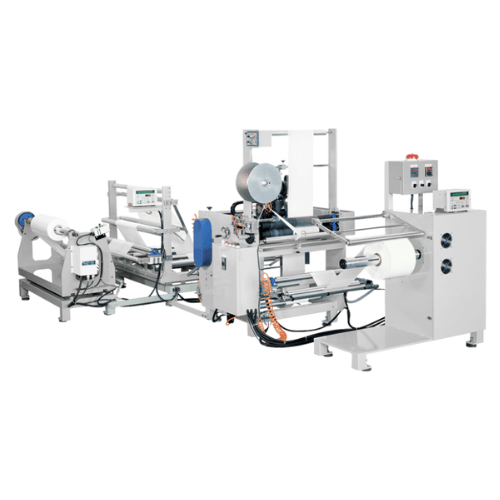

Fully Automatic Hot Slitting & Sealing Machine LY-1200HS

Categories : Plastic Bag Making Machines

Introduction LY-1200HS is a fully automatic, high speed hot slitting and sealing machine which converts sheet film into tubular film with good quality of sealing at the edge of film. It is suitable for full printing film. Features Servo motor for rewinding unit. Line position control. Auto-tension control for unwinding stand. Auto-tension control for rewinding stand. Edge trimming and waste collecting unit.

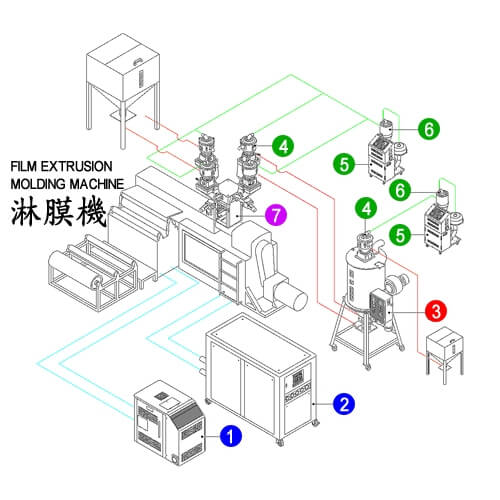

Film Extrusion Molding Machine Auxiliary Solutions

Categories : Assembly Systems

We have a wide range of auxiliary equipment for film extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

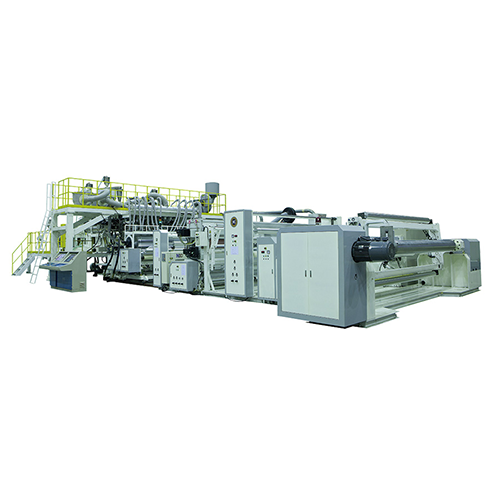

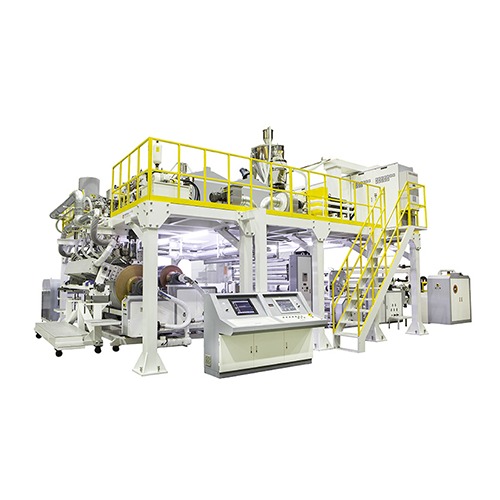

Automatic Cast PE Breathable Film Line

Categories : Film and Sheet Extrusion Lines

This machine is using 2.7M wide Automatic T-die from Cloeren, USA, with Automatic thickness Gauging System from NDC, USA. This machine has been designed to be a complete automatic machine and easy operation.

