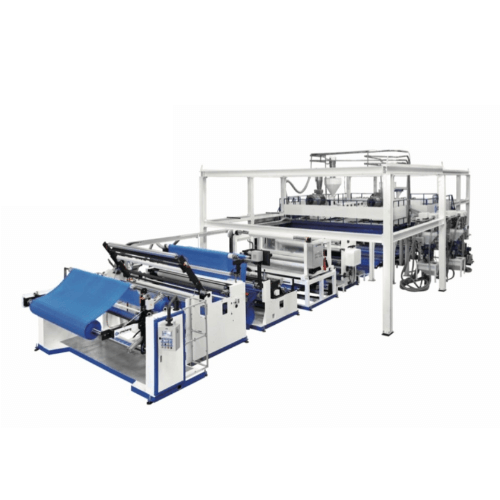

Multi-Layer High Speed Co-Extrusion Zipper Profile Extruder ( AB45AZ)

Categories : Co-Extrusion Blown Film Machines

MULTI-LAYER HIGH SPEED CO-EXTRUSION ZIPPER PROFILE EXTRUDER

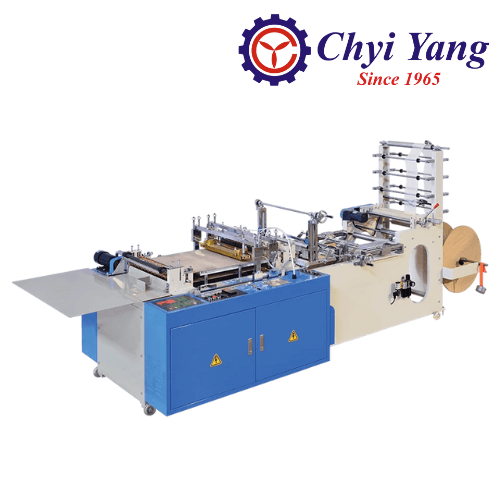

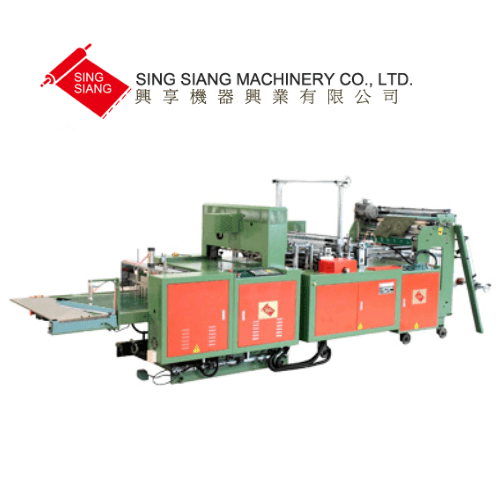

Servo Motor Driven Double Layer T-Shirt Bag & Bottom Bag Making Machine

Categories : Plastic Bag Making Machines

Double Layer Bottom Sealing

Servo Motor Driven Perforating Bag Making Machine

Categories : Plastic Bag Making Machines

1. Equipped with product counter. Once the set bag quantity is reached, the machine stops automatically and sounds an alarm. 2. Uses sensors to control feeding speed and ensure stability. 3. Double line production. 4. Adjustable taking up speed for making products neat and beautiful. 5. Automatic stopping when it is reminder line is break. 6. This machine can be used to perforate rolled bags, and can be replaced with bottom sealing bag and garment bag for optional.

2.5M wide, 3-layer Air Bubble Film Extrusion Line (With 2 Unwinders)

Categories : Air Bubble Film / Sheet Extruders

Various models to meet with your needs. Sheet width from 1,200MM to 2,500MM, from 2 layers to 10 layers. Tailored-made machine available.

