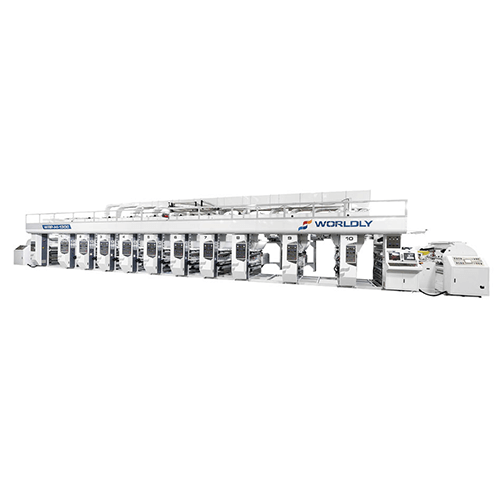

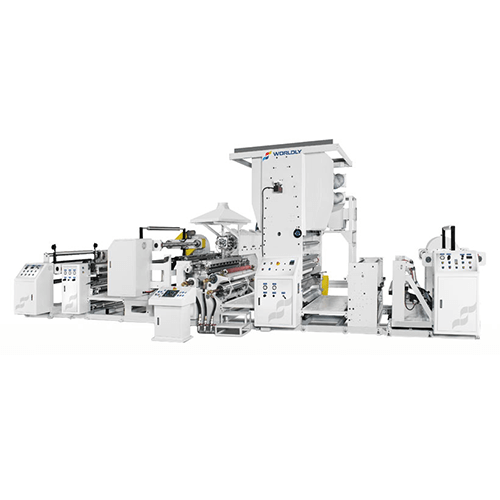

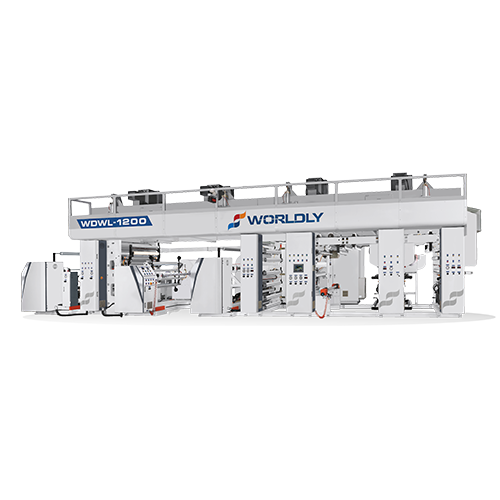

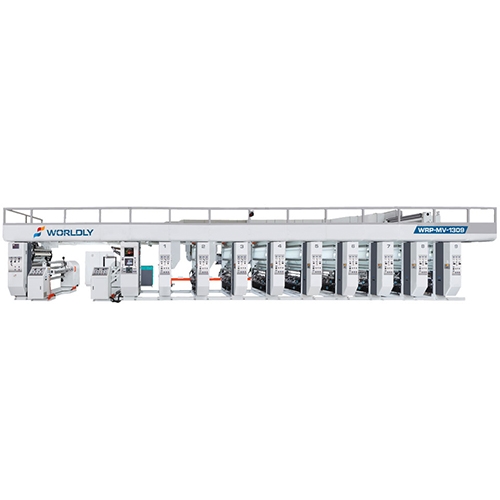

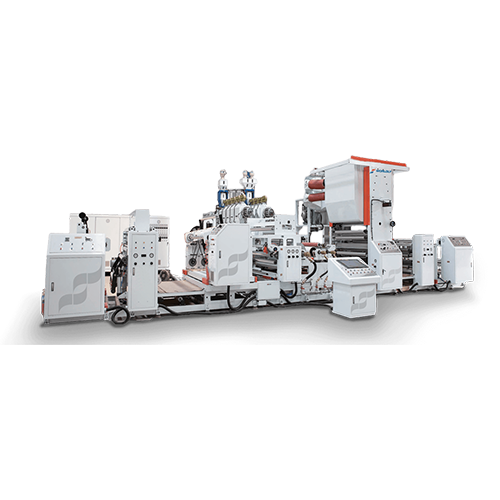

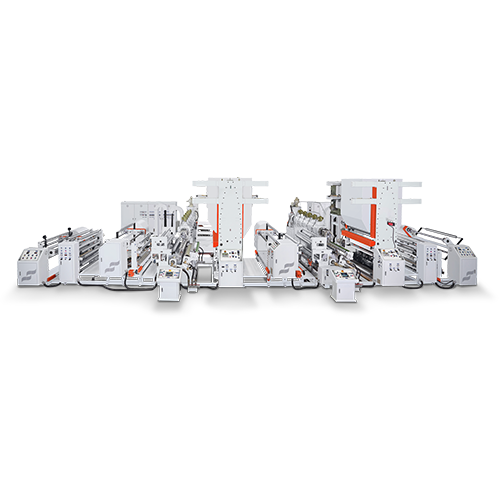

Classification : Rotogravure Printing Machine

Country: Taiwan

Phone: 886-4-23599850、23599851

Fax: 886-4-23596625、23584485

Contact Person: Mr. Klive Lai

In pursuit of efficient high quality printing machinery, Worldly develops machines featuring user friendly automatic operation and high stability of mechanical equipment made by specialized technology and deliberate design.

Optional Features

● Ink circulating pump

● Ink viscosity controller

● Reverse bar

● Pre-heat chamber

● Vertical & Horizontal splicing device

● Drying system options: Steam, thermal oil, gas burner, electricity heater

| Model | WRP-HI |

| Maximum Machine Speed | 310 m/min |

|

Printing Maximum Speed

(Must depend on relevant printing condition, |

300 m/min |

| Printing Width | 1000mm/1200mm/1300mm |

| Printing Cylinder Circumference | 350mm - 900mm |

| Material Diameter | Ø800mm/Ø1000mm |

PET, CPP, PVC,OPP, PP, PE, Nylon, Aluminum Foil, Paper.