Twin Shaft Shredder (Kroko Twin Series)

Categories : Plastic Shredders

Intelligent control system The program system monitoring the shredding status and allows automatically reverse and forward motion to keep most stability while creating best production. High radial loads with high efficiency and great stability The professionally designed shaft and blades are made with high wear-resistant steel and processed by heat-treatment to increase the service life. It can withstand higher radial load and create higher efficiency while keep the best stability.

Twin Shaft Shredder

Categories : Plastic Shredders

Design especially for bulky plastic products. Eliminate the disadvantage of traditional high horse power crusher. Also for cracking unusual objects, waste tyres, logs, sleepers, etc. High capacity; low noise; installing easy replaced screen makes the desired output size available The knife is detachable, mutiple used and can minimise the wear and tear cost Easy operation Particle in uniform size Customized size is accepatable

Solvent-less Laminating Machine (WSL Series)

Categories : Industrial Lamination

For the solvent-free lamination, WORLDLY launches solvent-less laminating machine WSL series. The manipulation is much easier and simple with the PLC digital control system and touchable human-machine interface. Solvent-less laminating machine WSL series is the leading popular machines for solvent-free. It has higher compound speed in order to increase productivity. And, there is no wasted costs caused by the solvent evaporation. Also, the coating thickness is very thin with 100% solid ingredient which can reduce a lot of cost. The production won't produce solvent evaporation and there is no solvent residue. It all conforms to food safety regulations. Meanwhile, there's no need for drying chamber which can save energy. The machine itself can be shorten to save space for additional use which can make a significantly cost reduction.

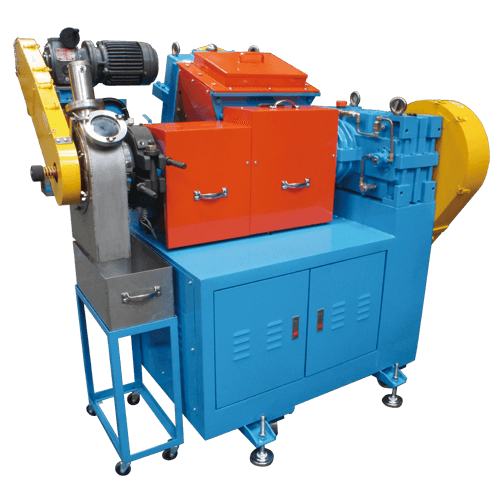

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Side feeding barrel is better for storage and steady material input at same time. Main Extruder can extrude the material whose moisture below 7%. Sub extruder conducts second time filtering and ventilating for dirtier materials. Die face cutting frame made in SUS304 to prevent the rust and corrosion. Knives adjustments automaticlly patent design.The knife and die plate always set at 90 degree. No need to adjust frequently. High speed dryer is soundproof with double layer sealing design. The underneath water tank can gather the waste water and filter the impurity. Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryer. The triple layers vibrating screener is easy to clean, disassemble and assemble. Can customize the diameter of the hole. Blower with noiseless design. Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

Force Hopper Feeding Plastic Recycling Machine (H Series)

Categories : Plastic Pelletizer Machines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost save up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean

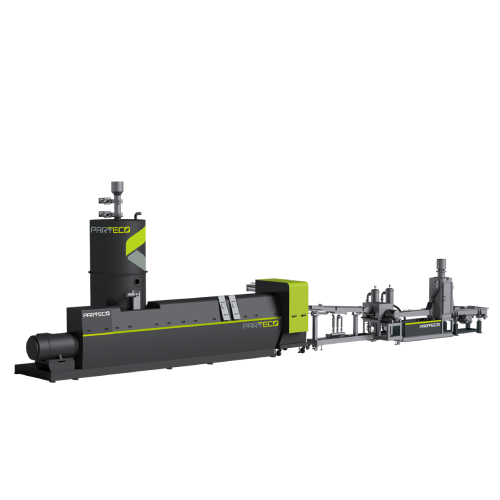

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pelletizer Machines

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly applied to the processing of PET crushed chips recycled from PET bottles. By means of vacuum degassing system to remove the water and impurities, then go through the melting extrusion, filtering and granulating process to tailor made the complete PET recycling solutions for you. Applicable materials Film or Flakes : PET Bottle Flakes

