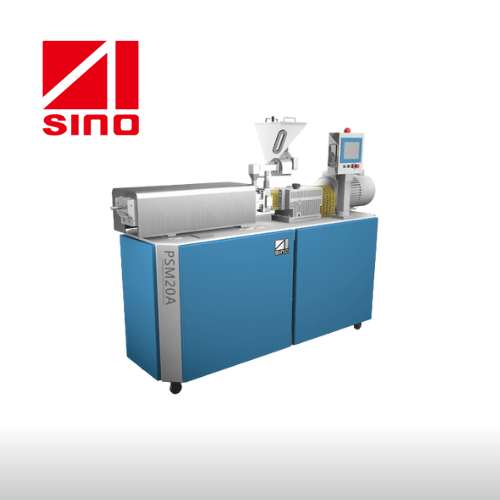

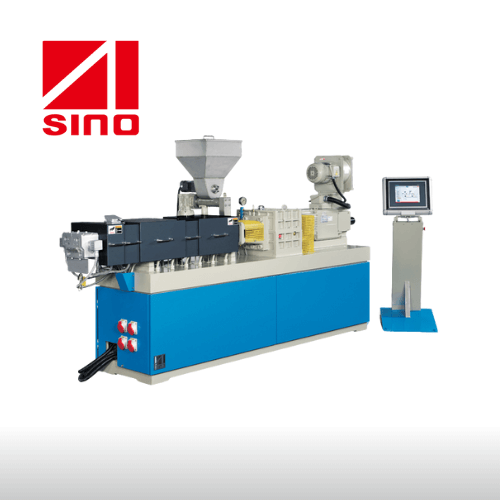

Clam-Shell Design Co-Rotating Twin Screw Extruder-PSM20A

Categories : Granulators

The PSM20A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

Plastic Pelletizing Machine / Pelletizer Extrusion Line

Categories : Plastic Pelletizer Machines

Optional Accessories:(1) Wood flour drier(2) Humidity tester(3) Chiller(4) Water cooling tower(5) Movable electronic balance with portable sewing machine (6) Wood flour grinder

