Co-Extruder, Co Extrusion Machine

Categories : Extrusion Lines For Pipes and Profiles

Part for indoor and outdoor application: Door Frames, Furniture Components, Spacing Panels, etc.

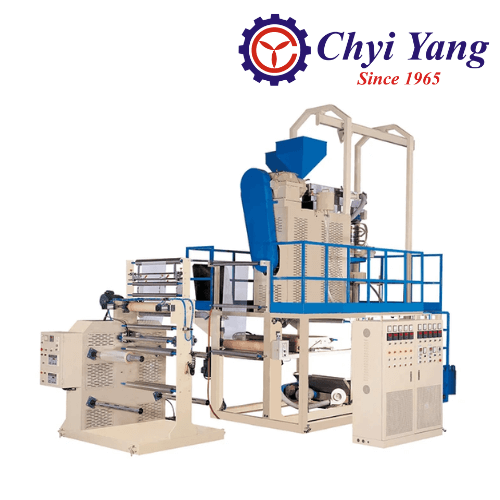

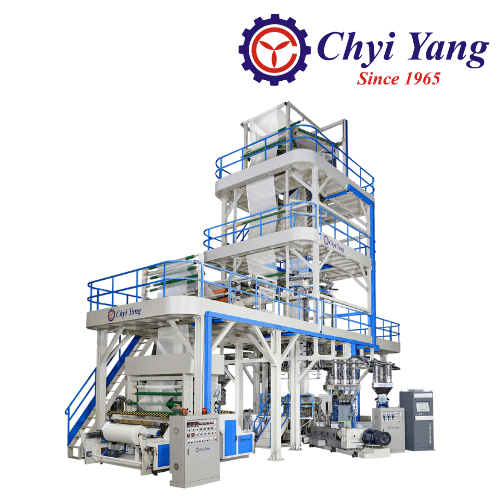

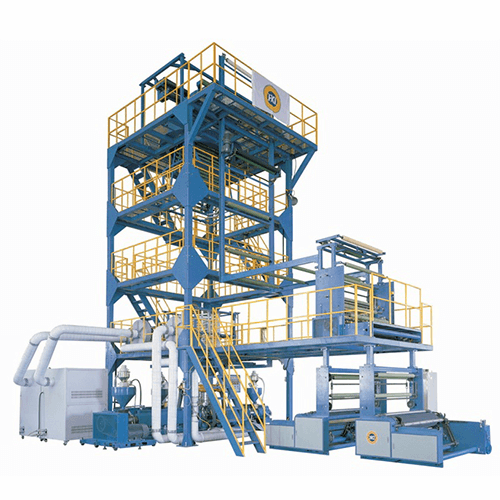

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine, CHYI YANG is Multilayer Co-Extrusion Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

