Tube Loader (AL)

Categories : Loading and Conveying Machines

Stainless unique design is dust-free and clean –free for optics users perfectly. Light weight and compact size can be directly mounted to any vessel and machine without purchasing another vacuum loader. Save your cost and space. By using compress air efficient venture draws resin from material tank. No motor and low noise is perfect for clean room, indoor work, and electronics and medical users. Good for small batch and various kinds of production, high stability, high efficient supply to prevent moisture return of resin. Glass sight window gives a clear view of loading and safety protectors to help operators working more efficiently.

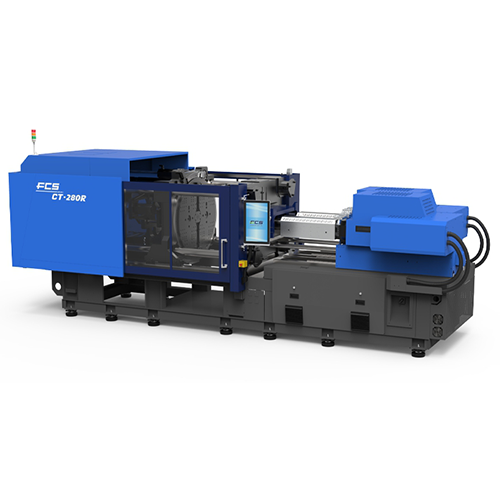

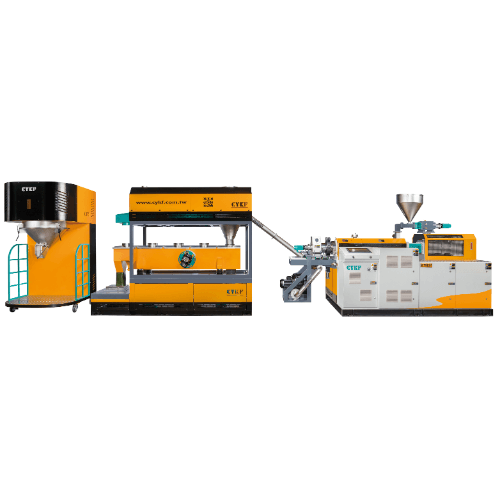

All-Electric Two-Component Injection Molding Machine (CT-R series)

Categories : Electrical Injection Molding Machines

It is All-Electric Two-Component injection molding equipment. It is suitable for two-component and multi-component products, including electronic parts, medical appliance, cosmetic containers, etc.

Small Roll Slitter Series FSL-D

Categories : Slitters and Rewinders

The Small Roll Slitter is ideal for slitting large parent roll into small bobbins such as POS, ATM, cash register, ticket, receipt, thermal paper, fax, lottery, medical report and various paper roll for office use.

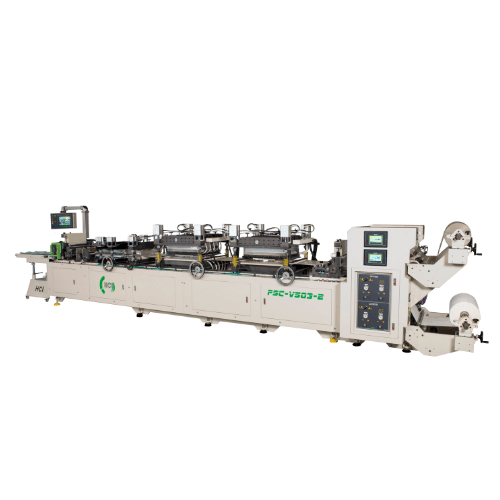

Pouch Making Machine For Sterilized Reel Pouch - FSC-V603-2

Categories : Plastic Bag Making Machines

The Sterilized Reel Pouch Making Machine is designed for producing Medical Pouch, Sterilized Reel, Sterilized Pouch used in the pharmaceutical industries.

