Product Serial: QKL-B1T/QKL-B3-1/QKL-B3-1A

Low Pressure Proportional Regulator(0-8bar)

There are 3 different series of 0-8 bar proportional pressure regulator- low flow < 20L/min, high flow >500 L/min, and economic type high flow. The low flow version consists of two solenoid valves, one high-processing speed digital electronic board, and one pressure transducer. The high flow version’s construct is similar, but adding a volume booster. The economic type of proportional pressure regulator is the one where we offer a reasonable accuracy 0.5%, high speed, and economics type for customers requiring simple operations.

Features and Applications

QKL-B1T low flow electro pneumatic pressure regulator have selections of three output pressure range- 2 bar, 4 bar, 8 bar. With the 2 bar version, it is possible to customize the pressure range to lower value. This features ultra-high resolution of 0.0005 bar, ultra-high stability and quick response time. This electro pneumatic pressure regulator has been widely used in the microfluidics industry in world-leading US medical device manufacturer, and it is also popular amongst dispensing and dosing industry.

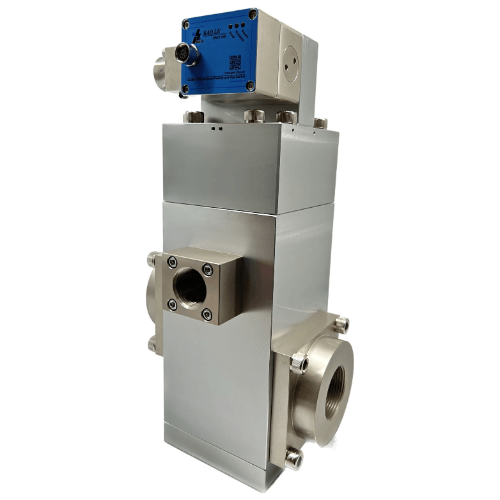

QKL-B3 is the high flow version of 8 bar electronic pressure regulator valve. Having an extra volume booster provides a higher flow to the application and allows dynamic working conditions. It offers a high accuracy of 0.1 – 0.25%, high repeatability, and flow rate of 1200 L/min. Many have used QKL-B3 to control pressure in a large closed tank applications encompass semi-conductor testing equipment, dry-process equipment, and manufacturing equipment.

QKL-B3-A is the economic high flow version of electronic pressure regulator valve where the customers have simple applications of pressure regulation. It features quick pressure switch time, high flow, and economic. There is a major application of this electro pneumatic pressure regulator in low pressure gas control in laser cutting machine.

