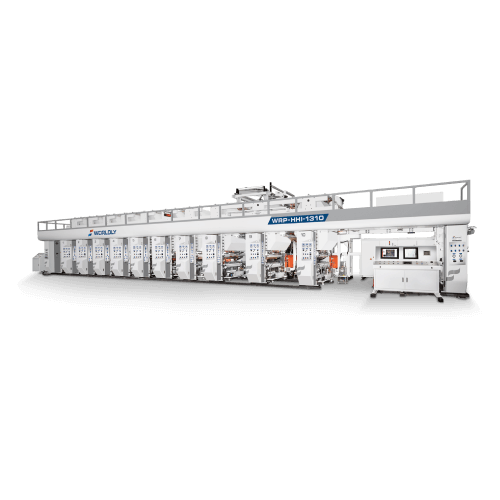

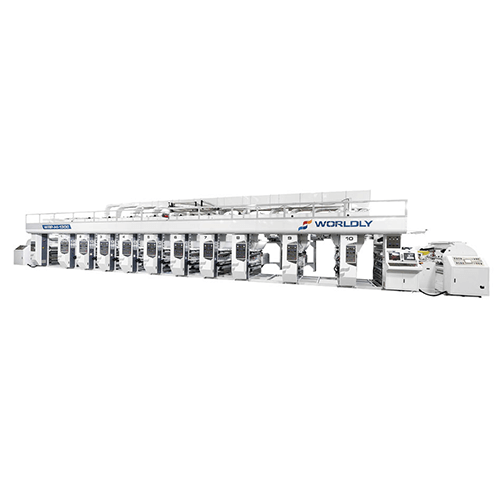

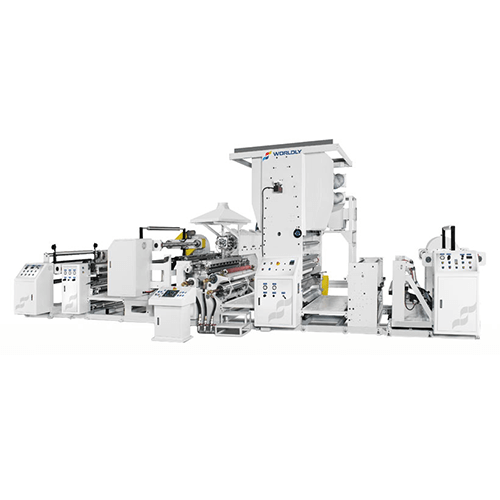

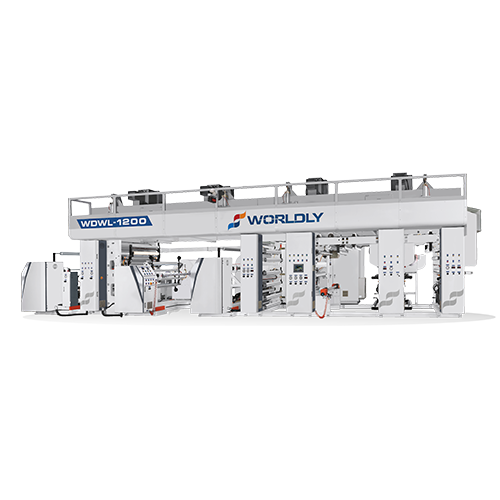

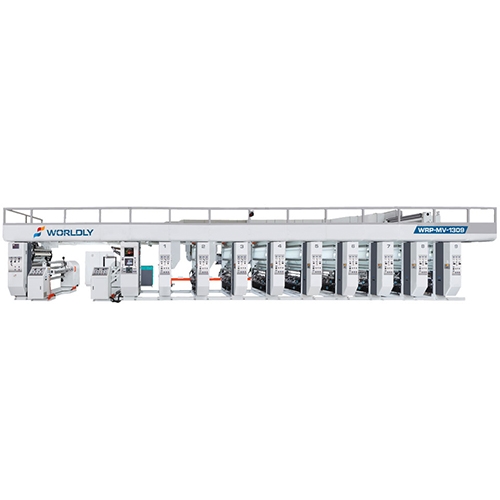

In order to meet the special requirement of aluminum foil printing, the quality and R&D oriented manufacturer-- Worldly Industrial Co., Ltd., has developed the best solution for this special printing accordingly-WAP series. Considering the diverse needs of product printing, Worldly has designed the six-color printing station in printing structure, and combined a coating machine in the terminal. This coating machine has the outstanding capacity to lacquer over aluminum foil after printing to Improve printing effect, and it is also equipped with spine glue function for many different printing requirements. Also, adopts special reverse structure for aluminum foil between each color printing station, and sets up doctor blade units on both sides to enable reverse printing in any color. Easily fulfills various requirements in printing. Besides of that, adopts "Sumimoto" sectional motor system in every printing station; therefore, saving operation time and improve effect/respond time of color register during printing cylinder replacement.

This machine also equips a drying tunnel system on the top of it. It is a four-zones drying tunnel which makes drying more efficiently. Unwinding and Rewinding units are splicing materials with double shaft automatically turret type. All machine is link-controlled by High-efficiency PLC logic controller and HMI touch interface, so the controlling effect is very precise and high efficient. In addition to that, this machine also equips with automatic color register function which makes printing quality beyond perfection.

- Each printing unit has a double sided doctor blade mechanism for reverse printing in any of the following combinations, for example, 3+5, 2+4, 4+4

- The last coating unit along with the drying tunnel can perform in-line HSL coating

- Worldly utilizes the latest E.L.S technology

| Model | WAP |

| Maximum Machine Speed | 180 m/min |

| Printing Maximum Speed | 150 m/min |

| Printing Width | 600mm / 800mm |

| Printing Cylinder Circumference | 350mm - 800mm |

| Maximum Material Diameter | Ø600 mm |

Aluminu Foil, PET, OPP