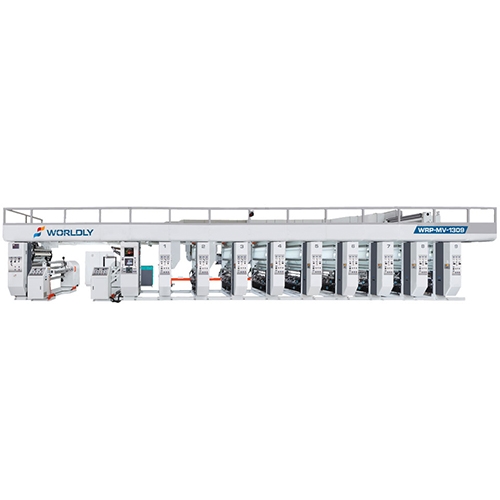

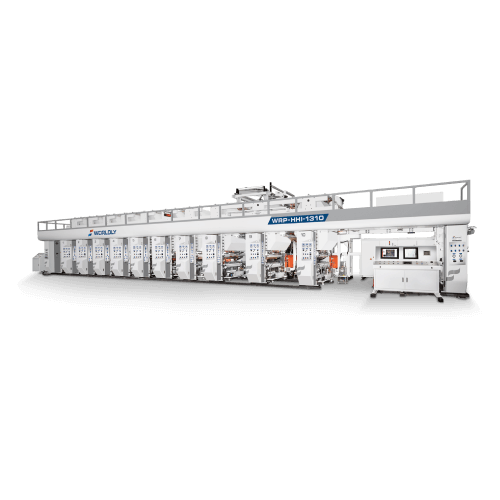

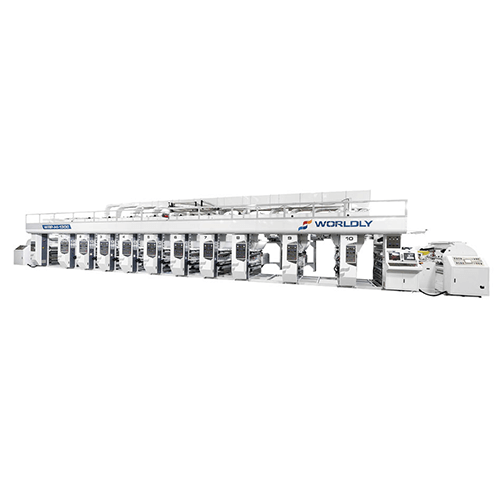

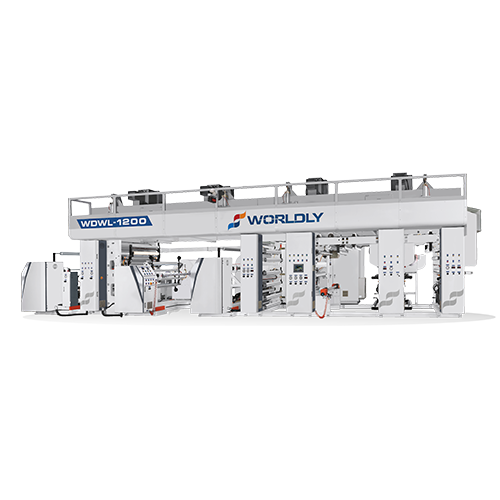

Worldly company has good experience and technology development in new rotogravure machine over the years. The printing press equipment with powerful combination of central control system, and ease for operation. Simply and easily function and control parameter display on the human-machine interface touch screen, synchronized with PLC control system, also automatic alarm system provide the most efficient printing management for operators and leads to reduced default rates and less waste. Otherwise the exhaust recycle system can recycle the air up to 75% energy,The design leads to high productivity, lowers production costs, and provides a competitive advantage.

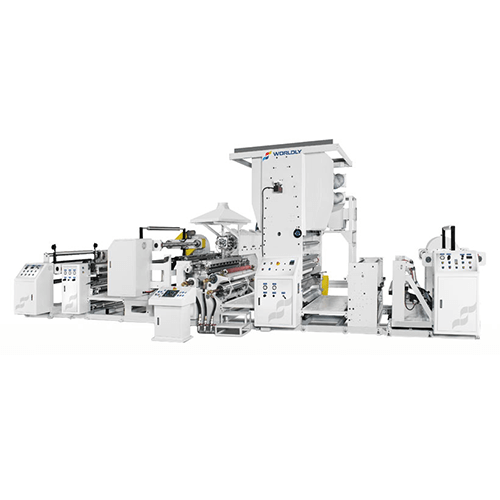

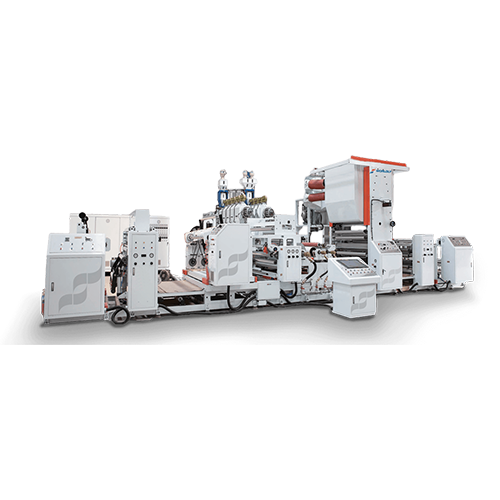

- Quick change over doctor blade holder design

Doctor blade quick locking by tool-less. The group allows horizontal, vertical and angular adjustment for the doctor blade position on engraved cylinder.

- Heating recycling energy saving

Heating recycling & energy saving : Exclusive energy-saving design to increase the recycling benefit of investment costs. The system is constructed of connection ducts, ventilation modules, hood drying chambers, and central exhaust system. Recycle waste hot air to save energy consumption.

- Ink resistance material of furnishing roller optimized ink circulation, avoid cylinder cell ink stock and improve printing quality. The roller driven by motorized can manual or automatic mode synchronized with printing speed.

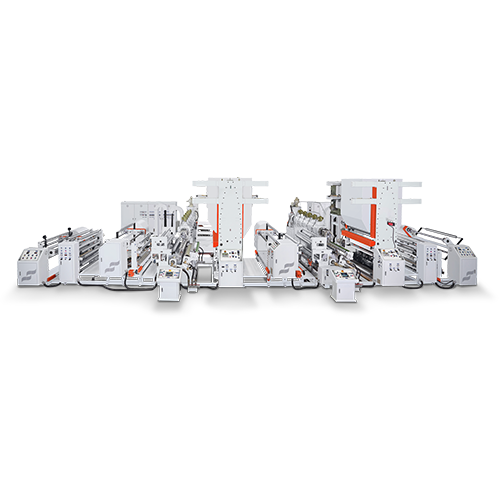

| Model | WRP-MV |

| Maximum Machine Speed | 250 m/min |

| Printing Maximum Speed | 230 m/min |

| Printing Width | 800mm / 1000mm / 1200mm |

| Printing Cylinder Circumference | 350 mm - 900mm |

| Maximum Material Diameter | Ø600 mm / Ø800 mm |

PET, CPP, PVC,OPP, PP, PE, Nylon, Aluminum Foil