Repet Wood WPC Granule Pelletizer Plant

Categories : Plastic Pelletizer Machines

Indoor & outdoor building material Outdoor furniture

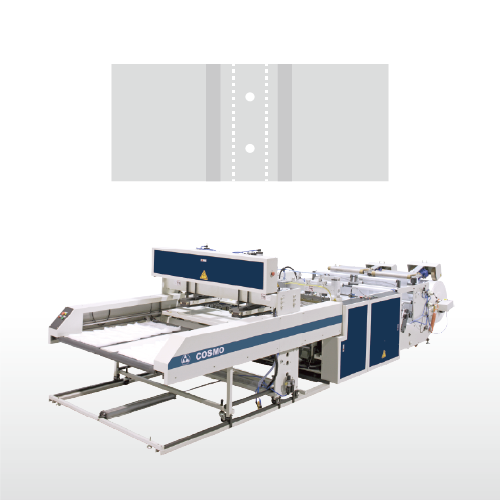

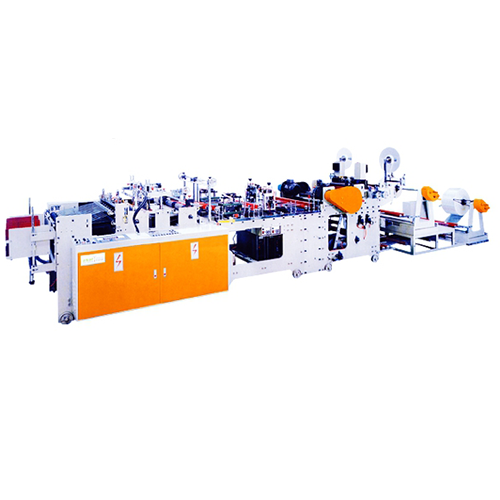

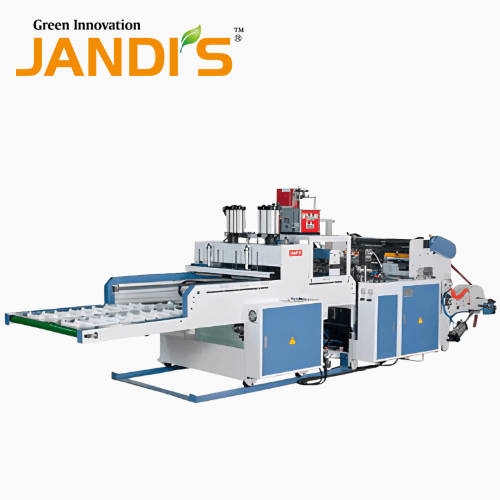

Fully Automatic High Speed 2 Lines Saddle Bag & Wicket Bag Making Machine-SSD-600 / SSD-1000

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatically stop when running out of film / film feeding blocks or jam High-productivity performace saves time and labor

Volumetric Dosers - SCM

Categories : Dosing and Measuring Equipment

SCM series volumetric doser is suitable for even feeding of masterbatch, additive, and virgin material to the plastic process machine. The unit has a selection of four dosing screw sizes for different throughput needs. The unit can supports up to four sets of dosing screws for various material receipt. In SCM-D with three components application, two material dosed via a screw unit and free flow of main material through neckpiece. In SCM-4 with five components application, four materials can be dosed via a screw unit and free flow of main material through neckpiece. SCM in high drying temperature application, such as PET preform production. Water cooling kit should be added to prevent masterbatch from sticking in the screw. Add "H' at the end of the model code. SCM syncronize dosing speed in extruder mode via analog 0~10V input from the extruder. Combination of Shini VL venturi loader realizes auto conveying of material to SCM at all time.

Granulating System: Flow Channel of Plastic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

The plastic strand pelletizing system consists of a die, water-cooling channel, pelletizer, centrifugal hydroextractor and a circulating water-cooling system. Mainly used for plastic materials such as PET、PA、PC etc

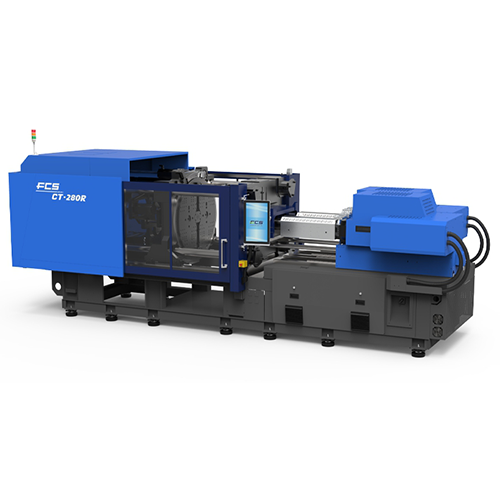

All-Electric Two-Component Injection Molding Machine (CT-R series)

Categories : Electrical Injection Molding Machines

It is All-Electric Two-Component injection molding equipment. It is suitable for two-component and multi-component products, including electronic parts, medical appliance, cosmetic containers, etc.

Rotary Shaft Two-Component Injection Molding Machine (FB-T Series)

Categories : Horizontal Injection Molding Machines

The rotary shaft two-component injection molding equipment, which is suitable for two-component products covering the penetration, including tool handles, buttons, handles and other products.

Large Horizontal Rotary Table Two-Component Injection Molding Machine (HB-R Series)

Categories : Horizontal Injection Molding Machines

It is a large injection molding machine, which is suitable for large-scale home appliances and panels, automotive skylights, lights,

Twin Shaft Shredder (Kroko Twin Series)

Categories : Plastic Shredders

Intelligent control system The program system monitoring the shredding status and allows automatically reverse and forward motion to keep most stability while creating best production. High radial loads with high efficiency and great stability The professionally designed shaft and blades are made with high wear-resistant steel and processed by heat-treatment to increase the service life. It can withstand higher radial load and create higher efficiency while keep the best stability.

