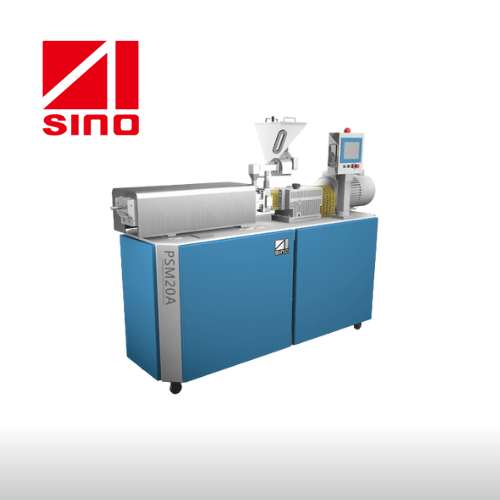

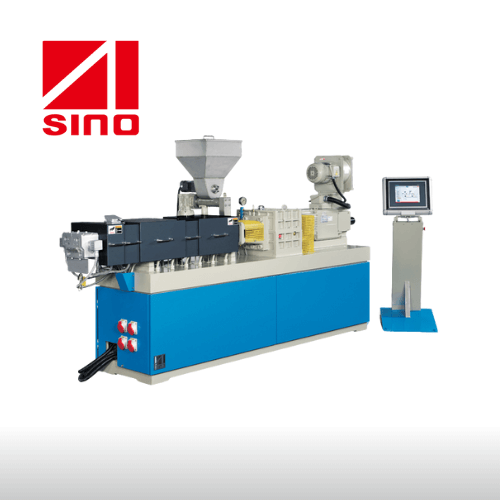

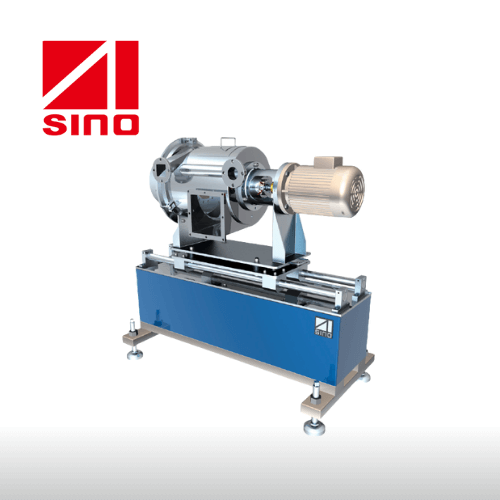

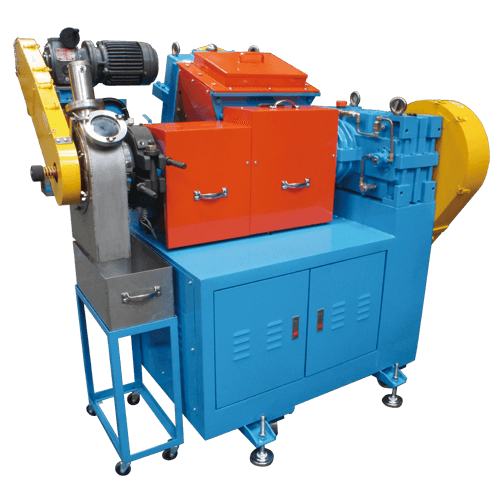

Clam-Shell Design Co-Rotating Twin Screw Extruder-PSM20A

Categories : Granulators

The PSM20A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

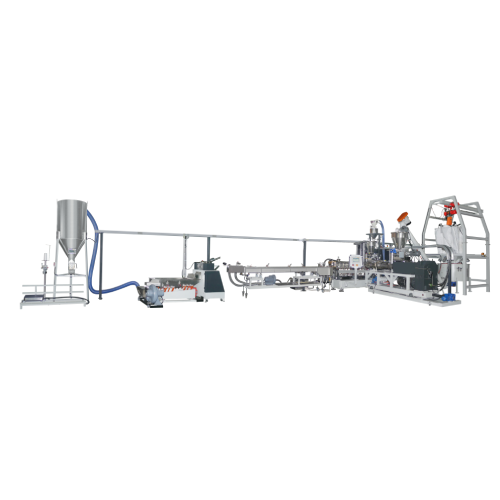

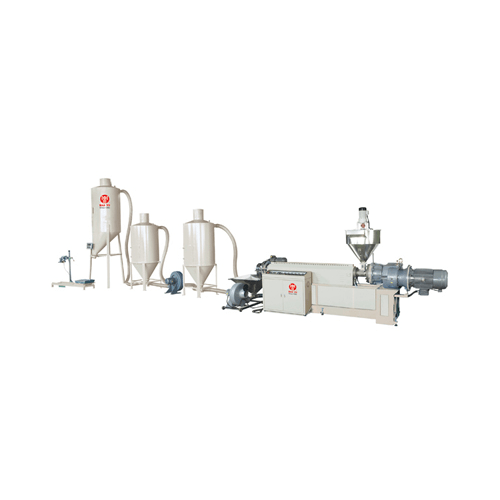

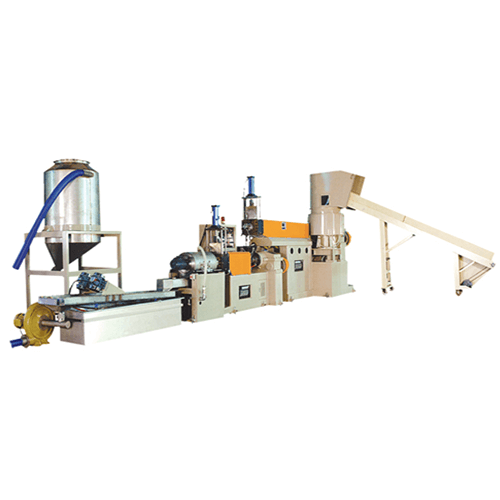

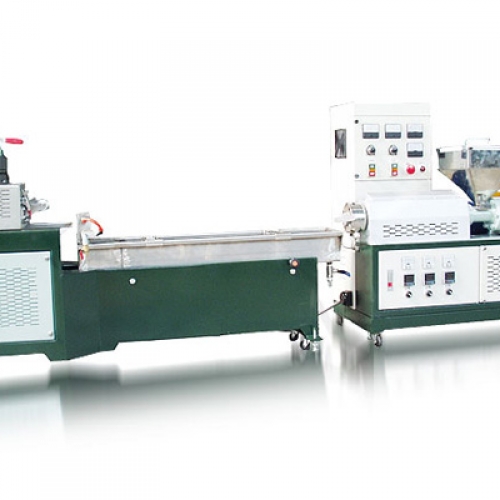

Plastic Pelletizing Machine / Pelletizer Extrusion Line

Categories : Plastic Pelletizer Machines

