Slant Mixer / Blender (YBVRM)

Categories : Mixers and Blenders

Mixing quickly and evenly with motor overload protector and power safety device. The mixing barrel can be tilted freely at the angle degrees for discharge and maintenance.

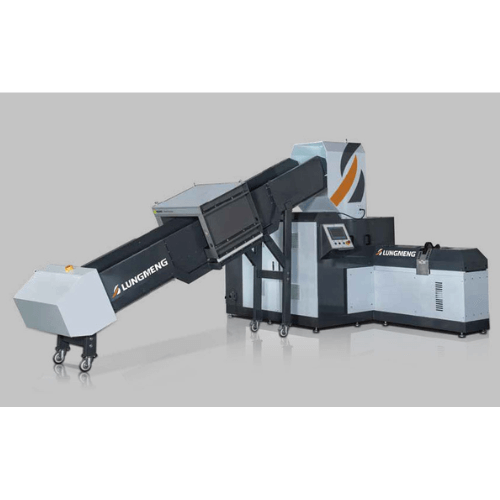

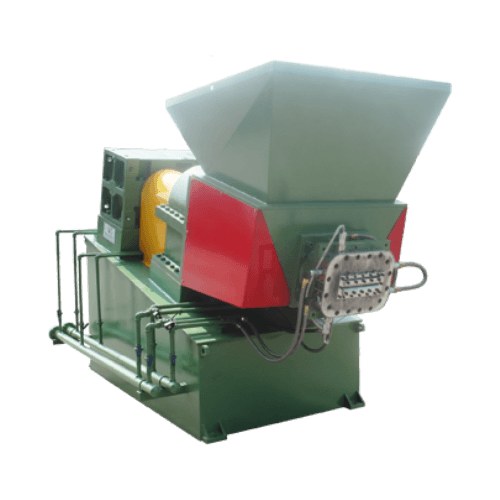

Side Entrance Two Stages Die-Face Cutting Recycling& Pelletizing Machine

Categories : Plastic Waste Recycling Machines

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

Taper Screw Batch Pre-former

Categories : Dryers and Dehumidifiers For Plastic Materials

FUNCTION: This uniquely designed Taper Twin Screw Extruder has a large volume open top hopper, which will accept a whole batch from your mixer without performing. The twin screws continuously and automatically bite and feed the compound, which then is extruded through a die. This simple but effective feeder, allows you to eliminate many labor intensive material handing processes, between your mixer and existing conventional extruders or other equipments.. BENEFITS: Large volume hopper capacity Exceptional cooling and temperature control Full and easy access for cleaning Simple, automatic and continuous operation Easy maintenance Cost effective and affordable

