with 3 selections of input signal: 0-10VDC,4-20mA, or RS485 Modbus. Monitor signal can be chosen from 1-5V, 0-10V, or 4-20mA. Internal pressuretransducer comes with B1T, B3-1, and B3-1A series, whereas B2T and B3-2 uses an external pressuretransducer for feedback (ideal for when the vessel is distant away from the regulator). All our products have CE, SGS, RoHS certification with ISO13485 quality system.

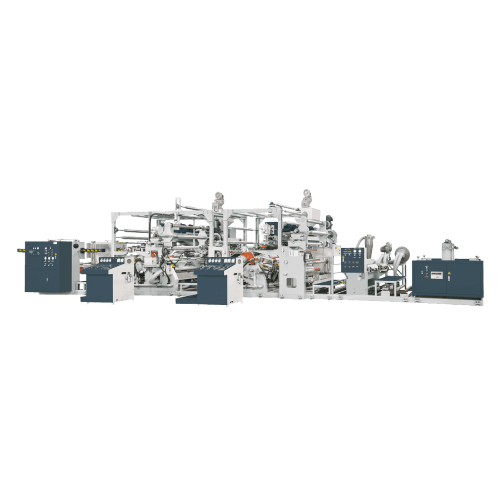

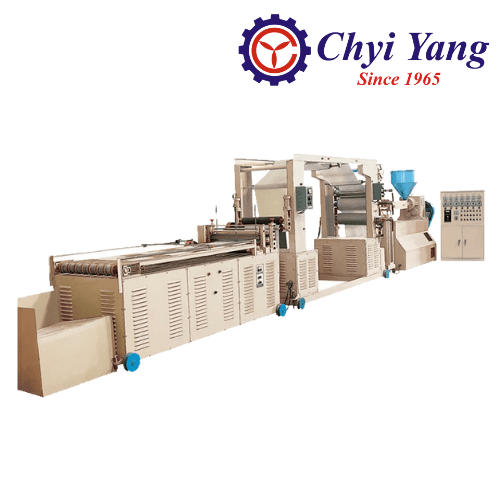

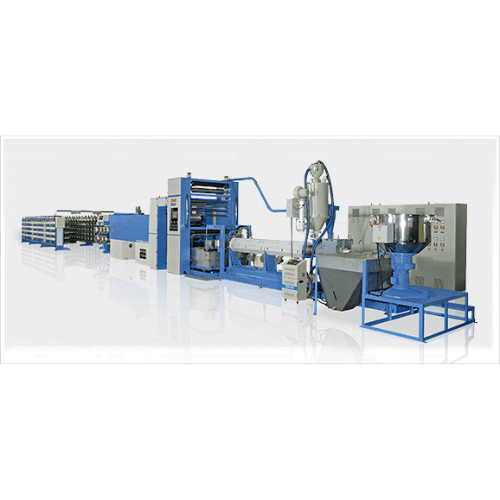

Tandem Extrusion Lamination Machine (YSL-T)

Categories : Industrial Lamination

This series of machines are available for tubular woven bag, other working materials to do double side lamination process.

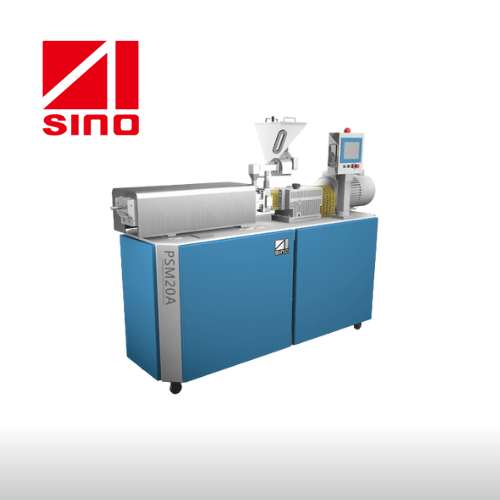

Clam-Shell Design Co-Rotating Twin Screw Extruder-PSM20A

Categories : Granulators

The PSM20A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

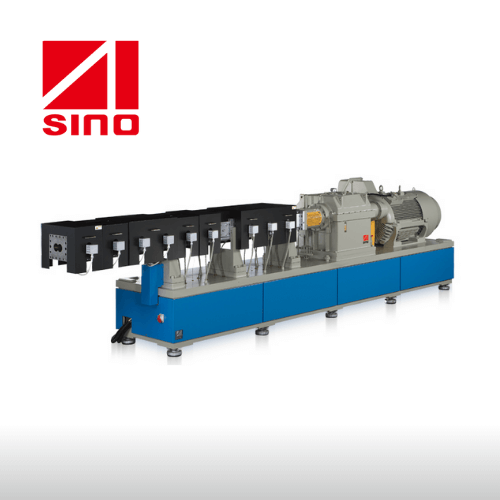

Co-Rotating Twin Screw Extruders-PSM72A

Categories : Twin Screw Extruders

The optimization of the PSM72 series resulted in more efficient and durable designs. The PSM72 series has mid range production capabilities, and easy operation in reasonable price. All PSM72 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