Optional Accessories:(1) Wood flour drier(2) Humidity tester(3) Chiller(4) Water cooling tower(5) Movable electronic balance with portable sewing machine (6) Wood flour grinder

Repet Wood WPC Granule Pelletizer Plant

Categories : Plastic Pelletizer Machines

Indoor & outdoor building material Outdoor furniture

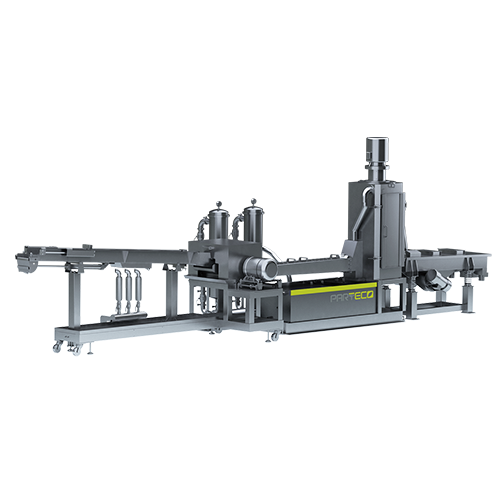

Granulating System: Flow Channel of Plastic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

The plastic strand pelletizing system consists of a die, water-cooling channel, pelletizer, centrifugal hydroextractor and a circulating water-cooling system. Mainly used for plastic materials such as PET、PA、PC etc

