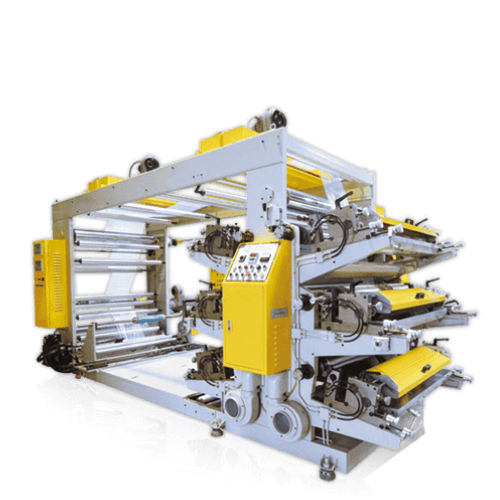

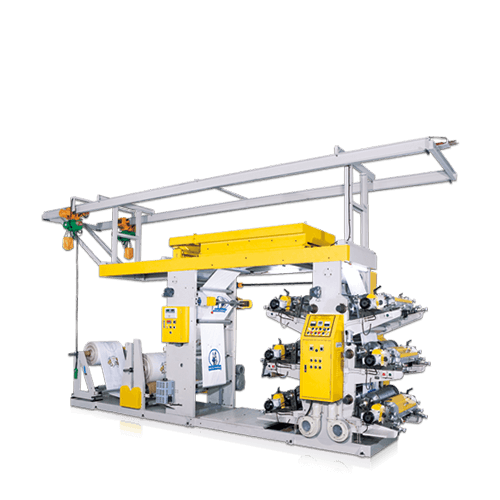

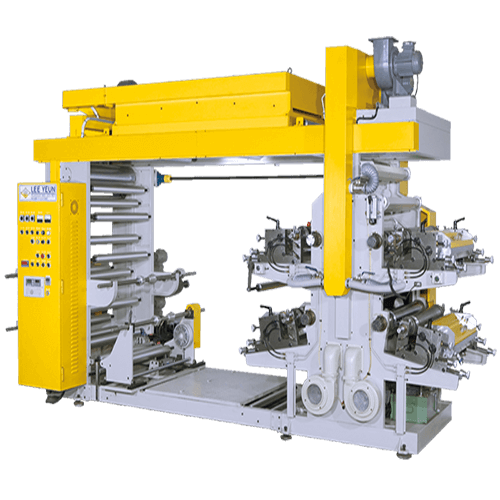

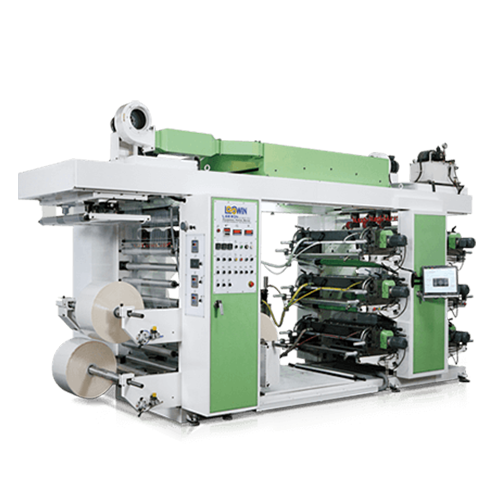

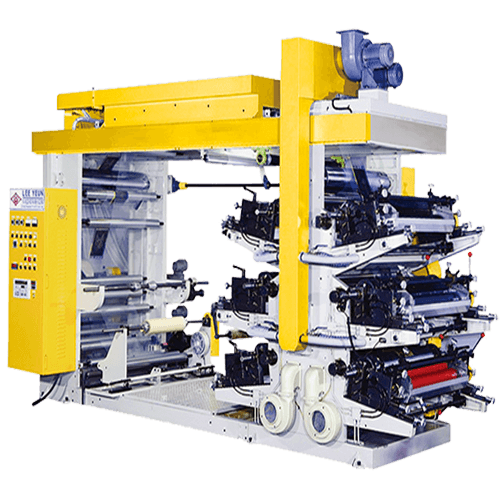

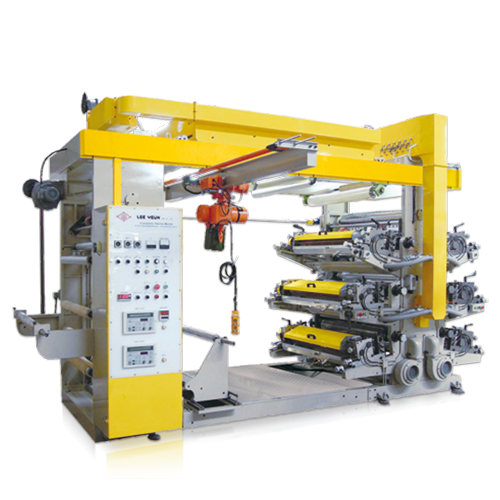

Classification : LL Off-Line Flexo Printing Machine

Country: Taiwan

Phone: +886-2-2674-7799

Fax: +866-2-2674-7818

Contact Person: Linda Liu

Features

Require small space, easy operation, and maintenance; manpower, and cost-saving.

Application Material

The Flexographic Printing Press Machine is suitable for printing: roller paper, packing paper, cellophane, fiberglass web, tubular films, PP woven sack, and PP/LOPE/LLDPE/HDPE/BOPP poly bags.

Equipment

-

Used with either solvent or water-based flexo-printing ink only.

-

The photopolymer plate or rubber plate with 2.50 mm in thickness is the first priority, other size is available by request.

-

The printing plate cylinder is controlled by a pneumatic system; easy operation and high accuracy, there will be no defect while starting or stopping the flexo printing machine on the color fixing.

-

Have a counter device to control production Q'TY, which is reached the presetting numerical then the flexo printing machine will stop working at the same time.

-

When the printing roller stop working, the rubber roller and screen anilox roller will be continuously running to avoid drying of printing ink on such rollers.

-

The hot air fan and blower with respective heaters are mounted on the flexo printing machine. For ink drying to increase production speed.

-

The heater and fan will take off automatically when the blower stops working. Let this flexo printing press machine keep in a safe position.

6 Color Flexo Printing

Web Width: 600mm ~ 1200mm

Printing Width: 500mm ~ 1100mm

Repeat Printing Length: 250mm ~ 1000mm