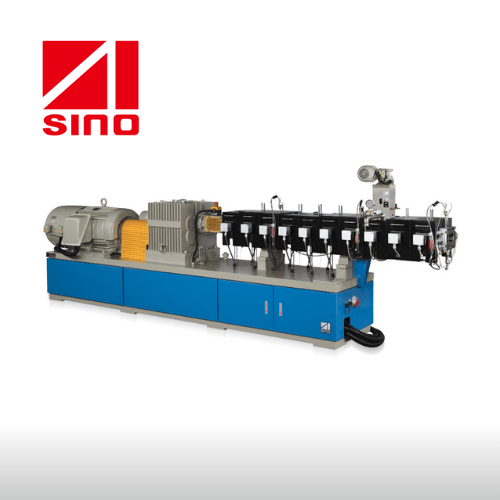

Co-Rotating Twin Screw Extruders-PSM50

Categories : Twin Screw Extruders

The optimization of the PSM50 series resulted in more efficient and durable designs. The PSM50 series has mid range production capabilities, and easy operation in reasonable price. All PSM50 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

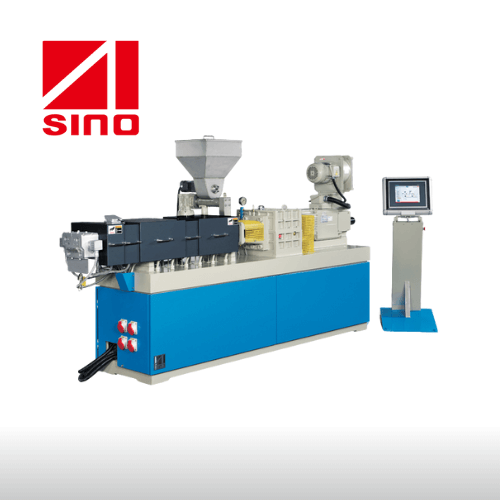

Compact Co-Rotating Twin Screw Extruder-PSM30A

Categories : Twin Screw Extruders

The PSM30A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM30 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

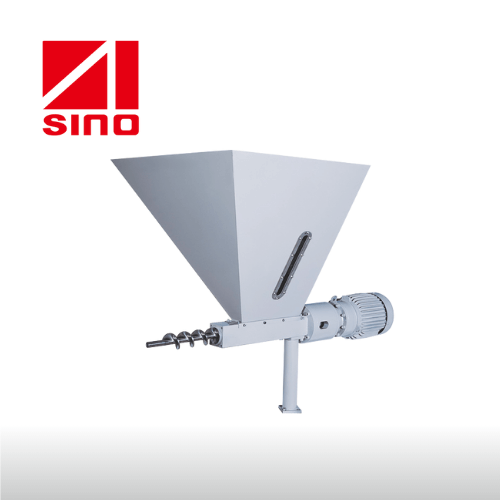

Single Screw Feeder-PSA

Categories : Feeders

The PSA series single-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSA single-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Options include standard double-flight, single-flight, T-type, and spring type screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

