New Titan Series of 650T-4000T Injection Molding Robot Arm

The New Titan series of robotic arms are used for 650-4000 tons of various large plastic horizontal injection molding machines, 3-axis servo drive, robot arm for taking out products, and the vertical arm is telescopic stage. This series is used for large sized product removal, especially for long product, like bumpers, door strips. Redstone series is also a kind of top entry IML robot that is able to place the labels inside the mold and take out the finished products precisely. It is different from the side entry IML robot, the robotic arm goes into the mould from the top, which would not require much space around the machine.

TN□□□□WS/S3/S5

Model: 1500/1700/1900/2500/3000/4000

W: Telescopic stage

S: single arm (product arm)

S3: Three-axis servo (Traverse/vertical/crosswise)

S5: Five-axis servo(Traverse/vertical/crosswise/A axis/B axis/C axis as optional)

Main Specification

The New Titan series of robotic arms are used for 650 -6000 tons of various large plastic horizontal injection molding machines,3 -axis servo drives, and robot arms for taking out products. This series is used for large-sized product removal, especially for long products, like bumpers, door strips, trash bins, and so on.

| model | TN1500WS-S3 | TN1700WS-S3 | TN1900WS-S3 | TN2500WS-S3 | TN3000WS-S3 | TN4000WS-S3 |

| Power supply capacity (KVA) | 2.7 | 2.7 | 2.7 | 5.4 | 5.4 | 7.2 |

| Applicable molding machine (ton) | 650-1000 | 800-1300 | 1000-1600 | 1600-3000 | 2500-4000 | 3000-6000 |

| Traverse stroke (mm) | 2400 | 2700 | 2700 | 3500 | 4500 | 6000 |

| Crosswise stroke (mm) | 1240 | 1320 | 1480 | 1950 | 2260 | 2350 |

| Vertical stroke (mm) | 1500 | 1700 | 1900 | 2500 | 3000 | 4000 |

| Maximum load (Kg) | 25 | 25 | 25 | 50 | 50 | 50 |

| Dry take out time (sec) | 3.3 | 2.6 | 2.9 | 4.5 | 5.2 | 6.5 |

| Dry cycle time (sec) | 12 | 14 | 19 | 23 | 24 | 28 |

| Air consumption (NI/cycle) | 25 | 27 | 34 | 104 | 120 | 140 |

| Net weight (Kg) | 800 | 850 | 920 | 2500 | 2800 | 3500 |

TN Series General Specifications

| power supply Power Source |

working pressure Working Pressure |

Maximum allowable air pressure Max.Allowed Pressure |

Drive mode Drive System |

Swivel |

| 1Φ/3ΦAC220V±20V 50/60HZ |

5Kgf/cm 2 0.49Mpa |

8Kgf/cm 2 0.8Mpa |

AC Servo Motor | 90° Fixed Pneumatic |

Air pressure scissors: Air pressure scissors can be installed for runner cutting.

Photoelectric inspection on finished products: The sensor can be installed at the conveyor. Place the finished product on the conveyor to avoid hitting among products.

Tricolor light: installed with tricolor light, so the user can easily check the robot operating state from a distance to workshop management. It can also distinguish the condition of the robots in auto, manual, or failure status.

A&C axis servo driven: The ends of the arm rotary mechanism can be driven by an AC servo motor with multiple angles and gestures.

Middle plate inspection: The position of the middle plate should be checked after mold opened the end position to avoid the runner arm from hitting the middle – plate.

Lubrication function: Manual central lubrication or auto lubrication can be equipped. For auto lubrication, when robot running times achieve a setting value, it will lubricate automatically.

Quick EOAT changing: To realize the quick separation of the EOAT and the robot. It’s simple and can save EOAT changing time.

|

|

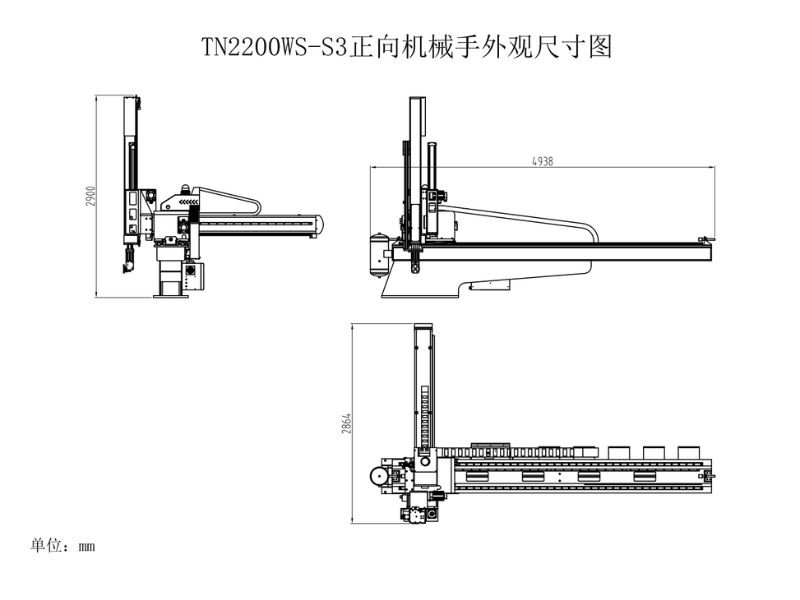

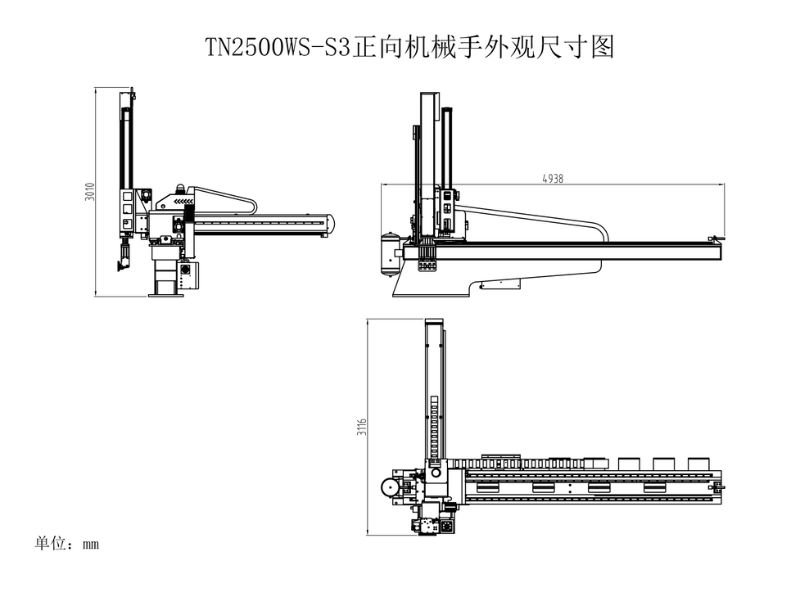

| TN2200WS-S3 | TN2500WS-S3 |