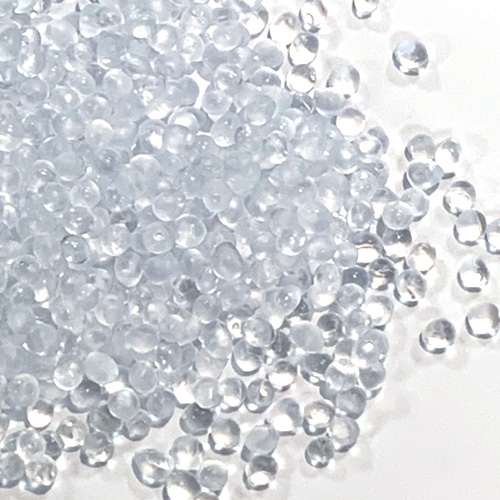

Medical grade TPE: SEBS Base, Stable and Purity Materials, none Extractable for Medical and Food Contact Uses

Comply with international standard , such as ISO 15759, usp class VI, YBB standard. Application on plastic plunger, Syringe, thin film, medical tube, pull cap...etc.

What is medical-grade TPE

Medical-grade TPEs are made with USP Class VI and FDA compliant thermoplastic elastomers (TPE) raw materials that must have extremely low extractable or leachable, when in contact with bodily fluids.

To design a medical part for the first time it is critical to research the materials first. This can help you make a decision on which type is most suited to your body or medical device, fits with the environmental views and product life expectations.

What are the advantages of medical-grade TPE

- TPE is a popular material for tooling, cost effective and less energy consumed to manufacture TPE products.

- TPE can be applied through wide range of processing methods, such as injection, extrusion, casting and blowing etc.

- TPE can be recycled at any steps and re-molded for environmental concerns.

- Wide range of hardness available, fitting the medical parts design from soft to rigid requirements.

- TPE can be easily dyed or colored for making medical device.

- High compression set strength formulations available for medical sealing and stopper designs improved performance on tight sealing significantly, maintains its shape throughout its lifetime.

- TPE can be sterilized under 121°c for 30 minutes.

Everlon TM Series choice

Everlon team focused on developing TPE formulations for medical fields, researched each material and their pros and cons for medical devices. TM series based on TPE has more advantages, such as ease of manufacturing, recyclability and cost competitive on raw material, stabilize end product and its physical properties for high requirements from medical devices design.

| Compound Name | TM Series |

| Hardness | 30-90 Shore A ; 30-65 Shore D |

| Color | Transparent / Translucent |

| Bonding | PC, ABS, PC / ABS, PP, PE |

| Typical Applications |

|

| Material Advantages |

|

TPE in Medical and Healthcare Applications

TPE material for medical industry is critical for high performance designs and applications, addresses sterilization and allows the contact with body without skin sensitization issue, meet high standards of regulatory requirements, comply to ISO 10993, USP Class VI and FDA. TPE solutions from Everlon technical expertise supporting design flexibility for medical devices development for decades.

Discover More TPE Advantages

The medical-grade TPE compounds from Everlon can be conducted through a variety of cost-efficient production process, such as injection molding, extrusion molding, blowing and casting molding. The designs of medical parts can be injected parts, tubes, films, sheets, profiles for wide range of medical device requirements.

Everlon TM series compounds are recyclable, easy to be colored and various levels of transparency materials available, high heat resistance property, superior compression set performance for stopper requirements, kinking free for tube designs.

TPE materials owned the key advantage as substitution to PVC and silicon rubber. The issue of environmental-friendly to be concerned when applying PVC materials. High cost on both materials and operating process from silicon rubber for making medical parts. TPE offers more opportunities for designing cleaner and eco-conscious medical devices, they are disposable and recyclable at any step without releasing halogens.