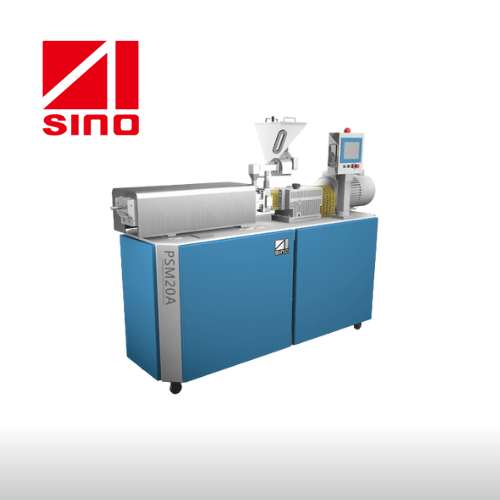

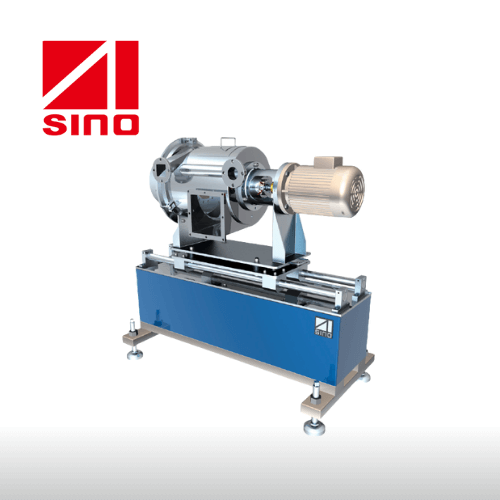

Clam-Shell Design Co-Rotating Twin Screw Extruder-PSM20A

Categories : Granulators

The PSM20A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

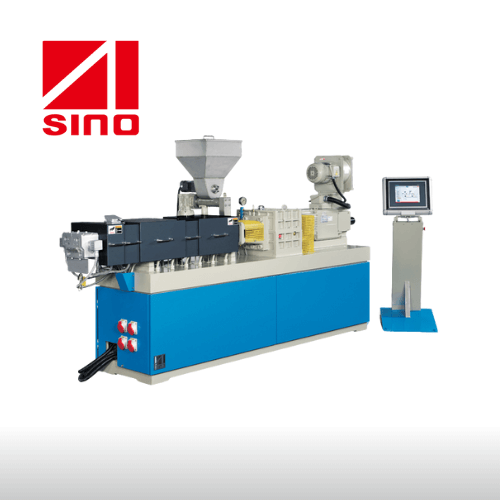

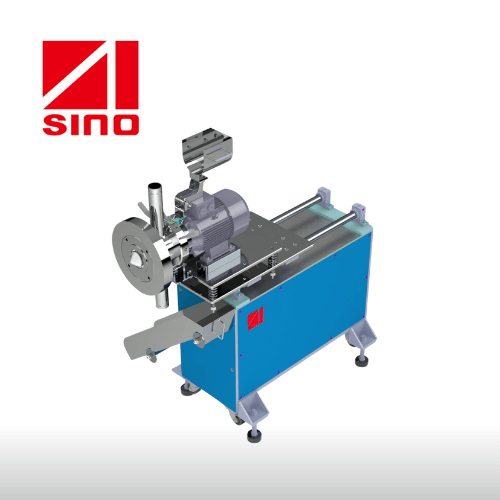

Compact Co-Rotating Twin Screw Extruder-PSM30A

Categories : Twin Screw Extruders

The PSM30A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM30 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