Twin Shaft Shredder

Categories : Plastic Shredders

Design especially for bulky plastic products. Eliminate the disadvantage of traditional high horse power crusher. Also for cracking unusual objects, waste tyres, logs, sleepers, etc. High capacity; low noise; installing easy replaced screen makes the desired output size available The knife is detachable, mutiple used and can minimise the wear and tear cost Easy operation Particle in uniform size Customized size is accepatable

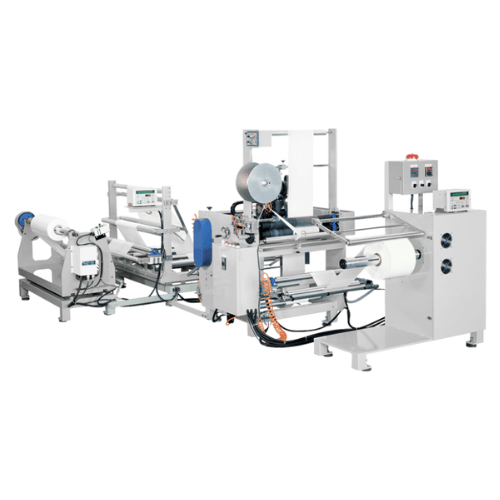

Surface Winding Slitting Machine Series-FSL-BT

Categories : Slitters and Rewinders

Design for slitting thin and slip plastic films of uniform thickness such as laminating paper, aluminum foil, stretch film, isolated film, sticker and other film rolls. The most smooth edge after slit is ensure by the surface wind method.

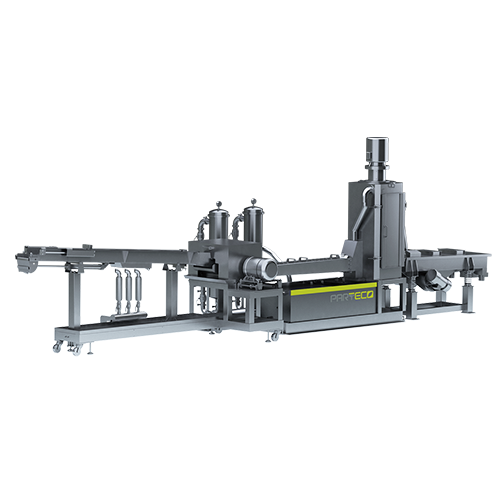

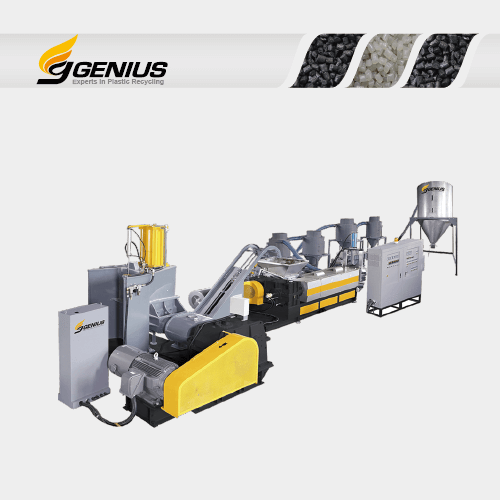

Automatic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Born For Extreme Automation The molten polymer been extruder from the die, fall into automatic water flow. High-pressure water flow from a special designed spray nozzle pulls the strands immediately while cooling at the same time. No more drawing strands before pelletizing. Minimize the lump waste during drawing the strands. GENIUS

Air Cooled Mini Plastic Recycling Machine - Piranha Series

Categories : Plastic Pelletizer Machines

Auto pellet length control via motor load to keep pellet length constant Low temperature heat soak feature - 20 minutes to soak prior to starting To build perfect granules in real-time Full access to dicer and safe access to blade changing Air cooled pelletizer Dual geometry low L/D ratio screws, manufactured from SACM-645, nitride hardened, ground and polished Barrels are manufactured from SACM-645, honed finish and nitride hardened Cold start protection No material shutdown

Compact Co-Rotating Twin Screw Extruder-PSM30A

Categories : Twin Screw Extruders

The PSM30A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM30 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

Co-Extruder, Co Extrusion Machine

Categories : Extrusion Lines For Pipes and Profiles

Part for indoor and outdoor application: Door Frames, Furniture Components, Spacing Panels, etc.