PVC/NYLON Reinforced Hose Making Machine

Categories : Extrusion Lines For Pipes and Profiles

Hose Making Machine

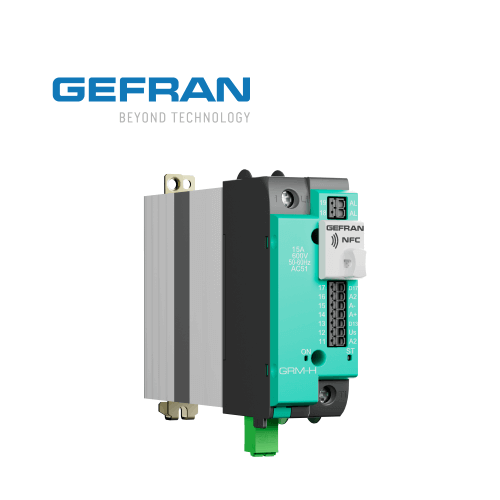

GRM-H Compact single phase Power Controller up to 120A

Categories : Control Equipment

The features of GRM-H Series Power Controllers ensure efficient heating management even in the case of complex electrical loads, which require special features, as in the case of infrared lamps or Silicon Carbide heating elements. Compact size from 15A to 120A Load voltage 480V, 600Vac Digital IO-Link communication Configurable control mode Zero Crossing, Burst Firing, Half Single Cycle or Phase Angle Feedback V,I,V2, I2, P, Z Soft start and current limits Logic command Vdc, Analog, PWM or IO-Link Advanced partial load break diagnostics (1/8) Slave control output (Two-phase/Three-phase) Configuration and Diagnostics via smartphone App with NFC technology Calibration and alarm reset commands via Digital Input Overview The ability to propose customized control solutions allows to rapidly satisfy the most different automation needs. For this purpose, the GRP series provides a wide range of extremely compact SSRs, with a solid basic structure but scalable as current sizes (from 15A to 120A), control type and configuration features. Control An accurate process control is the condition to achieve a constant and a high-quality production. To reach this goal it is necessary to manage in the best way the different types of industrial heaters from linear resistances to infrared lamps. For this purpose, the new series of SSR provides a series of control functionalities (ZC/ /BF/HSC/PA/Softstart) fully configurable to adapt to the various needs. Diagnostics Preventing possible anomalies allows to limit or eliminate harmful downtime and production. The GRP series includes dedicated functions such as the HB alarm for partial load breakage with accuracy of 1/8 of the total load, SCR short circuit, overtemperature and power failure. IO-Link communication Factory digitization is reaching its final frontier, the field level of the automation pyramid. In this level IO-Link is confirming itself as the most suitable communication to easily reach devices such as sensors and actuators. From this perspective, the GRP series has been developed to be integrated within this automation architecture. NFC configuration Simple and safe commissioning, maintenance and quick diagnostics are now within the capabilities of devices like SSR. All this thanks to the NFC technology, which allows to extend the user interface using normal Smartphone or Tablet as intelligent configurators. Thanks to an intuitive graphical user interface, setup or diagnostics are particularly easy.

Co-Extrusion Cast Film Line For Food packaging

Categories : Film and Sheet Extrusion Lines

Co-Extrusion Cast Film Line for Food packaging

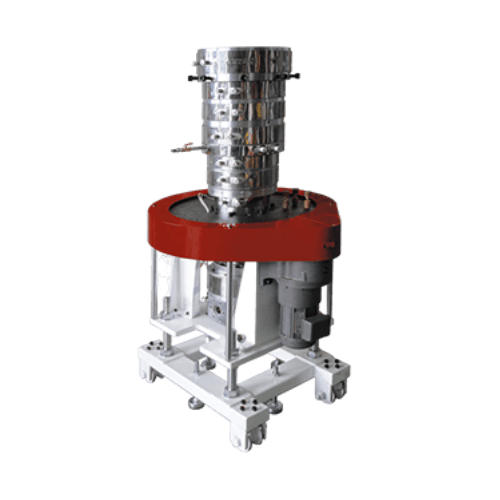

Screws and Barrels For Blown Film Extrusion

Categories : Screws and Barrels

The heart of blown film extrusion is screw part, the screw and barrels for blown film extrusion machine Nan Yun designed is able to deliver optimally developed polymer melt, at rates that meet the throughput target of the processor. Furthermore, the screw and barrel we designed for blown film plant or inflation machine also can have outstanding performance on melt quality, meilt temperature and gauge uniformity.

Washing Machine JK-400T

Categories : Hydrographic / Water transfer Machines

Water Washing Machine Conveyor Type, 10 meters of length. This machine is perfect for those large size products and large volume of production/day. This washing machine is including a water heating system. The model of the same machine without water heating system is YH-400. With 360° water washing by high performance nozzle surrounded, all of residue of films and activator will completely washed away with perfect decoration remained. High daily working output with conveyor speed adjustment and 100% water circulation are all very efficient for your production.

Blow Molding Machine PBI SERIES

Categories : Extrusion Blow Molding Machines

Screw type with first-in and first-out accumulation type die head provide fast color change. 4 tie-bars for mold platens ensure uniform mold clamping.

