Special bonding grade TPE: base on SEBS, with good adhesion for double injection.

Comply to UL Certification. Insert molding: able to bonding with ABS, PC, PC/ABS, PMMA, AS, PBT, PETG, PA (NYLON). With excellent Weatherability, stability of UV and excellent flexibility. Suitable for computer, MP3, cell phone, camera, PDA, mouse and so on.

|

Compound Name |

TA Series |

|

Hardness |

45 – 90 Shore A |

|

Color |

Natural / Black |

|

Bonding |

PC, ABS, PC/ABS, PA, PBT, PETG, PMMA, POM |

|

Typical Applications |

TPE Computer & Laptop TPE Cell phone case & Digital camera TPE Industrial parts |

|

Material Advantages |

Excellent adhesion Good weather resistance Good scratch resistance Comply with UL certificate Easy coloring Excellent resistance against UV light Free of PVC & Recyclable

|

High quality of strength and transparency: including crystal-clear grade TPE.

Based on SEBS, which is excellent at flexibility and elongation rate. Comply with the FDA standard, suitable to use on the medical instruments and food products.

|

Compound Name |

TC Series |

|

Hardness |

00 – 95 Shore A |

|

Color |

Transparent / Translucent |

|

Bonding |

PP, PE |

Typical Applications |

TPE Food container TPE Baby teethers & Children toys TPE Goggles & Earplug TPE W/P Sealing |

|

Material Advantages |

Excellent adhesion to PP, PE High transparency Excellent elastic properties Comply with SGS FDA certificate Excellent surface quality |

General grade TPE: Base on SEBS. suitable for insert molding, excellent bonding PP.

Available in wide range of hardness customized TPE, excellent weatherability, stability of UV and the physical mechanical property. With competitive price.

|

Compound Name |

TS Series / TZ Series |

|

Hardness |

10 – 95 Shore A |

|

Color |

Natural / Black |

|

Bonding |

PP, PE |

|

Typical Applications |

TPE Flippers TPE Gas mask TPE Industrial parts TPE Toothbrush & Shaver |

|

Material Advantages |

Excellent adhesion to PP, PE Well UV stability Well weather resistance Excellent mechanical properties |

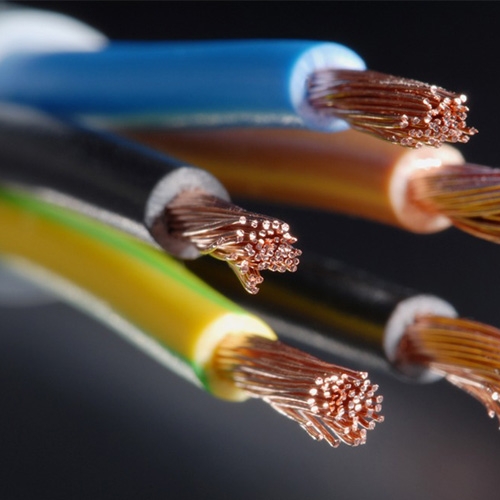

Flame Resistance Grade TPE

Thermoplastic Elastomers (TPEs) based on SEBS.

|

Compound Name |

TF Series |

|

Hardness |

30-95 Shore A, 20-50 Shore D |

|

Color |

Natural / Black |

|

Bonding |

PP, PE |

|

Typical Applications |

TPE Headphones cable. TPE Connector cable TPE Cable plug |

|

Material Advantages |

Excellent resistance against UV light Good V0, V1 & V2 Fireproof |

EVERLON® is a SEBS base TPE, which the middle of it is the Ethylene Butylene rubber and the end of it is the Polystyrene. Through the hydrogenation reaction, it results in excellent weatherability and stability of heat-resistant ability.

Thermoplastic Elastomers (TPEs) based on SEBS. Applications: Computer & Laptop, Cell phone case & Digital camera, Industrial parts.

What is industry - grade TPE

TPE compounds are normally soft and flexible to various applications depending on unique requirement from each application. These compounds are dedicated to wide range of industry applications, soft and flexible TPE can be applied for shoe industry, wire and cable, tools, toys, hose and tube fields, window profiles etc. Everlon accumulates more than 20 years experiences on developing TPE formulations which were mature to be proceeded through injection, extrusion, blowing and casting for making industry parts.

What are the advantages of Everlon TPE

-

TPE is a popular material for tooling, cost effective and less energy consumed to manufacture industry parts.

-

TPE can be applied through wide range of processing methods, such as injection, extrusion, casting and blowing etc.

-

High bonding strength between TPE to engineering plastics, such as POM, Nylon, ABS and PC etc.

-

TPE can be recycled at any steps and re-molded for environmental concerns.

-

Wear resistant & low noise materials.

-

Wide range of hardness available, ranged from 0A to 70D.

-

TPE can be easily dyed or colored for making industry parts.

-

High compression set strength formulations available, maintains the shape throughout its lifetime.

-

High performance TPE can be sterilized under 121°c for 30 minutes.

-

Excellent chemical and weather resistance property.

-

Comply to certifications associated, such as FDA, USP Class VI, REACH and Rohs etc.

Everlon Industry Fields choice

Everlon team focused on developing TPE formulations for wide range of industry fields, researched each material and their pros and cons for industry parts. The series of TA, TC, TS, TZ and TF based on TPE has more advantages, such as ease of manufacturing, recyclability and cost competitive on raw material, stabilize end product and its physical properties for high requirements from industry parts design.