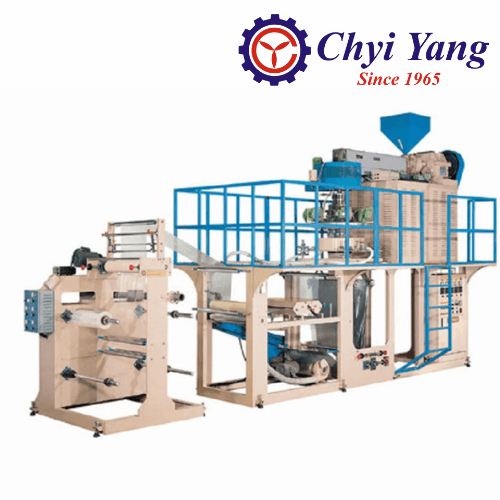

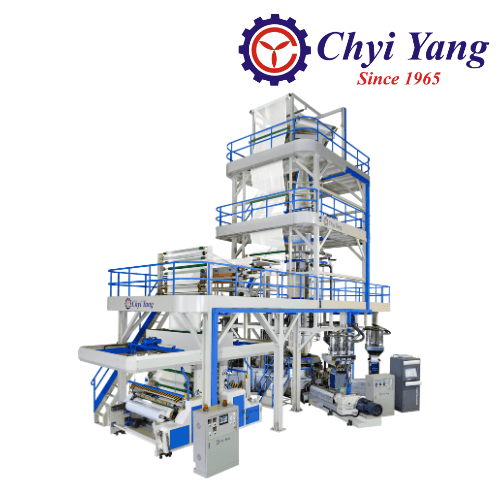

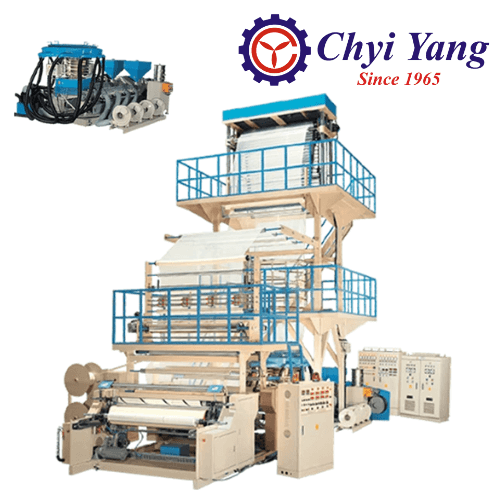

Two Stripe Color Blown Film Machine

Categories : Blown Film Extruders

TCP-H is designed by two independent motors, gear boxes and extruders to produce films with two colors stripes TCP-SE is designed by one motor, one gear boxes & two extruders to produce film with two colors stripes TCP-H makes width of two colors can be adjustable TCP-SE is for saving cost of machine & less capacity The precise die design makes the colors vivid, clear & won’t be mixed together Purchasing a 2-layer co-extrusion die can produce 2-layer film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

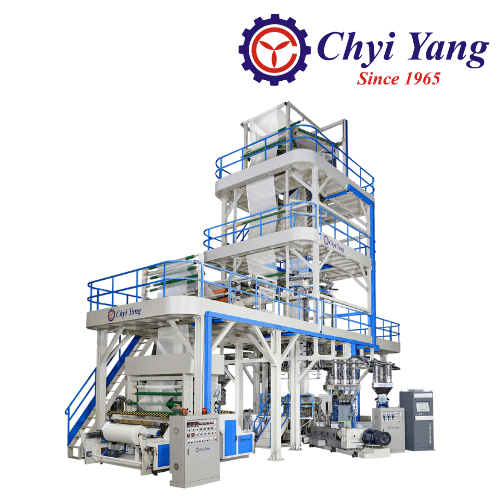

Super High Speed Two Stripe Color Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

TCP-H series is two gear boxes driven by two motors makes colors width can be easily adjustment. TCP-SE series is one gear box driven by one motor for small capacity & saving cost. TCP-TD series is two dies & two gear boxes driven by two motors for double output. TCP-FD series is forced feeding type with two dies & two gear boxes driven by two motors for more than double output & faster speed. Purchasing extra LDPE die can produce LDPE film. Purchasing extra 2-layer co-extrusion die can produce 2-layer film. Double extruders increase the output. Precise die design makes sure the colors vivid & clear.

Super High Speed HDPE/LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Easy installation & operation Adjusting thickness easily by screws of die, high capacity & less plastic waste Automatic flying cutter & manual change reels winder, flying cutter to match the machine speed, won’t be re-winded on the nip roller Main Motor is driven by inverter for better performance & less electricity Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

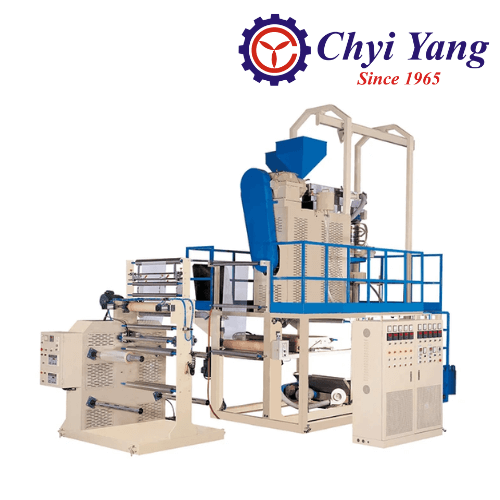

PP Blown Film Machine

Categories : Blown Film Extruders

Water cooling system makes glossier and more transparent PP film for food or garment packing. Unique screw provides high production for a long period life and holds film uniformly steady. Dry chamber provides a fast water removal, for food package purpose. Optional tension control for winder provides good tension film in rolls, used in food packaging & printing. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