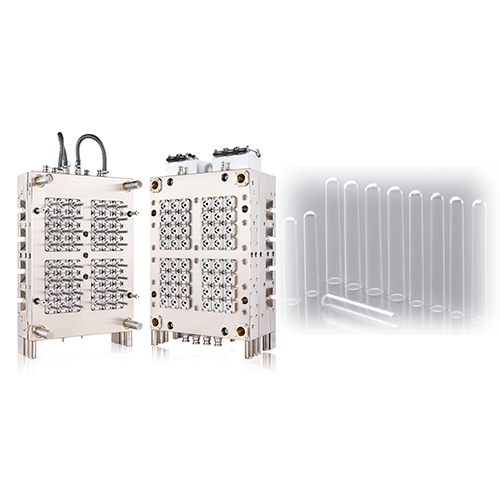

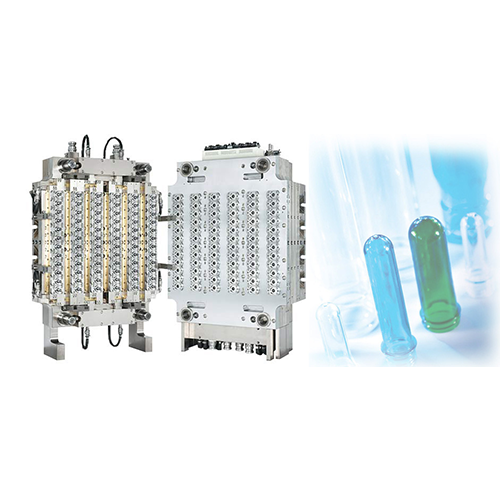

High Precision Injection Mold

Categories : Injection Molds

-Design & Development of Diversified Precise Molds -Mold flow analysis & optimized solution for mold design -Specialized molding system: Sale & Integration (PET/IML/Medical series) -Turnkey Solution Planning & Technology Transferring (operators’ training included)

Silicone Injection Molding Machine - FCRS SERIES

Categories : Silicone Injection Molding Machines

For solid silicone material products only. Automobile spark plug soft tubing, medical treatment equipment parts, drinking water machine parts and other silicone products.

Hot Runner Controller / Multi-Cavity Hot Runner Temperature Controller - TC5200

Categories : Hot Runner Systems

The TC5200 multi-cavity hot runner temperature controller. One single temperature controller has 26 to 72 zones and even up to 240 zones in a network. Maintenance operations can be simplified with its modularized device design and requirement-based configuration. The purchasing costs are greatly reduced by its unique temperature control, with two zones within one level. High light of the TC5200 Hot Runner Control system is the GUI based user interface, along with its adjustable perspective angle, is easy for fast adoption in multi-points control. The RS485 communication function enables you to set up multiple controls at once to simplify the required operations. The built-in and practical current sensor and indicator functions benefit various applications, especially automotive, bottle billet injection, and medical supplies, by realizing the concept of one-stop control. Arico

Corona Electrostatic Treater

Categories : Non Woven Production Line

This CORONA ELECTROSTATIC TREATER is used to turn materials such as melt-blown fabric (face mask sheet),non-woven fabric (non-woven sheet) and polymers into electrets. The equipment includes a high-frequency inverter power supply, special electrodes and rollers. Through the mutual control of these components, the electret material can deeply capture the charge energy, and maintaining the polarization for a long period. This equipment can be used for application such as turning melt-blown fabric, non-woven fabric (non-woven fabric) and air filter into electret. It greatly increases the filtration efficiency of the filter material by capturing tiny particle which is smaller than filter density. More importantly, this CORONA ELECTROSTATIC TREATER helps melt blown fabric increase 45~65% of filtration efficiency and turns it to the most important layer for medical face mask such as N95, KN95 etc. to reduce infected by corona virus COVID-19. Note: An electret is a material that almost remains electric polarization permanently and is able to generate an electric field in the surrounding area. The electret strength will last longer when corona electrostatic charges deeply by high voltage and frequency.

