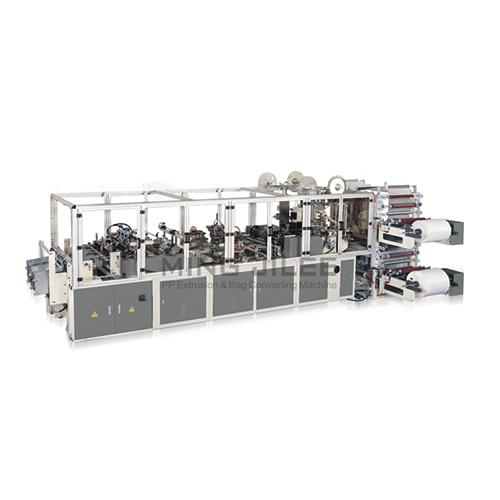

Fully Automatic High Speed With Core T-shirt Bag & Bottom Seal Bag on roll Making Machine with Slitting & Gusseting Unit-STBCR-40+OS

Categories : Bag Making Machine by Applications

Computer control over the entire process From film roll to final pruduct, one process flow Automatic film feeding, cordination free from tension adjustment Oscillation film feeding system for stability and high out put Automatically stop when running out of film / film feeding blocks or jam Automatically core changing system Punch system on magnetic roller

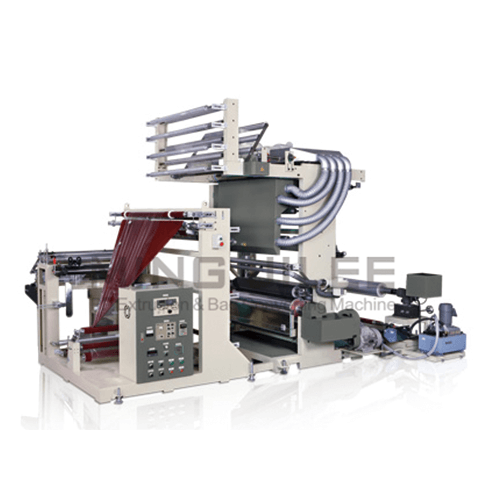

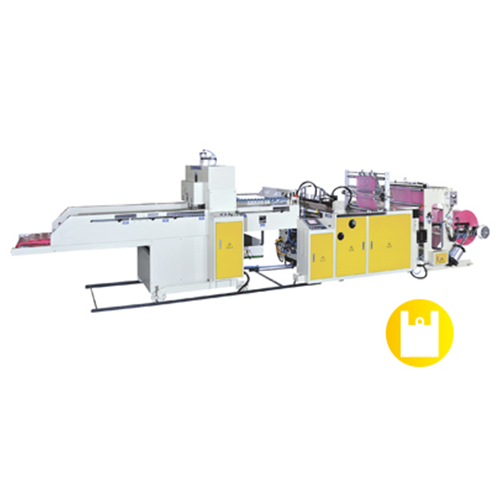

Sandwich Folding Machine With 1 Colors Rotogravure Printing

Categories : Rotogravure Printing Machines

Sandwich Folding Machine With 1 Colors Rotogravure Printing

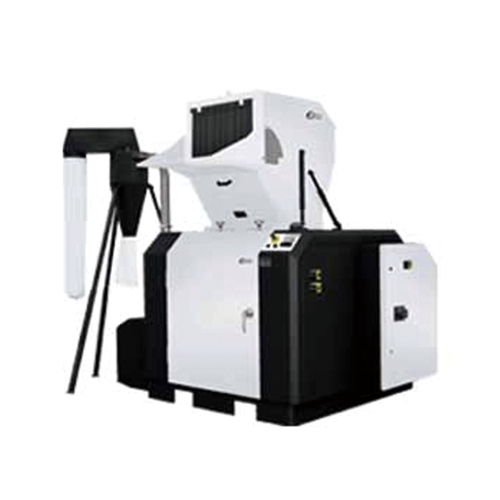

Sound-proof Central Granulators - SG-43

Categories : Granulators

SG-43 series are suitable for centralized recycling of waste and rejected parts form injection, blowing molding and extrusion lines. This series feature compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level ensures low energy consumption.

