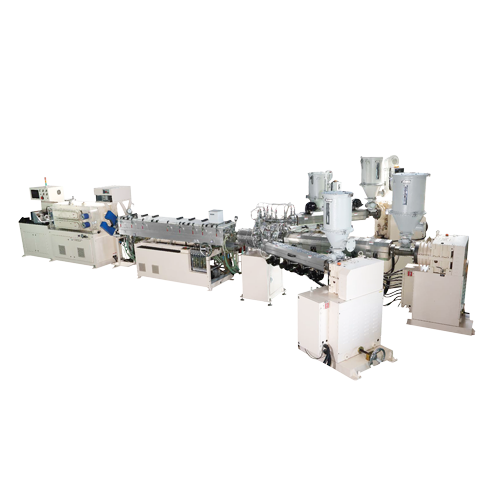

High Speed Multi-layer PE Tube Extruder and Cutting Machine EDC-16-05

Categories : Cutting Machines

-High speed & high output -High precision thickness control on each layer of tube -Simplified control -Quick tooling change by one operator -Closed loop cooling water circulation system -Caterpillar haul-off -Automatic outer diameter control unit (optional) -Low power consumption and high production efficiency

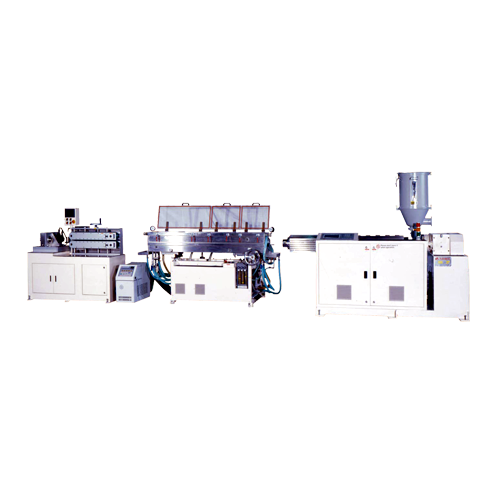

Mono-Layer PE Tube Extruder & Cutting Machine EDC-08-01

Categories : Cutting Machines

Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials. For years of research and development, our remarkable achievements on LLDPE & LDPE melting, screw design, device of die head, material adoption, and surface treatment, together with size control by figuration and length restraint by encoder have produced valuable and high-quality tubes.

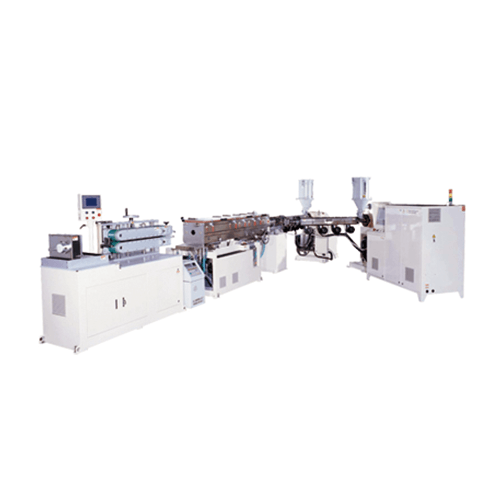

Two-Layer PE Tube Extruder & Cutting Machine EDC-08-02

Categories : Cutting Machines

-Two-layer extrusion tube can reduce material cost. (using: Pearl + PE/PE + Pigment) -The temperature controllers of different materials can be controlled individually. In this way, we can find out the best running condition on the materials both in running fluency and dissolubility. -The surface of co-extrusion tubes made by two-layer machine is more glossy than the surface of mono-layer tubes. -Using the same material on two-layer same material on two-layer co-extrusion can increase the water-resistance and anti-penetration of the materials for about 20~30%. (using: PE + Pigment. inner: recycled material.)