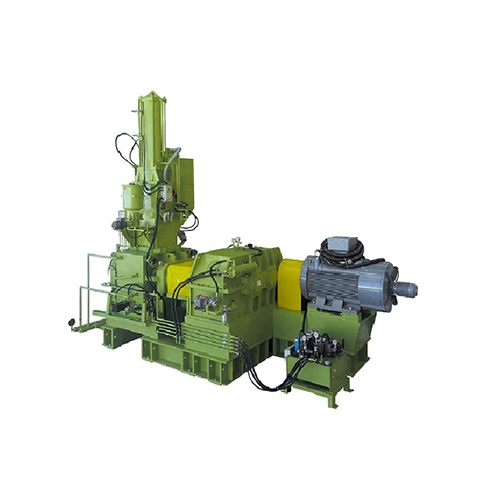

Intensive Mixer

Categories : Rubber Mixers

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber: Drill hole type jacket. Excellent cooling ability. Material contact surface: Hard chrome plating and fine polish. 3.Discharge door: Excellent sealing. No material leakage. 4.Ram: Drive by air cylinder. Good mixing and dispersion quality.

Screws And Barrels For Plastic Injection Molding

Categories : Screws and Barrels

Nan Yun's injection molding screw design team is able to provide ideal screw solutions for injection molding screw application. As the largest screw and barrel manufacture in Taiwan, Nan Yun has invaluable experience on screw barrel design for plastic moulding machine, vertical plastic injection moulding machine. there are more wear and tear on these components for injection moulding machine due to its cycle is longer than the rest of plastic machinery, so that it’s essential to have correct combination of material between screw and barrel for plastic injection molding to ensure a better performance and lasting lifetime.

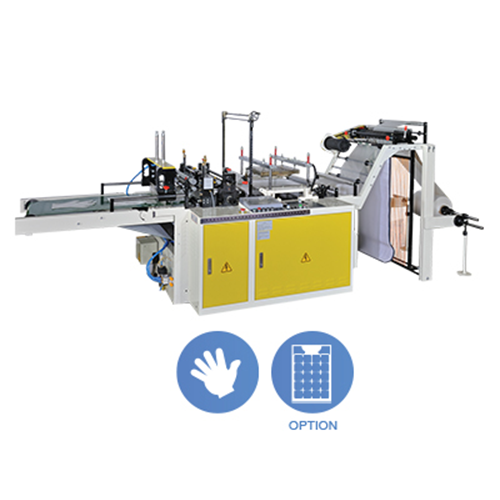

Automatic High Speed HDPE Disposable Gloves Making Machine With Servo Motor Control (CWAG-500-SV)

Categories : Bag Making Machine by Applications

Japan made servo motor & servo driver controls bag length precisely and stable speed, reducing electric consumption. Bag length & speed can be changed easily from touch screen. It specializes to make HDPE disposable gloves. Aluminum alloy for glove mould, strong sealing & easy tear. Hot pins for auto stacking easy to pack. Customized Ice bag mould as OPTION. plastic gloves making machine

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Force Side Feeding Plastic Recycling Machine (RECOi Series)

Categories : Plastic Waste Recycling Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

LT67_Rectilinear Displacement Transducer With ip67 Protection

Categories : Indicators and Sensors

This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) The grooves on the profile provide an excellent alternative to the usual system of fastening with brackets Ideal for applications on plastic injection presses with installation at points that are highly exposed to lubricants Also indicated for processing machines on which the transducer cannot be protected by guards

Servo Robot For Mobile Frame Loading

Categories : Industrial Robots

This industrial robot is used for automatic embedding feeding device for steel sheets for I.M.M, which solves the problem of manual insert(low efficiency, high scrap rate and high production cost). Using magnetic sensor to positioning with 1 axis servo control system make the insert more accurate. HMI interface is easy to operate.

