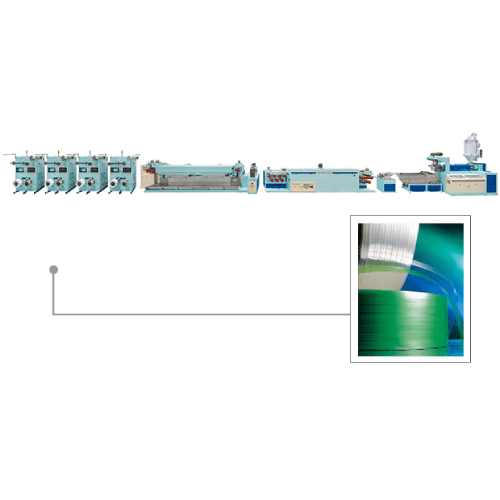

Get the maximum production from JUMBO STEEL PET Band making Machine. This machine produces band widths of 9.5-19MM. Production speed of up to 120 meters per minute for each line. The JS 237APR is simple to run and requires minimal training. If increasing your PET band production is your goal, come to JUMBO STEEL.

JUMBO STEEL's JS 237APR ,JS 2310APR2 has all the very latest technology for increased productivity in PET strapping band production. This newly designed machine provides faster production and superior product.

Quality Features For Outstanding Performance :

- Extruding output range: 40 - 100 kgs/hr or 80 - 220 kgs/hr.

- Band width: 9.5 -19mm.

- High precision band width +/- 0.5mm.

- Entire machine employs direct drive for low noise running.

- Gears are hardened and precision ground for quiet running performance.

- SACMI screw is nitrogen treated, precision ground, and stress relieved.

- SACMI barrel is nitrogen treated, precision ground, and stress relieved.

- #304 stainless steel cooling water tank.

- Separate adjustment for winding torque and running speed ensures uniformity of band.

- Stretching unit is all-gear driven with oil bath lubrication for stability, quiet running and long service life.

WINDING UNIT

- The winding unit is driven by a DC torque motor, featuring torque adjustment.

- The buzzer sounds when the preset length of band is reached.

- Changing the gears conveniently changes the winding width.

- Aluminum winding rollers.

- Choice of 200 or 400mm core bobbin.

PRE-HEAT STRETCHING UNIT

- The machine uses electric heating to quickly achieve high temperature.

- The four stretching rollers are individually driven, and heated for efficient stretching.

- Stretching speed is controlled by a frequency inverter for maximum stability.

EMBOSSING ROLLER

- The embossing rollers are manufactured from SKD11 material,

vacuum heat treated for superior hardness and maximum wear resistance. - Embossing depth is pneumatically adjusted with indication reader for accurate reading.

- Separate motor drive.

MAIN CONTROL PANEL

The temperature for the barrel, screw, and die are separately displayed

on the main control panel.

Temperature can be preset.

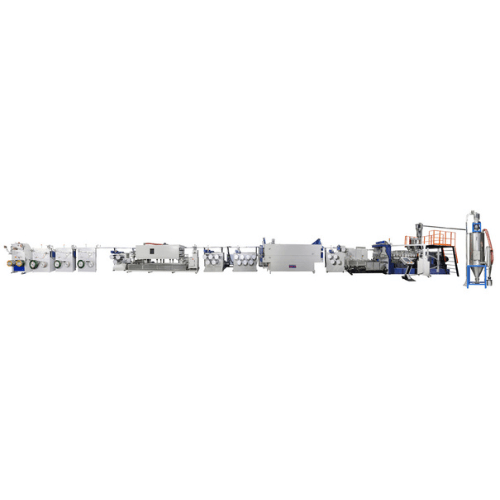

JS 2310APR2

Hydraulic screen change.

JS 2310APR2

- 2 layer straightening operation extends heating time,

ensuring the stability of bands and superior tensile strength. - Hot air circulation provides for a more efficient heating solution.

- Equipped with a water cooling tank for upgrading cooling and stiffening performance.

Outstanding dehumidifying performance ensures constant band quality.