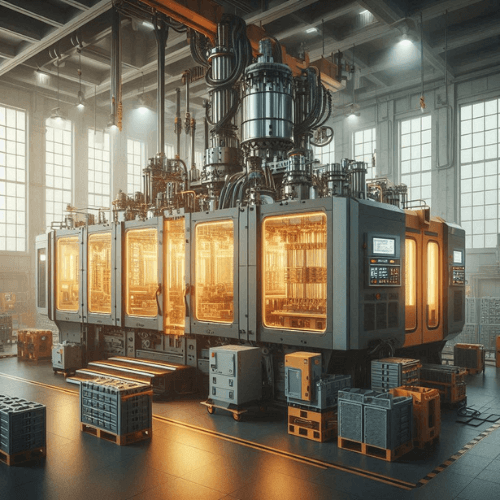

Blow Molding Machine Multi Layer Series

Categories : Electric Blow Molding Machines

VS series: suitable for visistripe bottles (ex. Motor oil bottle) -TC series: for the production of two-color plastic containers or toys -TL series: suitable for 2-layer bottles (ex. Cosmetic bottle only outside layer with pearl or color & made of virgin material) -Double-head or 3-layer machine can be delivered to order

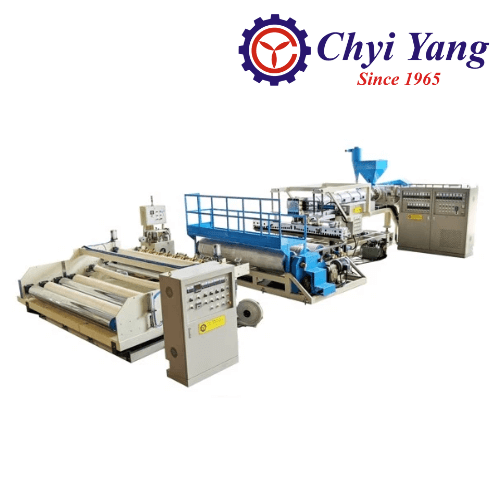

PE Stretch Casting Film Extrusion Machine

Categories : Film and Sheet Extrusion Lines

T-Die Extruder machine can produce waterproof PE film for baby diaper, sanitary napkin, folders, table cloths, medical film, etc. Film thickness 0.03~1 mm Equipped with a fully automatic winder with cutting and changing rolls functions Hydraulic screen changer for short maintenance stop We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

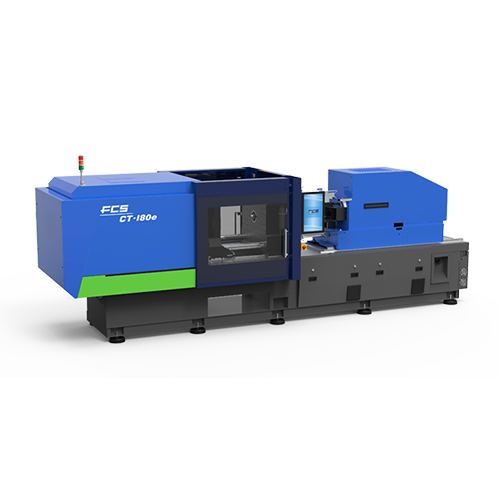

All-Electric Injection Molding Machine (CT-e Series)

Categories : Electrical Injection Molding Machines

It is a newly released model of All-Electric injection molding machine by FCS. The applicable industries include packaging, optical element, medical, and 3C appliance such as laptop or multifunction printer parts, etc.

Inspection Rewinding Machines INSPECT-SB

Categories : Slitters and Rewinders

This double-side rewinding machine can do more serious inspection for the better quality, especially for packages of medical, cosmetics and some high-price food products. Integrated with automatic defect system, this machine can reach precise and continuous inspection to ensure zero defects.

High Degree Water-type Mold Temperature Controller

Categories : Control Equipment

Economic and advanced design for high degree is your new choice. Water-type mold temperature controller (High Degree) do not pollute environment with oil gas that is the best choice for electronics, medical and cosmetic packing industries where strictly require better working environment. When oil-type model cannot satisfy for your need, you should change to water compression one. By direct supply method, it will not transform to steam even the temperature up to 160℃. Heat up faster, long machine life, high stability, precise control within ±0.3℃, and energy save for you. Precise temperature control and high stability control by 0.1℃ as a unit to display. The inaccuracy rate below ±0.3℃. Perfect for any precise requirement such as electronics industry. Heat-insulated design extend operating lifetime. PID temperature controller. Excellent overheat security protecting device. SSR relay control for durability. Unique design to prevent water leakage and pollution when mold is changed.

