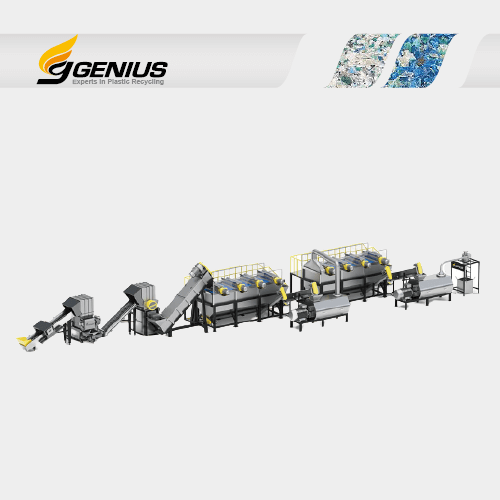

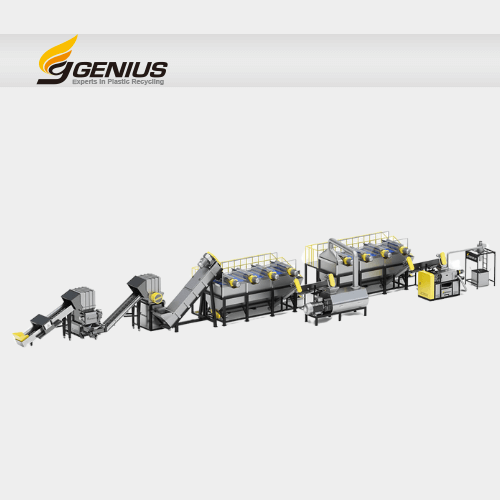

Classification : Plastic Recycling Machine

Country: Taiwan

Phone: 886-4-2630-1621

Fax: 886-4-2630-1716

Contact Person: Peter Tsai

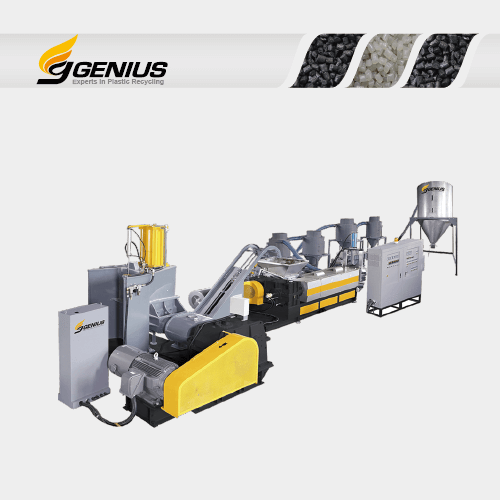

1.Drivetrain: High torque precision gearbox.

2.Extruder is equipped with pressure sensors. Replace filter screen as necessary.

3.Filler masterbatch is used to mix with a plenty of plastic raw materials to produce high-concentration masterbatch.

4.Applicable Materials: PP,LLDPE, LDPE, PLA, EVA, and PVC.

5.Maximum CaCO3 up to 80%~90%.

2.Extruder is equipped with pressure sensors. Replace filter screen as necessary.

3.Filler masterbatch is used to mix with a plenty of plastic raw materials to produce high-concentration masterbatch.

4.Applicable Materials: PP,LLDPE, LDPE, PLA, EVA, and PVC.

5.Maximum CaCO3 up to 80%~90%.

| Model |

CCP-100 |

CCP-125 |

CCP-150 |

CCP-175 |

CCP-200 |

|

| Extrusion capacity | Up to 350 kg/hr | Up to 450 kg/hr | Up to 600 kg/hr | Up to 850 kg/hr | Up to 1000 kg/hr | |

| Screw diameter | Φ100 mm |

Φ125 mm |

Φ150 mm | Φ175 mm | Φ200 mm | |

| Main motor | 75 HP |

125 HP |

150 HP | 175 HP | 200 HP | |

- The screw is made of wear resistance materials. Ensure the longevity of product life.

- Sufficient dispersion

- Save cost of plastic raw materials

- Steady operation

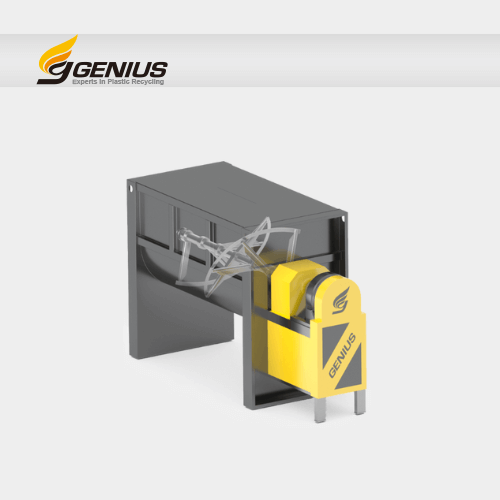

Double-elbow feeding device

Dough-like plastic raw materials are preferable.

The design of double- elbow allows larger amount of input quantity.

Great compounded of plastic raw materials and filler masterbatch.

Hot die face air cutting device

Pelletizing knife is a universal joint design. Dust-free.