|

Dome Loaded Regulator Types |

Low Pressure Proportional Pressure Regulator |

Comments |

|

Air Pressure Ratio Regulator |

2 bar – 10 bar selections |

1: 20 ratio |

|

Volume Booster |

0 – 8 bar selections |

From 1/2’’ to 2’’ port, 4200 L/min at 3 bar. |

|

Steam Pressure |

0 – 8 bar, higher pressure is also available. |

Stainless steel material available. Up to 220∘C |

|

Water Pressure |

0 – 8 bar, high pressure is also available. |

Fluid type can be pure water to slurry |

|

Back Pressure Regulator |

Requiring higher performance regulator, consult for customization. |

Used for back pressure control or flow rate control |

Features

◆ Small Size

◆ High Precision

◆ High Sensitivity

◆ Wide Pressure Range

Industrial application

◆ Laser Cutter

◆ Leak Tester

◆ Tension Control

◆ PET bottle molding machine

◆ Multi-Stage Pressure Control

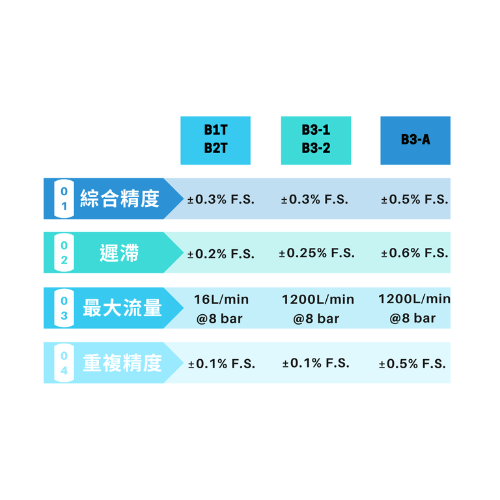

| Type | B1T | B3-1 | B3-A | |||

|---|---|---|---|---|---|---|

| Input Signal | 0-10V / 4-20mA/ RS485 | 0-10V / 4-20mA | ||||

| Output Range | 0-2bar (29 psi) |

0-4bar (58 psi) |

0-8bar (116psi) |

0-4bar (58 psi) |

0-8bar (116psi) |

0-8bar (116 psi) |

| Suggesting Supply Pressure Max | 3bar (43 psi) |

5bar (73 psi) |

9bar (131 psi) |

5bar (73 psi) |

9bar (131 psi) |

9bar (131 psi) |

| Max working pressure | 9 bar(131 psi) | |||||

| Monitor Output | 1-5V / 0-10V / 4-20mA | 0-10V / 4-20mA | ||||

| Power Supply | DC24V (≦4W) | |||||

| Response | 0.8S | |||||

| Medium | Clean compressed air or with 5 μm filter | |||||

| Repeatability | ±0.1% F.S. | ±0.25% F.S. | ±0.5% F.S. | |||

| Hysteresis | ±0.2% F.S. | ±0.25% F.S. | ±0.5% F.S. | |||

| Linearity | ±0.3% F.S. | ±0.5% F.S. | ||||

| Accuracy | ±0.3% F.S. | ±0.5% F.S. | ||||

| Flow Rate | 4L/min @2bar |

7L/min @4bar |

13L/min @8bar |

525L/min@4bar | 1050L/min@8bar | 1050L/min@8bar |

| Temp. Range(Operating) | 0-70⁰C ( 32-158 ⁰F) | |||||

| Port Size | G1/8" | G1/4" | ||||

| Manifold Material | Aluminum | |||||

| Electrical Connection | M12 Connector(2m) | |||||

| Ingress Protection | IP 65 | |||||

| Life Cycle | Over 1 Billion Times | |||||

| Weight | 420 g | 550 g | 430 g | |||

| Series | Type | Input Signal | Monitor Output | Mounting Bracket | Pressure and Flow | Display Unit | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| QKL- | B1T | - | E | - | C | - | M | - | P8 | - | U |

| B1T: Low flow with internal feedback | **E: 0-10V | C:0-10V | M:M type | For B1T, B2T P2:0 - 2 bar, 8LPM P4:0 - 4 bar, 10LPM P8:0 - 8 bar, 20LPM |

S:psi | ||||||

| B2T: Low flow with external feedback | A: 4-20mA | A:4-20mA | L:L type | U:bar | |||||||

| B3-1: High flow with internal feedback | R: RS485 Modbus | D:1-5V | For B3-1, B3-2 P4:0 - 4 bar, 320 LPM P8: 0 - 8 bar, 640 LPM |

||||||||

| B3-2: High flow with external feedback | |||||||||||

| *B3-A: High flow with internal feedback | For B3A P8:0 - 8 bar, 640 LPM |

*B3-A is an economic type, only with 8 bar. B3-A does not have RS485 modbus interface and does not have 1-5V monitor output.

** For Command Signal type 0-10V, the minimum driving current is 50mA.

★Please consult us for customized pressure range.

The wiring diagram shows from top view.

| No. | Color | Function |

|---|---|---|

| 1 | Blue | 24V DC Power (-) Command (-) Output monitor (-) 2nd loop transducer 0 -10 V (-) |

| 2 | Brown | 24V DC Power (+) 2nd loop transducer 4 - 20 mA (+) |

| 3 | Black | Monitor output (+) |

| 4 | White | 0-5 V Command (+) 0-10 V Command (+) 4-20 mA Command (+) |

| 5 | Gray | RS485(D-) |

| 6 | Green | 2nd loop transducer 0 -10 V (+) 2nd loop transducer 4 - 20 mA (-) |

| 7 | - | - |

| 8 | Red | RS485(D+) |

** Warning: Do not rotate the connection socket when connected, to avoid damage to the internal sensor.

Product Precautions

Installation

The valve can be mounted in any position. For very low pressure control, works best when mounted upright.

And Ensure a minimum closed end volume of 40c.c. to allow proper functioning.

※Preparation Before Piping

Before piping is connected, it should be thoroughly blown out with air (flushing) or washed to remove chips, cutting oil and other debris from inside the pipe.

Wrapping of Sealant Tape

When screwing together pipes and fittings, etc., be certain that chips from the pipe threads and sealing material do not get inside the piping. When sealant tape is used, leave 1.5 to 2 thread ridges exposed at the end of the threads.

Operating Environment

- Do not operate in locations having an atmosphere of corrosive gases, chemicals, sea water, or where there will be contact with the same.

- In locations where the body is exposed to water, steam, dust, etc., there is a possibility that moisture or dust could enter the body through the EXH port, solenoid valve EXH port and/or built-in regulator EXH port, thereby causing problems.

- In locations which receive direct sunlight, provide a protective cover etc.

- In locations near heat sources, block off any radiated heat.

- Employ suitable protective measures in locations where there is contact with water droplets, oil or welding spatter, etc.

Air Supply

- Compressed air, nitrogen, oxygen or argon can be used as a fluid.

- Do not use compressed air which includes chemicals, synthetic oils containing organic solvents, salt, or corrosive gases, etc., as this can cause damage or malfunction.

- If oxygen is used as the fluid, it can lead to serious and unforeseen risks. However, it is possible to manage and control the risk of hazards and economic loss. In order to use the product safely, it should only be handled by personnel with appropriate knowledge, with support from a suitably qualified specialist.

- Oxygen gas increases the susceptibility of substances to burning; Oxygen gas can be ignited by frictional heat and static electricity. If oxygen is ignited, the metal and seal materials burn. Therefore, flush the piping thoroughly and mount a suitable filter to prevent foreign matter such as metal powder and dust from entering the product.

- Take safety measures by installing safety devices (e.g. a circuit that stops the supply of oxygen gas) to prevent fire and explosion in the event of failure, taking flameproof safety standards into consideration.

- Since there are some exhaust ports on the product, connect the piping in order to exhaust oxygen. Do not block the exhaust port.

Warranty

KaoLu Ent. Co. Ltd. products are warranted to the original purchaser only against defects in material or workmanship for 6 months from the date of manufacture. The extent of KaoLu’s liability under this warranty is limited to repair or replacement of the defective unit at KaoLu’s option. KaoLu shall have no liability under this warranty where improper installation or filtration occurred.