PPV Proportional Pinch Valve

Categories : Separators

Product Serial: PPV Pinch valve works in a way to open or to close a fluid path in a flexible tube by squeezing or pinching the tube. With a proportional pinch valve, the shaft that pinches the tube is driven by a stepper motor, thus that the extent of pinching can be adjusted, which indirectly controls the fluid flow rate inside the tube. The advantage of using a pinch valve is that it has no contact with the fluid, making it an ideal option for biotechnology processing, food industry, dosing system, blood process/analytical, CIP and SIP process, and biopharmaceutical equipment. Our PPV series pinch valve is driven by the PM series driver that accept either analogue ( 0-10V or 4-20mA) or digital RS485 modbus signal. What is a Proportional Pinch Valve? A Proportional Pinch Valve is a type of pinch valve that combines the characteristic and features of a pinch valve and a linear stepper motor. It is a great way to control fluid flow or fluid pressure in applications that emphasize sterile, clean, non-contact, avoid cross-contamination environment, such as Biotechnology Chemical Processing Dispensing, Filling, & Mixing Process Equipment Bioreactors Medical Devices Pharmaceuticals Life Sciences Food Processing In this article, we will start by introducing what type of proportional pinch valve KaoLu could offer, followed by the working principle, and when should you use a proportional pinch valve, and then conclude with what you should consider before making a decision on which valve to purchase. What type of Proportional Pinch Valve does KaoLu offer? KaoLu offers mainly two types of proportional pinch valve – miniature and high torque version. Miniature version: please click on photo to product brochure ,or visit https://www.genndih.com/pinch-valve/proportional-pinch-valve.html Three versions are now available: PPV-04, for tube outer diameter (O.D.) 3.5 – 4.5 mm (~0.125” to 0.188”) PPV-06, for tube O.D. 5.5 – 7 mm (~ 0.25” ) PPV-08, for tube O.D. 7 – 9 m (0.375”) The tube O.D. is flexible because we are using flexible plastic tube, and as long as the tube can fit into the insertion slot, it will be functional. The higher torque version is suitable for soft and more rigid tubing, up to durometer of 75 shore A. Please click on photo for product brochures, or visit https://www.genndih.com/pinch-valve/proportional-pinch-valve.html It is available to up 5 different sizes PPV-930-64 – tube O.D. 6 – 7 mm (~ 0.25”) PPV-930-95 – tube O.D. 9 – 10 mm (~0.375”) PPV-930-127 – tube O.D. 12 – 13.4 mm (~0.5”) PPV-930-191 – tube O.D. 18.6 – 19.6 mm(~0.75”) PPV-930-254 – tube O.D. 24.8 – 25.8 mm (~ 1”) All our proportional pinch valve can be controlled by either analogue (0-10V or 4-20mA) or digital signal. There is also an option for encoder. For the correct selection of product, please contact our product consultant. We also provides a video demo on how proportional pinch valve function, please visit and subscribe for our latest videos. https://www.youtube.com/watch?v=5z31SR9wqgk What is the Working Principle of a Proportional Pinch Valve? A proportional pinch valve combines the features and advantage of a pinch valve and a linear stepper motor. Let’s firstly introduce you the concept of these two items. Pinch Valve A pinch valve works in a way by pinching or squeezing a flexible plastic tube through a shaft that can be controlled by solenoid electromagnetic principle, by pneumatic pressure, or by a linear stepper motor. Pinch valve is especially useful in applications that does not allow valve to be in contact with the fluid inside the tube, such as chemical reagents, food, corrosive fluid…etc. A traditional pinch valve only provides full open or full closure function, and the disadvantage is that there is a flow rate drop when the tube is inserted into the pinch valve, and there is no way to control fluid flow rate. Linear Stepper Motor A linear stepper motor is a type of actuator that used the characteristic of a stepper motor to achieve linear motion. The degree in which one can control a step distance and torque is greatly dependent on the control system and the stepper motor quality and characteristics. A stepper motor is commonly used when one requires high resolution, high repeatability, and high torque. Pinch Valve + Linear Stepper Motor = Proportional Pinch Valve The combination of both provides an excellent solution for application that requires an automation on process line that requires sanitary environment and applications that require cleanliness and sterility, as well as highly accurate incremental flow or pressure regulation. This eliminating the need for multiple-valve, high-maintenance assemblies, and this single valve offers a compact, efficient solution. When should I use a Proportional Pinch Valve? KaoLu is expert in pressure and flow regulation. Please refer to the graph below: Pressure Regulation: The left had side is the control of inline pressure with a traditional on/off pinch valve. The right hand side shows the pressure control with a proportional pinch valve. In a process line that does not allow fluid to be contaminated, one could consider a proportional pinch valve to adjust the inline pressure by controlled the opening of the tube via a proportional pinch valve. With a fine step control, the pressure could be adjusted in a high resolution manner. Flow Regulation: The graph shows that the inline fluid flow rate could be regulated by a proportional pinch valve. The curve could be shift leftward with either a higher resolution stepper motor control or by adjusting zero offset of the pinch valve. With a proportional pinch valve, one can easily control (non-contacting method) the inline fluid pressure and flow rate, this offers a great advantage to many industries. What should you consider when purchasing a Proportional Pinch Valve? 1. Tube: outer diameter, material, shore A, inner tube pressure 2. Performance: resolution, repeatability, can achieve desired accurate flow or pressure control 3. Control: analogue or digital control We called it TPC. It is important to understand the characteristics of the tube you are using and the operating pressure. Sometimes, a suitable tube may not work if you have a high inner tube pressure which the pinch valve could not squeeze or pinch at all. Secondly, the performance of the proportional pinch valve should be taken into account when choosing which brand of proportional pinch valve is suitable for you. With KaoLu’s proportional pinch valve, we are able to achieve up to 40000 steps per revolution and the velocity in which the pinch shaft moves to squeeze and the torque of the motor could be calibrated easily by our customers to suit different requirements. The third important factor is control method. With our digital control method, it is possible to operate the valve half a mile away from the valve itself. We also provide RS485 holding register where the user could adjust zero offset and other parameters to fit customized solution. Please visit our product website for further information. https://www.genndih.com/pinch-valve/proportional-pinch-valve.html and remember to visit our youtube channel and subscribe for latest video updates: https://www.youtube.com/channel/UCjQ9bjuSOT_csnVA9if4_EQ/videos