LDPE / HDPE Single Layer BLOWN FILM MACHINE

Categories : Blown Film Extruders

LDPE and HDPE Blown Film Machine is commonly used type in the blown film industry. This is the most economical type which HSIN LONG has rich manufacturing experiences for many years. Most of its final applications are widely used in our daily life which from people’s livelihood to the rising industry of biodegradable. Despite there are lots of advantages in other types of Blown Film Machine, Single Layer LDPE and HDPE Plastic Film Blowing Machine is still a great choice for use of many applications.

Trim Winder For Slitting Machine-FDS-V

Categories : Slitters and Rewinders

-The Trim Winder is driven by a vector motor and inverter, providing synchronous motion with the slitting machine. -Equipped 3" winding air shaft for easy unloading. -The left and right movement of trimming guider is using the Germany made slide screw, it is more efficient and safety than using the liner guider. -Equipped with pneumatic dancing roller unit, the winding tension could be adjusted. -Rewinding speed auto control function.

Fully Automatic Hot Slitting & Sealing Machine LY-1200HS

Categories : Plastic Bag Making Machines

Introduction LY-1200HS is a fully automatic, high speed hot slitting and sealing machine which converts sheet film into tubular film with good quality of sealing at the edge of film. It is suitable for full printing film. Features Servo motor for rewinding unit. Line position control. Auto-tension control for unwinding stand. Auto-tension control for rewinding stand. Edge trimming and waste collecting unit.

Narrow Width Slitting Machine Series FSL-J

Categories : Slitters and Rewinders

For all kinds of high grade thin paper, cellophane, plastic film, and aluminum foil. Especially suitable for positive, and negative foils of condenser and electrolyze paper. For slitting electronics, computer and optical materials, film roll and foil roll.

Slitting Machine Deluxe Type-FSL-V

Categories : Slitters and Rewinders

FSL-V Slitting Machine is specially designed for the plastic films which are of variable thicknesses, low tension demand or tension strictness. It is also suit for slitting a wide variety of materials such as, cellophane, PET, OPP, CPP, PE, PVC, paper roll, and printed films.

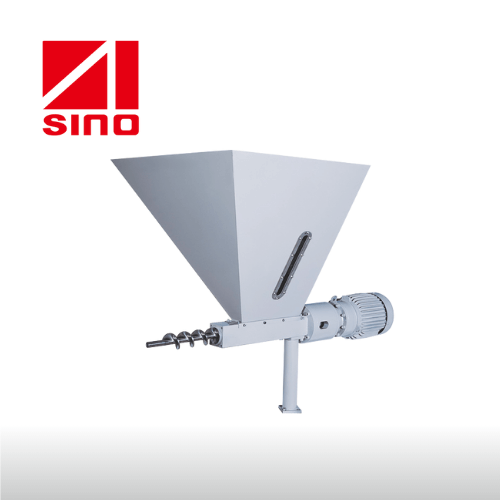

Single Screw Feeder-PSA

Categories : Feeders

The PSA series single-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSA single-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Options include standard double-flight, single-flight, T-type, and spring type screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

Single Shaft Shredder

Categories : Plastic Shredders

Single-shaft shredder system can be almost universally used to and are able to process a board range of different materials (woods, copper wire, plastic lump, tire paper, etc.)

Single Shaft Shredder (Kroko Series)

Categories : Plastic Shredders

Cost Effective Precision Installed with STM gearbox made from Italy. Ensure the best effective precision and the higher torque density. High radial loads with high efficiency and great stability Equipped with professionally designed shaft and blades, it can withstand higher radial load and create higher efficiency while keep the best stability. GENIUS