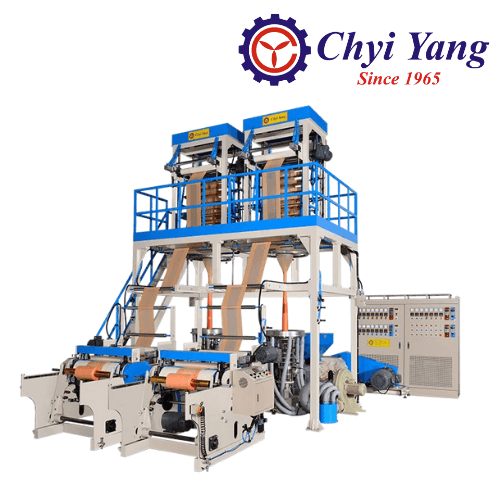

High Speed Twin Die Blown Film Machine

Categories : Blown Film Extruders

TDH series is one extruder provides two dies to get bigger capacity & less space. TDH-S series is standard machine. TDH-F series is forced feeding type for more output & faster speed. Purchasing extra LDPE die can produce LDPE film.

Mini Type Blown Film Machine

Categories : Blown Film Extruders

Designed for T-Shirt bag and flat bag production Small occupancy of space Simple, flexible and economic operation High output and saving energy Also can work with LDPE resin if changing air ring Film thickness HDPE 0.008~0.06 mm

LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Double lip air ring & better cooling system to support the high speed capacity Can produce LDPE, LLDPE and shrinkable film Slitting device and double winder (up-and-down & back-to-back type) is offered to produce single layer film rolls. Optional Rotating die device is making uniform thickness film for printing & laminating purpose Optional Co-speed controller matches same speed for take-up unit and winder to avoid film to be stretched Purchasing HDPE die can produce HDPE film Fully automatic winder makes machine automatically & save time of operators We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

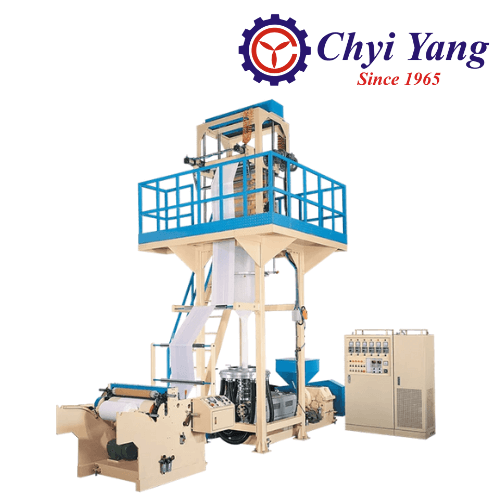

HDPE Blown Film Machine

Categories : Blown Film Extruders

HDPE Blown Film Machine, CHYI YANG is Blown Film Extrusion Machine and Blown Film Machine Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

PVC Shrinkable Film Making Machine

Categories : Blown Film Extruders

Produce shrinkable PVC film for labels, goods packaging etc. Hot water chamber & cooling size ring help to get a glossier, and non-wrinkle film Machine direction shrink ratio and transverse shrink ratio can be adjusted easily. Machine direction shrink ratio can be 2-5 % We didn't show all our models, please don't hesitate to contact us for bigger extruders.

2-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Available for agricultural film, coated film, stretch film, cling film, greenhouse film etc. Max film width up to 4.2 m (8.4 m in single-layer-opened film) Raw material HDPE, LDPE, LLDPE, EVA, MPE etc. Two sets of gearbox, motor & extruder for independent control For producing PE stretch/cling film, PIB liquid adhesion system can inject liquid adhesion into screw directly to save resin cost & adjust the stickiness ratio you need Purchasing PIB system can produce out-layer film non-sticky to prevent dust, in-layer film sticky to pack subjects Optional “Waste film recycling machine” lets this machine doesn’t have any waste plastic film, it can feed waste film directly into screw to save your cost We didn't show all our models, please don’t hesitate to contact us for bigger extruders.

5-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

CHYIYANG specializes in manufacturing 5-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

7-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

CHYIYANG specializes in manufacturing 7-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

ABA 3-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine, CHYI YANG is Multilayer Co-Extrusion Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

ABA 3-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

3-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Application for greenhouse sheet, agricultural films, construction sheets, food packaging, sacks, shrink films, shrink hood films, and more. Max. film width of up to 4.2 m (8.4 m for single-layer-opened films) It supports a wide range of raw materials such as HDPE, LDPE, LLDPE, EVA, MPE, PP, and others. The machine is equipped with three sets of gearboxes and motors for independent control. Optionally, a 360º Oscillating Nip roller device can be added to ensure uniform film thickness and improve the performance of the rotary die device. The machine can be equipped with a "Waste Film Recycling Machine" which enables direct feeding of waste film into the screw, eliminating any waste plastic film and reducing costs. Please note that the models shown here are not exhaustive. If you require larger extruders, please feel free to contact us.