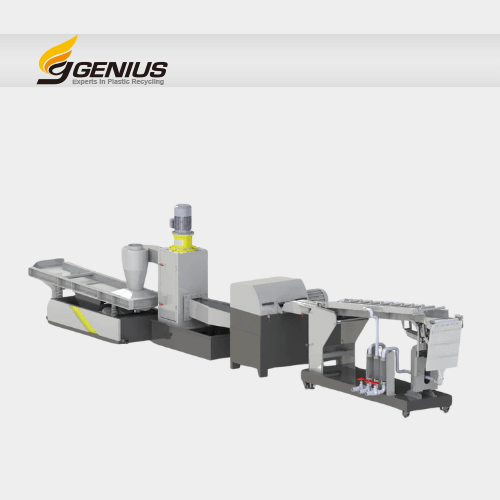

Automatic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

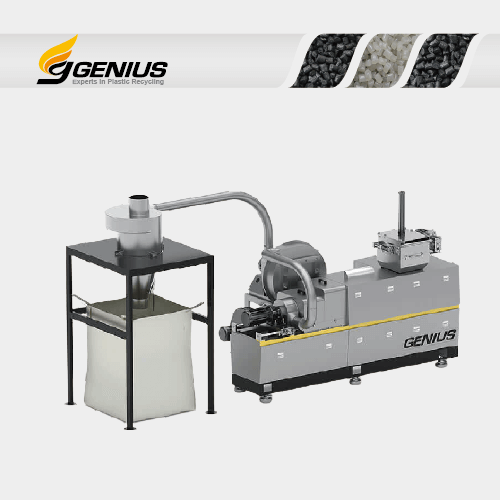

Born For Extreme Automation The molten polymer been extruder from the die, fall into automatic water flow. High-pressure water flow from a special designed spray nozzle pulls the strands immediately while cooling at the same time. No more drawing strands before pelletizing. Minimize the lump waste during drawing the strands. GENIUS

Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Minimize The Powder Waste Suitable for higher MI or sticky materials. Production line is equipped with high-precision pellets cutter and specially designed vibrating screener.

Air Cooled Mini Plastic Recycling Machine - Piranha Series

Categories : Plastic Pelletizer Machines

Auto pellet length control via motor load to keep pellet length constant Low temperature heat soak feature - 20 minutes to soak prior to starting To build perfect granules in real-time Full access to dicer and safe access to blade changing Air cooled pelletizer Dual geometry low L/D ratio screws, manufactured from SACM-645, nitride hardened, ground and polished Barrels are manufactured from SACM-645, honed finish and nitride hardened Cold start protection No material shutdown

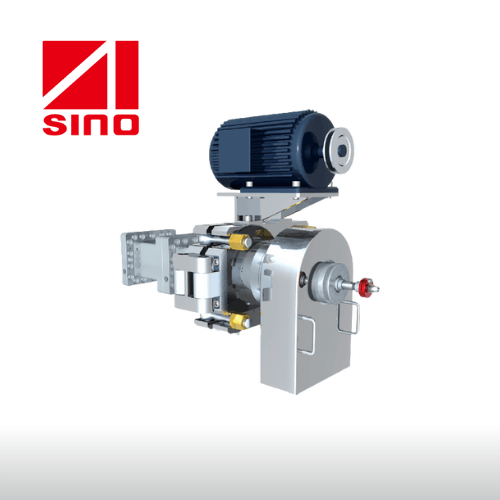

Compact Co-Rotating Twin Screw Extruder-PSM30A

Categories : Twin Screw Extruders

The PSM30A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM30 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