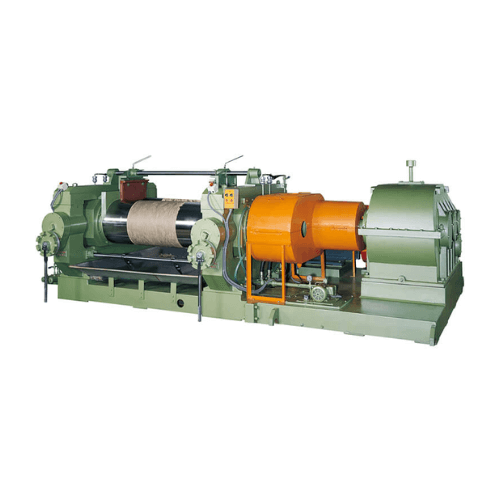

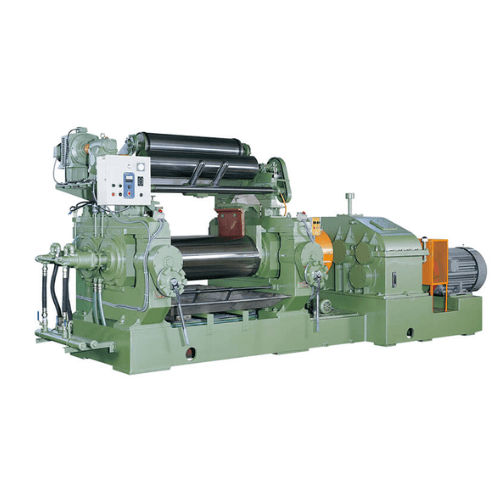

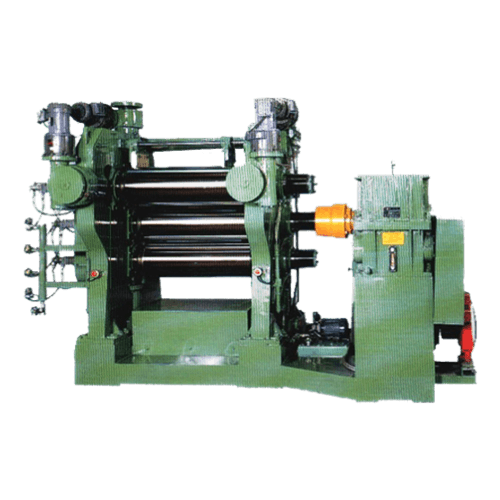

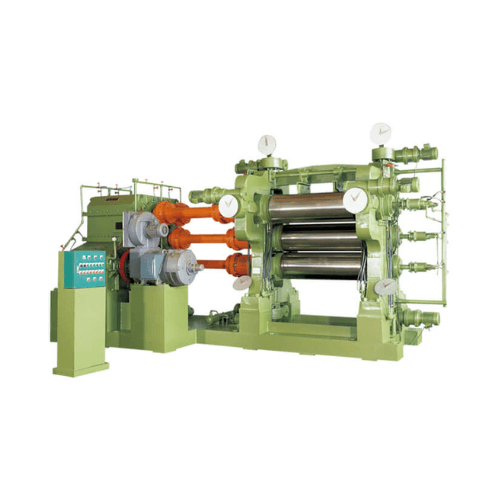

Mixing Mill / Sheeting Mill

Categories : Calendering Machines / Mixing Mills

For Rubber、Plastic & Chemical Mixing/Sheeting This machine is suitable for mixing rubber, synthetic rubber, E.V.A. or PVC and various kind chemical material or sheeting for Extruder, Calender, Hot Press or other processing machinery to make Rubber or Plastic products.

Mixing Mill / Sheeting Mill

Categories : Mixers and Blenders

This machine is suitable for mixing rubber, synthetic rubber, E.V.A. or PVC and various kind chemical material or sheeting for Extruder, Calender, Hot Press or other processing machinery to make Rubber or Plastic products..

Pellet Blender

Categories : Mixers and Blenders

Pellets Blending for Rubber, Plastic & Chemical Industries For Pellets blending

Rubber Mixing mill

Categories : Calendering Machines / Mixing Mills

Designed for mixing and kneading raw rubbers, synthetic rubbers, thermoplastics, E.V.A and chemicals, ensuring maximum uniformity of material. The processed materials are normally used on calenders, hot presses, or other processing machinery for producing various rubber and plastic products.