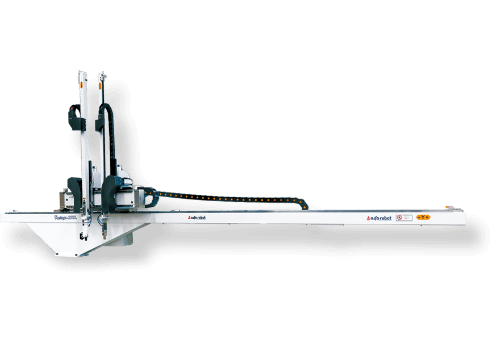

Three Axes Servo Driven Robot - ST3

Categories : Industrial Robots

The ST3 industrial robot is designed for rapid and precise removal of products from injection molding machine, and place them at desired locations. Standard and telescopic arm are selectable to coopera with 2 plate mold or hot runner system. Capable of arranging, stacking, quality checking and in mold placement. Suitable for injection molding machine under 3600T clamp force.

Two Color HDPE High Speed Inflation Machine KMTC Series

Categories : Blown Film Extruders

Each blown film machine is equipped with an electronic length counter and an accumulated time meter. In addition, all main output shafts are precision ground for exceptional stability and quiet operation.

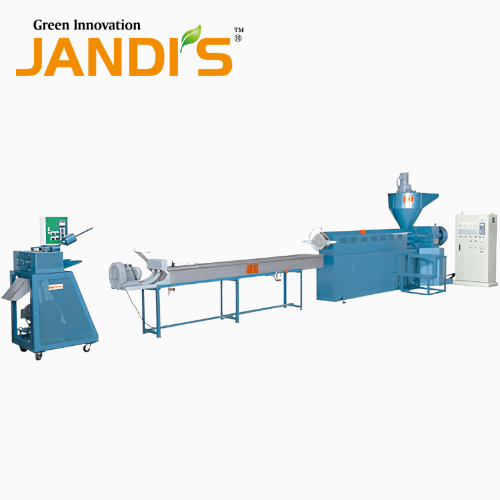

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

Categories : Plastic Waste Recycling Machines

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

Mega Aspirator

Categories : Plastic Waste Recycling Machines

This product is a new label separator developed by Boretech. The principle is to make use of the different aerodynamic characteristics of the flakes and the label.Relying on the negative pressure air flow generated by the centrifugal fan, it can accurately and quickly separate the label and other light impurities in the PET flakes. Scope of application: 10-16mm PET, PP, PE flakes Material status: dry material or wet material

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

Categories : Plastic Crushers

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

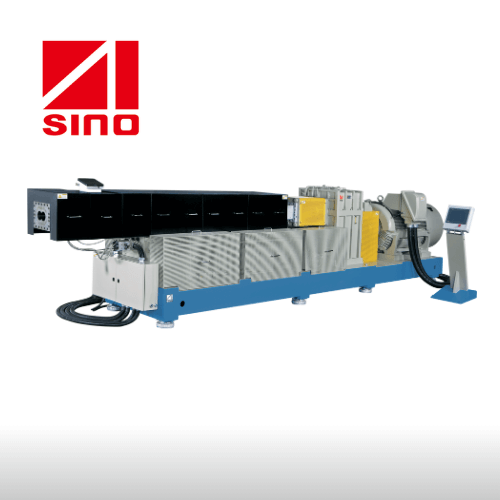

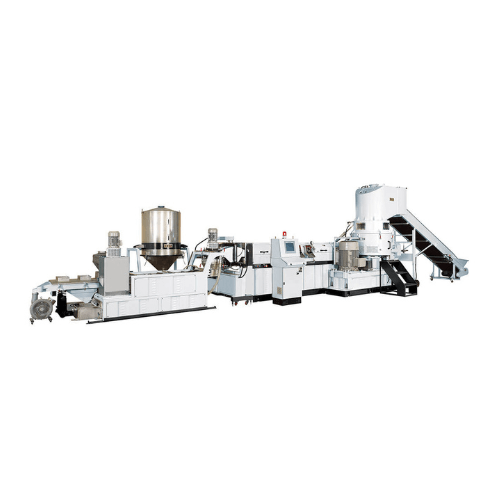

Co-Rotating Twin Screw Extruders-PSM92, 92A

Categories : Twin Screw Extruders

The optimization of the PSM92 and PSM112 series resulted in more efficient and durable designs. The PSM92 and PSM112 series have high range production capabilities, and easy operation in reasonable price. All PSM92 and 112 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

Vertical Batch Mixers - SVM-U

Categories : Mixers and Blenders

SVM-U is mainly used for mixing plastics as raw materials, masterbatch and recycled materials. SVM-U can not be used dealing with plastic powder and all kinds of foods, chemicals, and inflammable, explosive and volatile materials. Bulk density should be taken into account when the dimension of material is uneven or in other forms.