JS 336 PVC Shrinkable Film Making Machine

Categories : Film and Sheet Extrusion Lines

PVC Shrinkable file offer many excellent benefits, such as glossiness, high transparency, durability, water resistance and easy control of shrinkage. They have been applied to a wide variety of product packaging, such as foodstuff, beverage bottles, sporting goods, etc.

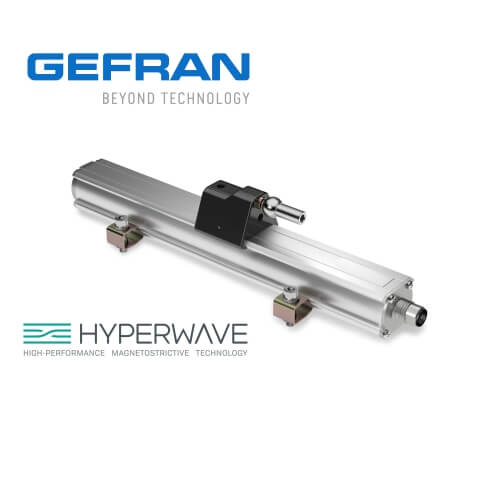

WPG-A Contactless Magnetostrictive Linear Position Transducer(Analog Output)

Categories : Indicators and Sensors

Strokes from 50 to 1500 mm Sliding or floating magnetic cursor Direct and reverse analog output for displacement Standard valve or M12 connector Work temperature: -20...+75°C IP67 protection Power supply 24Vdc ±20% Electromagnetic compatibility EMC 2014/30/EU Compliant to the directive RoHS 2011/65/EU

Force Feeding Single Stage Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing, Suitable for a variety of raw materials, Easy to operate; prority transcends traditional model, Spaghetti cutting is suitable for high melting index plastic, Optional equipment- crusher and mixer, enables every batch of material to mix well, No noise during pellet cutting

Automation Equipment - Vertical Transporter

Categories : Industrial Robots

The mechanical arm signals are connected to accurately catch the finished product and protect the finished product. After tilting, the angle is automatically tilted to slide the finished product toward the workbench. RRP plastic countertop, does not scratch the finished product, beautiful appearance and wear resistance.

Laboratory dispersion kneader

Categories : Dispersion Kneaders

FEATURES: Mixer IT IS AN INDEAL EQUIPMENT FOR RESEARCH AND DEVELOPMENT OF THE LATEST RUBBER AND PLASTICS MATERIAL. IT IS SPECIALLY DESIGNED FOR COMPOUNDING WIDE RANGE AND SMALL BATCH OF RUBBER OR PLASTICS MATERIAL. EXCELLENT COOLING SYSTEM IS EQUIPPED TO CHILL THE MATERIAL TO BE COMPOUNDED INTO A HIGH QUALITY COMPOUNDED MATERIAL. DESIGNED TO COMPOUND THE MATERIAL EVELY SO AS TO MEET THE REQUIRMENT OF HIGH QUALITY AND EVEN COMPOUNDED MATERIAL. THE MIXING CHAMBER IS CONSTRUCTED WITH HEAT RESISTANCE, WEAR OUT RESISTANCE AND ANTI-CORROSIVE.