85-150 ton injection molding machine product

Categories : Injection Molded Products

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

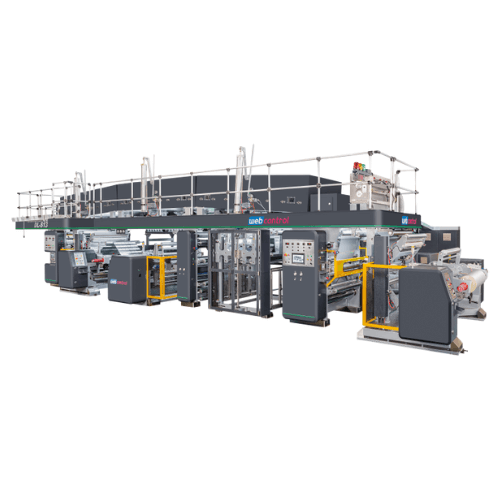

Dry Laminating Machine Shafted Type DL-1000/1300

Categories : Industrial Lamination

This machine is for the Laminating process that uses a solvent-based adhesive. Reliable tension control with a mature lamination process able to make high-end products such as retort, sterilize and medical pouches. The gravure coating station allows high precision and consistency in coating weight. An efficient drying tunnel has high performance in vaporizing solvent completely to keep the product safe. Various options of heating solutions for drying tunnels are available. The energy-saving system is an option to help decrease carbon footprint and the cost of production