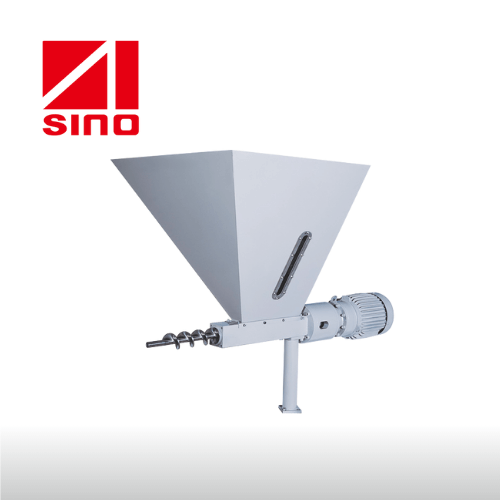

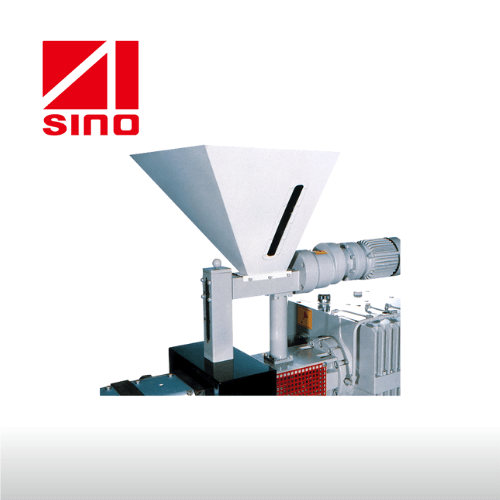

Single Screw Feeder-PSA

Categories : Feeders

The PSA series single-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSA single-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Options include standard double-flight, single-flight, T-type, and spring type screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

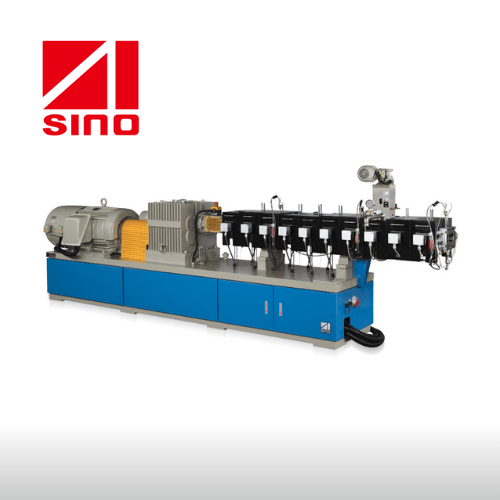

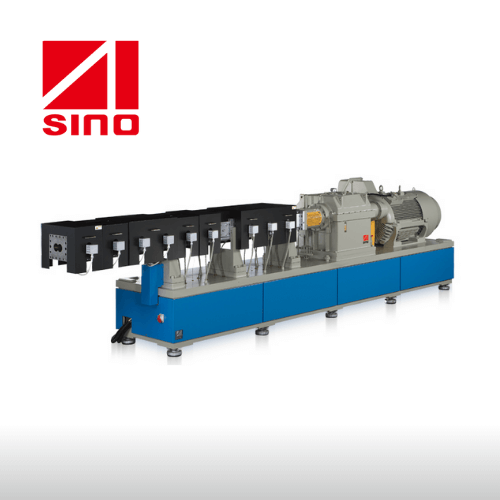

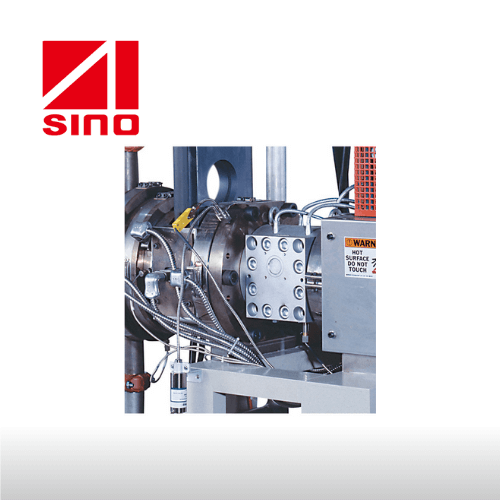

Co-Rotating Twin Screw Extruders-PSM50

Categories : Twin Screw Extruders

The optimization of the PSM50 series resulted in more efficient and durable designs. The PSM50 series has mid range production capabilities, and easy operation in reasonable price. All PSM50 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

Co-Rotating Twin Screw Extruders-PSM72A

Categories : Twin Screw Extruders

The optimization of the PSM72 series resulted in more efficient and durable designs. The PSM72 series has mid range production capabilities, and easy operation in reasonable price. All PSM72 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

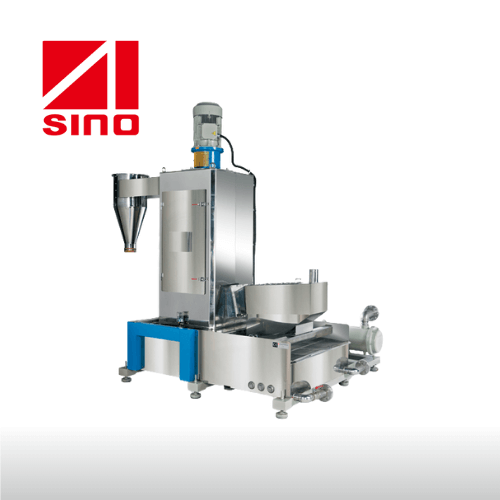

Water Ring Pelletizer-PSF

Categories : Plastic Pelletizer Machines

The PSF water-ring pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and material which may be too brittle for strand pelletizing. Variable speed cutting blade to control pellet size and surface quality. Use in line with our PSL series centrifugal dryers to complete the water-ring pelletizing system.