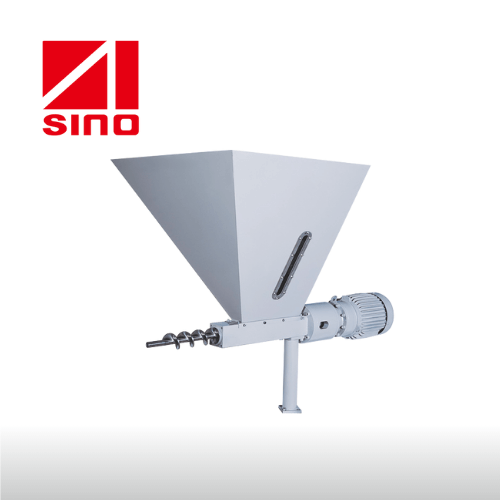

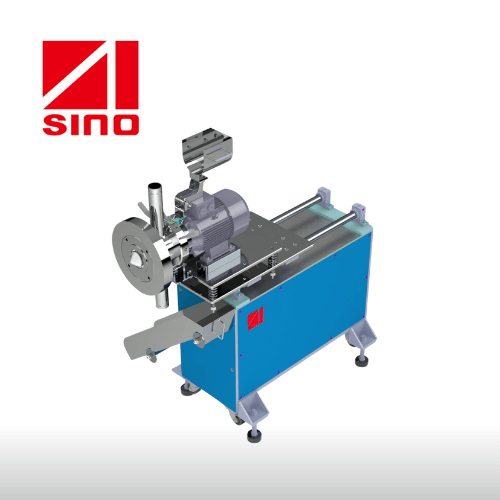

Single Screw Feeder-PSA

Categories : Feeders

The PSA series single-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSA single-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Options include standard double-flight, single-flight, T-type, and spring type screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

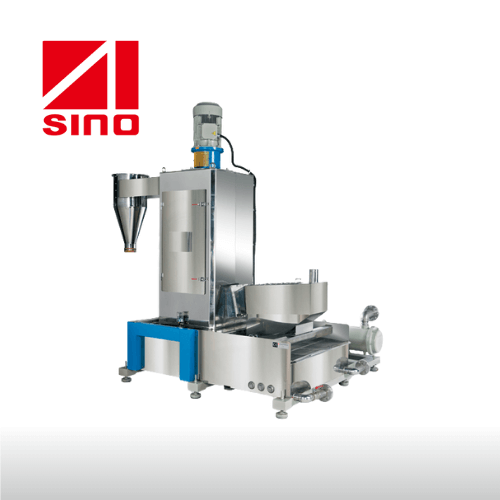

Water-Cooled Type PVC Pelletizer

Categories : Plastic Pelletizer Machines

Water-Cooled Type PVC Pelletizer, wpc pelletizing machine.

Twin-Cone High Speed Pelletizing Machine-Die-Face Cutting

Categories : Compounding Lines

Process Rubber/Plastic mixed material, EVA, TPR, PVC, CaCO3, PVB, PU, TPU compounding, various kinds of masterbatches pelletizing High capacity Low electricity usage Easy to clean and change materials Knead well Die-face cutting Adequate kneading

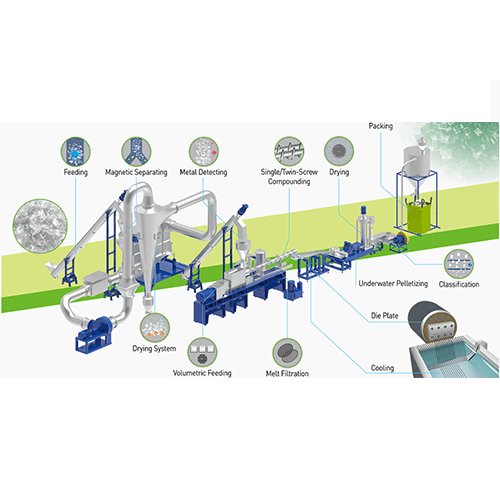

Granulating System: Underwater Pelletizer

Categories : Plastic Pelletizer Machines

Underwater pelletizer with advanced water cooling technology. Energy saving, Easy Operation Underwater Pelletizing System. Mainly used for plastic materials such as PP、TPU、TPR、TPE etc.

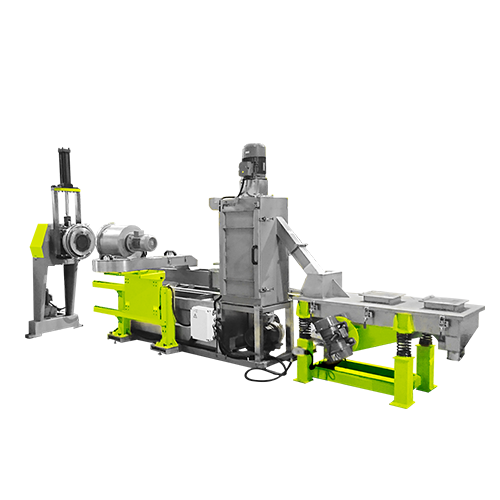

PLASTIC WOOD COMPOSITE MATERIAL PELLETIZER

Categories : Plastic Pelletizer Machines

Our Plastic Wood Composite Material Pelletizer is a state-of-the-art WPC pelletizing machine designed to deliver consistent, high-quality pellet production for wood-plastic composites. This WPC pelletizing machine offers precise temperature control and an optimized extrusion process to ensure uniform pellet size and superior material characteristics. With a robust and efficient design, the pelletizer reduces energy consumption while maximizing output, making it an essential solution for manufacturers looking to enhance productivity and material quality in their WPC pelletizing operations.