1-Layer PE Wrapping Film Making Machine

Categories : Wrapping Equipment

Designed to produce industrial stretch film, cling film for food packing purpose, can produce shrinkable film, LDPE/LLDPE film also Slitting devices are provided to produce exactly film width you need, no need extra Slitting machine Rotating die device is provided for higher quality & uniform thickness film Producing film thickness depends on raw resin from 0.008mm Purchasing fully automatic winder makes machine automatically & save time of operators & cut film easier Co-speed controller matches same speed for take-up unit and winder to avoid film to be stretched We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

PE Foam & PE/PP Sheet Extrusion Line

Categories : Foam Extruders

T-Die Extruder machine is equipped with cutter or winder to produce PP/PE sheets PP sheet is available in file cover, stationary etc. Film thickness 0.5~2.5 mm For different machines’ structure, can produce PE, PP sheet & PE foam sheet. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

2-Layer PE Stretch Film Making Machine

Categories : Blown Film Extruders

Available for agricultural film, coated film, stretch film, cling film, greenhouse film etc. Max film width up to 4.2 m (8.4 m in single-layer-opened film) Raw material HDPE, LDPE, LLDPE, EVA, MPE etc. Two sets of gearbox, motor & extruder for independent control. For producing PE stretch/cling film, PIB liquid adhesion system can inject liquid adhesion into screw directly to save resin cost & adjust the stickiness ratio you need. Purchasing PIB system can produce out-layer film non-sticky to prevent dust, in-layer film sticky to pack subjects. Optional “Waste film recycling machine” lets this machine doesn’t have any waste plastic film, it can feed waste film directly into screw to save your cost We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

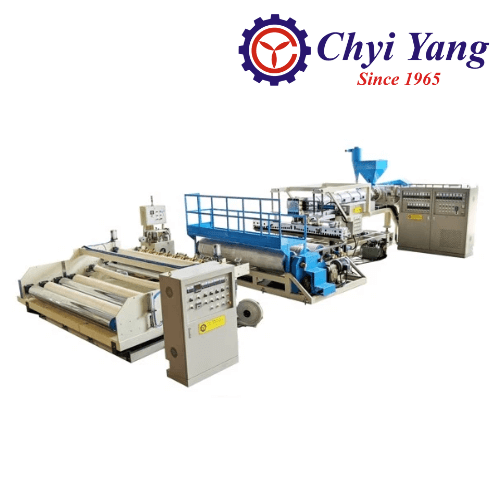

PE Stretch Casting Film Extrusion Machine

Categories : Film and Sheet Extrusion Lines

T-Die Extruder machine can produce waterproof PE film for baby diaper, sanitary napkin, folders, table cloths, medical film, etc. Film thickness 0.03~1 mm Equipped with a fully automatic winder with cutting and changing rolls functions Hydraulic screen changer for short maintenance stop We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

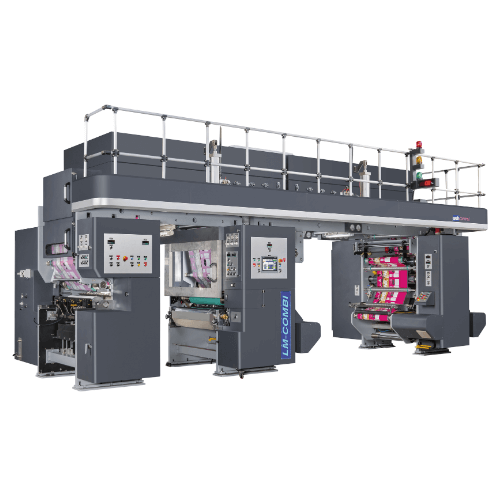

Solventless Laminating Machines LM-COMBI

Categories : Industrial Lamination

This COMBI type laminating machine combines two coating technologies, gravure and solventless coating. Stand along coating station design allows quick change between jobs. Able to clean either one of the stations during the other station is under production. Perfect choice for those who doing both coating solutions. Increasing production flexibility and securing laminating quality.

