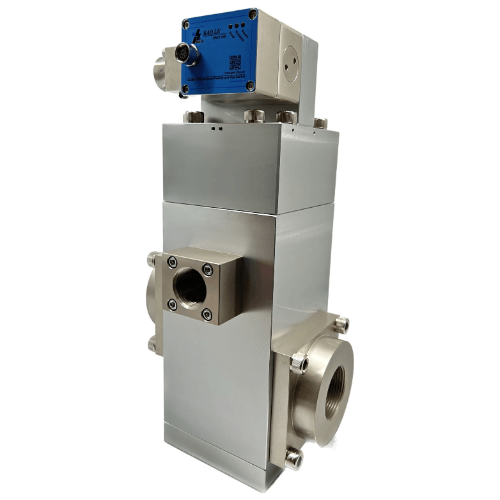

Product Serial: FC-20+PM-20

High Resolution Electronic Flow Control Valve

Introduction

The High Resolution Electronic Flow Control Valve is the next-generation of flow control valves designed to meet the needs of the semiconductor industry. Using a servo motor and optical position sensor, it delivers ultra-high resolution and repeatability with low leakage rates for leak and purge applications. With a single seat design and no differential pressure, the High Resolution Valve provides superior performance over legacy needle valves.

The high resolution electronic flow control valve

The High Resolution Electronic Flow Control Valve is a single-seat design, which means no differential pressure is required to actuate the valve. The servo motor and optical position sensor allow for ultrahigh resolution, repeatability and low leakage rates for leak and purge applications.

The High resolution valve is the next-generation of flow control valves designed to meet the needs of the semiconductor industry.

The High Resolution Valve is the next-generation of flow control valves designed to meet the needs of the semiconductor industry. Using a servo motor and optical position sensor, it delivers ultra-high resolution and repeatability with low leakage rates for leak and purge applications. With a single seat design and no differential pressure, the High Resolution Valve provides superior performance over legacy needle valves.

Features

- Compact

- Low cost

- High sensitive

- Analog / Digital signal

- Easy-control

- Full scale linearity flow rate control

Industrial Applications

- Pneumatic Operated Soldering Equipment

- Gas Mixing

- Analytical Instrument

- Semiconductor equipment

- High Accuracy and High Resolution Flow Control

- Laser machine

PM

| Input signal | VDC 0-10V / 4-20mA/RS485 |

|---|---|

| Supply | DC24V (≦12W) |

| Indicator LED Status(* with Encoder function ) | on/off (LED on is motor running) on/off (LED off is motor stopping) on/off (LED flashing is motor error) *error/null (LED on is encoder error) *error/null (LED off is encoder normal) |

| Encoder Resolution | 1.587×10-3 mm |

| Motor Status output | Sink 50mA |

| Temp. Range(Operating) | 0-60℃ |

| Cable Length | 1 meter, consult for longer cable |

FC

Wiring

| No. | Function |

|---|---|

| 1 | DC24V + |

| 2 | DC24V - |

| 3 | Signal +/A、RS485 + |

| 4 | Signal -/B、RS458- |

Encoder Wiring Description

| No. | Color | Function |

|---|---|---|

| 4 | Yellow | B channel |

| 3 | Orange | +5V DC |

| 2 | Blue | A channel |

| 1 | Brown | Ground |

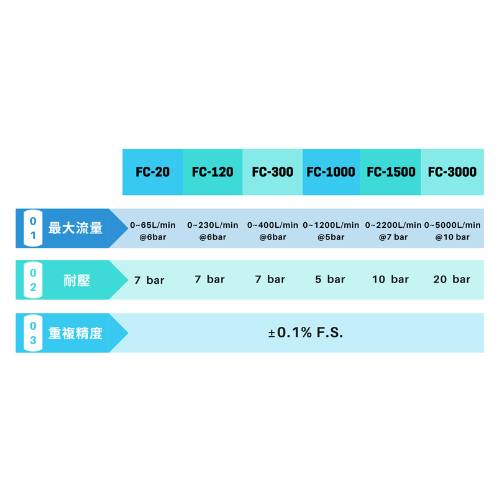

| Model | FC-20 |

|---|---|

| Valve Type | 2-Way Proportional Needle valves |

| Port Size | G 1/8” |

| Medium | Compatible gases and liquids |

| Pressure Range | -1~7bar |

| Flow Range of air | 0~65L/min@6bar |

| Flow Range of water | 0~1L/min @6bar |

| Repeatability | ±0.1% F.S. |

| Flow Resolution | 0.1L/min@3bar |

| Temperature Range | 0~84°C |

| Full Stroke Time | 1.5 sec |

| Body material | Aluminum or Stainless steel |

| Seals | Viton or FFKM |

| Ingress Protection | IP52 |

| Series | Type | Type | Input Signal | |||

|---|---|---|---|---|---|---|

| FC | 20 | + | PM | 20 | - | E |

| 20: 0~65LPM | 20: For FC-20 | **E: 0-10V | ||||

| 120: 0~230LPM | 120: For FC-120 | A: 4-20mA | ||||

| 300: 0~400LPM | 300: For FC-300 | R: RS485 Modbus | ||||

| 1000: 0~1200LPM | 1000: For FC-1000 | |||||

| 1500: For FC-1500 |

** For Command Signal type 0-10V, the minimum driving current is 3mA

- The indicated flow rate is air, please consult for liquid flow rate

- Please contact us for customized flow range

★ FC and PM series are calibrated in pair. Before operating, please ensure the serial numbers on FC and PM are in pair in order to prevent potential leakage issue.

Product Precautions

- Before piping is connected, it should be thoroughly blown out with air (flushing) or washed to remove chips, cutting oil and other debris from inside the pipe.

- When screwing together pipes and fittings, etc., be certain that chips from the pipe threads and sealing material do not get inside the piping. When sealant tape is used, leave 1.5 to 2 thread ridges exposed at the end of the threads.

- Do not operate in locations having an atmosphere of corrosive gases, chemicals, sea water, or where there will be contact with the same.

- Ensure the fluid passing through the valve does not contain solid particles. Please use a filter before the inlet port.

- In locations which receive direct sunlight, provide a protective cover etc.

- KaoLu’s product cannot be used as an emergency shutoff. A redundant safety system should be installed in the system to prevent serious injury or loss of life.

Warranty

KaoLu Ent. Co. Ltd. products are warranted to the original purchaser only against defects in material or workmanship for 6 months from the date of manufacture. The extent of KaoLu’s liability under this warranty is limited to repair or replacement of the defective unit at KaoLu’s option. KaoLu shall have no liability under this warranty where improper installation or filtration occurred.