MONO LAYER BLOWN FILM MACHINE - LE Series (Cost Efficient)

Categories : Blown Film Extruders

MONO-LAYER-HDPE-LDPE-MLDPE-PP 2-LAYER HDPE/LDPE/MLDPE/PP

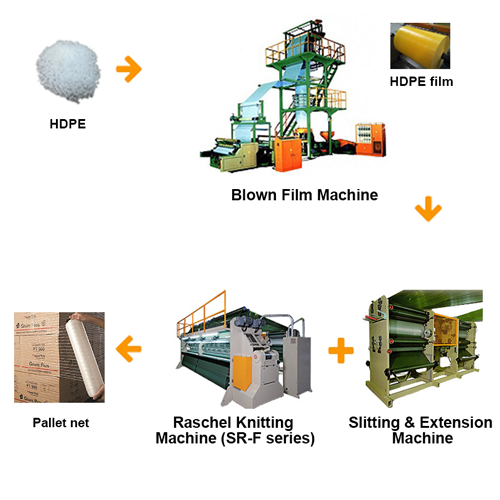

Pallet Net

Categories : Industrial Knitting Machines

Raschel Knitting Machines,, Blown Film Machines, Pallet Net

Rewinder Machine

Categories : Slitters and Rewinders

This machine can rewind large roll to become small roll.

Auto Tension Control

Categories : Flexo Printing Parts

The auto tension control is from Italy, Europe, which can automatically control web tension

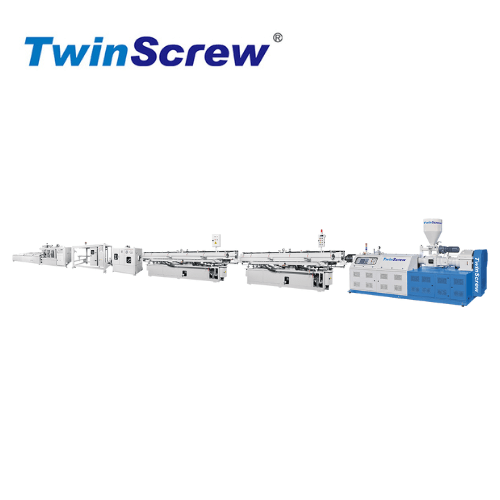

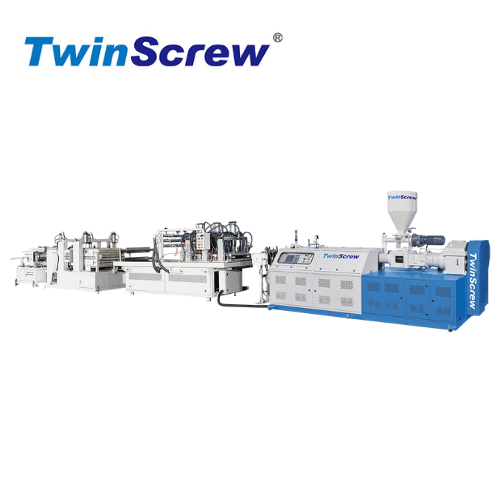

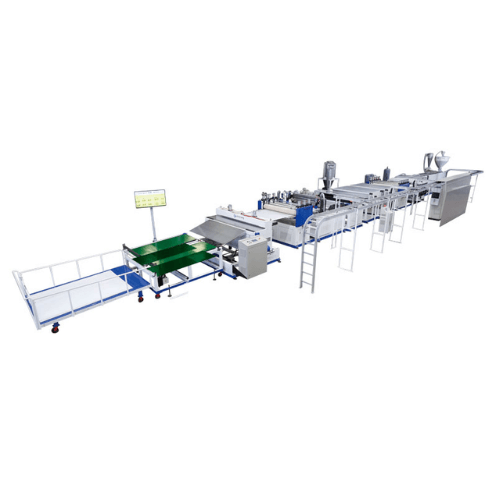

1600mm Wide , PP / PC Hollow Profile Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

For thirty years, Chi Chang has been designed and manufacturing fully computerised lines for sheet & film extrusion and co-extrusion. Our highly qualified team of engineers, operators and technicans has always been searching for high extrusion technology to meet your requirements. After years reserching since our first PP hollow profile sheet extrusion line in 1987, our new generation will produce PP hollow profile sheet with width from 1200mm to 2500mm, thinckness from 2mm to 10mm and output upto 500 kg/hr. In the mean time, we are pleased to introduce our new PC hollow profile sheet extrusion line. It is able to produce two-layer and three-layer PC hollow profile sheet with width 1200mm & 2100mm and thickness 5mm-10mm (two-layer) and 16mm (three-layer), and output upto 500 kg/hr.