Weaving Circular Loom

Categories : Industrial Knitting Machines

● PLASTIC CONVERTING MACHINES ● INDUSTRIAL KNITTING MACHINES ● CIRCULAR LOOMS

Success Story - Waste Plastic Wash Plant

Categories : Plastic Washing Line

Waste Plastic Film Wash Plant / PE Film / Taiwan

Valve Forming Line VS-20

Categories : Plastic Bag Making Machines

This line is designed to process product from #GS-2002, finishing with feeding valve forming and mouth fold & sew, sectional elements including: ● Feeding table with optical position control ● "L" shape cold cutting unit ● Automatic "feeding valve" forming unit ● Mouth fold & sewn unit ● Automatic count stacker unit

Solvent-less Laminating Machine (WSL Series)

Categories : Industrial Lamination

For the solvent-free lamination, WORLDLY launches solvent-less laminating machine WSL series. The manipulation is much easier and simple with the PLC digital control system and touchable human-machine interface. Solvent-less laminating machine WSL series is the leading popular machines for solvent-free. It has higher compound speed in order to increase productivity. And, there is no wasted costs caused by the solvent evaporation. Also, the coating thickness is very thin with 100% solid ingredient which can reduce a lot of cost. The production won't produce solvent evaporation and there is no solvent residue. It all conforms to food safety regulations. Meanwhile, there's no need for drying chamber which can save energy. The machine itself can be shorten to save space for additional use which can make a significantly cost reduction.

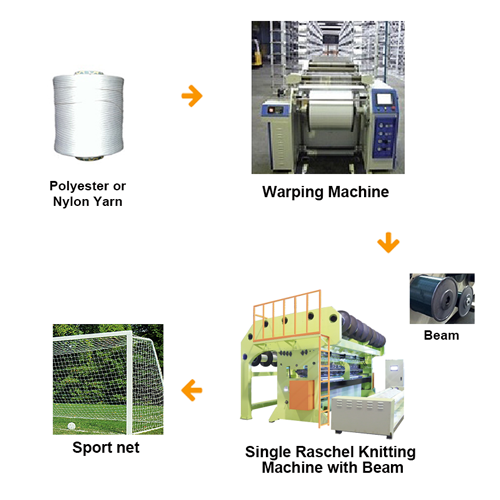

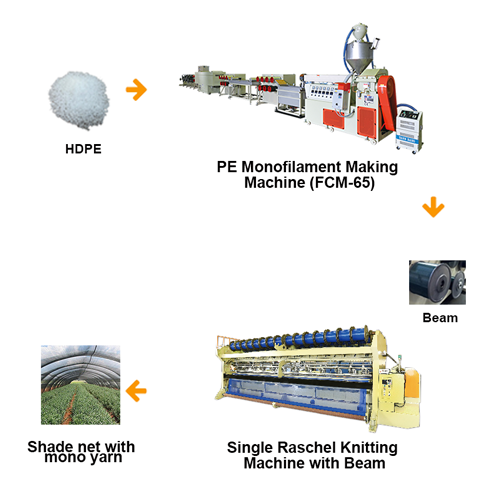

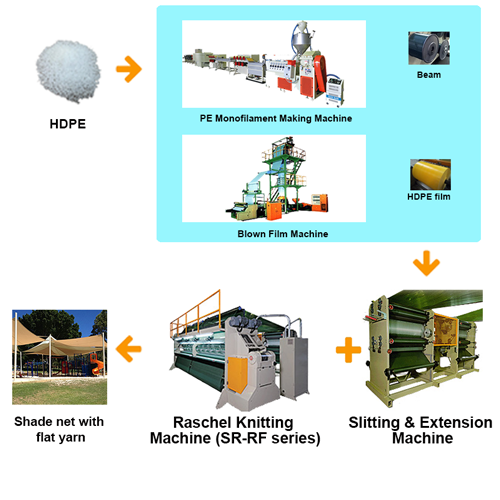

Shade Net with Mono and Flat Yarn

Categories : Industrial Knitting Machines

Shade Net with Mono and Flat Yarn

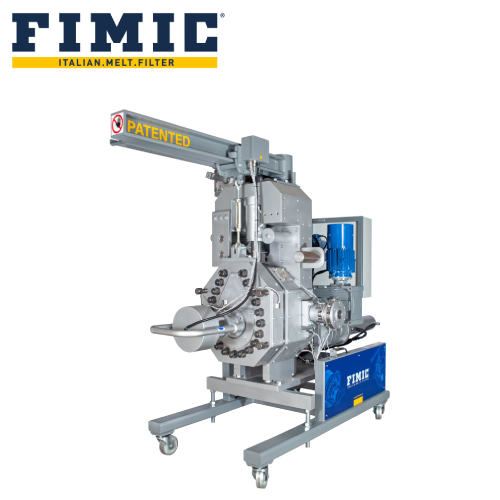

Automatic Melt Filter - RAS+REF

Categories : Plastic Waste Recycling Machines

The melt filter that made FIMIC technology renowned in the recycling field, enhanced with the possibility to work in backflush. RAS+REF melt filters can in fact operate in two different ways: in scraping mode or in backflush mode, providing more options to anyone wishing to process materials with mesh filters. REF therefore represents an ideal option for mesh processing with exceptional final results. FIMIC - Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

RAS UP 800

Categories : Plastic Waste Recycling Machines

FIMIC’s latest innovations are aimed to address the current challenges in the plastics recycling industry. RAS 800 is the new addition to the automatic self-cleaning melt filters models produced by FIMIC, its increased filtration surface (4775cm2) allows recyclers to reach a higher hourly production capacity with the efficiency and simplicity characteristic of FIMIC’s filtration technology.