Gravimetric Blenders - SGB

Categories : Dosing and Measuring Equipment

• Evenly mixing of materials after accurately weighing, control accuracy strictly of ±0.1~±0.3%. • Auto calibration after each material weighting ensures accuracy. • Up to 100 recipes can be stored for later use. • Alarm log function. • All parts detachable for easy cleaning. • For SGB-600 and models below, machine mount model is the standard supply (equipped with magnetic base,manual discharge valve), optional pneumatic slide gate is available also. • For SGB-2000 and models above, floor stand is the standard supply (equipped with moveable floor stand, storage hopper and pneumatic slide gate), optional SBU suction box is available also. • Has the function of recycled material compensation (recycling hopper is standardly equipped with low level switch). Aberration coompensation can be automatically calculated based to the feeding amount of recycled materials. • Memory card can be optional selected to store ratio information for product quality control. • Hopper low level sensor can be optional selected to send alarm when material is insufficent. • Optional analog signals (0~10V) output function for screw automatic adjusting of extrusion molding machine. • RS485 communication is optional to realize the centralized monitoring of connecting with molding machine. • Floor stand, pneumatic slide gate, storage bin and suction box should be optionally purchased for floor mounting. (Applicable for SGB-600 and models below)

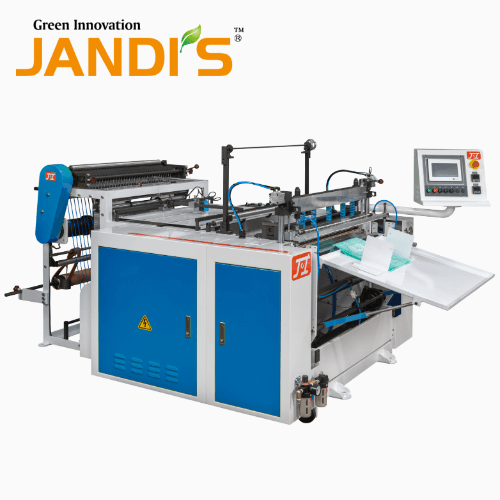

Full Servo High Speed Face Mask Machine

Categories : Bag Making Machine by Applications

Full Servo High Speed Face Mask Machine

Insert Injection Molding

Insert Injection Molding Technology is a manufacturing process that integrates pre-placed components, such as metal inserts, electronic parts, or other materials, into a plastic injection mold. During molding, molten plastic encapsulates the insert, creating a single, durable, and high-precision component. This technology enhances product strength, reduces assembly costs, and improves reliability, making it widely used in automotive, electronics, medical devices, and consumer products. By ensuring strong adhesion between plastic and inserted components, insert injection molding enables lightweight designs, enhanced durability, and improved performance in various applications. Key Advantages: Seamless integration of metal and plastic components Higher product strength and durability Cost-efficient by reducing assembly steps Customizable for complex geometries Enhanced precision and consistency Common Applications: Automotive Parts – Armrest trim panels, dashboard components, connectors Electronic Components – Connectors, circuit boards, protective casings Medical Devices – Surgical tools, sensor housings, implantable components Consumer Goods – Power tool grips, ergonomic handles, durable casings

Dynisco 1490 – 5 Digit 1/8 DIN Panel Indicator

Categories : Indicators and Sensors

• Universal input • 2 alarm outputs • Retransmission • Min/max valuehold • Modbus communications • Transmitter power supply

