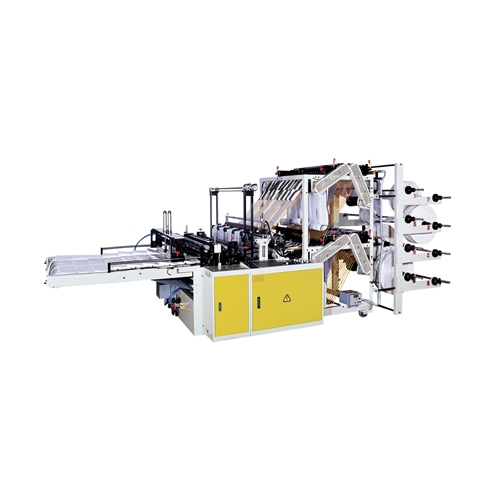

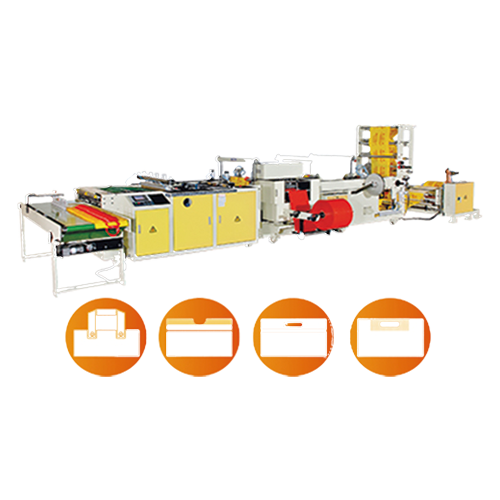

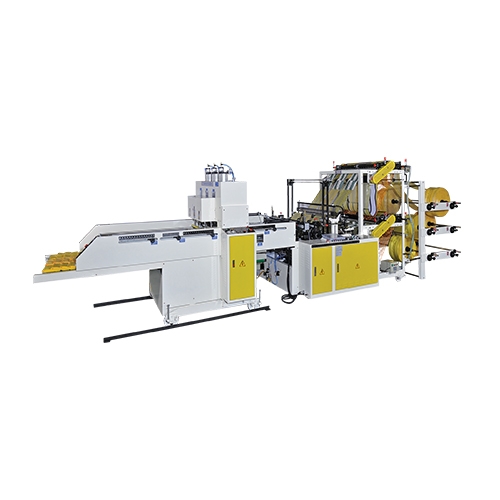

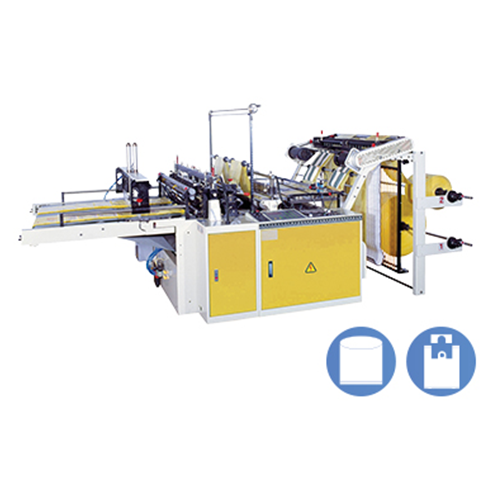

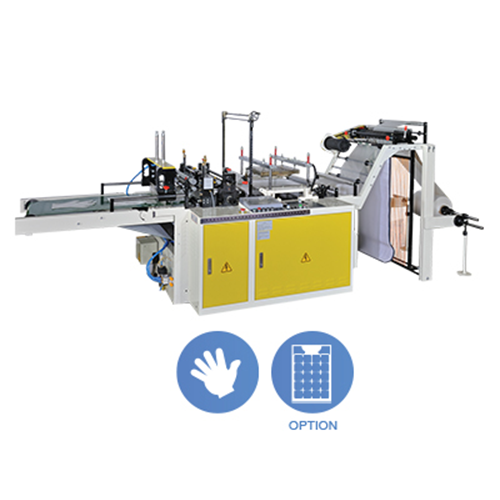

Classification : Perforating Bag Making Machines

Country: Taiwan

Phone: 886-5-2686688

Fax: 886-5-2687821

Contact Person: Cathy Chang

-

Special for two lines perforating coreless bottom and star sealing bags on roll.

-

In-line triangle folding device for star sealing bags.

-

E.P.C. (Edge Position Control) for the film at correct position.

-

Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption.

-

Bag length & production speed can be changed easily from touch screen.

-

German made photocell-SICK for accurate printing mark.

-

Automatic lift up reel unwinder with air shaft, reducing the number of employees.

-

Automatic tension control with AC motor and inverter system for jumbo diameter film roll.

-

Two lines automatic roll changing system.

| Model | CW-800R-SV | CW-1000R-SV |

| WIDTH OF FILM ROLL BEFORE FOLDING (mm) | 150 ~ 330 x 2 | 150 ~ 430 x 2 |

| FINISHED ROLL WIDTH (mm) | Max. 300 x 2 | Max. 300 x 2 |

| BAG LENGTH (mm) | 300 ~ 1000 | 300 ~ 1200 |

| PRODUCTION SPEED(meter/min/line) | Max. 100 | Max. 100 |

| THICKNESS (mm/layer) | 0.01 ~ 0.035 | 0.01 ~ 0.035 |

| HEATER (kw) | 6 | 7 |

| POWER REQUIRED (tw) | 11 | 12 |

| AIR VOLUME & PRESSURE |

800 L/min 6 kg/cm² |

800 L/min 6 kg/cm² |

| DIMENSIONS L x W x H (cm) | 650 x 295 x185 | 650 x 315 x185 |

| PACKING L x W x H (cm) |

200 x 220 x 170 255 x 200 x 200 350 x 230 x 180 |

200 x 220 x 170 255 x 200 x 200 370 x 230 x 180 |

| NET WEIGHT (kg) | 2500 | 2700 |

| REMARK |

2 Photocells 2 Servo Motors |

2 Photocells 2 Servo Motors |