3 Layer Co-Extrusion Cast Film Line

Categories : Film and Sheet Extrusion Lines

3 Layer Co-Extrusion Cast Film Line

Taper Twin-Screw Sheet Preforming Machine

Categories : Film and Sheet Extrusion Lines

Sheet Pre-forming for Rubber, Plastic & Chemical Industries This new model TAPER TWIN-SCREW SHEETS PREFORMING MACHINE usage for the rubber compound mixing after DISPERSION KNEADER conveying to the hopper of this machine to go extruding and rolling for sheet. This machine not only simply to operate but also upgrading the work efficiency, and may go with the mixer to do the integrated production

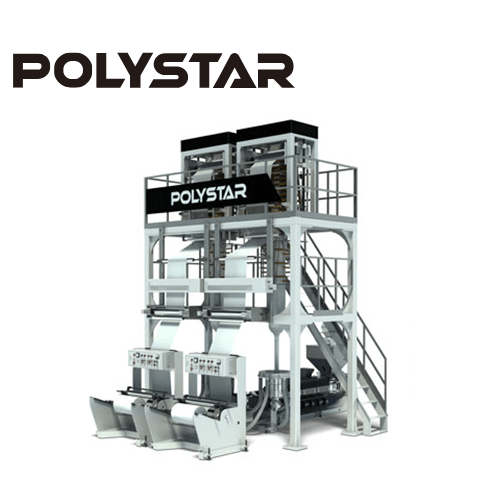

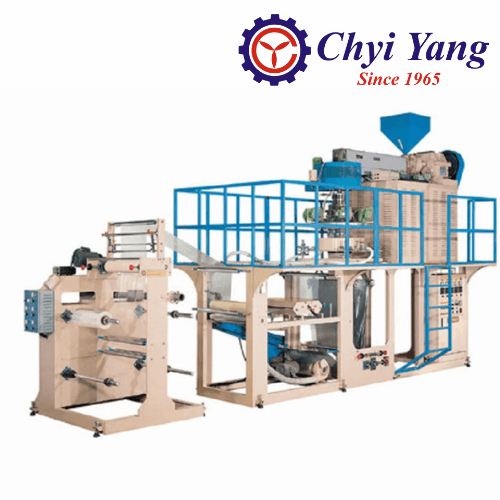

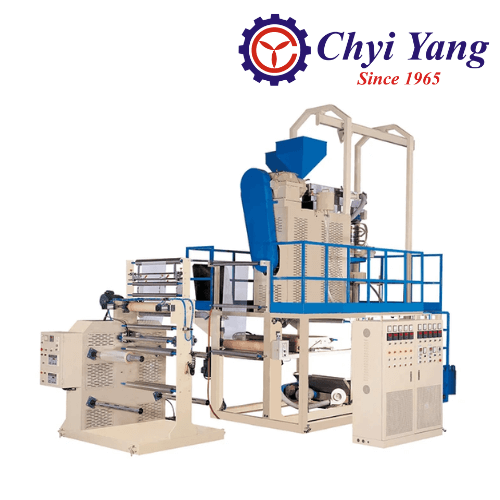

One Layer Twin Head Blown Film Machine

Categories : Blown Film Extruders

High speed for T-shirt bag conversion For film width 100~800mm Extruder dia. 45mm, 55mm or 75mm