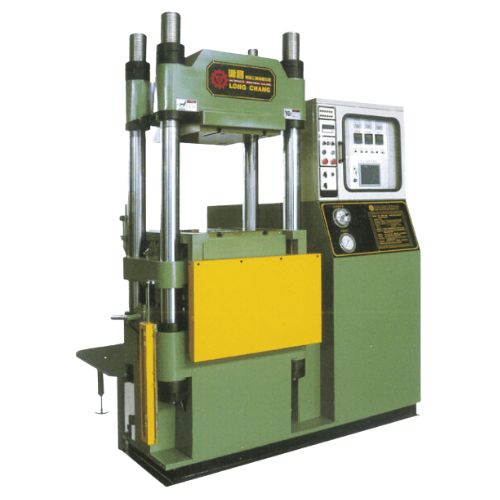

Single Body Oil Hydraulic Compression Molding Machine of Break Pad - FC-D Series

Categories : Compression Molding Machines

APPLICATIONS: For automobile, motorcycle , truck, train any kind of butterfly and drum type of friction break lining products.

Micro Processor Controllers

Categories : Control Equipment

ARICO - The Best Solution Of Micro Processor Controllers ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision Micro Processor Controllers and related application equipment, but also provides high-quality Micro Processor Controllers with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with Micro Processor Controllers, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.

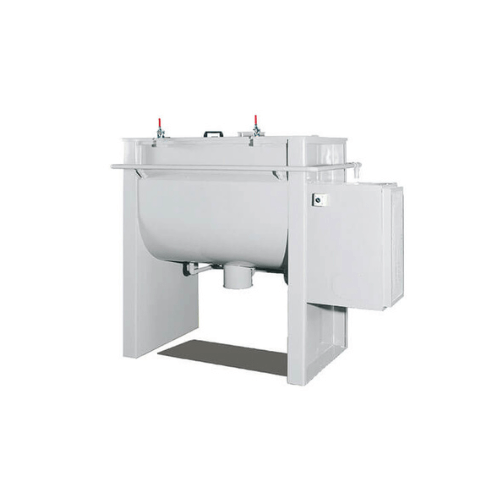

Horizontal Blender

Categories : Mixers and Blenders

Horizontal Blender is used for mixing two or more additives, especially for the mixing of pellets and powders that are viscous or easily occurring materials bridging. The blender equips with counter-rotating blades, which allows the materials to be mixed quickly, evenly, and efficiently. Even the materials have different specific gravity and size, the blender still can reach good result by its high-performance blade design.

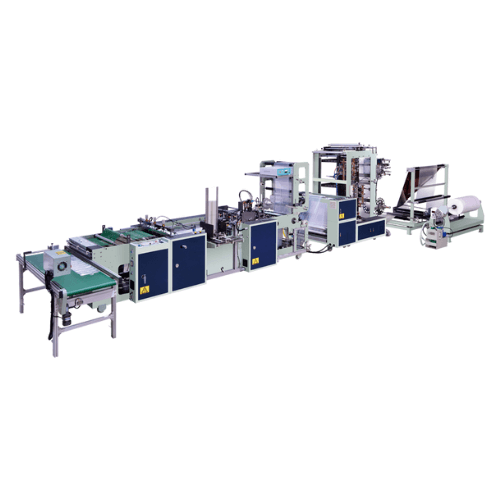

Servo Motor Driven Double Layer Bag Making Machine

Categories : Plastic Bag Making Machines

1. Servo Motor Driven, Efficient mechanical structure produce 120 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Optional accessories: hot pin conveyor stack for T-Shirt bag making machine.

Pellets Blenders

Categories : Mixers and Blenders

Stabilize The Pellet Quality The screw transports the pellets to the upper opening then release the pellets back to the mixing zone to form a circulating flow. The pellet’s color and chemical properties become more stable after being mixed. This minimizes the NPL ratio of final products. Flexible Out Systems From 25KG bags to 1 ton big bags, the twin-way output system is suitable for both packages. GENIUS

Corona Treater - High Speed THH-2H

Categories : Surface Treatment Equipment

Corona treater for Printing purpose, features Output 8~20 kw Treat width 1000~3000 mm Speed 100~300 m/min. 2 side treatment 38-46 dyne Apply to inflation, lamination,printing, cutting application Stainless discharge 12 steps

Fully Automatic Side Sealing Machine with Zipper Device LY-800SZP

Categories : Plastic Bag Making Machines

Fully Automatic Side Sealing Machine With Zipper Device LY-800SZP

Spout Inserting & Sealing Machine-HCI-L1

Categories : Sealing Machines

Suitable for sealing an additional spout on various multi-layer bags.