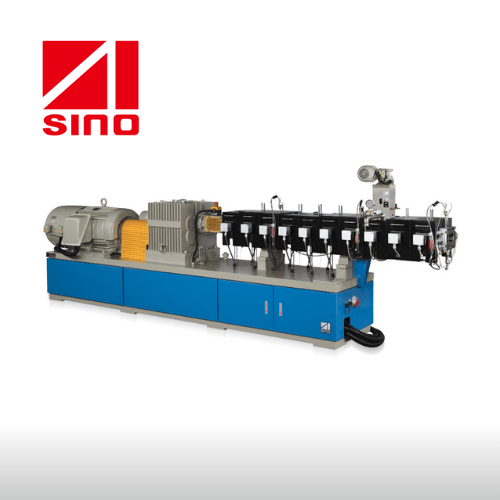

Co-Rotating Twin Screw Extruders-PSM50

Categories : Twin Screw Extruders

The optimization of the PSM50 series resulted in more efficient and durable designs. The PSM50 series has mid range production capabilities, and easy operation in reasonable price. All PSM50 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

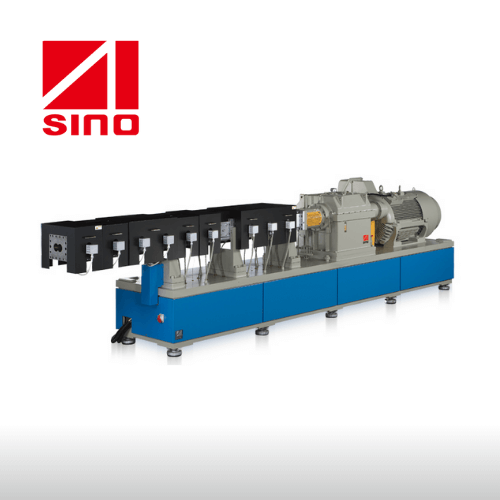

Co-Rotating Twin Screw Extruders-PSM72A

Categories : Twin Screw Extruders

The optimization of the PSM72 series resulted in more efficient and durable designs. The PSM72 series has mid range production capabilities, and easy operation in reasonable price. All PSM72 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

Underwater Pelletizer - PSQ

Categories : Plastic Pelletizer Machines

The PSQ underwater pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and sticky materials. Hot melt is extruded through a die into a water-filled cutting chamber where it is die-face cut by a high-speed cutter. The resulting spherical pellets are conveyed via water slurry to a centrifugal dryer. Use in line with our PSL series centrifugal dryers to complete the underwater pelletizing system.

Strand Pelletizer-PSH

Categories : Plastic Pelletizer Machines

The PSH strand pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Strands from the extruder are pulled through a water-filled cooling bath and blown dry by an air knife before entering the pelletizer. This simple pelletizing process is applicable to many different types of plastics and rubber. Our knives are made with tungsten carbide steel to ensure a long life and clean cuts. Puller and rotary knife can be synchronized to ensure uniform pellet size regardless of the extruder throughput. Designed with built in safety features, the moving parts are all enclosed within a protective cover.

Water Ring Pelletizer-PSF

Categories : Plastic Pelletizer Machines

The PSF water-ring pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and material which may be too brittle for strand pelletizing. Variable speed cutting blade to control pellet size and surface quality. Use in line with our PSL series centrifugal dryers to complete the water-ring pelletizing system.

Air Cooling Pelletizer-PSW

Categories : Plastic Pelletizer Machines

The PSW air-cooled pelletizer was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Especially good for hygroscopic materials. Variable speed cutting blade to control pellet size and surface quality. Use in line with our cyclone tanks to complete the air-cooled pelletizing system.