Three-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

THREE-LAYER CO-EXTRUSION Blown Film Machine

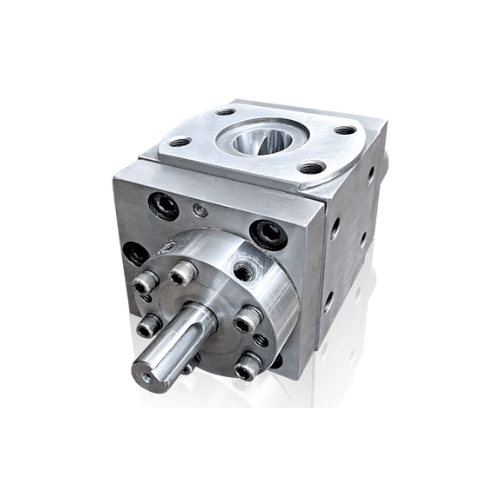

EXTRUSION GEAR PUMP

Categories : Gears

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

Categories : Plastic Crushers

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

Sieving Machine

Categories : Separators

Sieving device for PET recycling separates solid wastes such as sands, metal, small stones, labels in PET bottle recycling production. Bottle sieving is useful to reduce equipment running abrasion, production loss to enhance production performance with water-saving. PET flakes sieving improves the final PET flakes quality and stabilizes the quality of flakes. 3 types of sieving machines which are dry trommel, disk screener, and dust remover are available for different materials. They have the same function to remove impurities such as sands, metals, small stones, labels in different washing sections. The disk screener is more compact than the dry trommel, it's good to be placed after de-baling and pre-washing to separate impurities. It can evenly spread PET bottles on the next process like belt conveyor and filter residual water. Dry trommel can remove caps and sands separately through multiple meshes filtrations. Dust remover has two specifications for the choice. One is named Zig-zag separator, the other is label aspiration separator. These two machines can separate small plastic labels and films by taking advantage of the gravity and machine structure.

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

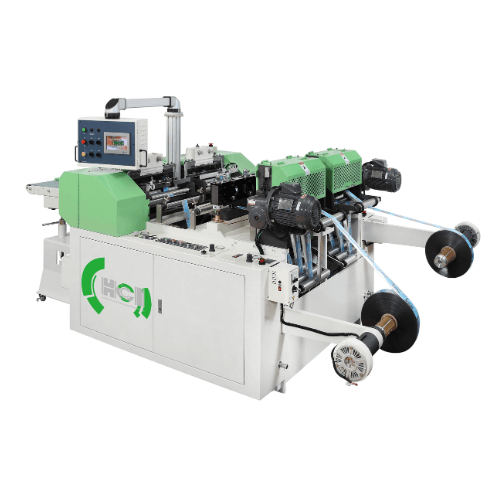

High Speed Double Line Shrink Label Cutting Machine

Categories : Cutting Machines

This FSC-XD301 is the next-generation ultra-high-speed dual-line shrink label cutting machine, designed to deliver a perfect combination of efficiency, stability, and accuracy, setting a new standard for high-performance production equipment.

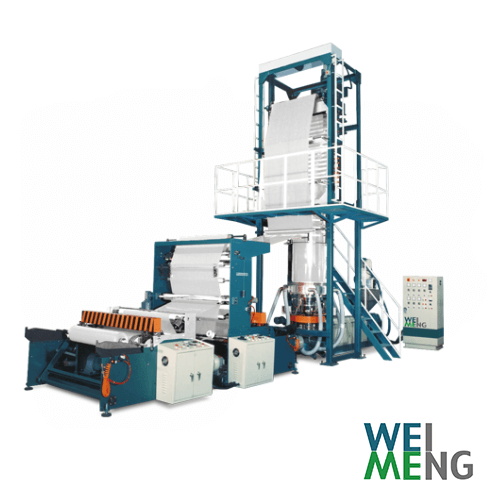

HDPE Blown Film Machine

Categories : Blown Film Extruders

HDPE Blown Film Machine In the past 30 years, we have been keeping receiving very good reputation from our worldwide customers on our quality products and satisfactory services.