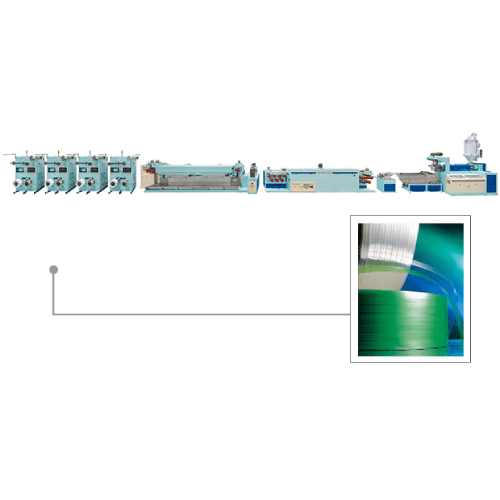

JS 237APR / JS 2310APR2 PET Heavy Duty Strapping Band Making Machine

Categories : Tape Extrusion Machines

Extruding output range: 40 - 100 kgs/hr or 80 - 220 kgs/hr. Band width: 9.5 -19mm. High precision band width +/- 0.5mm. Entire machine employs direct drive for low noise running. Gears are hardened and precision ground for quiet running performance. SACMI screw is nitrogen treated, precision ground, and stress relieved. SACMI barrel is nitrogen treated, precision ground, and stress relieved. #304 stainless steel cooling water tank. Separate adjustment for winding torque and running speed ensures uniformity of band. Stretching unit is all-gear driven with oil bath lubrication for stability, quiet running and long service life. WINDING UNIT The winding unit is driven by a DC torque motor, featuring torque adjustment. The buzzer sounds when the preset length of band is reached. Changing the gears conveniently changes the winding width. Aluminum winding rollers. Choice of 200 or 400mm core bobbin. PRE-HEAT STRETCHING UNIT The machine uses electric heating to quickly achieve high temperature. The four stretching rollers are individually driven, and heated for efficient stretching. Stretching speed is controlled by a frequency inverter for maximum stability. EMBOSSING ROLLER The embossing rollers are manufactured from SKD11 material, vacuum heat treated for superior hardness and maximum wear resistance. Embossing depth is pneumatically adjusted with indication reader for accurate reading. Separate motor drive. MAIN CONTROL PANEL The temperature for the barrel, screw, and die are separately displayed on the main control panel. Temperature can be preset. JS 2310APR2 Hydraulic screen change. JS 2310APR2 2 layer straightening operation extends heating time, ensuring the stability of bands and superior tensile strength. Hot air circulation provides for a more efficient heating solution. Equipped with a water cooling tank for upgrading cooling and stiffening performance. Outstanding dehumidifying performance ensures constant band quality. DEHUMIDIFYING DRYER The dehumidifying dryer lowers the moisture content below 0.2% to achieve the utmost performance from production materials. The dryer prevents such problems as cracking, streaking, bubbles, flow marks, poor transparency, etc., which are all caused by incompletely dry resin.

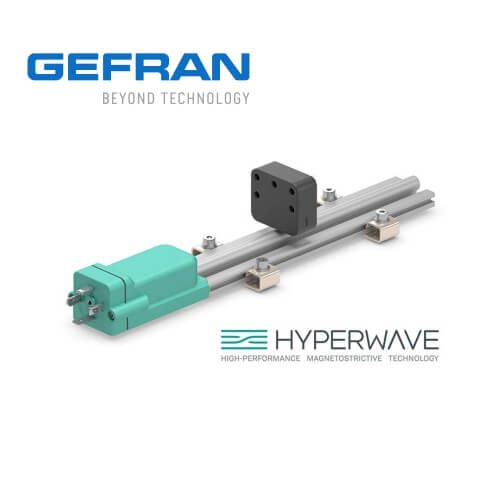

WPP-A Contactless Magnetostrictive Linear Position Transducer(Analog Output)

Categories : Indicators and Sensors

Contactless linear position transducer with HYPERWAVE magnetostrictive technology. The absence of electrical contact on the cursor eliminates all wear and guarantees almost unlimited life. High performance in terms of environmental IP protection and EMC immunity. High accuracy of the mesurement with reference to the non linearity, repeatability and hysteresis. High resistance to vibrations, mechanical shocks for use in a harsh industrial environment.

Screws and Barrels for Profile Extruders

Categories : Screws and Barrels

+Suitable for all kinds of PVC profile products. +High production & high mixing. +The bi-metallic screw is wear-resisting & long life span.