High Speed Triangle Folding Machine LY-1200T

Categories : Bag Making Machine by Applications

- High speed wicket bag making machine. - 2 sets of servo motors for feeding system. - 2 sets of servo motors for punch position and indexing station alignment. - 1 set of servo motor for indexing station position control. - 6 or 8 vacuum arms depends on size of bag. - Human-machine interface for easy setting. - Super heavy duty unwind stand with hydraulic auto-lifter and electric type EPC. - Triangle folding device.

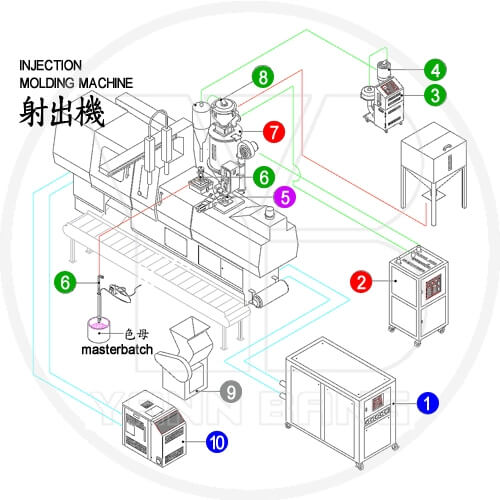

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Vertical Injection Molding Machines

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

Flexographic Jumbo Bag Printing Press

Categories : Flexographic Printing Machines

● This Printing Press is Specially Designed for Jumbo Bag Printing. ● Equipped Ink Circulation Pump in Each Color for Manage Proper Ink Consistency. ● Patented Separation Device between Printing Roller and Conveyor Belt to Avoid Stain ●Conveyor During Empty Load. ● 1 to 5 Printing Press Flexibly Provided According to Customer's Demand. ● Custom-made designs are available.

Material Distribution Station

Categories : Dosing and Measuring Equipment

The function of material distribution station is to distribute materials to corresponding storage hoppers. There are five models of SMDS series, each equipped with quick couplers, so the loading and unloading of material are convenient. The stainless steel is adopted for bulid of the station to eliminate material contamination.

PVA Water Soluble Film Bag Machine - GF-AJ811

Categories : Blown Film Extruders

PVA base water soluble, compostable and biodegradable eco-friendly material

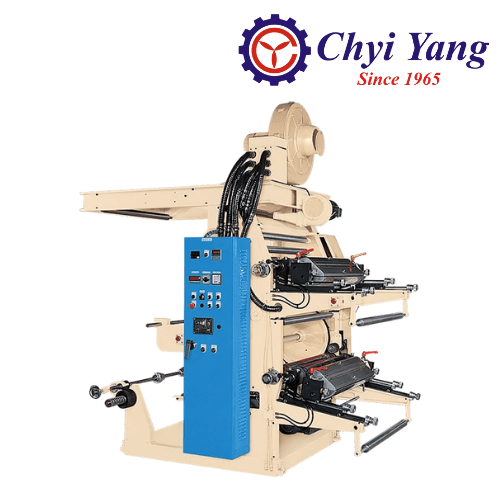

2 COLORS FLEXO PRINTING MACHINE (STANDARD TYPE)

Categories : Flexographic Printing Machines

These flexographic printers are able to print in two colors with the following possibility: 0+2, 1+1 Max. printing speed 60-70 mts/min Standard printing length is max. 1200mm, bigger printing length can be requested as your demand We didn’t show all our models, please don’t hesitate to contact us for bigger printing machines.

Stepper-Controlled Proportional Valve 0-65L/min

Categories : Separators

Product Serial: FC-20+PM-20 Proportional Flow Control Valve consists of PM series driver and FC series proportional flow valve. With an input signal either through analogue or digital, the needle inside the proportional valve moves proportionally to the signal. This series is able to control the flow rate of air and liquid with high resolution, high accuracy, and high repeatability. It is developed for industries that require a high degree of adjustment in flow rate. Series PM driver provides series FC valve with the required power and control signal (step and direction). It controls the step of a bipolar stepper motor with an analogue signal (0-10 VDC/4-20mA/RS485 Modbus).

