Product Serial: FC-120+PM-120

Proportional Flow Control Valve

Introduction

A proportional flow control valve is used to regulate the amount of fluid that passes through it. This is done by changing the size of an electrical pulse. The amount of fluid that passes through the valve can be adjusted by simply altering the electrical pulse.

Electronic proportional flow control valves provide precise control of air/water flow with the latest technology.

Electronic proportional flow control valves use the latest technology to provide precise control of air or water flow. With electronic control, you can monitor and adjust your equipment quickly and easily without the need for manual adjustments. Our electronic valve can be used in a variety of applications including fluid regulation, fluid pressure regulation, fluid level regulation and many others. It provides accurate proportioning of fluids at any pressure.

Electronic proportional flow control valves utilize a transducer that converts process signal into an electrical output signal. The electrical output signal is then converted to hydraulic output signal by means of a hydraulic amplifier connected with the valve spool through hydraulic piping system which controls valve position according to variable process requirements by opening or closing it as required during operation like opening/closing flow path etc

Mechanical Flow Control Valves are used where very accurate control over process flows is necessary but can be less expensive than electronic options with fewer moving parts

A proportional flow control valve is ideal for applications which require accuracy and reliability.

A proportional flow control valve is ideal for many applications where accuracy and reliability are essential. Proportional flow control valves are used for a wide range of applications such as sealing, dark room automation, and process cooling water control.

Proportional flow control valve

The Proportional Flow Control Valve is a device that regulates the flow of fluid. The valve uses an electrical pulse and can be used in a wide range of applications.

The proportional flow control valve features a high flow rate.

The Proportional Flow Control Valve features a high flow rate, which is also known as the maximum flow rate. This means that for a given input pressure, you can achieve higher output flow rates than with other valves. In addition to this, the proportional flow control valve offers high accuracy and reliability.

A proportional flow control valve restricts the amount of fluid that passes through it.

A proportional flow control valve restricts the amount of fluid that passes through it. The amount of fluid that passes through the valve is changed when the electrical pulse changes, which means that when there is a small flow rate, pressure will be higher than if there was no flow at all and vice versa.

The valve body, shaft housing and seat are all made from materials that can withstand high temperatures and pressures without melting or deforming. A proportional flow control valve will often use a hydraulic actuator to open or close depending on user instructions; however some designs do not require an actuator in order for them to function properly because they use springs to control how much pressure is exerted upon each other instead.

The amount of fluid that is passed through the valve is changed when the electrical pulse changes.

When the electrical pulse is low, very little fluid will pass through the valve. When the electrical pulse is high, the amount of fluid that passes through the valve increases significantly. The amount of fluid that passes through the valve is proportional to the change in the electrical pulse.

The relationship between these two variables can be described using a mathematical equation:

Three main elements in the proportional flow control valve: a body, a seat, and a spool.

There are three main elements in the proportional flow control valve: a body, a seat and a spool.

The spool is able to move within the valve body and seat. The spool is responsible for changing the size of the opening between itself and its seat so that it can control how much fluid flows through them. When an electrical pulse changes, this causes an even larger change in how much fluid can pass through that opening. An external power supply generates these electrical pulses to make sure your water heater stays warm enough all night long!

The spool is able to move within the valve body and seat.

Proportional flow control valves have a spool that is able to move within the valve body and seat. This spool can be moved by an electrical pulse and is a movable element in the valve that controls fluid flow.

A typical proportional control valve requires an external power supply to adjust the size of the opening to regulate the flow of fluid.

With a proportional control valve, the valve changes the size of its opening based on the flow rate. A typical proportional control valve requires an external power supply to adjust the size of the opening to regulate the flow of fluid.

Applications of proportional flow control valves: sealing, dark room automation, and process cooling water control.

Proportional flow control valves can be used for a wide range of applications such as sealing, dark room automation, and process cooling water control.

Proportional flow control valves are typically installed on the suction side of pumps. The valve is used to maintain the pressure in the system by regulating the amount of fluid in the pump's suction line. They can also be used on gas lines or liquid lines with pressurized fluids that need to be measured or controlled accurately.

A proportional flow control valve regulates flow by changing an electrical pulse.

A proportional flow control valve is a device that regulates the flow of fluid to a system, often by changing an electrical pulse. A proportional flow control valve uses an electronic sensor to measure changes in pressure and then actuates a servo motor which adjusts the throttle setting of the valve.

Conclusion

The proportional flow control valve is ideal for many applications where accuracy and reliability are essential. The proportional control valve can be used in the control of air, water or other fluids at any pressure. It provides accurate proportioning of fluids at any pressure.

PM

| Input signal | VDC 0-10V / 4-20mA/RS485 |

|---|---|

| Supply | DC24V (≦12W) |

| Indicator LED Status(* with Encoder function ) | on/off (LED on is motor running) on/off (LED off is motor stopping) on/off (LED flashing is motor error) *error/null (LED on is encoder error) *error/null (LED off is encoder normal) |

| Encoder Resolution | 1.587×10-3 mm |

| Motor Status output | Sink 50mA |

| Temp. Range(Operating) | 0-60℃ |

| Cable Length | 1 meter, consult for longer cable |

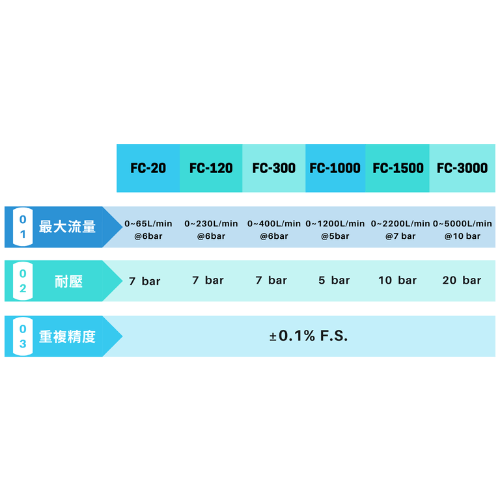

FC

| Model | FC-120 |

|---|---|

| Valve Type | 2-Way Proportional Needle valves |

| Port Size | G 1/8” |

| Medium | Compatible gases and liquids |

| Pressure Range | -1~7bar |

| Flow Range of air | 0~230L/min@6bar |

| Flow Range of water | 0~4L/min @6bar |

| Repeatability | ±0.1% F.S. |

| Flow Resolution | 0.1L~0.2L/min @3bar |

| Temperature Range | 0~84°C |

| Full Stroke Time | 2 sec |

| Body material | Aluminum |

| Seals | Viton |

| Ingress Protection | IP52 |