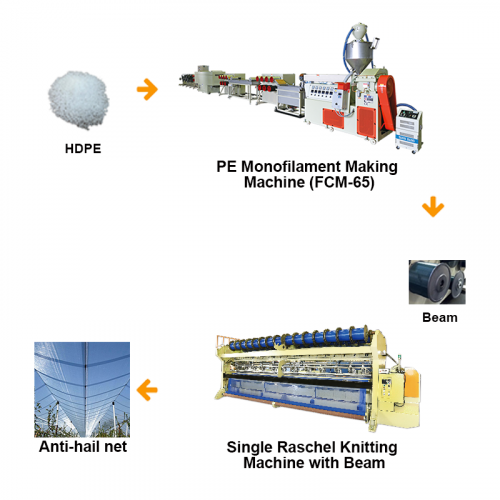

Anti-hail Net

Categories : Industrial Knitting Machines

Raschel Knitting Machines, Monofilament Machines, Anti-hail Net

HDPE Two-Color High Speed Blown Film Line

Categories : Blown Film Extruders

Kung Hsing HDPE Two-Color High Speed Blown Film Line

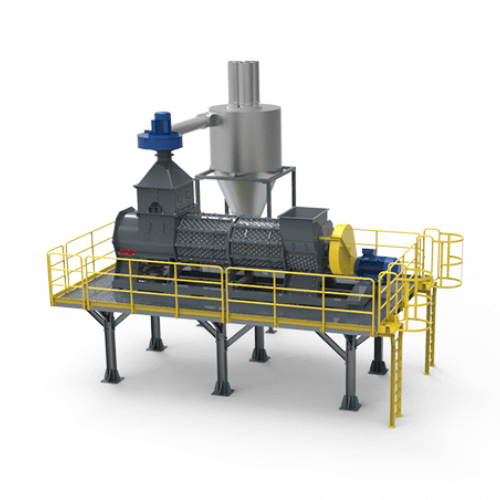

PE Waste Plastic Recycling Making Machine

Categories : Plastic Waste Recycling Machines

DIE-FACE CUTTING MODEL(PE)

ASTP- Universal Bag Making Machine

Categories : Plastic Bag Making Machines

ASTP800C, ASTP1000C, ASTP1200C

Accumulator Head Blow Moulding Machine for Water Pressure Tank

Categories : Extrusion Blow Molding Machines

Accumulator Head Blow Moulding Machine for Water Pressure Tank For producing 20 liter to 1000 liter volume, all kinds of jerry can, containers, air duct and industrial blow moulding products.

Label Remover Plus

Categories : Plastic Waste Recycling Machines

The Label Remover Plus integrates heat-shrink label scrapping and label removal functions • which can adapt to dry desorbing and wet desorbing at the same time, effectively improve the production environment, and significantly improve the label removal rate and finished product quality.

Mould Dryer / Mold Dryer (AC)

Categories : Dryers and Dehumidifiers For Plastic Materials

Too high humidity in air may affect the quality of your mold surface because of the condensation forming on the molded surface. An industrial air conditioner is perfect working with preform injection molding machine. The dry air from the industrial air conditioner reduces the condensation while the mold is cooling. That accurately controls the humid around the mold to ensure your product in good quality. P.I.D temperature controller system (IC control panel). Abnormal warning display (IC control panel). Motor overloading & phase-reversing protection. The through-out air temperature from the air conditioner can be adjusted. Special water-exhausting design.

Side Entry Robot SSE

Categories : Industrial Robots

SSE industrial robot is designed for thin-walled products which cycle time below 6sec. With its high speed features can improve the production efficiency. Suitable for injection molding machine with clamping force under 400 tons.

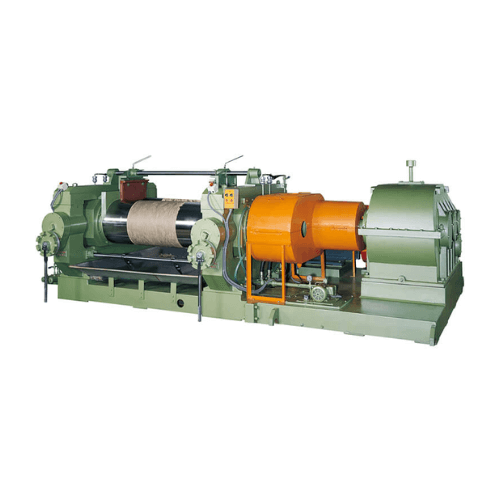

Rubber Mixing mill

Categories : Calendering Machines / Mixing Mills

Designed for mixing and kneading raw rubbers, synthetic rubbers, thermoplastics, E.V.A and chemicals, ensuring maximum uniformity of material. The processed materials are normally used on calenders, hot presses, or other processing machinery for producing various rubber and plastic products.

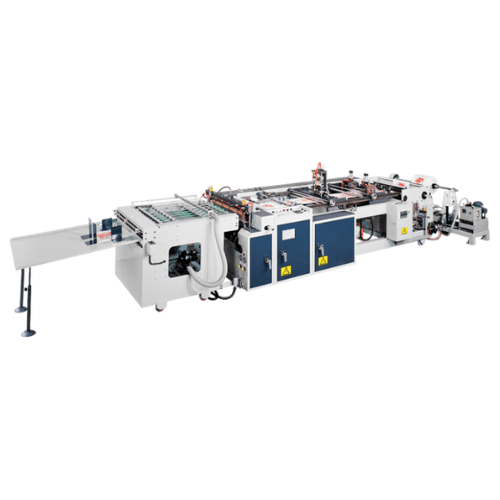

Free-Tension Thick Bag Bottom Sealing And Cutting Machine With 3 Servo Motors LY-650BF / LY-800BF / LY-1000BF

Categories : Cutting Machines

Introduction LY-650BF/800BF/1000BF series are free-tension heavy duty bag making machine, its 3-sets servo control system allowing customer to make very thick bag with good quality of sealing. All series have HMI system for easy operation. Features Free-tension, heavy -duty bottom sealing bag making machine. Servo-driven feeding system with one set of photocell for printed bag. Servo-driven flying knife system for cutting. Servo-driven sealing bar for good quality of sealing. Human-machine interface for easy setting.