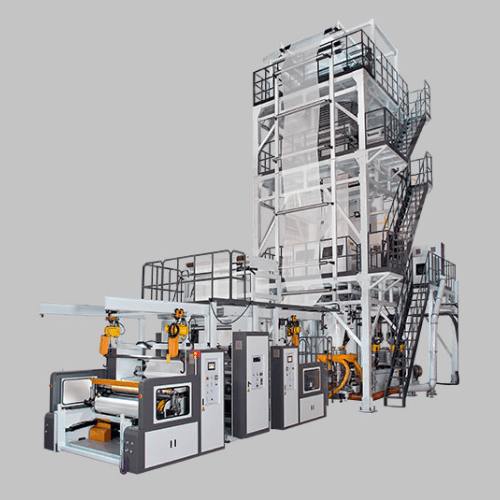

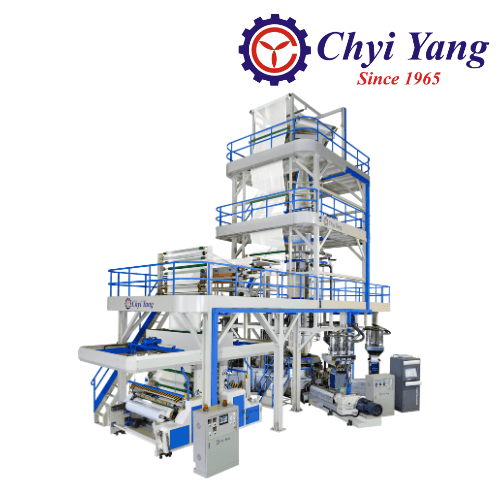

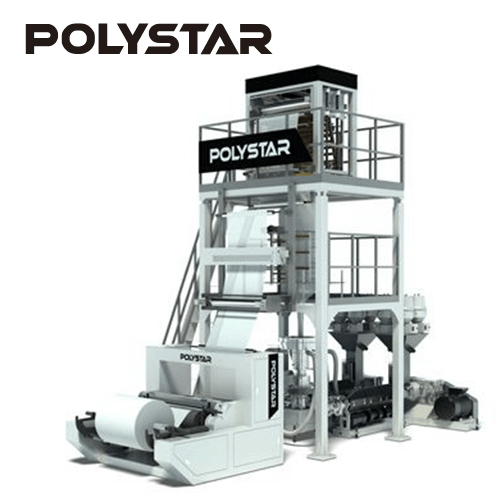

3-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Application for greenhouse sheet, agricultural films, construction sheets, food packaging, sacks, shrink films, shrink hood films, and more. Max. film width of up to 4.2 m (8.4 m for single-layer-opened films) It supports a wide range of raw materials such as HDPE, LDPE, LLDPE, EVA, MPE, PP, and others. The machine is equipped with three sets of gearboxes and motors for independent control. Optionally, a 360º Oscillating Nip roller device can be added to ensure uniform film thickness and improve the performance of the rotary die device. The machine can be equipped with a "Waste Film Recycling Machine" which enables direct feeding of waste film into the screw, eliminating any waste plastic film and reducing costs. Please note that the models shown here are not exhaustive. If you require larger extruders, please feel free to contact us.

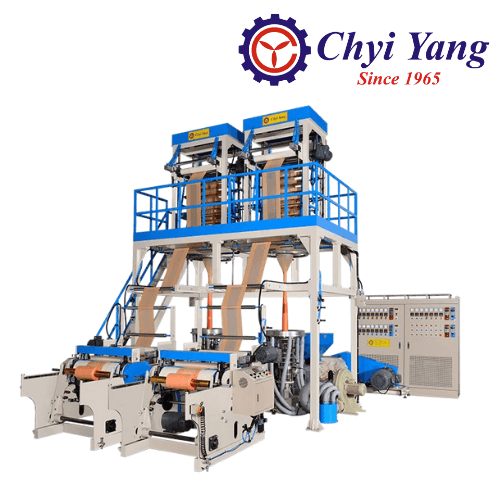

2-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Available for agricultural film, coated film, stretch film, cling film, greenhouse film etc. Max film width up to 4.2 m (8.4 m in single-layer-opened film) Raw material HDPE, LDPE, LLDPE, EVA, MPE etc. Two sets of gearbox, motor & extruder for independent control For producing PE stretch/cling film, PIB liquid adhesion system can inject liquid adhesion into screw directly to save resin cost & adjust the stickiness ratio you need Purchasing PIB system can produce out-layer film non-sticky to prevent dust, in-layer film sticky to pack subjects Optional “Waste film recycling machine” lets this machine doesn’t have any waste plastic film, it can feed waste film directly into screw to save your cost We didn't show all our models, please don’t hesitate to contact us for bigger extruders.

Three-Layer Co-Extrusion For Jumbo Bag (Industrial And Agricultural Use)

Categories : Co-Extrusion Blown Film Machines

THREE LAYER CO – EXTRUSION LINE -- KS – CFLL100 + 120T WITH FLAT FILM WIDTH UP TO 5M, MAX. EXTRUSION OUTPUT 1.1 TONS

5-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Extruder 5-Layer PE Group/Recycled/PA/EVOH 5-Layer Co-Extrusion Blown Film Machine 5-LAYER CO-EXTRUSION BLOW

3-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Extruder 3-Layer (ABC) PE Group/PP/Recycled 3-Layer Co-Extrusion Blown Film Machine

ABA 3-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

ABA 3-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

5-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

CHYIYANG specializes in manufacturing 5-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

7-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

CHYIYANG specializes in manufacturing 7-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

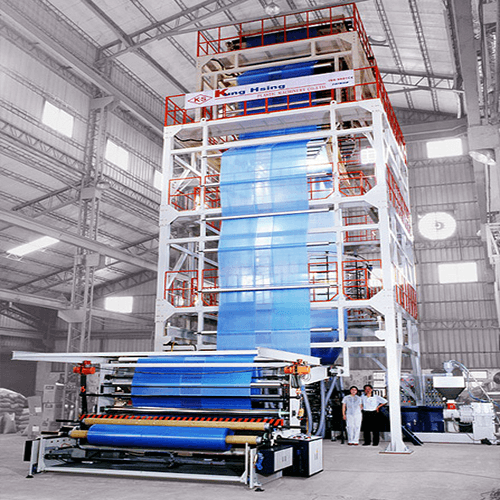

LDPE Two Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Kung Hsing LDPE Two Layer Co-Extrusion