Fully Automatic High Speed Disposable Plastic Gloves Making Machine / SSD-800-HGL(Standard)

Categories : Bag Making Machine by Applications

-Computer control over the entire process -Jumbo film roll to final pruduct ( 2 line output ) , one process flow -Automatically stop when running out of film / film feeding blocks or jam -Automatically tear off the waste edge film -Melting cut-off ( no cutting knife ) system save time and manpower on adjusting knife -Capable to produce 3 types in same machine

PT46X5 Series

The PT46X5 Series transmitter is a +/- 0.5% sensor ideal for general purpose melt pressure measurements requiring simple installation, repeatability and reliability. The PT46X5 transmitters provide the industry standard 0 – 5 Vdc amplified signal designed to work with DCS and PLCs, 1 – 6 Vdc outputs are also available. The PT46X5 comes equipped with zero and span pots to adapt the transmitter to process conditions. Optional thermocouple or RTD configurations are available to provide melt temperature. The PT46X5 features a 1/2-20 UNF thread for installation in standard transducer mounting holes and can be supplied with a variety of electrical connections. The PT46X5 Series includes models PT4605, PT4625, PT4635, TPT4605, TPT4625, and TPT4635.

Mixer

Categories : Mixers and Blenders

The tank and agitating blades are made of stainless steel and the agitating blades can be easily removed and cleaned.It is perfectly safe for the operator and can produce sufficient mixing in a short time.

Doctoring and Rewinding Machine Series-FSE

Categories : Slitters and Rewinders

-Quality inspection of round rolls. -Surface inspection after printing. -Roll small rolls into big rolls or vice versa. -For quality inspection for converting materials, electronics, computer and optical materials, film roll and foil roll.

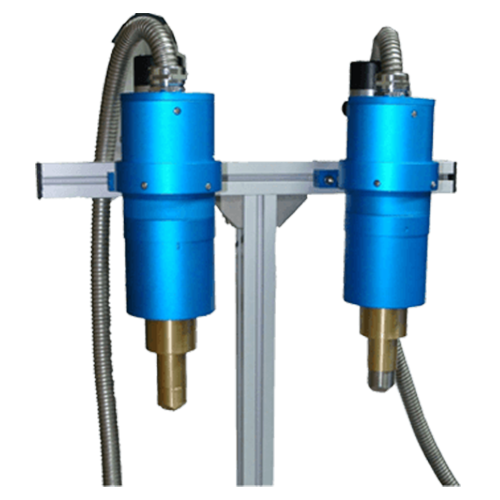

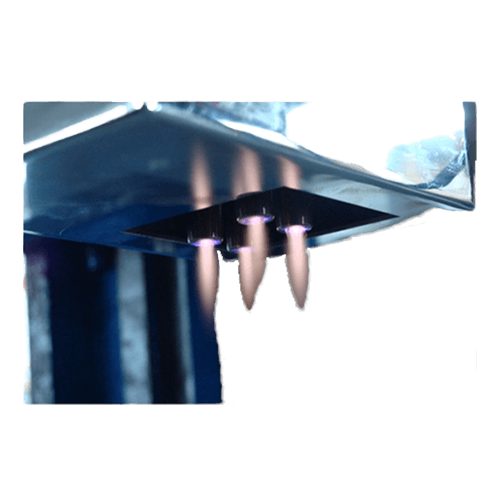

Plasma - JR

Categories : Surface Treatment Equipment

Applied to 30mm width or tube inside surface treatment. Detail specification contact please. Plasma treaters produce plasma surface treating to promote the adhesion of inks, adhesives, coatings, sealants & paints. Manufacturers integrate in-line plasma treatment equipment to enhance adhesion on plastics, composites, metals & glass surfaces. The plasma pretreatment process cleans, etches, & functionalizes surfaces to activate bonding sites by increasing wettability & surface energy.

Ultrasonic Metal Welding Machine KWG2620-EW

Categories : Automatic Welding Machine

Ultrasonic metal welding, generally for the fusion of low melting point metal materials such as copper, aluminum, etc. Taking the ultrasonic welding metal plate as an example, the two metal plates are overlapped and placed on the base, and the ultrasonic welding head is pressed against the coincident metal plate with appropriate pressure, and a lateral vibration of 20,000 to 40,000 times per second is applied. The two metal plate joints are subjected to high frequency vibration friction and welded. In this welding mode, the solvent is not required, and the welding portion does not need to pass current and heat, and is close to the cold joint, and the intermetallic compound is less likely to occur, and the structure changes little. The welding feature is that the deformation of the joint is less, the material is not melted, and the thermal influence of the material is not significantly changed. The fragile cast structure or the intermetallic compound can be obtained, and the fusion of the foil and the small joint can be achieved without strong resistance welding. Long foil can be applied by roller type continuous welding. KWG0935 model can be applied to lithium battery copper aluminum foil and aluminum nickel sheet welding, copper aluminum foil spot welding, capacitor copper aluminum foil spot welding, etc. KWG2020 model can be applied to lithium battery aluminum shell and aluminum nickel sheet welding, wire and terminal welding, wire butt welding, wire and metal plate welding, metal plate spot welding, etc........