Screws and Barrels for Waste Plastic Recycling Pelletizing Machine

Categories : Screws and Barrels

● Wear-resistant,high mixer,production increased,life span extended ● Cautious process procedures ● Design of advanced extrusion by net pressure ● Design of advanced and high quality plasticization ● Screws are designed for the ratio and properties from different plastic material

Bi-metallic Screws and Barrels

Categories : Screws and Barrels

Over Welding of nickel based alloy on top of the thread surface (screw) and internal diameter (barrel). +Evenly hardened surface with 2mm thickness. +Hardness will not decrease under normal temperature. +The hardened surface is 2 or 3 times more wear-resistant than regular surface. bimetallic

LAB EXTRUDER-Pelletizer (PR-50)

Categories : Plastic Pelletizer Machines

One of our main products, this can be attached to numerous different machinery lines, including pelletizing lines, master batch machines and compounding machines. Our machinery can process many different kinds of pellets including: (EVA, HDPE, PVC, PE, CaCo3 Sulfur etc) The PR-series is a combination of twin-screw feeder and extruder, which is able to process a round mass of raw materials produced by a banbury mixer. This twin-screw design feeds raw materials so stably that it’d decrease the risk of material supply shortage, and further, it’d increase both the yield rate and product quality. Besides, it would create a stable production line by reducing your labor cost and time with this unique design.

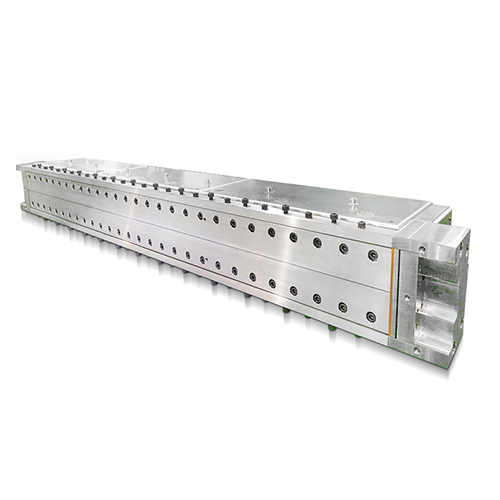

Extrusion Dies MELTBLOWN DIES

Categories : Extrusion Dies / Dies Heads

SUITABLE AVAILABLE FOR POLYMERS INCLUDING PET And PP High processing precision. Internal heating with heating rod, external heating with heating board, temperature control by heating oil cycle to ensure products of good uniformity. Meltblown filter in continuous and automated production to cut production losses more than 35%, cu costs, reliable product quality. Cut production materials consumption sharply. Featuring high yield, low power consumption, low loss, easy operation. Integrated meltblown Extrusion Die. Integrated meltblown Extrusion Die featuring precision aperture, good consistency and without maintenance wear out. Improved meltblown fiber quality and uniformity, improved product quality. Improved Extrusion Die life cycle and life span. Reduced Extrusion Die change operating time, cut maintenance cost and power consumption. Installation capacity down 30 ~ 40 KW. Cut production costs sharply.

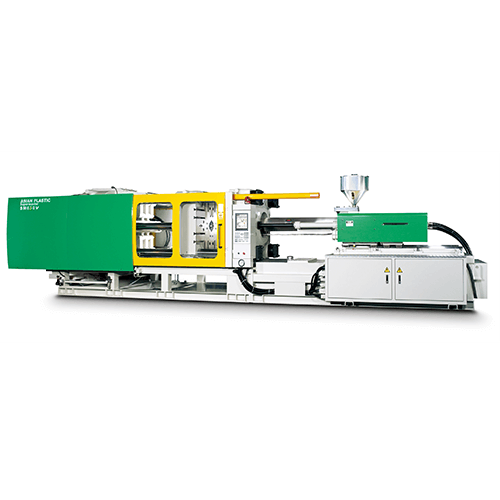

Heavy Duty Double Toggle Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision. The injection carriage uses a balanced double hydraulic cylinder to provide a secure hold between the mould and the nozzle to eliminate nozzle leakage. Linear guide ways reduce mechanical friction, decrease machine wear and increases accuracy over back pressure providing better control of the injection sequence. Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportional valves is more precise resulting in more accurate control.