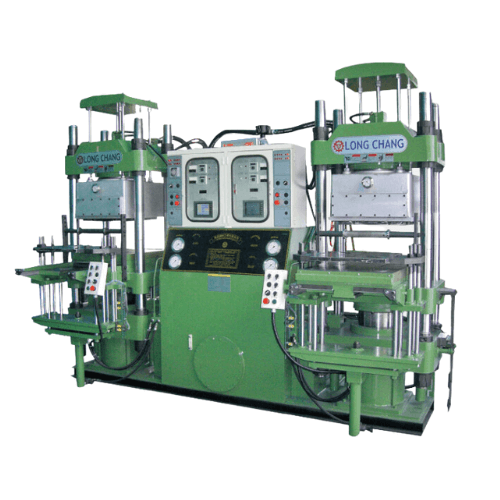

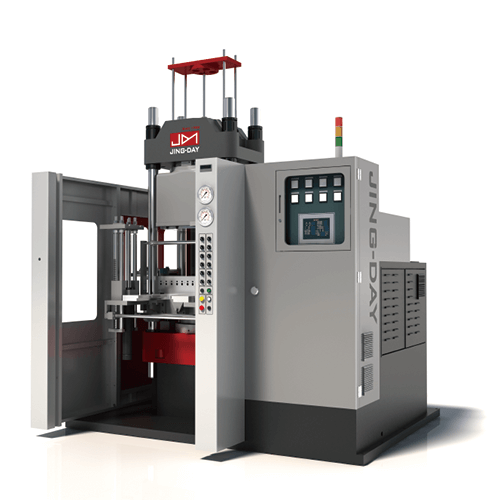

Single Body Die-removing Ejection Compression Molding Machine - FCS Series

Categories : Compression Molding Machines

APPLICATIONS: Conductive rubber, oil seal, automobile parts, keyboard pad, brake lining, mahjong, nontoxic rubber, thermos bottle plugs, nipple, medical rubber plugs etc.

Twin Body Vacuum Oil Hydraulic Compression Molding Machine - FBV Series

Categories : Compression Molding Machines

APPLICATIONS: Automobile oil seal, rubber o-ring, key board pad, electric capacitor rubber, medical treatment rubber, etc.

APV Electronic Pinch Valve

Categories : Separators

Product Serial: APV APV Series Miniature Pinch Valve is a solenoid operated device that is designed to open and close tubes for controlling flow of liquids and gases. Other valve types have internal passages that may cause small amounts of fluid to remain in the valve. Pinch valves have no areas or dead volume where fluid can become trapped. Only the inside of the tubing contacts the fluid. Energizing the solenoid retracts or attracts the plunger, which opens or closes the tube. De-energizing the solenoid will allow the plunger to return to its original state. Common industries that use pinch valves for the benefits of isolating fluid from a mechanical valve include: drug dispensing, laboratory equipment, waste water, medical devices, chemical, food and beverage equipment, ceramic/glass/plastic, and bulk and solids handling.

Insert Injection Molding

Insert Injection Molding Technology is a manufacturing process that integrates pre-placed components, such as metal inserts, electronic parts, or other materials, into a plastic injection mold. During molding, molten plastic encapsulates the insert, creating a single, durable, and high-precision component. This technology enhances product strength, reduces assembly costs, and improves reliability, making it widely used in automotive, electronics, medical devices, and consumer products. By ensuring strong adhesion between plastic and inserted components, insert injection molding enables lightweight designs, enhanced durability, and improved performance in various applications. Key Advantages: Seamless integration of metal and plastic components Higher product strength and durability Cost-efficient by reducing assembly steps Customizable for complex geometries Enhanced precision and consistency Common Applications: Automotive Parts – Armrest trim panels, dashboard components, connectors Electronic Components – Connectors, circuit boards, protective casings Medical Devices – Surgical tools, sensor housings, implantable components Consumer Goods – Power tool grips, ergonomic handles, durable casings

Medical Waterproof Disposable Table Paper Cutting Machine Model SHCG-42MP

Categories : Paper Bag Making Machines

The paper bag cutting and making machine features 1. Servo Motor Driven for precise length cutting. 2. Infeed Dance Roller Control with inverter Motor. 3. Air Cylinder Lifter Heavy Duty Unwinder for 300KG Paper Roll. 4. Collect Conveyor for friendly operation.

Ultrasonic Therapeutic Massager KUP-200

KUP-200 is working with 1 million times ultrasonic vibration per second which causes the tissues to compress and expand.The mechanical and thermal effects help to localized increase of blood flow and for the treatment of selected medical conditions such as temporary relief of minor pain, muscle spasms, and joint contractures.

