- Equipped with internet accessible control system for remote diagnoses of programming and electronic components.

- The central impression drum surface precise grind and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transport and precisely printed.

- 80mm thick cast metal plate frame provide a very steady, vibration free foundation for the printing work.

- Servo motors equipped for main drive / in-out feed / rewind, provide a smooth motion control for constant tension for film.

- Super fine printing impression adjustment device to achieve fine half tone work requirement.

- Long arch drying tunnel plus turbo blowers and suction motor to ensure drying of ink during high speed operation.

THE FOLLOWING CAN BE ADD ON :

- Servo driven impression automation with memory pack.

- Quick change over sleeve system.

- Auto splicing for rewind and unwind.

- Turn bar for reverse printing.

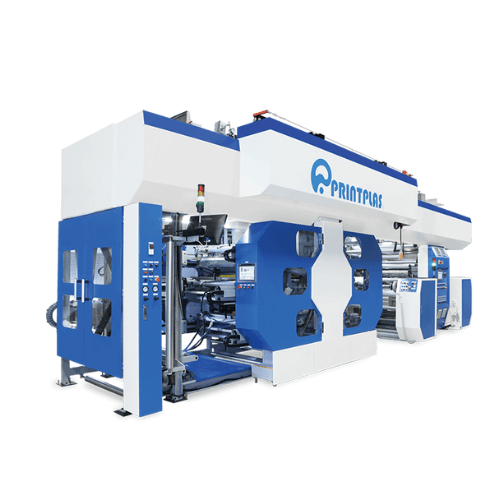

PKF1000-6CI with auto splicing device

* Printing speed varied depending on different printing condition.

CI FLEXO PRINTING

Flexographic printing machines, commonly known as flexo presses, engage in a printing technique that employs a pliable relief plate to transfer ink onto the desired substrate. Each printing task necessitates a unique set of dedicated plates. It has a central impression cylinder that transfer ink onto various substrates and enables multi-color printing in a continuous, uninterrupted manner. The central impression cylinder plays a crucial role in maintaining precise registration and consistent print quality throughout the process.

ADVANTAGES OF CI FLEXO PRINTING

CI flexo printing offers several advantages that make it a preferred choice for both small-scale and large-scale printing operations. Some key benefits include:

- High Print Quality: CI flexo printing ensures sharp and vibrant prints, even on challenging substrates, resulting in visually appealing packaging and labels.

- Versatility: It can accommodate a wide range of materials, including flexible films, paper, cardboard, and non-absorbent materials like metalized films and foils.

- Fast Production Speed: CI flexo printing machines can achieve high production speeds, reducing lead times and increasing efficiency.

- Cost-effective: With optimized ink consumption and minimal waste generation, CI flexo printing offers cost-effective printing solutions for businesses.

- Ability to Handle Complex Designs: CI flexo printing machines excel in reproducing intricate designs, fine details, and vibrant colors, making them suitable for branding and marketing applications.

PKF-6CI Specification:

| MODEL | PRINTING WIDTH | FILM WIDTH | REPEAT LENGTH | PRINTING SPEED * |

| PKF600-6CI | 600MM | 650MM | 300~800MM | 50~200M/MIN |

| PKF800-6CI | 800MM | 850MM | 300~800MM | 50~200M/MIN |

| PKF1000-6CI | 1000MM | 1050MM | 300~800MM | 50~200M/MIN |

| PKF1200-6CI | 1200MM | 1250MM | 300~800MM | 50~200M/MIN |

| PKF1400-6CI | 1400MM | 1450MM | 300~800MM | 50~200M/MIN |

| PKF1600-6CI | 1600MM | 1650MM | 300~800MM | 50~200M/MIN |

* Printing speed varied depending on different printing condition.

CI FLEXO PRINTING PROCESS

Flexographic printing presses utilize photopolymer printing plates that feature a reflective relief image of the desired print. The elevated portions of the plate receive ink through an anilox roller, which subsequently transfers it onto the substrate. The key steps involved in the printing process including:

- Ink Delivery System: The ink delivery system consists of the ink reservoir, pump, and pipes that transport ink to the anilox rolls. It ensures a steady supply of ink and maintains consistent ink flow throughout the printing process.

- Plate Cylinder: The plate cylinder holds the printing plates and rotates in sync with the anilox rolls. As the substrate passes through the press, the plate cylinder transfers the inked image onto the substrate.

- Print Unit: The print unit comprises the anilox rolls, doctor blades, printing plates, and impression cylinder. These components work together to apply the desired amount of ink onto the substrate and create high-quality prints.

- Web Tension Control: Web tension control systems ensure proper tension and alignment of the substrate throughout the printing process. They prevent issues like wrinkling, stretching, or misalignment, which can affect print quality.