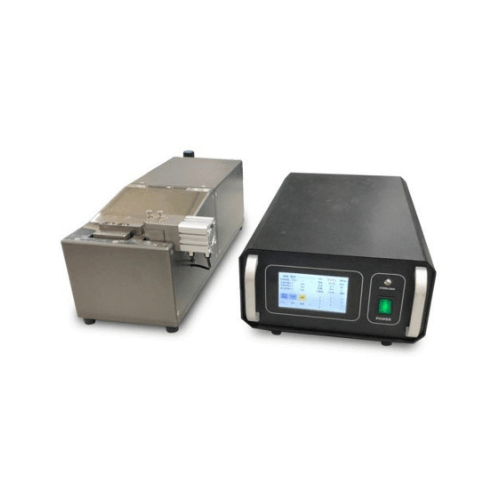

Plasma - J4

Categories : Surface Treatment Equipment

Plasma Treater Country of Origin:Taiwan Plasma treaters produce plasma surface treating to promote the adhesion of inks, adhesives, coatings, sealants & paints. Manufacturers integrate in-line plasma treatment equipment to enhance adhesion on plastics, composites, metals & glass surfaces. The plasma pretreatment process cleans, etches, & functionalizes surfaces to activate bonding sites by increasing wettability & surface energy.

Activator

Categories : Hydrographic / Water transfer Machines

Our Activator are engineered to optimally activate water transfer printing films. Packing: 15kgs/ drum

Flexographic Jumbo Bag Printing Press

Categories : Flexographic Printing Machines

● This Printing Press is Specially Designed for Jumbo Bag Printing. ● Equipped Ink Circulation Pump in Each Color for Manage Proper Ink Consistency. ● Patented Separation Device between Printing Roller and Conveyor Belt to Avoid Stain ●Conveyor During Empty Load. ● 1 to 5 Printing Press Flexibly Provided According to Customer's Demand. ● Custom-made designs are available.

Ultrasonic Plastic Welder KWD2615-N

Categories : Automatic Welding Machine

Full automatic frequency type ultrasonic plastic welder and synchronized with European and American technology.

High Speed 2 Lines Perforating Coreless Bags On Roll Making Machine with In-line Triangle Folding Devices by Servo Motors Control Model: CW-800R-SV

Categories : Plastic Bag Making Machines

‧ Special for two lines perforating coreless bottom and star sealing bags on roll. ‧ In-line triangle folding device for star sealing bags. ‧ E.P.C. (Edge Position Control) for the film at correct position. Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption. Bag length & production speed can be changed easily from touch screen. German made photocell-SICK for accurate printing mark. Automatic lift up reel unwinder with air shaft, reducing the number of employees. Automatic tension control with AC motor and inverter system for jumbo diameter film roll. Two lines automatic roll changing system.

Servo Motor Driven Side Sealing Plastic Bag Making Machine

Categories : Plastic Bag Making Machines

Servo Motor Driven, Efficient mechanical structure produce 180 bags per minute. User-friendly Control Panel, easy to understand easy to operate. Digital control for production length adjusting, precise and less wastage.

Fully Automatic High Speed 2 Lines with Core Vegetable Bag-on-Roll Making Machine with Hot Slitting & Side Gusseting Unit / SCR-40-G2

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatic film feeding, cordination free from tension adjustment Automatically stop when running out of film / color scanning error / film feeding blocks or jam Automatically core changing system Hot slitting device

TPE for Medical Instrument - TM Series

Categories : TPR (Thermoplastic Rubber)

Ever Polymer has the mission to satisfy all the application needs for thermoplastic elastomers (TPE) raw materials in the market. TPE TPE for Medical TPR tpe material tpe material eco friendly tpe material manufacturer tpe material properties tpe material toxic tpe plastic recycling tpe raw material tpe rubber what is tpe material tpe material safety