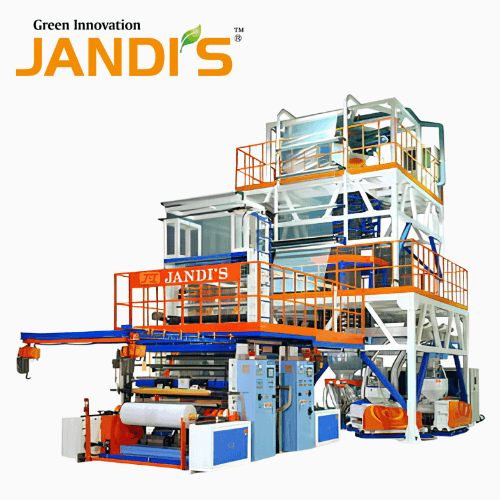

3 Layer Co-Extrusion Inflation Machine (GF-L3C-MT)

Categories : Blown Film Extruders

3 Layer Co-Extrusion Inflation Machine (GF-L3C-MT)

Three-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

THREE-LAYER CO-EXTRUSION Blown Film Machine

Multi-Layers Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Relying on the many years manufacturing experience of extrusion products, we understand the principle of each process of plastic blown film extrusion, we have the manufacturing capacity of blown film production line. Besides, Eterlong’s Plastic Film Blowing Machine is customized which depends on characteristics of raw materials and final applications. Before designing the products, HSIN LONG emphasizes on communications and discussion with customers in order to build the reliance with customers. Depending on the use of material, we offer from 3 layers up to 5 layers co-extrusion plastic film blowing machine. Also, the final products have all the desired properties at a significantly reduced cost.

3-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Extruder 3-Layer (ABC) PE Group/PP/Recycled 3-Layer Co-Extrusion Blown Film Machine

A/B/C BFS Series Co-Extrusion Blown Film Line

Categories : Blown Film Extruders

FKI offers one of the most advanced and adaptable blown film lines for various applications, such as shopping bags, vest bags, garbage bags, agricultural film, construction film, packaging film and lamination film, etc. The workable materials that can be used are such as LDPE , LLDPE, MLLDPE, and HDPE. The film production range is from 200mmto 7 meters in tubular width, and the production output rate is from40kg/hr to800kg/hr. Based on 30 years of experience, FKI is capable of offering blown film lines with reliability and versatility to meet different requirements from mono layer, double color, double layer, and three layer to four color designs.

Five and Seven-Layer Co-Extrusion High Speed Blown Film Line

Categories : Co-Extrusion Blown Film Machines

K.S. became a worldwide company; have achieved ISO 9002 certificate's requirements. K.S. machinery conforms to CE standard. Moreover, every machine must pass K.S. strict and careful quality control system, and pass test running before shipping out to the customer.

A/B/A BFT Series Co-Extrusion Blown Film Line- Oscillating Tower Type

Categories : Co-Extrusion Blown Film Machines

Tubular lay flat width:From 40mm to 7 meter. -MONO LAYER, TWO LAYER, THREE LAYER & FIVE LAYER -SINGLE COLOR, DOUBLE COLOR, UP TO 4 COLOR.

A/B/A BFT Series Co-Extrusion Blown Film Line- Rotary Die Head

Categories : Co-Extrusion Blown Film Machines

A/B/A BFT Series Co-Extrusion Blown Film Line- Rotary Die Head

ABA Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

● ABA 3 Layer Co-extrusion ● Film Width from 500~1500mm ● Extruder Dia: 40mm,45mm, 55mm, 65mm ● Material: HDPE,LDPE, LLDPE,CaCO3, Additives ● Output: 45~150 kgs/hr

Three-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

ABA Three-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

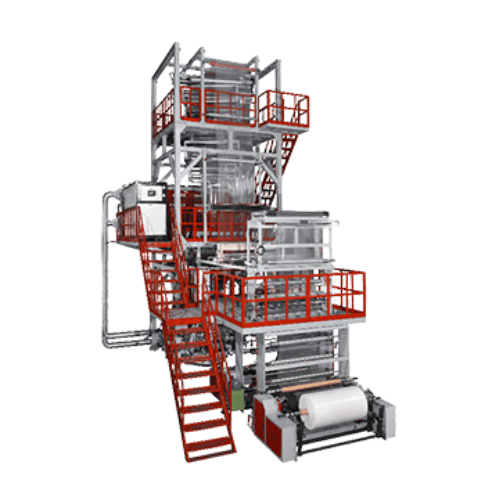

OSCILLATING TOWER ABC THREE-LAYER BLOWN FILM MACHINE

Categories : Blown Film Extruders

The ABC three-layer co-extrusion machine is your ideal choice for producing high-end plastic products, such as shrink films, agricultural mulches, electrical insulation films, packaging films, medical packaging films, stretch hood films. The raw material formula for each layer can be customized respectively according to your requirements. The oscillating haul-off unit provides excellent film gauge randomization, ensuring the production of high-quality and wrinkle-free films. The oscillating haul-off unit is also rather durable, and its equipment lifespan is much longer than the rotary die. Suitable for producing three-layer films for specific functions Recycled materials or CaCO3 is applicable to the middle layer in order to save material costs Die and air-ring specially designed for producing high-quality three-layer films 360° Oscillating Haul-off unit improves film thickness uniformity EPC (Edge Position Controller) Full customization according to your specific requirements

Five-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

TWO-COLOR CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Equipped with 2 extruders, A/B type blown film machine is able to produce two layer/two colours film. This machine can produce two-color-striped films. Final products have obvious streak of two separate colors. Upgrade die and air ring to produce HDPE and LDPE 2 layer film.

AB & ABA CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film. Co-extrusion able to choose from AB to ABA, ideally for 2 layer film with different colour or apply CaCO3 in middle layer for cost saving, etc. Perfectly suitable to agriculture film, shipping bags, shrink film, consumer packaging and many others.