HIGH PRECISION HYDRAULIC CUTTING PRESS CSS-607

Categories : Foaming Machinery

The Structure Of Press Body Is Made By Special Steel Shaped Materials That Features Pressure-Resistant Function To Maintain A Permanent Plane, With Its Integrated Shaping Of Punch And Slide To Fully Shows A High Resistance Of Wear And Tear, Excellent Strength And Stable Pressing That Would Help Prolong The Service Life Of The Mold. The Cutting Tool Can Be Used With Laser Cutter For Either Pressing Or Die Pressing, Thus Making Product No Burrs And Enabling Clear Angles. The Blowing Device Can Be Worked Further With Mechanical Action, One Punch And One Blowing Subsequently To Absorb Automatically The Well-Cut Finished-Goods That Makes An Easy Access And Safe To Take Feeds, Along With An Installation Of The Almighty Grooved Base Plate, The Mold Locking Is Convenient And Rapid. With A Device Of Fixed-Point Type Pedal Switch, It Shows Up A Mature Technologic Design For Industrial Use. With Its Semi-Automatic Knife Mold Design, It Enables Operators An Easy And Safe Operation.

PRECISION HYDRAULIC AUTOMATIC DIE-CUTTING MACHINE/4COLUMU TYPE CSS-603

Categories : Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance. 4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders. The unit performs precisely, stably, quietly, nimble and powerful. lt'sconvenient even for the use at the upstairs of a factory. Cutting depth can be precisely set up to a tolerance of 0.008 mm. Through the use of the longwearing special designed steel plate to replace conventional cutting board, can prolong lift of cutter and obtain better cutting quality and efficiency Processed item may be full or half cut-off. ltems with adhesive may be used as well Products are free from rough edges. The machine is equipped with a protecting device to ensure safety of people and the machine. Automatic cooling system and full-auto cutting device are available for additionally purchase and fitting. Designed in high-precision construction, this machine can be used to perform full-cut and half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with linear rail designed for the feeding mechanism. Two-step pressure control to achieve flexible and lower noise operation. It is suitable for multi-level factory buildings. Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy (0.001mm optional). High-precision german steel plate is used to achieve higher durability and wear free operation. This machine uses advanced and durable hydraulic system and electronic control circuits. The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

High Speed Injection Molding Machine (TSV Series)

Categories : Hydraulic Clamping Injection Molding Machines

• The double hydraulic cylinder provides secure hold on pressurefor the injection carriage eliminating nozzle leakage. • The toggles are lubricated with the graphite bronze bushes to ensure lower friction wear, assure greater accuracy and greatlyextended life of the clamp unit. • Fast clamping system equipped with regeneration circuit increase speed by 60% to shorten cycle time and save energy. • Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportion-al valves is more precise resulting in more accurate control.

Auto Batch Vacuum Foaming System SA-1BVF

Categories : Vacuum Forming Machines

The SA-1BVF can be used with an existing auto batch foaming machine or with SUNKIST's own SA-1B, SA-1BS, SA-1BM and SA-1HA. After the mixture is loaded into mold box, the mold box is moved into this chamber via a carriage. After the mold box us placed inside the curing chamber, the door of the chamber automatically closes and shut tightly. An operator can then adjust the pressure inside the chamber with the control panel. The quality and physical properties of the foam that is formed will be affected when the pressure is changed, ie. the volume of the foam size will increase, foam tensile strength will also increase dramatically, and the hardness of the foam will change. This machine is environmental friendly, reduce the amount of chemicals used and reduce the fire risk.