Twin Body Die-Moving & Ejection Compression Molding Machine - FBS SERIES

Categories : Compression Molding Machines

APPLICATIONS: Conductive rubber, oil seal, automobile parts, keyboard pad, brake lining, mahjong, nontoxic rubber, thermos bottle plugs, nipple, medical rubber plugs etc.

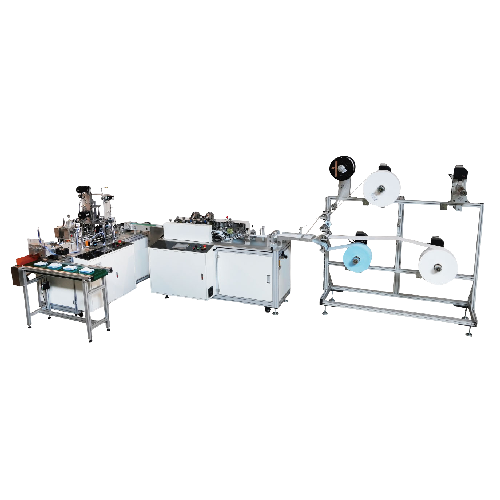

Medical Sterilization Bag Machine

Categories : Plastic Bag Making Machines

1. Main drive AC motor + inverter control. 2. The Sterilized Pouch length is accurately controlled by servo motor incorporated with mark sensor for greatly upgrading the production speed. 3. Twin Rolls unwind stand suits for two layers of different materials and multi-line production which upgrades efficiency greatly. 4. Two sets of dancer-roller unit provide the stable feeding tension both upper and lower web. 5. Equipped with microprocessor PID temperature controllers provide the most accurate and fastest heating performance. 6. Equipped with two sets of shear knives for bag partition. 7. Micro computer control system.

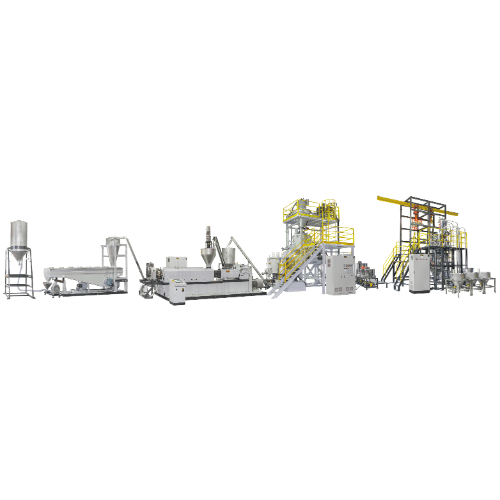

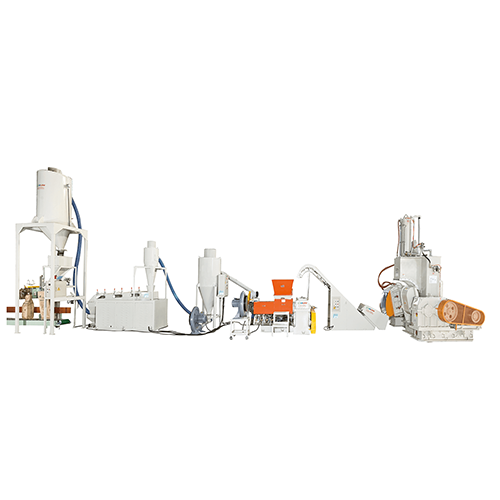

PVC Automatic Metering / Weighing / Conveying Pelletizing Extrusion Line | CK-DT

Categories : Twin Screw Extruders

CYKF has good reputation in PVC extrusion. Our CK-DT series Counter-rotating Twin Screw Extruder is especially designed for PVC. The available screw diameter is between 55 to 130mm. Thanks to our technical team put long term effort on this field which makes CYKF’s PVC extruder is competitive compared to other competitors. Our durable and high-efficient PVC extrusion pelletizing line is able to produce rigid PVC, soft PVC, medical grade PVC, UPVC, CPVC, and additives of foam or wood powders. We are pound to say the PVC extrusion line made by CYKF is no doubt the best choice for customers. Possible materials : UPVC, CPVC, Medical grade PVC, Soft PVC, Rigid PVC, Foam and wood powder additives.