Sieving Machine

Categories : Separators

Sieving device for PET recycling separates solid wastes such as sands, metal, small stones, labels in PET bottle recycling production. Bottle sieving is useful to reduce equipment running abrasion, production loss to enhance production performance with water-saving. PET flakes sieving improves the final PET flakes quality and stabilizes the quality of flakes. 3 types of sieving machines which are dry trommel, disk screener, and dust remover are available for different materials. They have the same function to remove impurities such as sands, metals, small stones, labels in different washing sections. The disk screener is more compact than the dry trommel, it's good to be placed after de-baling and pre-washing to separate impurities. It can evenly spread PET bottles on the next process like belt conveyor and filter residual water. Dry trommel can remove caps and sands separately through multiple meshes filtrations. Dust remover has two specifications for the choice. One is named Zig-zag separator, the other is label aspiration separator. These two machines can separate small plastic labels and films by taking advantage of the gravity and machine structure.

LM-L Contactless – with TWIIST technology – Multivariable – IO-Link

Categories : Indicators and Sensors

The high performance in terms of robustness, thermal stability and EMC immunity make the LM-L series suitable for use both in industrial environments and mobile hydraulics applications. The possibility to measure additional variables with respect to position (speed, triaxial inclination, acceleration and vibration, electronics temperature) combined with the IO-Link protocol, allows to benefit from the advantages of Industry 4.0 in terms of preventive product and process maintenance. Strokes from 100 to 900mm Measurement: position, velocity, triaxial tilt, acceleration and vibration, electronics temperature IO-Link output Self-aligning mounting mechanism Operating temperature: -40...+85°C IP67 protection Compliance with RoHS directive 2011/65/EU Output connector M12 - 5 poles male

Self-Cleaning Filter

Categories : Screen Changers / Filters

Quality Boosting & Cost Saving The two scrapers in the filter remove the residues filtered from the surface of the special precision processed screen. Then, they are emitted from the bottom screw. With the pressure sensor and inverter, this filter can control the scraping speed as well as stabilize and maintain the pressure inside the flow automatically. This filtration process can reduce residues by over 80% of the melted polymer. GENIUS

Side Shredding Type Recycling Pelletizing Extrusion Line | CK-SC

Categories : Plastic Pelletizer Machines

CK-SC series Side Shredding Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic film, fiber, carpet, fabric, jumbo bag, etc. Possible materials : PP, HDPE, LDPE, PET, PC film, Nylon fiber, PP carpet, Jumbo bag, EPE, EPP, EPS, etc.

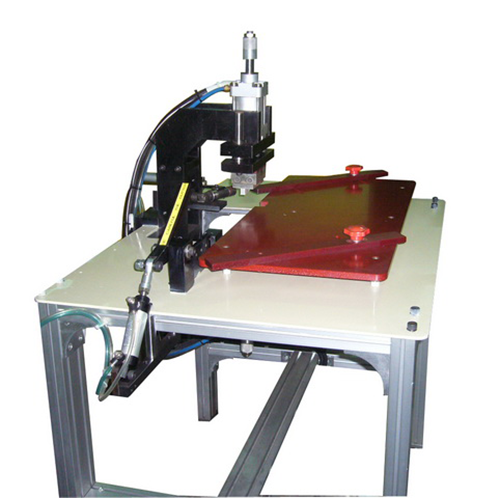

TX Die Clamp

Categories : Mold Parts

This compact, space saving, piston type clamp requires U-slots on the die shoe. The clamp leg is machined to fit the T-slot on the bolster. With the TX Die Clamp automatic slide model remote control is made possible.