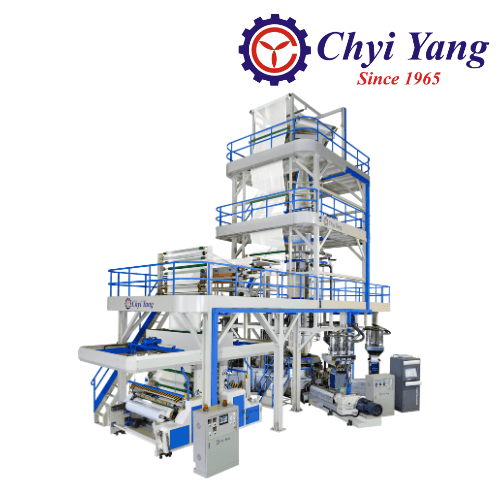

Three Layer Co-Extrusion Cast Film Line

Categories : Film and Sheet Extrusion Lines

Three Layer Co-Extrusion Cast Film Line

Three Layer Co-Extrusion Cast Film Line

Categories : Film and Sheet Extrusion Lines

Three Layer Co-Extrusion Cast Film Line

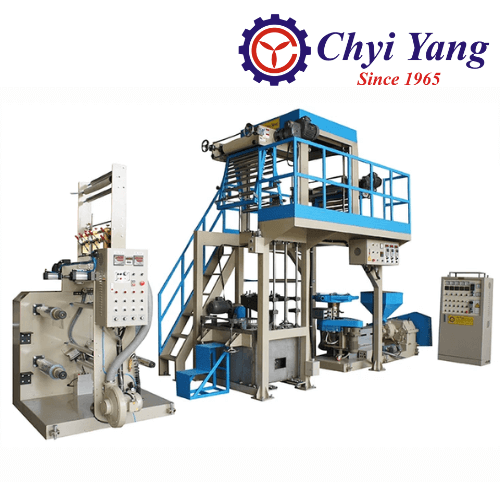

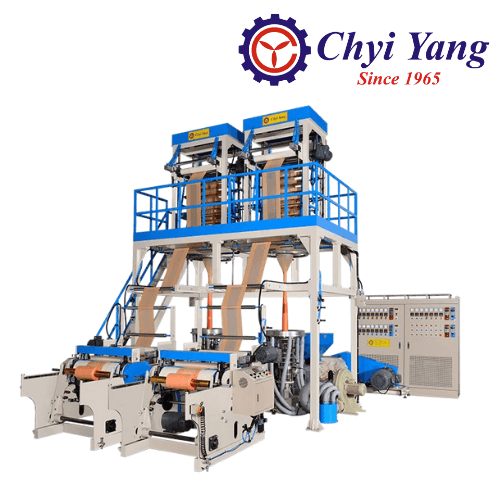

High Speed Twin Die Blown Film Machine

Categories : Blown Film Extruders

TDH series is one extruder provides two dies to get bigger capacity & less space. TDH-S series is standard machine. TDH-F series is forced feeding type for more output & faster speed. Purchasing extra LDPE die can produce LDPE film.

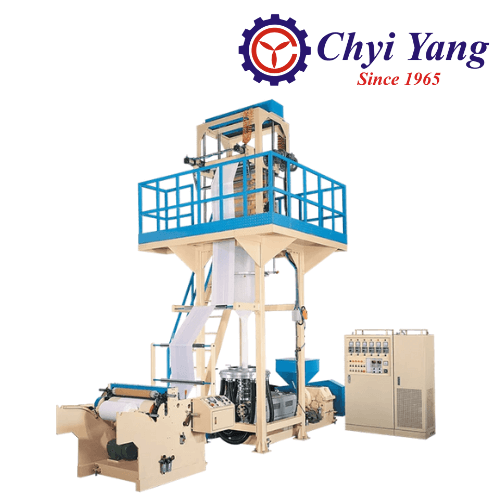

HDPE Blown Film Machine

Categories : Blown Film Extruders

HDPE Blown Film Machine, CHYI YANG is Blown Film Extrusion Machine and Blown Film Machine Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

PP Blown Film Machine

Categories : Blown Film Extruders

Water cooling system makes glossier and more transparent PP film for food or garment packing. Unique screw provides high production for a long period life and holds film uniformly steady. Dry chamber provides a fast water removal, for food package purpose. Optional tension control for winder provides good tension film in rolls, used in food packaging & printing. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Super High Speed Two Stripe Color Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

TCP-H series is two gear boxes driven by two motors makes colors width can be easily adjustment. TCP-SE series is one gear box driven by one motor for small capacity & saving cost. TCP-TD series is two dies & two gear boxes driven by two motors for double output. TCP-FD series is forced feeding type with two dies & two gear boxes driven by two motors for more than double output & faster speed. Purchasing extra LDPE die can produce LDPE film. Purchasing extra 2-layer co-extrusion die can produce 2-layer film. Double extruders increase the output. Precise die design makes sure the colors vivid & clear.

LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Double lip air ring & better cooling system to support the high speed capacity Can produce LDPE, LLDPE and shrinkable film Slitting device and double winder (up-and-down & back-to-back type) is offered to produce single layer film rolls. Optional Rotating die device is making uniform thickness film for printing & laminating purpose Optional Co-speed controller matches same speed for take-up unit and winder to avoid film to be stretched Purchasing HDPE die can produce HDPE film Fully automatic winder makes machine automatically & save time of operators We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

PVC Shrinkable Film Making Machine

Categories : Blown Film Extruders

Produce shrinkable PVC film for labels, goods packaging etc. Hot water chamber & cooling size ring help to get a glossier, and non-wrinkle film Machine direction shrink ratio and transverse shrink ratio can be adjusted easily. Machine direction shrink ratio can be 2-5 % We didn't show all our models, please don't hesitate to contact us for bigger extruders.

Mini Type Blown Film Machine

Categories : Blown Film Extruders

Designed for T-Shirt bag and flat bag production Small occupancy of space Simple, flexible and economic operation High output and saving energy Also can work with LDPE resin if changing air ring Film thickness HDPE 0.008~0.06 mm

Super High Speed HDPE/LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Easy installation & operation Adjusting thickness easily by screws of die, high capacity & less plastic waste Automatic flying cutter & manual change reels winder, flying cutter to match the machine speed, won’t be re-winded on the nip roller Main Motor is driven by inverter for better performance & less electricity Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Two Stripe Color Blown Film Machine

Categories : Blown Film Extruders

TCP-H is designed by two independent motors, gear boxes and extruders to produce films with two colors stripes TCP-SE is designed by one motor, one gear boxes & two extruders to produce film with two colors stripes TCP-H makes width of two colors can be adjustable TCP-SE is for saving cost of machine & less capacity The precise die design makes the colors vivid, clear & won’t be mixed together Purchasing a 2-layer co-extrusion die can produce 2-layer film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine, CHYI YANG is Multilayer Co-Extrusion Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

2-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Available for agricultural film, coated film, stretch film, cling film, greenhouse film etc. Max film width up to 4.2 m (8.4 m in single-layer-opened film) Raw material HDPE, LDPE, LLDPE, EVA, MPE etc. Two sets of gearbox, motor & extruder for independent control For producing PE stretch/cling film, PIB liquid adhesion system can inject liquid adhesion into screw directly to save resin cost & adjust the stickiness ratio you need Purchasing PIB system can produce out-layer film non-sticky to prevent dust, in-layer film sticky to pack subjects Optional “Waste film recycling machine” lets this machine doesn’t have any waste plastic film, it can feed waste film directly into screw to save your cost We didn't show all our models, please don’t hesitate to contact us for bigger extruders.

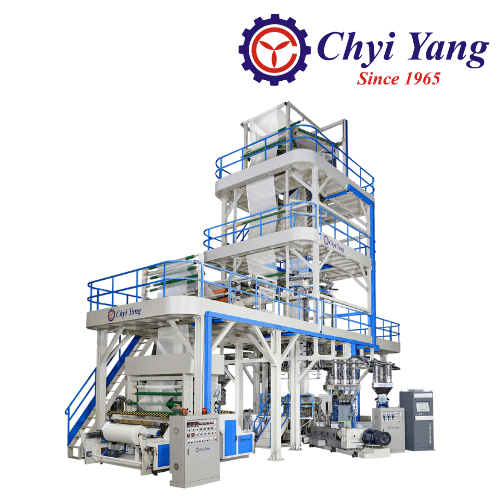

3-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Application for greenhouse sheet, agricultural films, construction sheets, food packaging, sacks, shrink films, shrink hood films, and more. Max. film width of up to 4.2 m (8.4 m for single-layer-opened films) It supports a wide range of raw materials such as HDPE, LDPE, LLDPE, EVA, MPE, PP, and others. The machine is equipped with three sets of gearboxes and motors for independent control. Optionally, a 360º Oscillating Nip roller device can be added to ensure uniform film thickness and improve the performance of the rotary die device. The machine can be equipped with a "Waste Film Recycling Machine" which enables direct feeding of waste film into the screw, eliminating any waste plastic film and reducing costs. Please note that the models shown here are not exhaustive. If you require larger extruders, please feel free to contact us.

