Master-batch Feeder (MF)

Categories : Feeders

The masterbatch mixes with your virgin resin at the machine hopper automatically. You don't need to pre-color nor pre-mix your resin anymore. It saves the manpower, resin, stock costs, and keeps working environment clean. The unit mixes and doses masterbatch, additives, free flowing powders, regrinded and virgin resin to ensure consistent and accurate mixing which results in better quality of product and less rejects. With the special process, the internal part of the unit has no dead corners and makes the dosing process more accurate. Both dosing-cylinder and dosing-screw can be easily changed. The motor feedback control is operated by the tacho-generator which will not be influenced by power fluctuations. It gives the utmost accurate dosing. If some reasons changed R.P.M. of the extruder after setting, the unit will automatically to be changed by the percentage of new R.P.M. By just entering the weight of the materials, screw back time, dosing capacity per turn and additional rate of the masterbatch, the CPU will calculate proper R.P.M. rate automatically. The control panel is user friendly & much more accurate. Besides, it also has the function to store up to 10 sets of R.P.M. setting. To work with the injection molding machines, the unit is also equipped with a timer to control the dosing time.

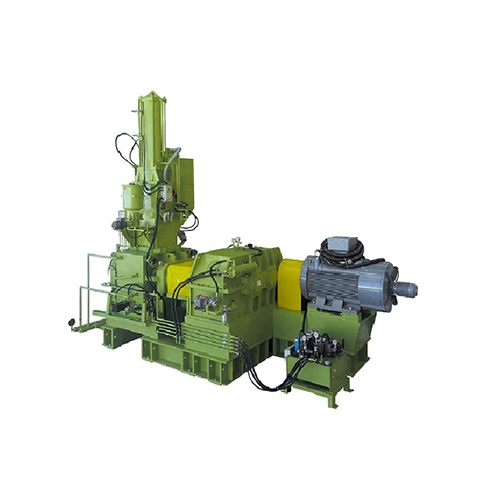

Intensive Mixer

Categories : Rubber Mixers

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber: Drill hole type jacket. Excellent cooling ability. Material contact surface: Hard chrome plating and fine polish. 3.Discharge door: Excellent sealing. No material leakage. 4.Ram: Drive by air cylinder. Good mixing and dispersion quality.

Rubber / Plastic Mixer Machine

Categories : Rubber Mixers

This Intensive Mixer is designed for mixing compounds and specific plastic. The structure of the machine consists of the main air cylinder, floating weight, feeding door, mixing chamber, rotors and discharge device. When performing mixing compound operations, the material and ingredients are fed together into the mixing chamber. The material in the mixing chamber is repeatedly sheared and squeezed by the rotors. This provides a series of chemical rotations between the material and the ingredients, which enables the material pieces to stick together into a paste mass shape. Mixing compound operations are performed according to the set temperature and conditions. This specially designed mixing machine provides efficient mixing and refining for a wide range of raw materials, such as raw rubber, resins, asphalt, cellulose, PVC ane EVA…etc.

Hydraulic Type Die Cutting Machine With Sliding Table Feeding

Categories : Cutting Machines

Four column of hydraulic cylinder, average cutting force. Microcomputer controller for maximum operation convenience. High speed sliding table feeding, motion is fast and safe. Safety sensor is equipped in front of cutter, (when sensor is touched, the machine automatically stops the action). Application:Special design for die cutting one layer or several layers of such material as rubber sheet, leather, plastic, foam, nylon, paper board and synthetic material. yicheen

Hydraulic Automatic Feed Die Cutting Machine (Four Column Press)

Categories : Cutting Machines

Application:Suitable for cutting one layer or several layer of such material as rubber sheet (bottom sole, medium sole), EVA, leather, plastic canvas, vacuum foaming products, nylons, carpet, mat, corks, soft tiles, paper boards and synthetic materials. yicheen The improved and upgraded traditional punching machines. Adopt four column of Hydraulic cylinder, average cutting force, high efficiency to raise the productivity. The upper die install by Magnetic platen, it is very convenient to change die. Microcomputer controller with touch sensing screen for maximum operation convenience and accuracy. Also, optional equipped with LCD screen computer control system is available, which it can memory operation program, provide the most convenient in operation and accurate cutting operation. Lubricated system design on Main shaft to avoid machine parts damage in movement and enhance machine lifetime. The Safety device (opening safe net for emergency stop motion) ensures the operator safety. Options: Air shaft unwind device, Air shaft rewind device