Heating Side Sealing Slitter Rewinder - FSH

Categories : Slitters and Rewinders

For Side Sealing Slitter Operations: Suitable for producing various film rolls for extruded materials, such as HDPE, LDPE, LLDPE, PP, CPP, and etc.. Product thickness range from 0.006 to 0.1 mm. Production speed 20-40 meters per minute in 2-6 lines (Slit width over 40mm). For Regular Slitter Rewinder Operations: Suitable for slitting various materials, such as, cellophane, PET, OPP, CPP, PE, PS, PVC film rolls and printed films.

SPX-T (3-Series)

Categories : Indicators and Sensors

The SPX-T delivers the best spec performance in the line. These amplified transmitters eliminate the need for external signal conditioning. All models can interface directly with distributed control systems, PLC's, computers, and similar high level control devices.

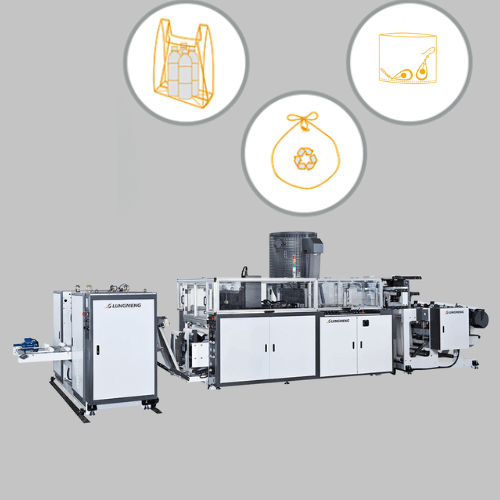

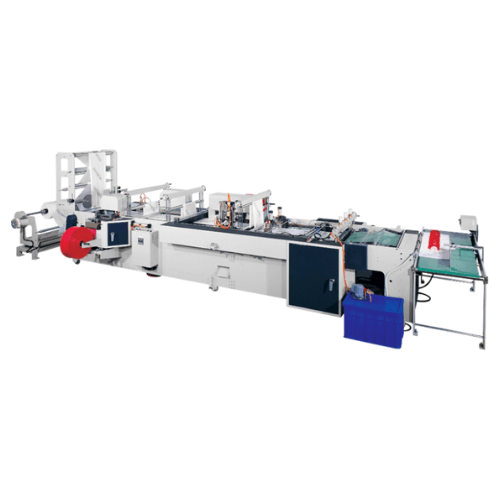

Fully Automatic Loop Handle Die Cut Handle Draw Tape & Patch Handle Bags Making Machine LY-800LDDP

Categories : Plastic Bag Making Machines

Introduction LY-800LDDP is a high-speed, multi-function machine which can produce 4 kinds of bags: soft loop bag, die cut bag, draw tape bag and patch handle bag. The unique control of servo-feeding system allowing customer having stable production and the human-machine interface lets customers never worry about operation. Features Specialize in soft loop, patch handle, die cut and draw tape bags. Servo-driven feeding system with one set of photocell for printed bag. Human-machine interface for easy setting. Pre-heating sealing for top and bottom gusset.

Sealing and Cutting Machine - One Step-FSC-301/ FSC-501

Categories : Sealing Machines

-The machine is ideal for the bottom sealing and cutting operation of poly bags. -For PVC shrink labels, paper and various plastic sheet cutting.

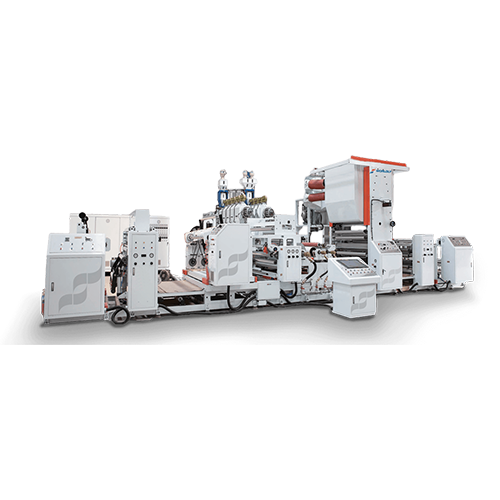

Co-extrusion Coating & Laminating Machine (WCL Series)