DEHUMIDIFYING DRYER

- The dehumidifying dryer lowers the moisture content below 0.2%

to achieve the utmost performance from production materials. - The dryer prevents such problems as cracking, streaking, bubbles,

flow marks, poor transparency, etc., which are all caused by incompletely dry resin.

OPTIONAL EQUIPMENT :

- Water chiller

- Tensile Tester

|

CHILLER |

Drying System |

Tensile Tester |

Micro-Computer Tensile Tester |

| MODEL | JS 237AP | JS 2310AP2 | ||

|---|---|---|---|---|

| Feature | Material | PET (IV 0.8 and up) | PET(IV 0.8 and up) | |

| Quantity of Line | 1 | 2 | ||

| Layflat Width | mm | 9.5 / 13 / 16 / 19 | 9.5 / 13 / 16 / 19 | |

| Extruding Output Range | kg/hr | 40 - 100 | 80 - 220 | |

| Extruder | Screw | Ø75 | Ø100 | |

| Screw L/D | 27 : 1 | 27 : 1 | ||

| Driving Motor | hp | AC 50 HP + Inverter | AC 75 HP + Inverter | |

| Heater Capacity | kw | 67 | 101 | |

| Auto Temperature Controller | sets | 6 | 10 | |

| Quenching Equipment | Stainless Steel Quenching Bath | set | 1 | 1 |

| Water Removal Device | Water Removal Air Blower | hp | 2 HP x 1 set | 2 HP x 2 set |

| Pre-heat Unit | Take Up Roller | mm | Ø213 x 1pc | Ø213 x 3pc |

| Motor | hp | 1 HP (Inverter) x 1 set | 2 HP (Inverter) x 1 set | |

| Roll Dimension, Stainless Steel | mm | Ø510 x 4 pcs | Ø510 x 4 pcs | |

| Driving Motor | hp | 3 HP (Inverter) x 1set | 3 HP (Inverter) x 1set | |

| Speed Range | m/min | 12 x 24 | 12 x 24 | |

| Temperature Controller | sets | 4 | 4 | |

| Stretching Unit No. 1 | Heating Controller | set | 1 | 1 |

| Temperature Controller | set | 1 | 1 | |

| No. of Roll | pc | 5 | 7 | |

| Driving Motor | hp | 10 HP (Inverter) | 20 HP (Inverter) | |

| Speed Range | m/min | 50 - 120 | 50 - 120 | |

| Disco | set | 1 (with cooling system) | 1 (with cooling system) | |

| Stretching Unit No. 2 | Heating Controller | set | 1 | 1 |

| Temperature Controller | set | 1 | 1 | |

| Roll Dimensions (Stainless Steel) | mm | Ø213 | Ø213 | |

| NO. of Roll | pc | 5 | 7 | |

| Speed Range | m/min | 50 - 120 | 50 - 120 | |

| Air Compressor | hp | 1 HP x 1 set | 1 HP x 1 set | |

| Embossing Unit | Embossing Roller | set | 1 (Pneumatic type) | 1 (Pneumatic type) |

| Motor | hp | DC torque 3 hp | DC torque 3 hp x 2 | |

| Thermo Setting Unit | Heating Oven | set | 1 | 1 |

| Temperature Controller | set | 1 | 1 | |

| Stainless Quenching Batch | set | 1 | 1 | |

| Water Removal Air Blower | set | 2 HP x 1 | 2 HP x 2 | |

| Take Up Unit | Motor | hp | DC Torque 3 hp x 1 | DC Torque 3 hp x 2 |

| Roll Dimension | mm | 213 x 1 pc | 213 x 2 pc | |

| Winding Unit | No. of Spindle | pc | 2 | 4 |

| Motor | hp | DC Torque 1 HP x 2 | DC Torque 1HP x 4 | |

| Winding Width Range | mm | 152, 200 | 152, 200 | |

| Core Bobbin | mm | Ø200, Ø400 | Ø200, Ø400 | |

| Others | Total Electricity | kw | 165 | 250 |

| Machine Weight | ton | 14 | 20 | |

| Machine Dimension | m | 28.8 (L) | 35.16 (L) | |

* All specifications and design characteristics are subject to change without prior notice.