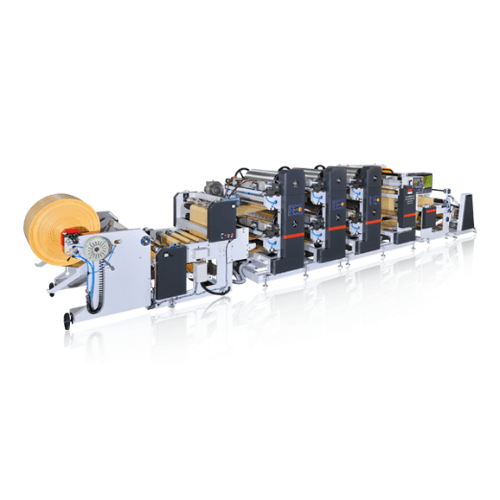

Aluminum Foil Printing Machine(WAP Series)

Categories : Rotogravure Printing Machines

In order to meet the special requirement of aluminum foil printing, the quality and R&D oriented manufacturer-- Worldly Industrial Co., Ltd., has developed the best solution for this special printing accordingly-WAP series. Considering the diverse needs of product printing, Worldly has designed the six-color printing station in printing structure, and combined a coating machine in the terminal. This coating machine has the outstanding capacity to lacquer over aluminum foil after printing to Improve printing effect, and it is also equipped with spine glue function for many different printing requirements. Also, adopts special reverse structure for aluminum foil between each color printing station, and sets up doctor blade units on both sides to enable reverse printing in any color. Easily fulfills various requirements in printing. Besides of that, adopts "Sumimoto" sectional motor system in every printing station; therefore, saving operation time and improve effect/respond time of color register during printing cylinder replacement. This machine also equips a drying tunnel system on the top of it. It is a four-sectional drying tunnel which makes drying more efficiently. Unwinding and Rewinding units are splicing materials in double shaft automatically turret type. And it is non- stop the machine when changing materials, very simple and convenient. All machine is link-controlled by High-efficiency PLC logic controller and HMI touch interface, so the controlling effect is very precise and high efficient. In addition to that, this machine also equips with automatic color register function which makes printing quality beyond perfection. As for Q.C, Worldly selects VIDEO monitoring system to achieve real-time Q.C inspection. It effectively assists printing work and improves quality Even if in high speed printing operation.