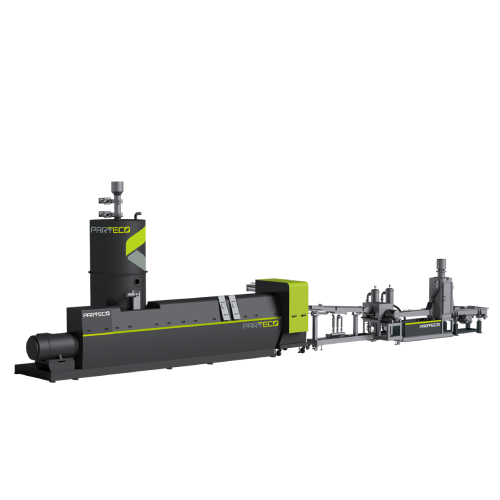

Granulating System: Strand Pelletizer

Categories : Plastic Pelletizer Machines

Advanced strand pelletizer for most plastic materials. Specialize in manufacturing of the plastic strand pelletizing system. PARTECO plastic granulating machine is applicable to most of plastic materials. Suitable for most plastic materials.

Hot Die Face Pelletizing System

Categories : Plastic Pelletizer Machines

Cost Reduction The molten polymer from the extruder is passed to the die head. A rotating blade cuts the hot material as it exits the die hole and falls into a water ring for cooling. The operator does not need to draw the strands, which reduces the lump waste during re-drawing. More Uniformity, More Profit The pelletizing cutter is a universal joint design. The cutter adjusts the blade automatically during operation. Final plastic pellets are in uniform size in order to be sold at a higher price and bring you more profit.

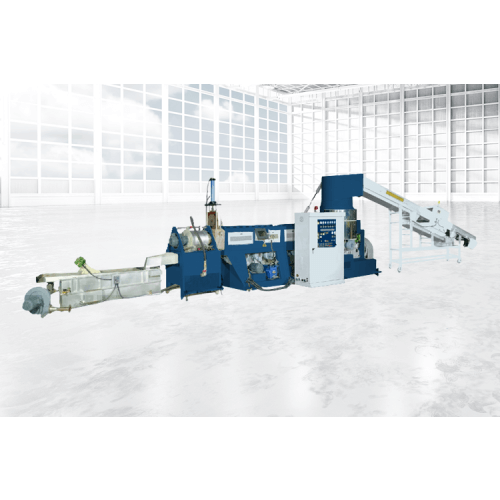

Side Entrance Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Feeding production is more stable than traditional force feeding. Able to open a input hole on top of barrel to conduct feeding formula and master batch pellets. It's a useful and productive type. Crusher is optional. With forced feeding hopper allows the machine to input two kind of material.

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean

Pelletizing & Recycling System

Categories : Plastic Pelletizer Machines

MGB-RPW-65 For PP, HDPE and LLDPE recycling.

Granulating System: Water Ring Pelletizer System

Categories : Plastic Pelletizer Machines

Structure and function of our plastic water ring pelletizer system and machine. Features and advantages of our plastic water ring pelletizing machine line. Applicable plastic materials of our plastic granulating series system and machine. Mainly used for plastic materials such as LDPE、HDPE、PP etc.

Twin-Cone High Speed Pelletizing Machine-Underwater Cutting

Categories : Plastic Pelletizer Machines

Suitable for high viscosity raw materials, such as PP, PMMA, TPU, PU, PLA, PET, TPU, PU, PLA and etc. High viscosity raw material. High Capacity, Low electricity usage, Easy to clean and change materials, Knead well, Underwater cutting

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pelletizer Machines

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly applied to the processing of PET crushed chips recycled from PET bottles. By means of vacuum degassing system to remove the water and impurities, then go through the melting extrusion, filtering and granulating process to tailor made the complete PET recycling solutions for you. Applicable materials Film or Flakes : PET Bottle Flakes