5-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

CHYIYANG specializes in manufacturing 5-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

7-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

CHYIYANG specializes in manufacturing 7-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

ABA 3-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

ABA 3-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

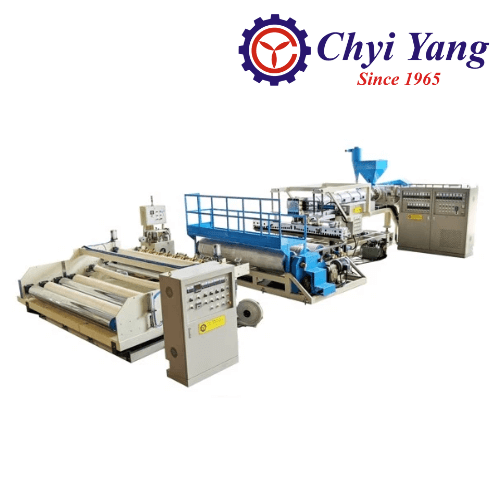

PE Stretch Casting Film Extrusion Machine

Categories : Film and Sheet Extrusion Lines

T-Die Extruder machine can produce waterproof PE film for baby diaper, sanitary napkin, folders, table cloths, medical film, etc. Film thickness 0.03~1 mm Equipped with a fully automatic winder with cutting and changing rolls functions Hydraulic screen changer for short maintenance stop We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

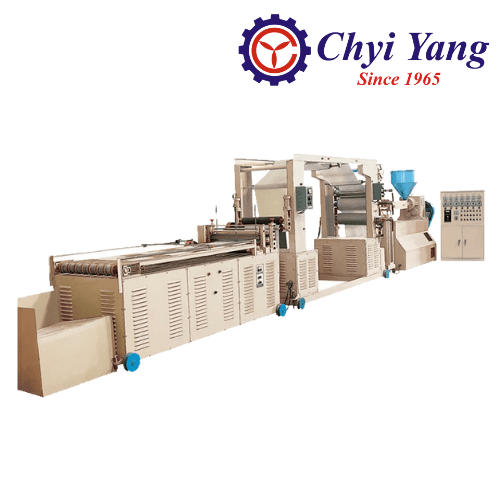

PE Foam & PE/PP Sheet Extrusion Line

Categories : Foam Extruders

T-Die Extruder machine is equipped with cutter or winder to produce PP/PE sheets PP sheet is available in file cover, stationary etc. Film thickness 0.5~2.5 mm For different machines’ structure, can produce PE, PP sheet & PE foam sheet. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

HIGH SPEED BLOWN FILM MACHINE

Categories : Blown Film Extruders

MONO-LAYER HDPE/LDPE/MLDPE/PP BLOWN FILM MACHINE

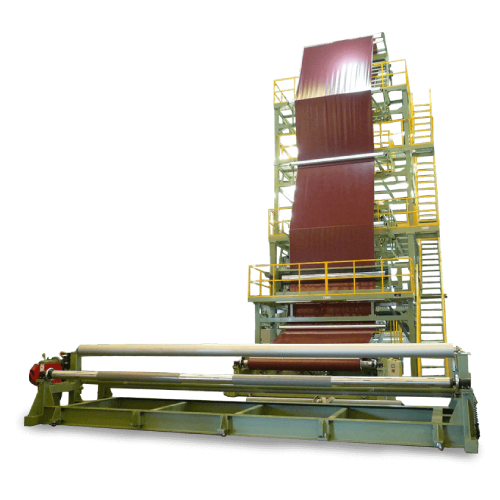

Agricultural Film and Geomembrane Blown Film Machine

Categories : Blown Film Extruders

The films is greatly helpful in agriculture and geomembrane. - Greenhouses that could increase the temperature to improve the growing environment and increase the available areas for planting, especially in high latitude and cold regions. - Mulch films could prevent the soil moist loss and preserve the temperature to keep soil warm that provide a suitable environment for seeds and sprout. - Silage films and stretch films is also more popular to store silage, hay and maize. - Geomembrane film could used to the construction for preventing leakage, water diversion for irrigation and reservoir and non-slip at side slope. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Opened film width range in 6 - 20 meters Designed output range 600 - 2000 kg/hr