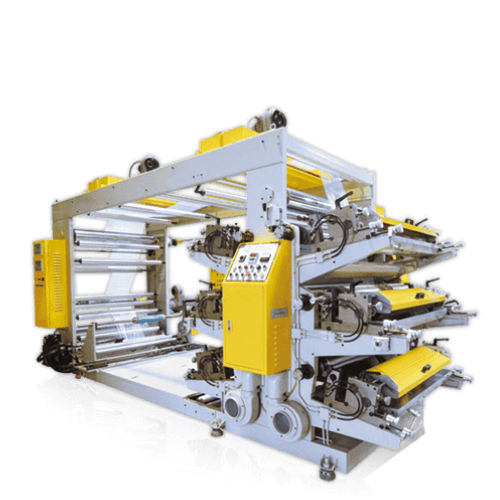

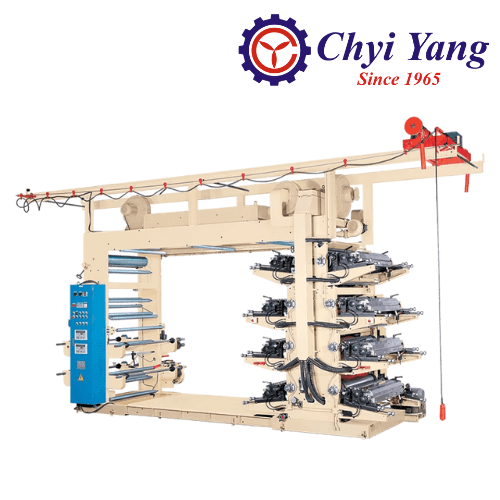

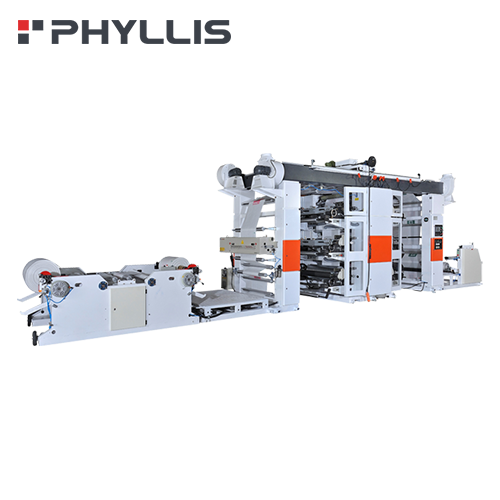

Flexo Stack printing Machine PKF-8 Series

Categories : Flexographic Printing Machines

● Machine framed with 50MM cast metal plate, provide a very steady, vibration free foundation for the printing work. ● All gears are helical design. ● AC main motor from Siemens and controlled by Japan made inverter to provide a steady speed performance. ● Inking rubber rollers are driven by European made hydraulic motor independently, speed can be adjusted for controlling ink transfer volume. ● Simple but accuracy and steady vertical and horizontal image adjustment device. ● Long arch type drying tunnel with high capacity blower, to allow ink quick drying during high speed operation. ● Bearing house design for holding rubber roller, plate cylinder and anilox roller. ● Machine can be equipped with Japan auto tension controlling system, close chamber doctor blade, EPC at unwind, rewind as optional choice. Flexo Stack printing Machine Flexographic printing machine CI Flexoprinting Machine Flexographic Printing Machine FLEXOGRAPHIC PRINTING MACHINE FLEXO PRINTING MACHINE FLEXO STACK PRESS FLEXO PRINTING PRESS CI PRINTING PRESS CI PRINTING MACHINE PAPER PRINTING MACHINE PAPER PREPRINT PRINTING MACHINE OFF LINE PRINTING MACHINE

Flexographic Printing Machine for PP Woven Bags

Categories : Flexographic Printing Machines

● The BOTHEVEN Flexographic Printing Press #MP Serial is design for fabric sheet printing, such as after cutting and bottom sewing of laminated or un-laminated bag, paper bag ....etc. ● Easy operation, easy change printing plate. ● Special design a Action Roller dispense device, the printing cylinder won't dirty conveyor when empty load.

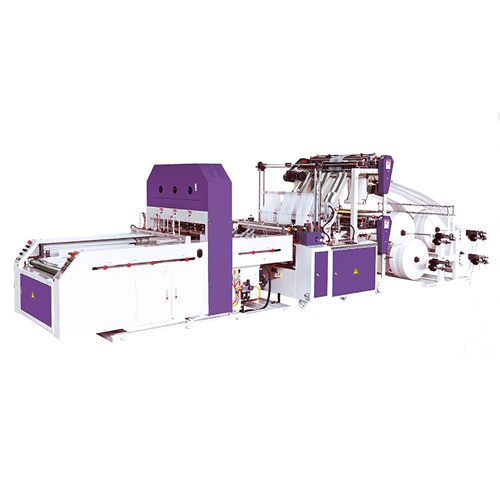

Bottom Seal Bag Making Machine + Bag Folding System

Categories : Plastic Bag Making Machines

Automatic Folding system - Servo-controlled 1st & 2nd fold individually (piece by piece), 3rd fold by pneumatic cylinder every 1-15 pieces pile. 4th & 5th folds by optional. Cold-cut system - For thin film material. Machine uses upper heating knife and silicon roller base for sealing. Cutting knife before bag outfeeding.

Mini Flexo Pringing Machine LW-LF100-F (Plate Cylinders Fix)

Categories : Flexographic Printing Machines

Portable flexographic printing machine, suitable for printing the marks, logo, literature, and various kinds of one color printing purpose. Passive type machine install on the extruder, bag making machine and any kinds of conveying type equipment, thru the films flow to drive the printing head no power supply required economic and easy operation.

