Classification : Auxiliary Equipments

Country: Taiwan

Phone: 886-3-4838475

Fax: 886-3-4839052

Contact Person: Donald A. Stephens

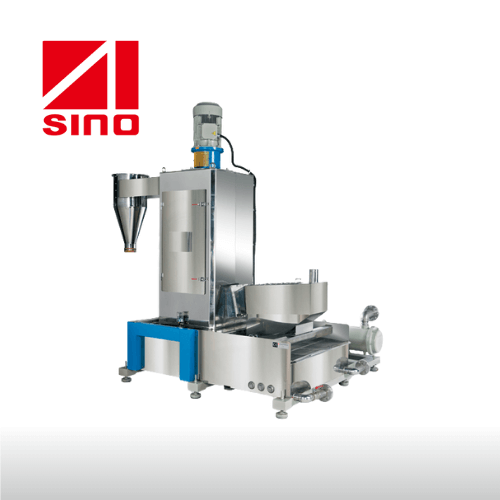

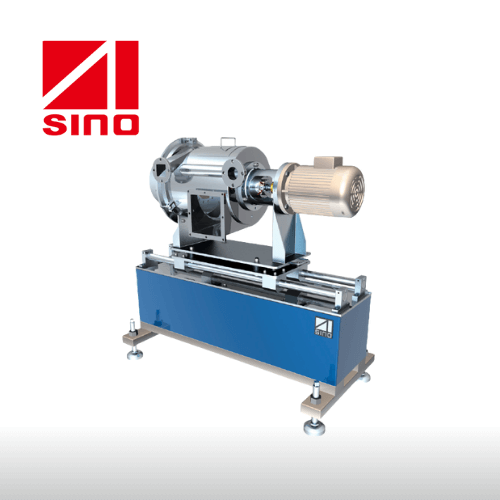

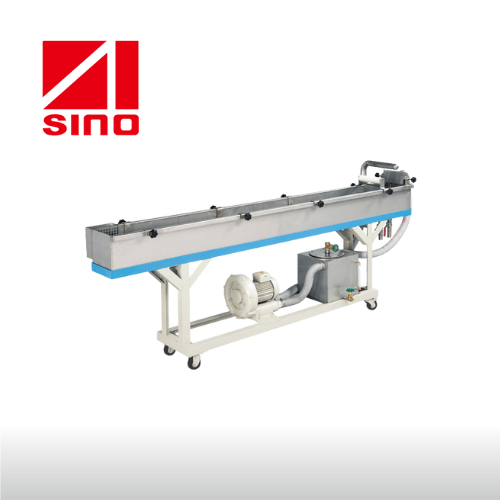

It’s an important accessory for plastic pellet formation and water ring pelletization. The PSL centrifugal dryer utilizes high-speed centrifugal force in combination with forced air flow and evaporation to dry the pellets.

The plastic or rubber pellets from a PSQ under water pelletizer or a PSF water ring pelletizer are put through a four-stage process: draining, centrifugal drying, heat evaporation, and transporting.

The PSL centrifugal dryer has superior performance over old vibrating dryers in terms of drying efficiency, throughput, space saving, and noise level. It’s the most popular and advanced design of its kind on the market. The PSL centrifugal dryer can be a great replacement for old vibrating dryers.

The plastic or rubber pellets from a PSQ under water pelletizer or a PSF water ring pelletizer are put through a four-stage process: draining, centrifugal drying, heat evaporation, and transporting.

The PSL centrifugal dryer has superior performance over old vibrating dryers in terms of drying efficiency, throughput, space saving, and noise level. It’s the most popular and advanced design of its kind on the market. The PSL centrifugal dryer can be a great replacement for old vibrating dryers.

| Model | PSL05 | PSL20 | PSL35 | PSL60 |

|---|---|---|---|---|

| Max Throughput (kg/hr) | 30 | 250 | 700 | 1500 |

| Motor Power (kW) | 0.75 | 1.5 | 4 | 15 |

| Rotation Speed (rpm) | 1750 | 1710 | 1740 | 1750 |

| Moisture Aspirator Motor (kW) | N/A | 0.37 | 0.75 | N/A |

| Power of Water Pump (kW) | 0.75 | 1.5 | 3.75 | 5.5 |

| Discharge Capacity (L/min) | 38 | 140 | 400 | 700 |