AUTOMATIC MELT FILTER- TEN

Categories : Plastic Pelletizer Machines

TEN is FIMIC’s automatic screen changer capable of blocking even the smallest contamination particles thanks to its mesh, whose resistance allows to adapt the temperature according to the requirements and the material to be processed. The adjustable opening on the mesh output is a further guarantee of the quality of the end product. A small scraper close to the mesh harvests most waste and prevents it from breaking when it is changed. Its 1.465 cm2 filtering surface has a low load pressure; it therefore excludes any danger of degradation. It is also possible to adjust the mesh changing speed, setting a target pressure at which it will be automatically switched, to fit all the workflow to the material to be filtered. Furthermore, when changed the mesh is held by the material pressure itself and doesn’t needany other auxiliary systems. The mesh proper is available in varying filtration levels, starting from 80 micron / 170 mesh. TEN can also be adapted to finer filtration levels equipping custom made meshes. Quick opening is also always guaranteed. There’s no need for dedicated tools or skills, for FIMIC provides a pneumatic screwdriver at the time of purchase. FIMIC - Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

Automatic self-cleaning screen changer - RAS

Categories : Plastic Waste Recycling Machines

Any contamination the filter collects is scraped from its surface by two blades, and then gathered by the blade-holder. Finally, anything harvested is automatically ejected through the front valve. Another important feature is the possibility to determine a pressure set-point (in pressure mode) with nothing more than a few taps on the touch screen, so that once such level is reached the blade holder (running at adjustable speed) will proceed to gather the contamination, opening the front valve only on a full cycle. In the event of a particularly contaminated input material, the filter cant be set to work in continuous mode: the blade holder will keep on scraping, while relying on temporized valve openings to discharge as needed. FIMIC- Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

EXCLUSIVE MELT FILTER- GEM

Categories : Plastic Pelletizer Machines

Differently from RAS, this model reaches a greater filtering surface due to the presence of two filtering meshes towards which all the melt is directed, alongside two scrapers and independent discharge valves. The two blades scrape the contamination the filter collects, while the blade holder rakes it in to automatically eject it through the valve. The pressure mode can be set from the touch screen, while the blade holder rotating speed is adjustable and the valve only opens on a full cycle. In the event of a higher degree of contamination, a continuous mode is available to let the blade holder scrape continuously. In this case, a temporizer will tell the valve when to discharge. FIMIC- Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

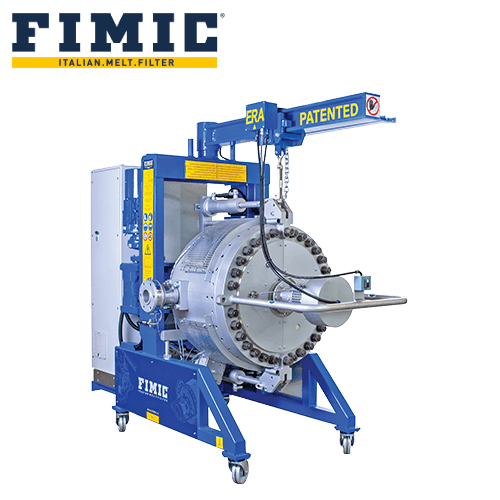

Automatic DOUBLE FILTER- ERA

Categories : Material Processing Machines

ERA is made of two internal filtration chambers and two independent discharge valves, thus enabling to setup a pre-filtration on the first step and a finer one in the second, all in the same machine! This means, in short, the possibility of using cheap punched screens (400-2000 micron) to protect the expensive laser screens (100-300 micron) coming afterwards. The resulting cost reduction is undeniable, both on the financial and energetic side. FIMIC screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