6 Color Reel-to-reel Offline Type Flexo Printing Machine: LL-6000 Model

Categories : Flexographic Printing Machines

The machine is suitable for printing: roller paper, packing paper, cellophane, fiber glass web, tubular films, PP woven sack and PP/LOPE/LLDPE/HDPE/BOPP poly bags. Require small space, easy operation and maintenance; man power and cost saving. Used with either solvent or water base flexo-printing ink only. The photo polymer plate or rubber plate with 2.50 mm in thickness is a first priority, other size is available by request. The printing plate cylinder is controlled by pneumatic system; easy operation and high accuracy, there will be no defect while starting or stopping the machine on the color fixing. Have a counter device to control production Q'TY, which is reached the presetting numerical then the machine will be stop working at the same time. When printing roller stop working, the rubber roller and screen anilox roller will be continuous running to avoid drying of printing ink on such rollers. The hot air fan and blower with respective heaters are mounted on the machine. For ink drying to increase production speed. The heater and fan will take off automatically when the blower stop working. Let this machine keep in safety position.

Proportional Valve (PV)

Categories : Separators

The unique air valve structure design stops dust from entering the cylinder of the unit and thus reduces waste. Can mix or feed one kind of resin only if required. The controller is fitted with digital readout (PV-A-D Series) and setting for the mixing cycles which gives a high rate of accuracy. It is easy to set and be set in the range of 0-9.9 seconds. Transparent cleaning cover design for quick cleaning and easy changing materials. Individual controller for convenient operation.

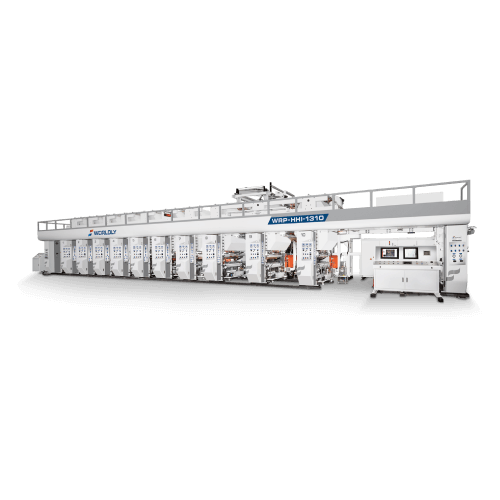

ELS Sectional Drive High Speed Rotogravure Printing Machine (WRP-HHI Series)

Categories : Rotogravure Printing Machines

Ink resistance material of furnishing roller optimized ink circulation, avoid cylinder cell ink stock and improve printing quality. The roller driven by motorized can manual or automatic mode synchronized with printing speed. - Quick change over doctor blade holder design - Ink group trolley system for quick job change over - Centralized control system allow man power saving - Latest E.L.S technology

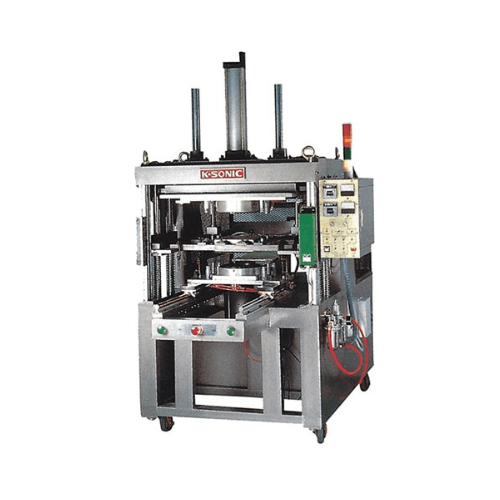

Hot Plate Plastic Welding Machine KH-31

The machine is constructed of main body, hot mold set and upper & lower fixtures. Only upper fixtures declined by cylinder. The welding part's surfaces melted in proper welding time when pressed against the hot plate The hotplate retracts and forced welding parts together in proper holding time Enable to weld two mold cavities in one stroke

Medical Waterproof Disposable Table Paper Cutting Machine Model SHCG-42MP

Categories : Paper Bag Making Machines

The paper bag cutting and making machine features 1. Servo Motor Driven for precise length cutting. 2. Infeed Dance Roller Control with inverter Motor. 3. Air Cylinder Lifter Heavy Duty Unwinder for 300KG Paper Roll. 4. Collect Conveyor for friendly operation.

Hot Plate Plastic Welding Machine KH-33 (upper and lower cylinder type)

1.The machine is constructed of main body, hot mold set and upper & lower fixtures. Upper and lower fixtures moved by cylinder. 2.The welding part's surfaces melted in proper welding time when pressed against the hot plate. 3.The hotplate retracts and forced welding parts together in proper holding time. 4.Enable to weld two mold cavities in one stroke.