Categories : Extrusion Coating Machines

In this fast changing packaging market the multi-layer laminates demand has increased. The Co-extrusion machine allows to use two kinds resin or more by two or more extrusion units to create multi-function extrusion layers. The variety of resin after melted and go through the feed block then join into the T-die. The side screw has corrosion resistance treatment. It’s fine to work with acid copolymer resin, such as EVA, EAA, EMAA and Surlyn etc. The barrel heated by ceramic heater to ensure more energy saving and short start up time. Worldly also developed the exclusive extrusion output control system with Germany leading dosing system company. So it provides very accuracy and stable output and coating gauge control during the production. It can save more material especially for long run job. The high speed H series version of the rewinding splicer adopted with tracking roller device. It provides two kinds gap & contact winding mode and gives uniform and perfectly straight finished winding during high speed running. Also the taper tension can proper control the winding from the beginning roll. So it can reduce the wastage and avoid the wrinkle generate at the inner roll.

Plastic Crusher, Plastic Scrap Grinding Machine

Categories : Plastic Grinding Machine

This plastic crusher is specially designed for crushing PP/HDPE film, dirty woven bags, used woven bags, PP/HDPE flat yarn to convert into pellets.

Micro Perforated Machine

Categories : Plastic Bag Making Machines

1. Powerful 2HP DC Motor driven for variable speed change. 2. Power break on unwinder ensures accurate tension control. 3. 2HPP DC torque motor on rewinder ensures accurate tension control. 4. The perforation device ensures constant temperature. 5. Equipped with length counter. 6. Unwinder with air shaft fast material handle. 7. Rewinder with air shaft and safety chuck provide convenient fast product unloan. * Application: Flower and vegetable ventilation package. * Applicable film material: PP, CPP, BOPP single layer film.

Slitting Machines ULTRA/ UHS

Categories : Slitters and Rewinders

The SLIT-UHS series slitter is ideal for the serious slitting all types of flexible packaging materials as well as label stock & paper. The slitter comes standard with razor cutters and groove roller configuration. A shear cutter system is offered as option for paper and other pressure sensitive materials. The machine uses three AC Vector Drives and has automatic tension on unwind and rewind controlled through easy-to-use PLC & MMI touch screen. The machine features a vacuum roller that keeps the material stable during operation at high speeds 600m/min. Friction rings are used on rewind shafts to ensure the production of quality slit rolls when the film thickness varies.

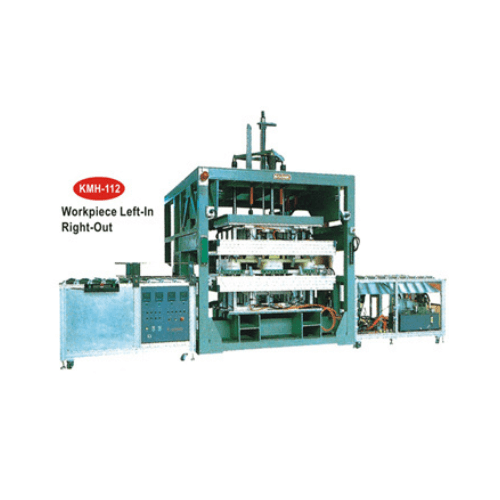

HOT PLATE PLASTIC PALLET WELDING MACHINE KMH-112 (LEFT-IN RIGHT-OUT)

1. Using a hot plate to melt the surface of the welding parts, then forced welding parts to join together. 2. It can meet the requirements of tight joint without damaging the surface of the working piece, and reach to welding effect of waterproof and airproof . 3. Suitable for large or irregular plastic pallet processing. 4. Machine type can be divided into semi-automatic and fully automatic equipment. 5. The pallet feed from left side of machine and collected from right side of machine by convey

Aluminum Foil Coating & Laminating Machine (WACL-1300)

Categories : Industrial Lamination

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension control, this machine has mainly designed for Alu-alu foil multi-layers lamination. The arch dryer roller has synchronized with line speed, it’s very low friction and steady when film pass through the dryer. The internal drying chamber has safety LEL detection, this system can automatically discharge when detected high VOC occur during the production. This machine also combined heat seal lacquering coating function. Additional primer coating unit before lacquering unit, so it allows to apply two side (primer+heat seal) coating in one pass. The coating unit has alternative function with direct gravure and semi-flexo coating systems. Coating trolley along with self-pump system and able for quick job change.