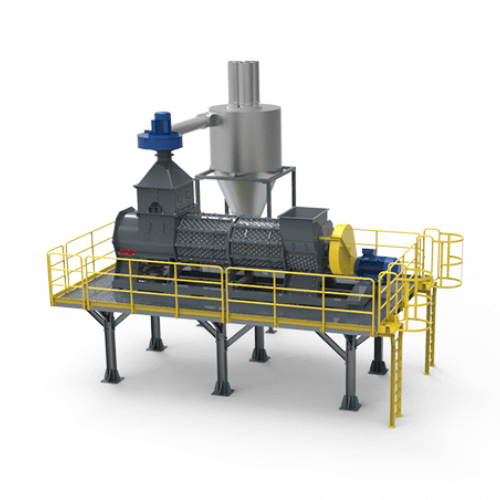

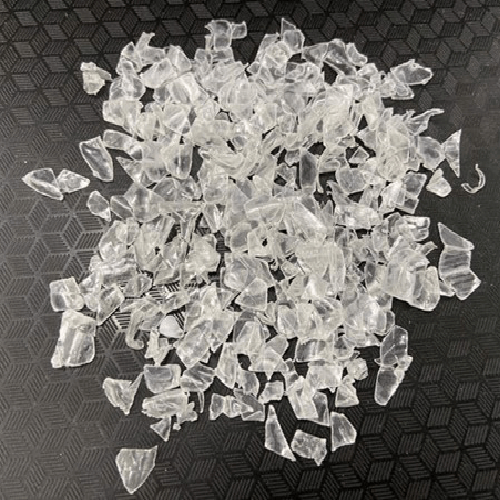

3 types of sieving machines which are dry trommel, disk screener, and dust remover are available for different materials. They have the same function to remove impurities such as sands, metals, small stones, labels in different washing sections. The disk screener is more compact than the dry trommel, it's good to be placed after de-baling and pre-washing to separate impurities. It can evenly spread PET bottles on the next process like belt conveyor and filter residual water. Dry trommel can remove caps and sands separately through multiple meshes filtrations.

Dust remover has two specifications for the choice. One is named Zig-zag separator, the other is label aspiration separator. These two machines can separate small plastic labels and films by taking advantage of the gravity and machine structure.