Underwater Pelletizer - PSQ

Categories : Plastic Pelletizer Machines

The PSQ underwater pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and sticky materials. Hot melt is extruded through a die into a water-filled cutting chamber where it is die-face cut by a high-speed cutter. The resulting spherical pellets are conveyed via water slurry to a centrifugal dryer. Use in line with our PSL series centrifugal dryers to complete the underwater pelletizing system.

Strand Pelletizer-PSH

Categories : Plastic Pelletizer Machines

The PSH strand pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Strands from the extruder are pulled through a water-filled cooling bath and blown dry by an air knife before entering the pelletizer. This simple pelletizing process is applicable to many different types of plastics and rubber. Our knives are made with tungsten carbide steel to ensure a long life and clean cuts. Puller and rotary knife can be synchronized to ensure uniform pellet size regardless of the extruder throughput. Designed with built in safety features, the moving parts are all enclosed within a protective cover.

Air Cooling Pelletizer-PSW

Categories : Plastic Pelletizer Machines

The PSW air-cooled pelletizer was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Especially good for hygroscopic materials. Variable speed cutting blade to control pellet size and surface quality. Use in line with our cyclone tanks to complete the air-cooled pelletizing system.

Twin Screw Feeder-PSB

Categories : Feeders

The PSB series twin-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSB twin-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Screw options include intermeshed, T-type, and single-flight screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. The deeper and wider groove from a single-flight conveyor, T-type, or non-intermeshed screw is more suited for particulate, flake, fiber, or powder feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

Centrifugal Dryer-PSL

The PSL series centrifugal dryer was developed by Sino-Alloy Machinery as an important and essential accessory for both the PSF series water-ring and PSQ series underwater pelletizers. The PSL series dryers utilize high-speed centrifugal force in combination with forced air flow and evaporation to dry the pellets. Superior performance over vibrating dryers in terms of drying efficiency, throughput, space-saving, and noise level. The PSL series centrifugal dryer can also be a great replacement for that old vibrating dryer.

Anti-Leakage Vacuum-PSY

Categories : Valves

The PSY anti-overflow vacuum was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Developed to prevent extruded material overflow from the vacuum vent during degassing and subsequent vacuum failure. The PSY anti-overflow vacuum is driven by a pair of vertical intermeshed screws to move overflow material back to the material barrel while degassing with the vacuum. Can also be installed on side feeders to prevent overflow.

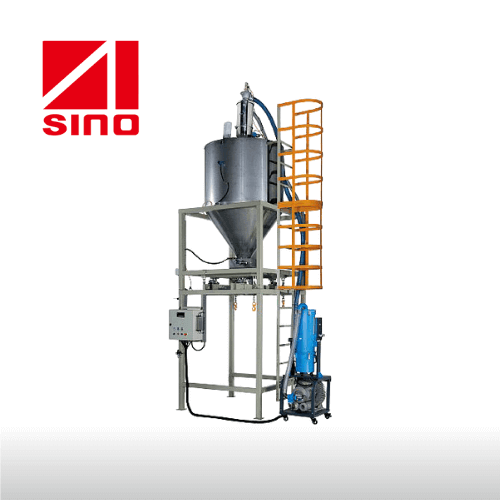

Storage Tank with Blowing-PSP

The PSP series storage tank with optional blower is Sino-Alloy’s solution for the temporary storage of the rubber or plastic pellets before packaging. The PSP series storage tank is made of stainless steel and can be customized to the customer’s specifications. The optional blower/dryer can help ensure there is no buildup of residual moisture. An optional vacuum loader can transport the rubber or plastic pellets from the PSN separator directly to the PSP storage tank. Also available with a packaging function includes air control valves to regulate the output quantity and an automatic weight scale.

