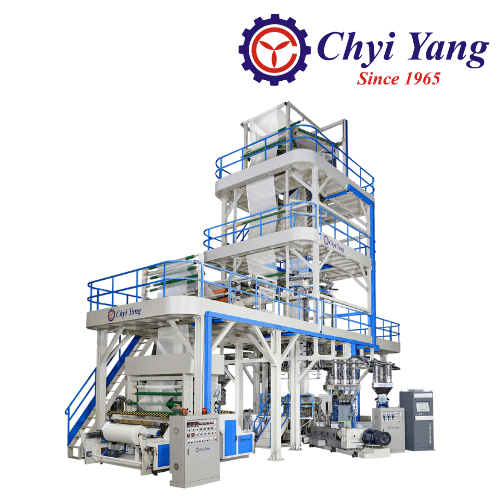

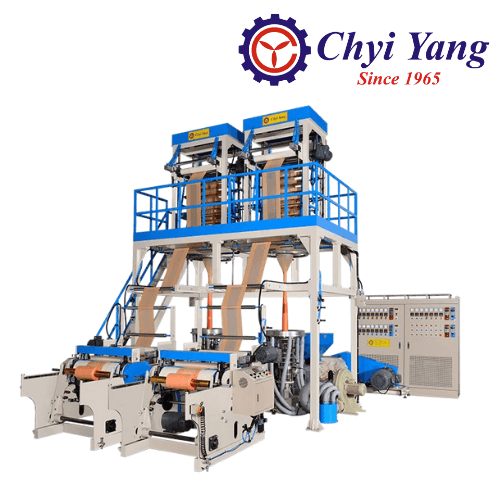

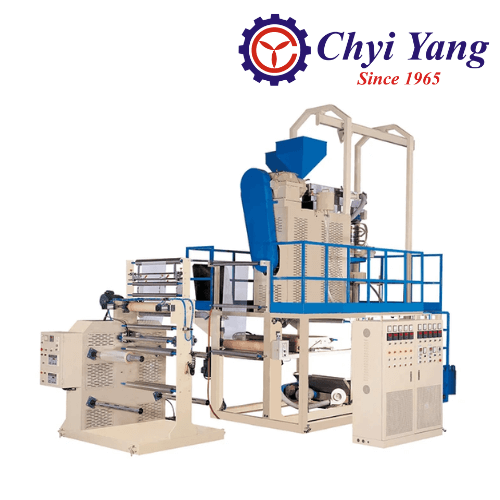

Classification : Blown Film Extrusion Machine

Country: Taiwan

Phone: 886-3-328-8686

Fax: 886-3-328-3737

Contact Person: Renee Kuo

- TCP-H series is two gear boxes driven by two motors makes colors width can be easily adjustment. TCP-SE series is one gear box driven by one motor for small capacity & saving cost. TCP-TD series is two dies & two gear boxes driven by two motors for double output. TCP-FD series is forced feeding type with two dies & two gear boxes driven by two motors for more than double output & faster speed.

- Purchasing extra LDPE die can produce LDPE film.

- Purchasing extra 2-layer co-extrusion die can produce 2-layer film.

- Double extruders increase the output.

- Precise die design makes sure the colors vivid & clear.

| Model No. | TCP-45TD | TCP-50TD | TCP-45FD | TCP-50FD |

| Screw Diameter (mm) | 45 x 2 sets | 50 x 2 sets | 45 x 2 sets | 50 x 2 sets |

| Output (Kg/hr) * | 40-90 | 50-120 | 60-140 | 70-170 |

| Roller Width (mm) | 600 x 2 sets | 750 x 2 sets | 600 x 2 sets | 750 x 2 sets |

| Film Thickness (mm) | HDPE: 0.008-0.06mm | |||

| Drive Motor (HP) | 20 x 2 sets | 25 x 2 sets | 20 x 2 sets | 25 x 2 sets |

| Die Diameter (mm) | 50 & 75 x 2 sets | 70 & 90 x 2 sets | 50 & 75 x 2 sets | 70 & 90 x 2 sets |

| Heating Zone | 16zones | 18 zones | 18 zones | 18 zones |

* Output depending on film width, thickness, die size, raw material.

★ For more details specification, special requirements & quotation, please kindly contact us.