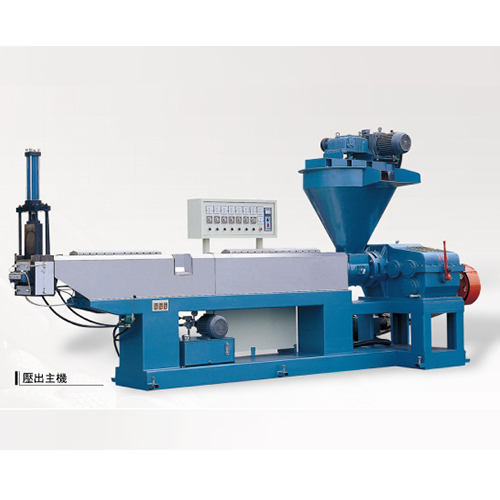

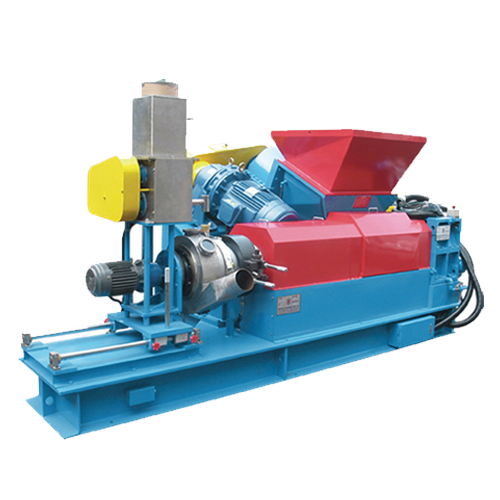

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

Extrusion & Pelletizing for Rubber、Plastic & Chemical Industries This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

Water Cooling Pelletizer Line (Vertical Force Type)

Categories : Plastic Pelletizer Machines

WATER COOLING PELLETIZER LINE(VERTICAL FORCE TYPE)

Water Cooling Pelletizer Line (Horizontal Type)

Categories : Plastic Pelletizer Machines

WATER COOLING PELLETIZER LINE (HORIZONTAL TYPE)

Three In One Cooling Pelletizing Machine

Categories : Plastic Pelletizer Machines

Three In One Cooling Pelletizing Machine

High-Speed Dyeing & Pelletizing Production Line

Categories : Compounding Lines

Suitable for masterbatch with fiber pelletizing, HDPE, LLDPE, LDPE, PP, PMMA, ABS, PC, Nylon, etc. Special screw design for compounding Changing material is easy Easy to operate Machine frame is very strong Customized screen changer

HF-FTO 3 In 1 Series:3 in 1 Pelletizing Extrusion / Extruder Pelletizer

Categories : Plastic Pelletizer Machines

Produced by experienced plastic recycling extruder machine manufacturer. Suitable for handling differences of materials. Suitable for processing most of the thermoplastic materials. Applicable materials Film or Flakes : PE、LDPE、LLDPE、HDPE、PP、PET、PS、PA、BOPP、ABS

KRS Air Cooling Recycling Machine

Categories : Plastic Pelletizer Machines

In the process of manufacturing plastic film, recycling is a vital step. In order to save production costs and create more profit, many manufacturers are recycling their in-house materials. The KRS Air Cooling Recycling Machine is specifically designed to process edge-trimmed recycling from PE bag production line. It can recycle light printed plastic films into homogenous and high-quality pellets. In most cases, 100% of the recycled pellets produced by KRS can be reused in products production line.

Twin Screw Squeezing Machine (RDF-5)

Categories : Plastic Washing Line

With a special designed twin screw, it is capable to squeeze and form multiple types of material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine). RDF-5 is easy to store and saves space.

RDF-5, Twin Screw Rubbing Drying Machine

Categories : Plastic Washing Line

With a powerful special designed single screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine).

Strand Pelletizer

Categories : Plastic Pelletizer Machines

CYKF self-made strand pelletizers are able to handle most kinds of plastics. The strand pelletizers can cut cylindrical plastic strands into even pellets. In order to response different demands on capacity, CYKF develops 5 models for choice. The modular design can easily fit into any existing production lines to immediately support production. Moreover, we provide the complete product range for strand pelletizer, including water tank, strand dryer, vibrating screen and storage tank. The comprehensive service saves time as well as solves troubles on system integration. All equipment is designed and manufactured by CYKF which guarantees the quality of the products. Currently the CYKF strand pelletizers are widely used in polymer, recycling, chemical, electronics, automobile, and food industries, etc. The stable operating performance and long service life earns good reputation from customers, and the excellent features have already made contributions to lots of industries in the world.