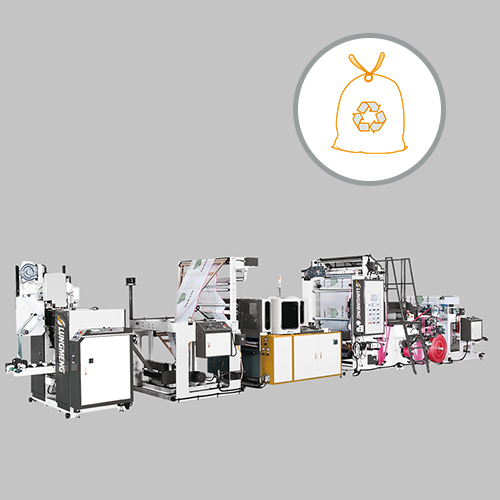

Suttle Track Draw Tape Bag On Roll Converting System

Categories : Plastic Bag Making Machines

Applications: Garbage bag, Drawtape bag making machine

Solid State Relay - SB / SV / SY Type

Categories : Hot Runner Systems

ARICO - The Best Solution Of SB / SV / SY Type ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision SB / SV / SY Type and related application equipment, but also provides high-quality SB / SV / SY Type with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with SB / SV / SY Type, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.

High Speed Mixer Machine

Categories : Mixers and Blenders

Special design for manufacturing processes for wood plastic composite resin.

Ultrasonic Nebulizer KUN-868

ULTRAMIST KUN-868 is a compact, professional designed nebulizer. It is suitable for clinic or home aerosol therapy.

Oven Dryer (YBO)

Categories : Dryers and Dehumidifiers For Plastic Materials

The Oven Dryer is a compact, convenient drying equipment which can dry more than one type of resin at the same. For plastics use, it can be used for annealing and product testing after molding. It can also dry electric motor and parts, electroplating, pharmaceutical, paint, printing, agricultural and food. (grain, garlic, tea, and etc.) Powerful, heated air flow system and unique air circuit are designed for evenly temperature control and the best baking quality. The oven dryer has stainless steel trays in which you can place your resins or material to be dried. Hot air recycling system is durable and energy saving. Equipped with 24-hour-timer which can be set in advance to operate the oven dryer.

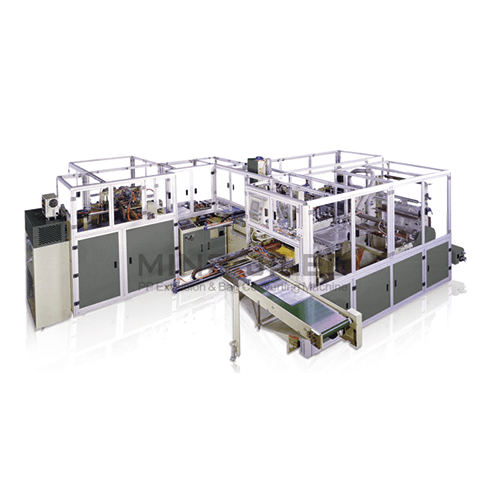

Twin Line Sheet Protector Machine ( Blown Film)

Categories : Bag Making Machine by Applications

MGA-17A-700DSP This machine is designed especially for all kinds of data bag (sheet protector) from the plastic feed material (CPP or IPP) to the finished product. The twin line machine can be operated in two ways: one or the other line machine can be operated independently or they can both be operated simultaneously. Manufacturing of the bag is fully automatic: the triangle folding device of the machine can run on either single layer film or double layer film; the Electronic Edge Position Controller maintains a uniform position for the feed material; the auto tension control maintains the stability of the feed material during the manufacturing process. Each functional aspect of the machine is essential to the stability of the manufacturing process, not only save labor costs, but also raise productivity. This machine is equipped with various precision and durable punching molds with a very low breakdown rate, connecting to the servo motor and digital computing unit for length control to allow a very precise punching position. This machine is equipped with a heat sealing device and twin blade cutting device (with a stationary lower blade and a guillotine-action upper blade) which ensure the size of the bags are uniform. The sealing line is neat and elegant and the waste ratio is reduced to a minimum. In order to reduce the impact pressure on the heat sealing device and to ensure a consis- tently smooth seal, the surface of the feed tray consists of a soft, silicon-based material. This machine is equipped with high quality, high performance parts to incorporate all kinds of control and monitor systems. During operation, anything unusual will automatically stop the machine in alarm to avoid waste material and protect the machine. glove making machine gloves making machine bag making machine plastic glove making machine plastic gloves making machine