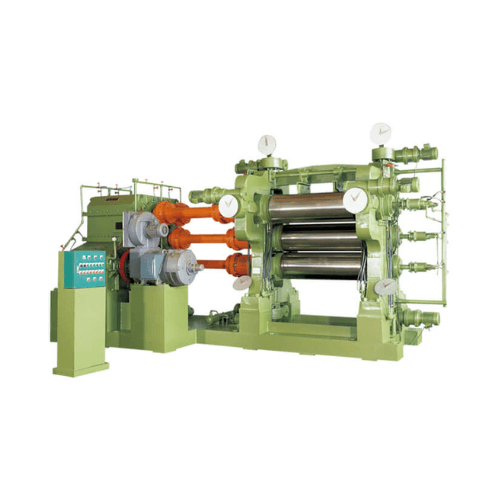

4 Roll Rubber Calender Machine

Categories : Calendering Machines / Mixing Mills

Four shaft gear couplings driven four roll inverted L Type Calender. The main use of Calender is to press the mixed and refinded rubber mixture or many kinds of plastic mixture into uniform-thickness of films, sheets, and plates. Also, it can be applied to rubber or plastic sheets in single or double sticking or topping operation with textile fabricas. Besides, in the procession of sheeting, the machine can also press out the air in the material for producing the products without air bubble after cure. The more quantity of rolls the calendar has, the more times of the sheets are pressed and the calendar can make high quality and even thickness of sheets. This is an four shaft gear coupling driven four roll inverted L type calendar. It applies to tire topping or friction and the manufacture of ball tubes and shoes. The operation of such durable and exquisite calendar equipment is very simple and can get high effects.

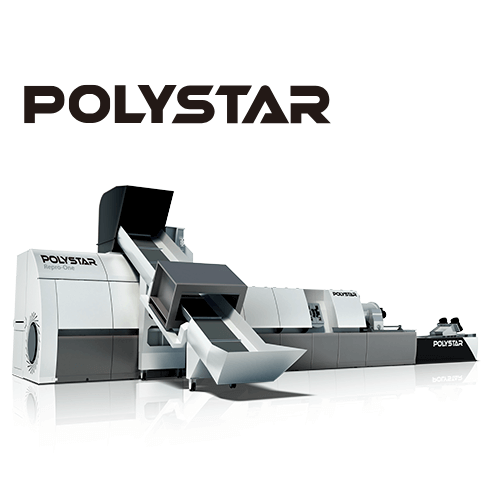

Shredder Integrated Recycling Machine: Repro-one

Categories : Plastic Waste Recycling Machines

One step technology for PP raffia, woven and PE/PP Film waste

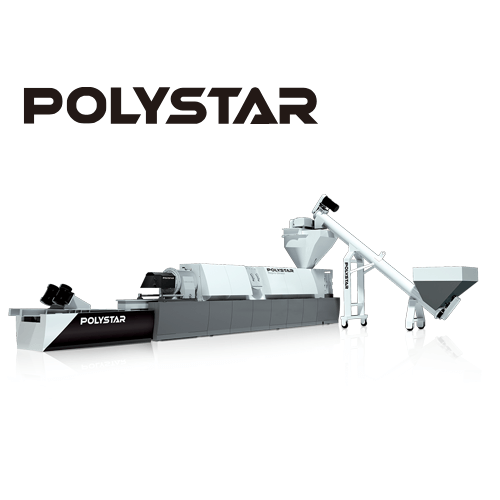

Hard Plastic Recycling Machine: Repro-Direct

Categories : Plastic Waste Recycling Machines

● The Perfect Solution for recycling plastic films waste/ regrind/ granules ● Crusher and conveyor can be added and combined into a complete recycling line

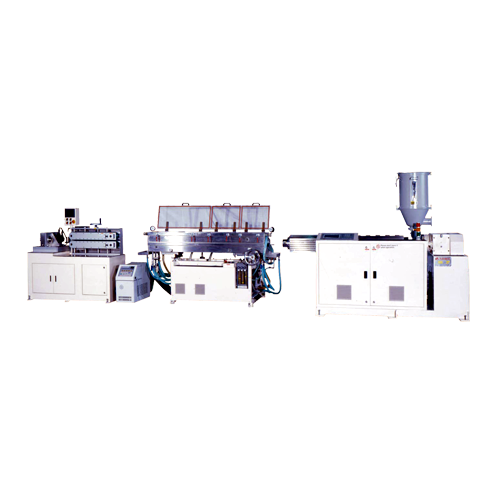

PP/PE Flat Yarn Making Machine

Categories : Extrusion Lines For Filaments and Yarn

● Screw, T-DIE adopt high quality alloy steel with hardness treatments. ● Equip High Level Synchronized Control System and Touch Screen Operation Interface for easy-operation. ● Auto Thermo Control adopts Ceramic Heater + SCR Control ● Double Layer (Upper & Lower) Heating Oven, increase the yarn quality and meet the standard stretching yarn strength.

Mono-Layer PE Tube Extruder & Cutting Machine EDC-08-01

Categories : Cutting Machines

Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials. For years of research and development, our remarkable achievements on LLDPE & LDPE melting, screw design, device of die head, material adoption, and surface treatment, together with size control by figuration and length restraint by encoder have produced valuable and high-quality tubes.