Rotogravure Printing Machines Control System

Categories : Rotogravure Printing Machines

PLC STATION 1 - Printing speed control. - Plate cylinder length setting. - Printing parameter setting. - Operation parameter setting. - Driver status monitoring. - Production additive memorizing. - Malfunction alarm information. - Tension information monitoring.

Proportional Valve (PV)

Categories : Separators

Proportional Valve (PV) The unique air valve structure design stops dust from entering the cylinder of the unit and thus reduces waste. Can mix or feed one kind of resin only if required. The controller is fitted with digital readout (PV-A-D Series) and setting for the mixing cycles which gives a high rate of accuracy. It is easy to set and be set in the range of 0-9.9 seconds. Transparent cleaning cover design for quick cleaning and easy changing materials. Individual controller for convenient operation.

Mini Flexo Printing Machine: LW-LF100-E Model (Plate Cylinders Changeable)

Categories : Flexographic Printing Machines

Plate Cylinder size changeable from 500mm to 800mm repeating printing length, standard equip with 500mm plate cylinder, Portable flexographic printing machine, suitable for printing the marks, logo, literature, and various kinds of one color printing purpose. Passive type machine install on the extruder, bag making machine and any kinds of conveying type equipment, thru the films flow to drive the printing head no power supply required economic and easy operation.

CPV Cylinder Pinch Valve

Categories : Separators

Product Serial: CPV Cylinder pinch valve are used in biopharmaceutical processing, food and beverage, and industrial applications requiring aseptic process. These compact valves provide reliability and high performance, especially when working with harder or larger outer diameter tubing and require stronger clamping forces. Designed for disposable tubing, each model includes a convenient installation slot for quick loading and unloading. It can be set to normally open or normally closed with an external solenoid valve. Cylinder pinch valve is also known as pneumatic pinch valve, as it requires external pneumatic supply to support its function. It is commonly used to open or close a fluid path through pinching and squeezing the plastic flexible tube. There is also an option with proportionally controlling the distance in which the tube is squeezed which indirectly controls the flow rate. The advantage of using a pinch valve is that it has no contact with the fluid, making it an ideal option for biotechnology processing, food industry, dosing system, blood process/analytical, CIP and SIP process, and biopharmaceutical equipment. Pneumatic pinch valve relies on the amount of external pneumatic pressure supplied to pinch the tube, and thus it provides a higher pinch force, making it suitable for tube with larger durometer or large outer diameter.

Reel to Reel Flexographic Printing Line FSRP-6C (No Cylinder Changing)

Equipped Servo Motors for Precise Printing Graphic and Printing Length Control On-line Servo Control Printing Position Registration System (with Touch Screen Operation) (Each printing station equipped with servo motor to adjust printing position during machine running) Equipped with On-line Camera Inspection (Italy made) Two Units, Monitoring Printing Quality during Machine Running. Equipped with Doctor Blade System and Ceramic Anilox Roller as Standard Equipment