Single Line Heat Cutting T-shirt Bag Making Machine Model: CW-500P-SV1/CW-700P-SV1/CW-800P-SV1

Categories : Bag Making Machine by Applications

Single Line Heat Cutting T-shirt Bag Making Machine Model: CW-500P-SV1/CW-700P-SV1/CW-800P-SV1

Electronic Vacuum Regulator (0~ -101kpa)

Categories : Indicators and Sensors

Product Serial: KaoLu's QKL-B3V electronic vacuum regulator is a type of inline vacuum regulator (Operating schematic diagram below). One port is connected to a vacuum source, and the other port is connected to a chamber. The precision vacuum regulator works electronically to regulate the highest level of uniform vacuum pressure despite various input conditions. The vacuum level is directly linearly proportional to the electronic command signal to the vacuum pressure controller. When 0-10V corresponds to 0 to (–)14 psig, a 5VDc command signal to the digital vacuum regulator will create a (-)7 psig vacuum pressure. The flow rate of QKL-B3V electronic vacuum regulator valve is 640 L/min. Should a higher flow rate is required, it is possible to couple a volume booster to the negative pressure regulator. QKL-B3V digital vacuum regulator allows user to regulate vacuum level via analog or digital control signal. The regulator is not self-relief, meaning that it does not exhaust excess air to reach target vacuum level. The monitor output is available either as analog output or switch output. QKL-B3V operates in dual solenoid valve principle with a closed loop electronic control. The internal negative pressure transducer monitors the vacuum level and controls the operation of the inlet and the outlet solenoid valve of the vacuum pressure regulator valve. With this special design, QKL-B3V electronic vacuum control regulator can be installed inline in any orientation, offering high flow rate, high accuracy, and high repeatability. Our vacuum pressure controller has the advantage of digital communication, which allows users to calibrate and monitor regulator status remotely. As for ingress protection, QKL-B3V digital vacuum regulator is compliant to IP65, and the M12 cable connection allows user to easily install and dismount from inline operation. QKL-B3V electronic vacuum regulator has been used in applications such as thermoforming, leak testing, tube extrusion, and tank blanketing. In order to control the both inlet and outlet pressure that allows massive air pressure into and out of the system, the user can utilize the vacuum flow regulator. Please consult our factory for further information. KaoLu also offers other types of vacuum regulator to control vacuum level in a chamber. Please refer to our FC series vacuum breaker applications. https://www.genndih.com/proportional-flow-control-valve.htm

Air Cooled Ceramic Band Heaters

Categories : Heating Equipment

To heat and cool the barrel Low maintenance Easy replacement Improves quality of finished products Space saving Increases productivity Available with various diameter, length, voltage, wattage and configurations Arico

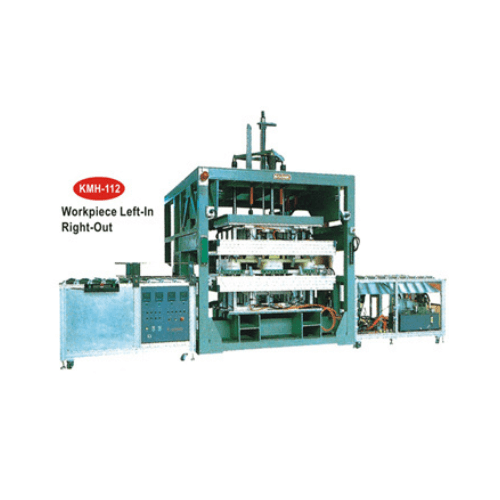

HOT PLATE PLASTIC PALLET WELDING MACHINE KMH-112 (LEFT-IN RIGHT-OUT)

1. Using a hot plate to melt the surface of the welding parts, then forced welding parts to join together. 2. It can meet the requirements of tight joint without damaging the surface of the working piece, and reach to welding effect of waterproof and airproof . 3. Suitable for large or irregular plastic pallet processing. 4. Machine type can be divided into semi-automatic and fully automatic equipment. 5. The pallet feed from left side of machine and collected from right side of machine by convey

Pellet Extruding Machines Screws / Barrels

Categories : Screws and Barrels

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.