THS 850/950

Categories : Industrial Robots

•Vacuum gripper circuits. •Automatic mode micro-modify. •Automatic stacking/palletizing. •Pick up parts from core/Cavity side of the mold. •Reject parts/alarms/operation history. •Stand by above mold,waiting outside mold. •Bad count/break down history/operate record.

Hydraulic Clamping Injection Molding Machine DHT Series

Categories : Hydraulic Clamping Injection Molding Machines

Direct hydraulic clamping injection molding machines are designed without toggle mechanisms that enable to avoid the toggle wear. This model can increase the position accuracy and is good for high technology and high precision plastic products.

Double Toggle Injection Molding Machine (SMV Series)

Categories : Horizontal Injection Molding Machines

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Multi steps injection pressure and speedcontrol. • Steel bushes have a hardness of HV800 for wear resistances. • Auto-lubrication system is provided to assure the constant lubrication of the toggle mechanism • Multi-stroke hydraulic ejector ensures positive ejection of the product and enables unmanned production with or without the use of a robotic arm. • Differential hydraulic circuit shortens cycle time and saves energy. • Low pressure mold protection system was used to avoid mold damage or excessive wear.

Vertical Electric Injection Molding Machine-YE-50V

Categories : Vertical Injection Molding Machines

A number of patented electric injection device Precision electric injection function Precision electric metering function Electric pedestal does not slide function Energy-saving hydraulic servo mold clamping function Accurate low pressure off mode protection function Energy-saving hydraulic servo thimble function Template rust plating processing Template parallelism fine tuning function Template low-top design With 8 T-groove, easy to fix the mold Thick template with high tensile guide posts Configuration template guide column anti-drip bumper sleeve Configure mechanical closing safety bars Configure mechanical shut-off safety electrical protection Open all the safety gates to stop the design Configuration key type safety door safety switch Configuration rail horizontal operation safety gate design Injection device can be flipped to maintain the factory accuracy to reduce the height of the handling method Injection closed loop feedback function Holding pressure switching point accuracy of 0.01mm Packing pressure accuracy of up to 0.1% High-speed rigid filling, to eliminate floating phenomenon Prevent the drawing function A variety of peripheral equipment chain function Equipped with peripheral equipment power outlet With robot centralized terminal block Hopper holder moving function Equipped with resin feed tube holder Equipped with adjustable height white iron trough Equipped with a perspective control water divider Equipped with cooling water quick connector The machine is neat and without any pipe exposure Than the same level of oil-saving 25% to 60% Than the same level oil machine to save cooling water 70% Equipped with 10.4 "color touch screen PID automatic temperature adjustment function Japan's Mitsubishi control system Equipped with wear-resistant material pipe

Disc Coupling

Categories : Gears

(1) NO-LUBRICATION REQUIRED: No lubricants are needed and no noises or wear and tear produced because there is no sliding or friction. (2) MAINTENANCE-FREE: ”LEAVE IT FOR GOOD AFTER INSTALLATION” It lasts forever as long as is used correctly. (3) LIGHT WEIGHT W/HIGH TORQUE: By operations, it is available in a wide range; it can be made of aluminum alloy to reduce the weight. (4) LARGE OFF-CENTER ALLOWED: With large range of off-centering, it can be used flexibly in all kinds of transmission systems. (5) SUITS HIGH-TEMPERATURE APPLICATIONS: All-metal-pars construct makes it suitable for high temperatures. (6) BACKLASH-FREE: WITH GOOD TORSIONAL RIGIDITY Perfect for axial rotation that requires accuracy and machines with phase-control. (7) CAN BE USED IN EVEN HIGHER SPEEDS: It is highly balanced due to being backlash-free and light weight. (8) EASY TO INSTALL: Comprising small number of pasts and being compact, it can be installed/uninstalled quickly. (9) ROBUST STRUCTURE AND HIGH SAFETY COEFFICIENT: With load stress kept at low standard, it works with very high safety coefficient. (10) AUTOMATIC PROTECTIVE DEVICE: In case of damage, an automatic protective device rotates via pads.