Stock Blender Rubber Mixing Mill

Categories : Mixers and Blenders

TYPICAL APPLICATIONS The stock blender is installed on the two roll open mixing mill to assist the operator in the mixing of rubber material and chemical power. It features automatic continuous operation, reducing labor requirements, providing safe working conditions, lowering the material temperature, speeding the mix rate and maintaining quality. The action of travel guide holder for the stock blender includes both guide bar type and hydraulic type.

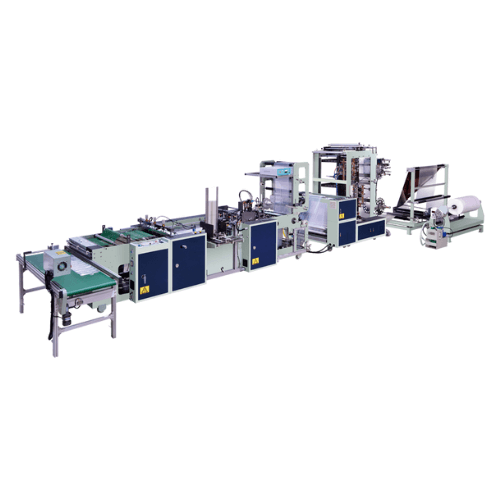

Automatic High-Speed Three Side Sealing Bag Making Machine

Categories : Plastic Bag Making Machines

AUTOMATIC HIGH-SPEED THREE SIDE SEALING BAG MAKING MACHINE

Fully Automatic Side Sealing Machine with Zipper Device LY-800SZP

Categories : Plastic Bag Making Machines

Fully Automatic Side Sealing Machine With Zipper Device LY-800SZP

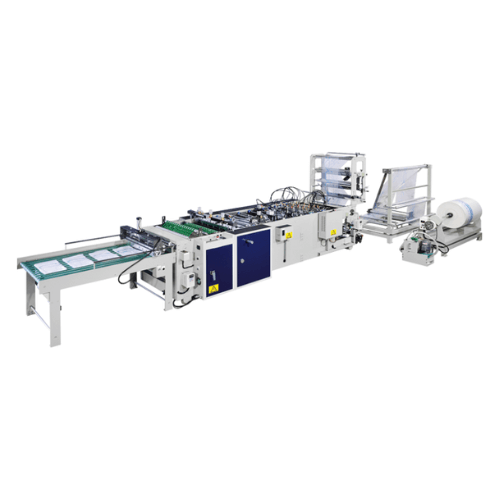

Fully Automatic Side Sealing Machine for PP, OPP, BOPP, CPP, LDPE, HDPE LY-650S / LY-800S / LY-1000S

Categories : Plastic Bag Making Machines

LY-650S/800S/1000S series are basic high-speed side sealing machine. It equips with servo-driven feeding system and human-machine interface for customers easy and friendly operation. It can put on many other options for customers having flexible production.

Shopping Bag Making Machine (GF-JD32E/SVP)

Categories : Bag Making Machine by Applications

Our plastic bag making machine can also handle biodegradable materials for manufacturing biodegradable plastic bag

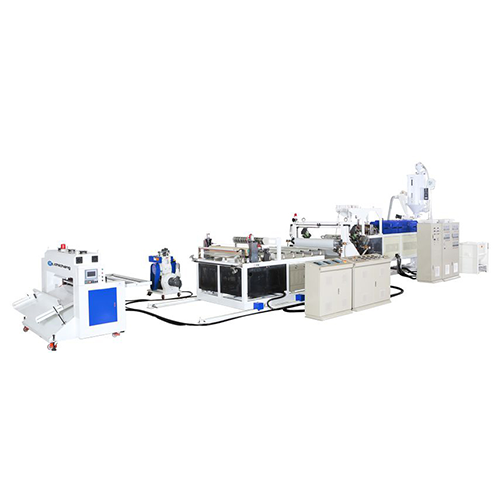

Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

Mono-layer and Multi-layer Sheet Extrusion System for up to 5 layers Versatile and reliable downstream equipment Complete Sheet Extrusion Line with extruders 55-200 mm Processing Capabilities: ABS, PE, PP, PS, PET, PC, PMMA, and other thermoplastic materials.