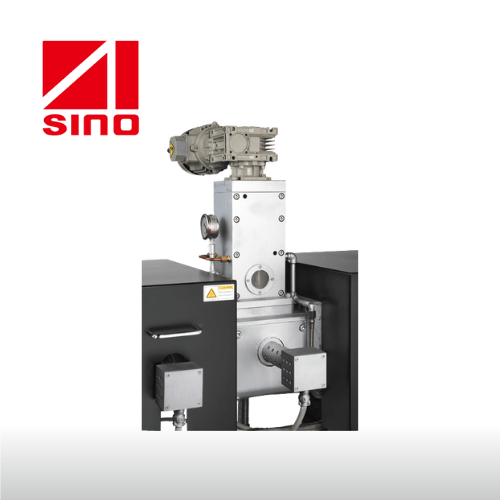

Diverter Valve-PSV

Categories : Valves

The PSV series diverter valve was developed by Sino-Alloy Machinery as an important accessory to their extruder line. The PSV diverter valve can divert scrap material during start up or in process. It can also interrupt incoming material input if there is a problem with production. The PSV diverter valve is made of special grade steel with surface treatments to reduce surface roughness. The parts are also machined to extremely high standards to ensure there is no leakage or internal wear. The thermal and flow dynamics of the internal design are also well thought out to ensure the smooth flow of material. The end result is easy cleaning and no dead spots in the melt flow.

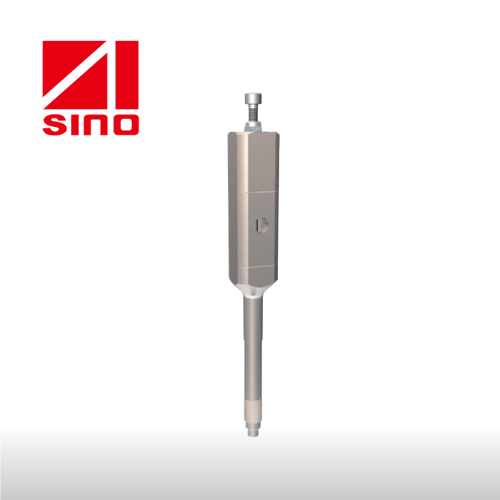

High Pressure Liquid Injector-PSX

The PSX high-pressure liquid injector was developed by Sino-Alloy Machinery as an important accessory to their extruder line. The PSX high-pressure liquid injector is made up of a storage tank, proprietary precision plunger pump, and one-way valve type fluid injector. It can generate pressures as high as 50 kg/cm. This feeder can be connected to any feeding port of the extruder. The PSX high-pressure liquid injector is also capable of injecting high pressure gases or super-fluid liquids. Not only is it suitable for the injection of liquid and gaseous additives in rubber or plastics materials, but also for may plastic and rubber reactive processes or the injection of liquid ingredients in food and pharmaceutical. The PSX high-pressure liquid injector can also be supplied with heating and insulation devices, loss-in-weight metering devices, or flow controllers for precise measurements of the input quantity.

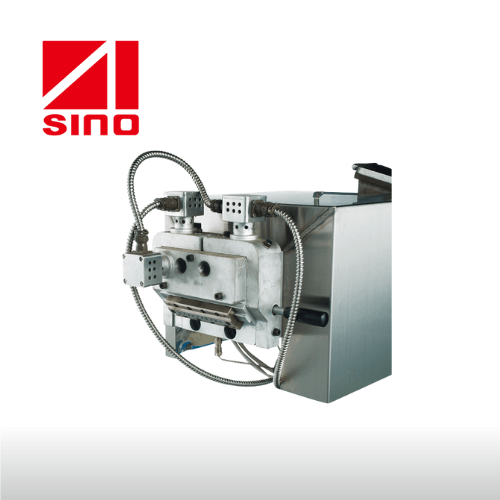

Twin Screw Side Feeder-PSC

Categories : Dosing and Measuring Equipment

The PSC series twin-screw side feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSC twin-screw side feeder has a large feeding screw chamber for a smooth flow of the feeding material. The intermeshed type twin-screw has a self-cleaning feature with powerful displacement force, high feed volume, stable feeding, and excellent aeration properties, making it suitable for moist, low coefficient of friction powders and mixed types of plastics which require forced side feeding. Sino-Alloy Machinery can also tailor the design of a PSC twin-screw side feeder to match extruders from other manufacturers. Customers can also specify options such as preheating or cooling to suit production needs.

Strand Die-PSZ

Categories : Extrusion Dies / Dies Heads

The PSZ series strand die was developed by Sino-Alloy Machinery as an important accessory to their extruder line and essential for strand pelletizing. In order to improve the flow smoothness, Sino-Alloy has brought in special 3D simulation software to help design the die. Precision machining of the parts and the careful selection of materials is part of the process of making the most appropriate strand die. The PSZ series strand die has optimized flow design and temperature balance to achieve ease of cleaning, durability, and a smooth flow of material. Furthermore, Sino-Alloy can also help to design or improve strand dies from other manufacturers.