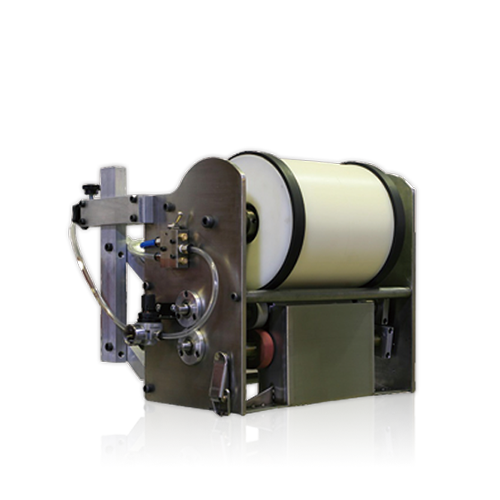

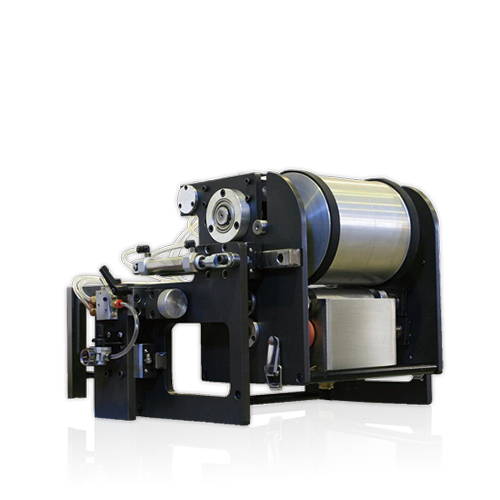

Proofing Machines FCM-1300

Categories : Slitters and Rewinders

Applications of FCM-1300 Proofing and sampling for engravers & packaging printers Functions of FCM-1300 Check cylinder engraving quality including the accuracy of text, colors and ink standards. Production press simulation for samples with different colors offers variety for customers. Benefits of FCM-1300 One man operation. 10 minute proofing. Reduces ink and material use. Maximizes production press time. Use production inks and materials. Features of FCM-1300 1. Machanical position on printing roller In combination with inductive proximity switch and mechanical headstock can make sure the printing roller will return to exact position before every proofing. 2. High solution cameras and video registration system With a high solution camera and an electronically generated dual cross on the screen which 16 times magnifies the arrow on every cylinder can eliminate parallax error. 3. Adjustable doctor blade device Consists of 2 doctor blade to intense the hardness. Adjustable angles and pressure accommodates variable patterns of the cylinder. 4. Shaft-less air chuck Allows easy and safe loading of a cylinder and wash-off by one operator. It can be suttle adjusted to accommodate different width of the cylinder. 5. Adjustable cylinder deck Easy and safe operation for loading the cylinder by pneumatically adjusting the deck upward and downward. 6. Superduper printing roller (1)Smooth, rustproof, and heavy-duty printing roller through chromium-electroplated and grinding process. (2)Bouncy compressible blanket, closely dovetailed with printing roller, can easily be replaced when it is blot and spoiled. (3)The proofing length is up to 2500mm. Depending on the size of cylinders, it can print at least 2 copies of samples in every proofing. 7. Powerful vector motor The printing roller is driven by an powerful 7.5 HP vector motor. 8. Adjustable proofing speed Accommodating different material and ink quality, the proofing speed can be adjusted from 20 to 90 m/min. 9. Linear guide way All of the sliders applied to air chuck and cylinder adopt linear guide ways. With height position exactitude, the device will not facilely glide on linear movement.

8 COLORS FLEXO PRINTING MACHINE (HIGH SPEED TYPE)

Categories : Flexographic Printing Machines

Our machines are suitable to print PP, PE, BOPP, OPP, PE shrinkable film, packing paper, glass paper, non-woven bags. Using hydraulic system to lift up & down the printing cylinders for easy operation. Equipped with meter counter, the machine will stop automatically when reaching the meter. Using high-capacity hot air dryer to make the production faster. The dryer and fan will shut down automatic when machine stops. When machine stops, the ink rolls keep running to avoid drying of ink. The rubber roller is ozone-resistance & solvent-resistance. The ink tray is with cover & faucet. Ink pump, air shaft, ceramic roller & doctor blade etc. are options.

BJA3P+S-Double Layer 6-Lane Fully Automatic Servo-Control Sealing & Cutting Machine

Categories : Sealing Machines

● Double layer for 6 lanes in total. ● Uses servo motor for feeding, with stable sealing abilities, and fast on speed change. Easy to change bag size, and size error is permissible. ● Machine stops when abnormality is detected. ● With auto punching unit. ● Hot pin positions can be moved freely. ● Able to produce flat bags and T-shirt bags. ● Air cylinder punching device featuring pressure boost. Enhancing speed and accuracy. Low noise, with no oil leakage. ● Enclosed with punching position calibrating plate to ensure accurate hole position on T-shirt bag handles.

Two Platen Injection Molding Machine NRH Series

Categories : Horizontal Injection Molding Machines

20% ~ 30% less from machine length, compare with toggle design. Less space required from a molding facility. Less space required from a molding facility. Fully automatic mold-close adjustment ready to reduce time required from mold change. Paten #I279312, Intellectual Property Office, MOEA, Taiwan. Available option for additional stroke from opening. Spare the larger machine needs for bigger opening stroke. Available option with Retractable Tie-bar function. With additional mold lifting module to accommodate jumbo machines in regular facility height. Extended Die service expectancy without deformation thanks to hydraulic cylinder clamping parallelism. Shortened high-pressure clamping stroke thanks to ability of fast building clamping force.