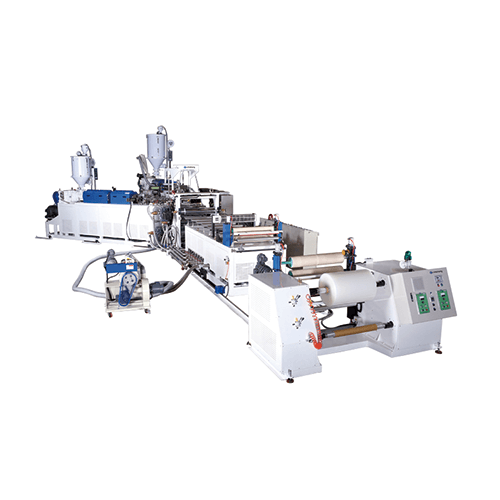

PP Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

Mono layer & Multi-layer Sheet Extrusion Systems for up to 5 layers. Versatile & reliable downstream equipment.Complete Sheet Extrusion Line with extruders from 55-250mm. Processing Capabilities: ABS, PE, PP, HI/PS, PET, PC, PMMA and other thermoplastic materials.

RAS UP 800

Categories : Plastic Waste Recycling Machines

FIMIC’s latest innovations are aimed to address the current challenges in the plastics recycling industry. RAS 800 is the new addition to the automatic self-cleaning melt filters models produced by FIMIC, its increased filtration surface (4775cm2) allows recyclers to reach a higher hourly production capacity with the efficiency and simplicity characteristic of FIMIC’s filtration technology.

Calender for Rubber/Plastic

Categories : Calendering Machines / Mixing Mills

Sheeting for Rubber、Plastic & Chemical Industries This machine is used for sheeting produce for Rubber, E.V.A. or PVC and various kinds chemical material.

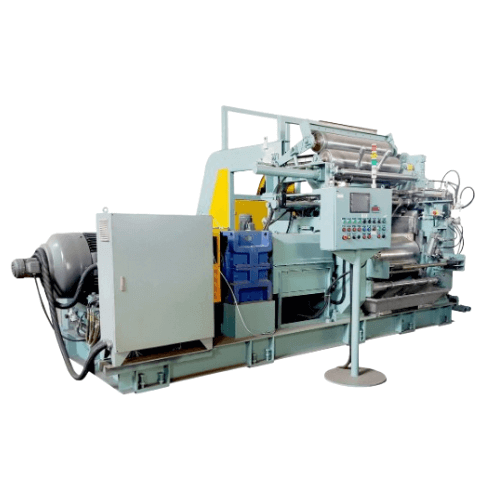

4 Roll Rubber Calender Machine

Categories : Calendering Machines / Mixing Mills

Four shaft gear couplings driven four roll inverted L Type Calender. The main use of Calender is to press the mixed and refinded rubber mixture or many kinds of plastic mixture into uniform-thickness of films, sheets, and plates. Also, it can be applied to rubber or plastic sheets in single or double sticking or topping operation with textile fabricas. Besides, in the procession of sheeting, the machine can also press out the air in the material for producing the products without air bubble after cure. The more quantity of rolls the calendar has, the more times of the sheets are pressed and the calendar can make high quality and even thickness of sheets. This is an four shaft gear coupling driven four roll inverted L type calendar. It applies to tire topping or friction and the manufacture of ball tubes and shoes. The operation of such durable and exquisite calendar equipment is very simple and can get high effects.

CNC AC Servo Beam Robots - New Titan Series

Categories : Industrial Robots

The New Titan series of injection molding robotic arms are used in 650-4000 tons of various plastic horizontal injection molding machines, 3-axis servo drive, arm for taking out products, and the upper and lower arm structures are double-cut. Used for quick removal or a variety of removal applications.