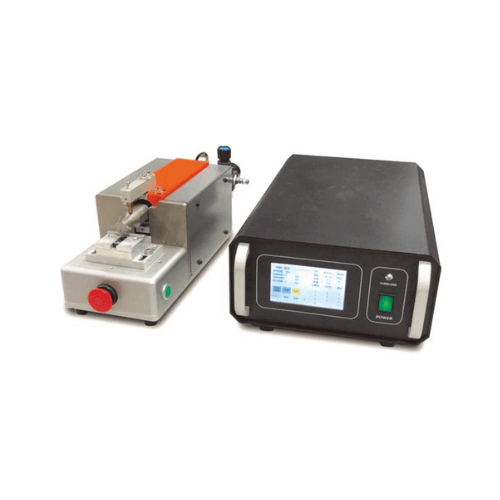

Ultrasonic Metal Welding Machine KWG0930-E

Categories : Automatic Welding Machine

Ultrasonic metal welding, generally for the fusion of low melting point metal materials such as copper, aluminum, etc. Taking the ultrasonic welding metal plate as an example, the two metal plates are overlapped and placed on the base, and the ultrasonic welding head is pressed against the coincident metal plate with appropriate pressure, and a lateral vibration of 20,000 to 40,000 times per second is applied. The two metal plate joints are subjected to high frequency vibration friction and welded. In this welding mode, the solvent is not required, and the welding portion does not need to pass current and heat, and is close to the cold joint, and the intermetallic compound is less likely to occur, and the structure changes little. The welding feature is that the deformation of the joint is less, the material is not melted, and the thermal influence of the material is not significantly changed. The fragile cast structure or the intermetallic compound can be obtained, and the fusion of the foil and the small joint can be achieved without strong resistance welding. Long foil can be applied by roller type continuous welding. KWG0935 model can be applied to lithium battery copper aluminum foil and aluminum nickel sheet welding, copper aluminum foil spot welding, capacitor copper aluminum foil spot welding, etc. KWG2020 model can be applied to lithium battery aluminum shell and aluminum nickel sheet welding, wire and terminal welding, wire butt welding, wire and metal plate welding, metal plate spot welding, etc........

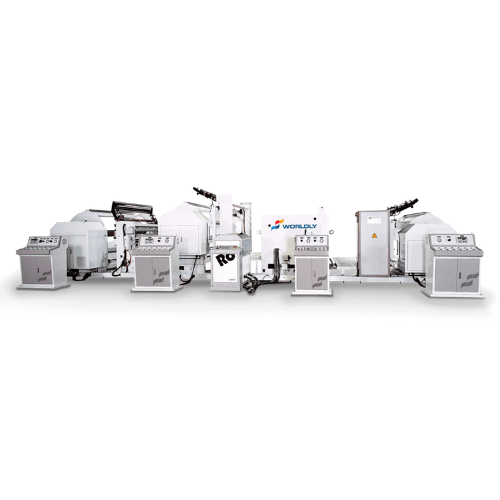

Reel to Reel Printing Line NRP-2012/8C (New Developed Model)

Categories : Flexographic Printing Machines

● Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to proide 12 colors(each side 6 colors) Reel to Reel Printing Line. ● Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

Stepper-Controlled Proportional Valve 0-1200L/min

Categories : Separators

Product Serial: FC-1000+PM-1000 Proportional Flow Control Valve consists of PM series driver and FC series proportional flow valve. With an input signal either through analogue or digital, the needle inside the proportional valve moves proportionally to the signal. This series is able to control the flow rate of air and liquid with high resolution, high accuracy, and high repeatability. It is developed for industries that require a high degree of adjustment in flow rate. Series PM driver provides series FC valve with the required power and control signal (step and direction). It controls the step of a bipolar stepper motor with an analogue signal (0-10 VDC/4-20mA/RS485 Modbus).

Dynisco Burst Plugs BP420

Categories : Indicators and Sensors

■ Welded one piece assembly – no degradation of joint strength at elevated temperatures ■ Iconel rupture disk – stable through a wide range of temperatures ■ Burst pressure ranges from 1,000 to 15,000 psig ■ Accuracy of ±10% of rated burst pressure at 300°C (750°F) ■ Leak rate exceeds 1x10-6 standard cc/sec

HDPE High Speed Inflation Machine (GF-H45)

Categories : Blown Film Extruders

HDPE High Speed Inflation Machine (GF-H45)

2-Folded T-shirt Style Garbage Bag Making Machine & Folding Machine

Categories : Plastic Bag Making Machines

2-Folded T-shirt Style garbage bag making machine & Folding machine