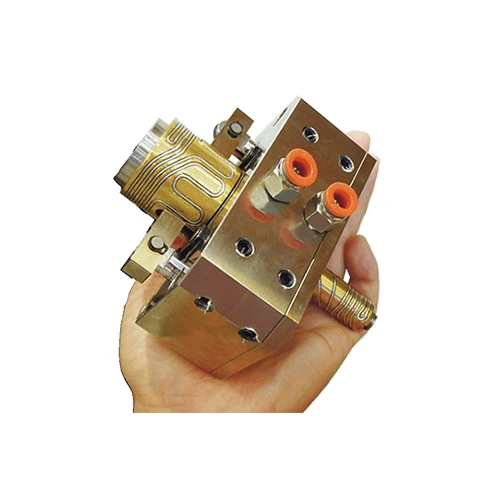

Single Valve Gate Hot Runner System

Categories : Hot Runner Systems

Dual-cylinder, powerful for gate seal. Nice gate mark. All in one, easy to install. Customize for your need.

Flexographic Printing Machine (Roll to roll)

Categories : Woven Bag Printing Machine

Flexographic roll-to-roll printing machine for coated and uncoated tubular PP woven fabric and film. Advantage of using same printing cylinder with various bag lengths. Easy touch screen operation with doctor blade system for high quality printing with minimum ink consumption.

Vertical Clamping Vertical Injection Machine-YH Series

Categories : Vertical Injection Molding Machines

- Four-column/vertical clamping, vertical injection. Rectangular shape between tie bars for easy insert. - Twin injection cylinder balanced for smooth and powerful injection. - Simple structure, small occupancy. - Double action clamping cylinder for fast clamping, slow speed high-pressure clamping. - Single sliding pushes the lower mold out for easy loading/unloading. - Double sliding use two lower mold, machine molding the parts while the operator is loading the other mold, to increase productivity.

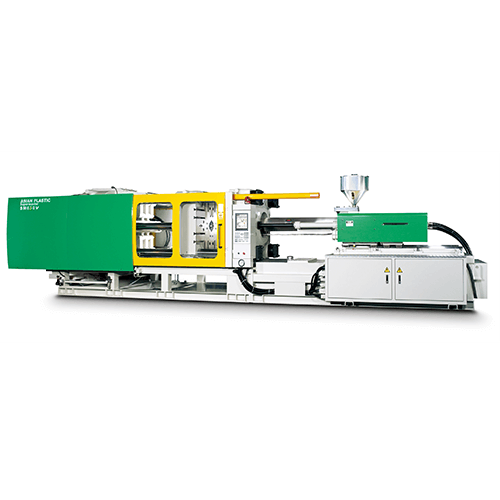

Heavy Duty Double Toggle Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision. The injection carriage uses a balanced double hydraulic cylinder to provide a secure hold between the mould and the nozzle to eliminate nozzle leakage. Linear guide ways reduce mechanical friction, decrease machine wear and increases accuracy over back pressure providing better control of the injection sequence. Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportional valves is more precise resulting in more accurate control.

Precision Four-Column Plan Hydraulic Cutting Machine-CSS-202B

Categories : Foaming Machinery

●The body of the machine is made of special steel and has gone through rigorous processing that shows a ram pressure-resistant function and precision. ●Up and down stroke applies steel pole as the rail that brings out an effect of high precision and shaking-resistant characteristic. ●A design of Two-pod oil cylinder shows the stable force and large torsion.

High Speed Injection Molding Machine (TSV Series)

Categories : Hydraulic Clamping Injection Molding Machines

• The double hydraulic cylinder provides secure hold on pressurefor the injection carriage eliminating nozzle leakage. • The toggles are lubricated with the graphite bronze bushes to ensure lower friction wear, assure greater accuracy and greatlyextended life of the clamp unit. • Fast clamping system equipped with regeneration circuit increase speed by 60% to shorten cycle time and save energy. • Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportion-al valves is more precise resulting in more accurate control.

Vertical Two Tie-Bar Injection Molding Machine

Categories : Hydraulic Clamping Injection Molding Machines

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production, then reduce the cost of production. High precision mold platen (Parallelism/flatness:0.01/100mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact, space-saving design, reduce the heavy burden of the floor of factory.

Vertical Single Shuttle Table Injection Machine

Categories : Vertical Injection Molding Machines

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.