CNC AC Servo Beam Robots - Redstone Series

Categories : Industrial Robots

The Redstone series of robotic arms are used for various types of horizontal plastic injection molding machines of 50-800 tons. There are 3-axis and 5-axis AC servo drives. The product arm robot is for taking out products and runners. The vertical arm structures are single stage and telescopic stage, runner arm can be added to take out runner. The Redstone series of robots are suitable for high-precision, high-speed removal and embedding/insert, with fast response and high positioning accuracy for quick removal for single cavity and multiple cavities and embedding/insert applications.

Rewinding Machine FSR-800

Categories : Slitters and Rewinders

For re-reeling operation of slit rolls with uneven edges or tension. FSR Rewinding Machine will help you to achieve high quality re-reeling, even without the use of an advanced slitting machine. Especially ideal for an automatic filling packaging machine which requires a large reel diameter and rigorous tension quality.

Folding and Rewinding Machine-FND-R1000

Categories : Slitters and Rewinders

Especially designed for folding and rewinding processes of plastic films. The folded edge is neat and stable after rewound. This Folding and Rewinding Machine can easily transform flat film into folding form.

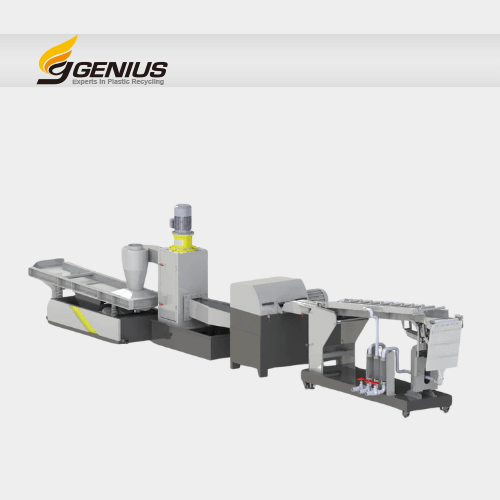

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic Waste Recycling Machines

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

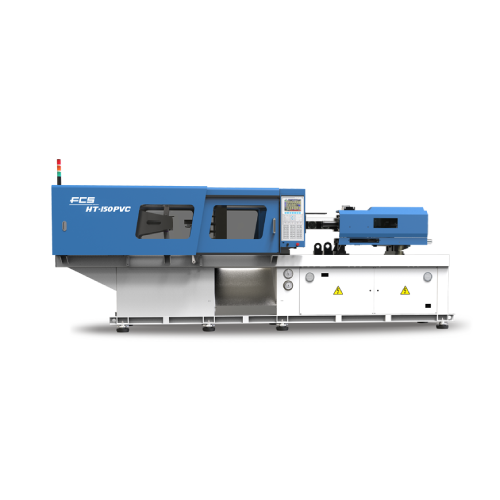

PVC Plastic Pellet Making Machine

Categories : Plastic Pelletizer Machines

Suitable for:PVC compound, rigid PVC, rigid waste recycle Soft PVC:DOP40%~100%

Water-Cooled Type PVC Pelletizer

Categories : Plastic Pelletizer Machines

Water-Cooled Type PVC Pelletizer, wpc pelletizing machine.

Twin-Cone High Speed Pelletizing Machine-Die-Face Cutting

Categories : Compounding Lines

Process Rubber/Plastic mixed material, EVA, TPR, PVC, CaCO3, PVB, PU, TPU compounding, various kinds of masterbatches pelletizing High capacity Low electricity usage Easy to clean and change materials Knead well Die-face cutting Adequate kneading

PVC Pipe Fitting Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The PVC injection molding machine is for producing PVC pipe fittings used in building and construction industries, such as pvc socket, pvc tee, pvc elbow, pvc coupler, and pvc valve.

CaCO3 Compounding Plant

Categories : Compounding Lines

1.Drivetrain: High torque precision gearbox. 2.Extruder is equipped with pressure sensors. Replace filter screen as necessary. 3.Filler masterbatch is used to mix with a plenty of plastic raw materials to produce high-concentration masterbatch. 4.Applicable Materials: PP,LLDPE, LDPE, PLA, EVA, and PVC. 5.Maximum CaCO3 up to 80%~90%.