Overmolding Injection Molding

Overmolding Injection Molding Technology is a multi-material molding process that combines two or more materials in a single mold to enhance structural integrity, comfort, and functionality. This process allows flexible materials (such as TPE, TPU, or silicone) to be molded over a rigid substrate (such as ABS, PC, or PA), providing superior grip, durability, and impact resistance. This technology is widely used in automotive, electronics, medical devices, and consumer products, particularly for components requiring ergonomic design, shock absorption, anti-slip surfaces, and sealing properties. Compared to traditional assembly methods, overmolding technology offers cost savings, improved structural integrity, and an enhanced product appearance and feel.

TPE for Medical Instrument - TM Series

Categories : TPR (Thermoplastic Rubber)

Ever Polymer has the mission to satisfy all the application needs for thermoplastic elastomers (TPE) raw materials in the market. TPE TPE for Medical TPR tpe material tpe material eco friendly tpe material manufacturer tpe material properties tpe material toxic tpe plastic recycling tpe raw material tpe rubber what is tpe material tpe material safety

Medical Grade PVC Pelletizing Extrusion Line | CK-DT

Categories : Twin Screw Extruders

CYKF has good reputation in PVC extrusion. Our CK-DT Counter-rotating Twin Screw Extruder is especially designed for PVC production; the available screw diameter is between 55 to 130mm. Thanks to our technical team put long term effort on PVC extrusion technology which makes CYKF’s PVC extruder is competitive compared to other competitors. The high-efficient and durable PVC pelletizing machine can produce rigid PVC, soft PVC, medical grade PVC, UPVC, CPVC, and additives of foam or wood powders. It has outstanding performances that has earned highly praises from global customers.

Medical Molds

Categories : Injection Molds

Blood Collection Tube Molds with multi-cavities solution – up to 48 cavities.

PET Preform Molds

Categories : Injection Molds

Mold platen steel: PDS-5 (P-5) high grade tool steel HRC 27°-32°.

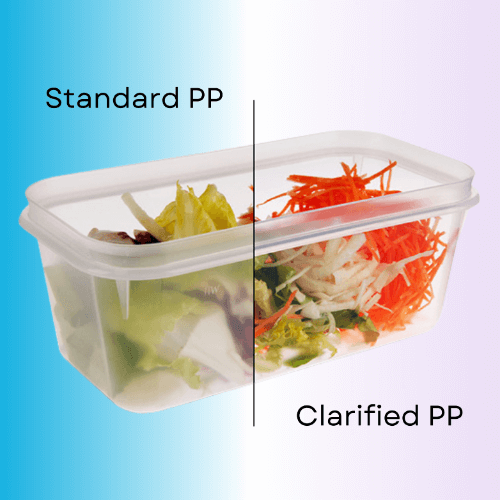

Millad® NX™ 8000

Categories : Additives

Millad NX 8000 helps PP producers and converters to stay ahead of packaging, appliances, medical, houseware and food storage trends by achieving unprecedented transparency in polypropylene. This innovative clarifier creates exciting new opportunities for your products, including significant energy savings and faster production in injection molding. Suitable for all conversion processes, Millad NX 8000 makes polypropylene a viable alternative to glass or amorphous polymers like PC, PET, PVC and PS. PP clarified with Millad NX 8000, known in the market as NX UltraClear PP, answers the growing demand for clear, attractive products and sustainable, cost-efficient production.

PVC、EVA、PP/PE + CaCo3、LSNH PVC+NBR、TPR Compounding System

Categories : Compounding Lines

•Pellets for Medical Tubes •Injection Tube (Medical Use) •Cable & Wire Pellets (LSNH) •Cable & Wire

Vacuum Type Oil Hydraulic Molding Machine JD-HV Series

Categories : Rubber Curing/Vulcanizing Machines

The vulcanization press Ideal for the production of making packing O-rings, keyboards, rubber medical products, etc.

3-Side-Seal Medical Bag Making Machine -AMMII-DS Series

Categories : Plastic Bag Making Machines

Applicable Material: Paper, plastic films.