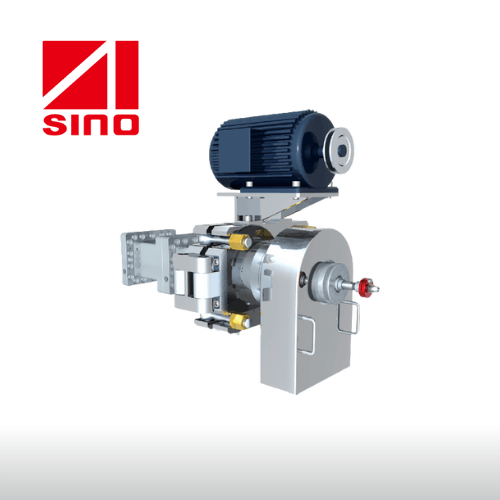

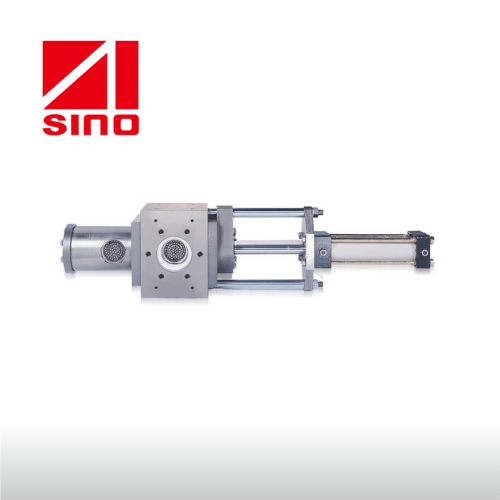

Screen Changer-PSG

Categories : Screen Changers / Filters

The PSG series hydraulic screen changer was developed by Sino-Alloy Machinery as an important accessory for filtering out contaminants. Suitable for filtering out impurities and the amount of filtration can be determined by using different mesh sizes to meet high quality filter requirements. The PSG screen changer uses a manually operated hydraulic actuator to move the dual-cavity piston, allowing for changes within a few seconds. Additionally, it has a simple compact design for ease of use and cleaning.

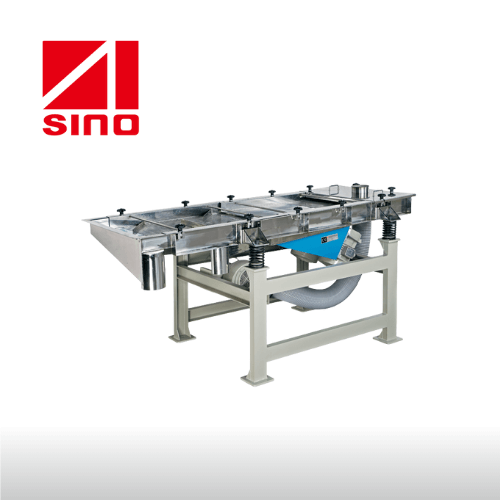

Separator-PSN

Categories : Separators

The PSN series separator was developed by Sino-Alloy Machinery as an important accessory to their extruder line to ensure uniform pellets Powerful high-speed vibration motors with multiple screens and mesh sizes to filter out small fines and large agglomerates. Optional air-cooling and dehumidifying functions can be added to further reduce the heat and moisture of the pellets.

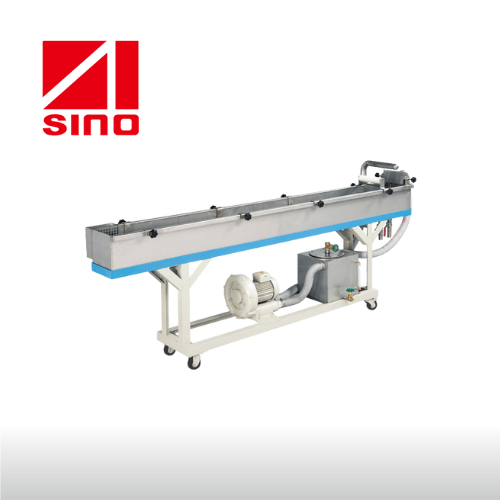

Water Cooling Bath-PSK

The PSK series cooling bath was developed by Sino-Alloy Machinery as an important and essential accessory for the strand pelletizing process. The extruded plastic strand is passed through the cooling bath then dried by an air blade and low pressure vacuum before entering the strand pelletizer to be cut to size. It has a simple design which can be customized with chillers or heaters depending on the production needs.