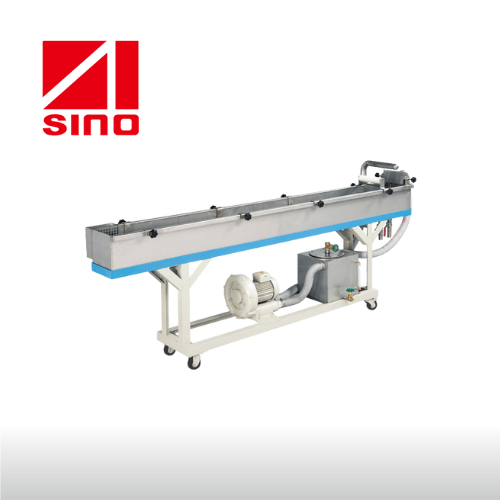

Water Cooling Bath-PSK

The PSK series cooling bath was developed by Sino-Alloy Machinery as an important and essential accessory for the strand pelletizing process. The extruded plastic strand is passed through the cooling bath then dried by an air blade and low pressure vacuum before entering the strand pelletizer to be cut to size. It has a simple design which can be customized with chillers or heaters depending on the production needs.

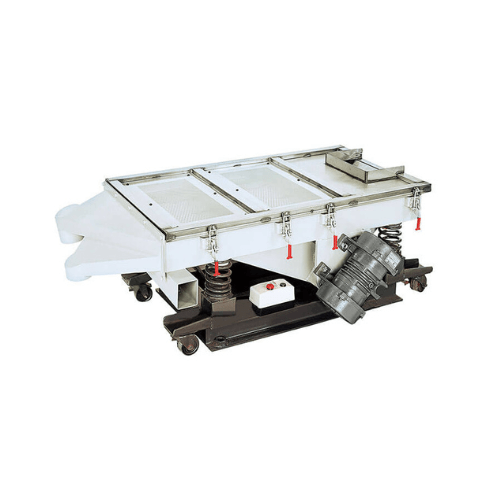

Vibrating Screen

Categories : Separators

The CYKF Vibrating Screen is used for sorting plastic pellets. It divides the pellets discharged from pelletizer. The machine can be combined with our strand pelletizing or underwater pelletizing extrusion lines.

Centrifugal Dryer-PSL

The PSL series centrifugal dryer was developed by Sino-Alloy Machinery as an important and essential accessory for both the PSF series water-ring and PSQ series underwater pelletizers. The PSL series dryers utilize high-speed centrifugal force in combination with forced air flow and evaporation to dry the pellets. Superior performance over vibrating dryers in terms of drying efficiency, throughput, space-saving, and noise level. The PSL series centrifugal dryer can also be a great replacement for that old vibrating dryer.

Single Screw Squeezing Drying Machine

Categories : Material Processing Machines

With a special designed screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine).

Single Screw Rubbing Drying Machine

Categories : Plastic Washing Line

With a powerful special designed single screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine).

3-in-1 Plastic Recycling and Pelletizing Machine

Categories : Plastic Pelletizer Machines

The machine consists conveyor, shredding drum, extruder and pelletizer to integrate the production to minimize working time and save the manpower.

LAB EXTRUDER-Pelletizer (PR-50)

Categories : Plastic Pelletizer Machines

One of our main products, this can be attached to numerous different machinery lines, including pelletizing lines, master batch machines and compounding machines. Our machinery can process many different kinds of pellets including: (EVA, HDPE, PVC, PE, CaCo3 Sulfur etc) The PR-series is a combination of twin-screw feeder and extruder, which is able to process a round mass of raw materials produced by a banbury mixer. This twin-screw design feeds raw materials so stably that it’d decrease the risk of material supply shortage, and further, it’d increase both the yield rate and product quality. Besides, it would create a stable production line by reducing your labor cost and time with this unique design.

Dyeing and Pelletizing Plant Color Testing

Categories : Plastic Pelletizer Machines

• Model: TY-DB Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS. • Specific resin: PC, PET, ACRYLIC, NYLON. • Capacity: 3-10 kg/hr