Success Story - Plastic Squeeze Dryer

Categories : Plastic Washing Line

DW-350 / Plastic Squeeze Dryer / Washed PE Film / South Africa DW-300 / Plastic Squeeze Dryer / LDPE Film / Romania DW-350 / Plastic Squeeze Dryer / Washed PP Woven Bag / Spain Japan Subsidy Policy Assisting the Growth of Genius’ Squeeze Dryers

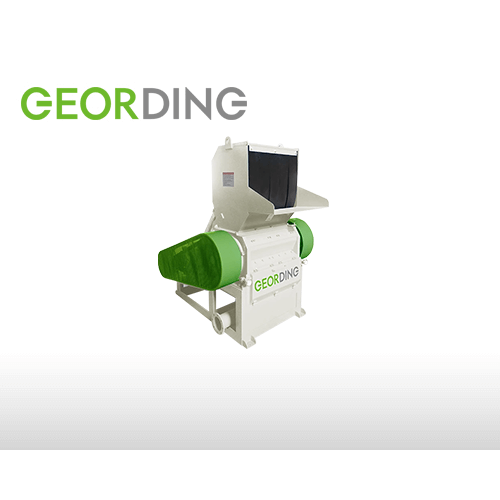

Plastic Bottles Crusher

Categories : Plastic Crushers

The round and hollow frame structure alows big processing volume. The capacity is 3 times more than the average type crushers. The round and hollow frame structure alows big processing volume. The capacity is 3 times more than the average type crushers. Well-designed angle cutters enables you to properly monitor and run easily the machine making the output estimate for other process. With water cooling system and clearance between cutters makes it easy for heat dissipation that helps reduce damage effect between bearings and machine body. Hardened crusher blades. The adapted ball bearings provide strong friction resistance, good centering and anti-vibration.

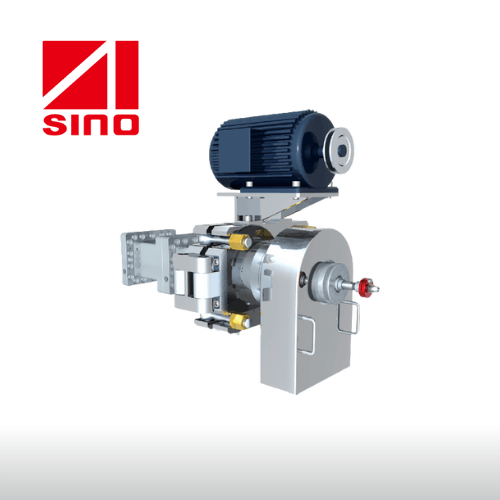

Air Cooling Pelletizer-PSW

Categories : Plastic Pelletizer Machines

The PSW air-cooled pelletizer was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Especially good for hygroscopic materials. Variable speed cutting blade to control pellet size and surface quality. Use in line with our cyclone tanks to complete the air-cooled pelletizing system.

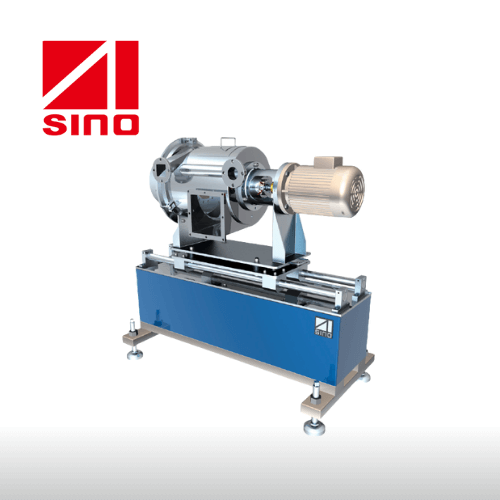

Water Ring Pelletizer-PSF

Categories : Plastic Pelletizer Machines

The PSF water-ring pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and material which may be too brittle for strand pelletizing. Variable speed cutting blade to control pellet size and surface quality. Use in line with our PSL series centrifugal dryers to complete the water-ring pelletizing system.

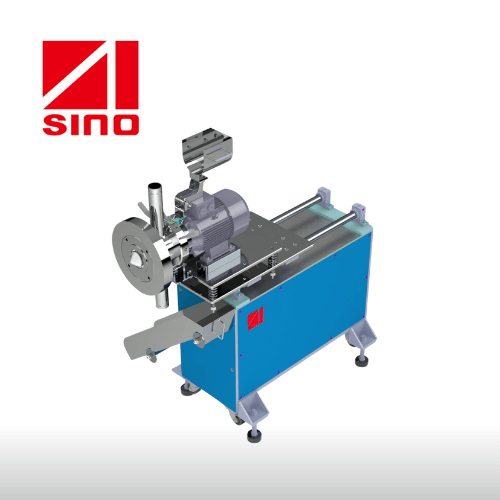

Strand Pelletizer-PSH

Categories : Plastic Pelletizer Machines

The PSH strand pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Strands from the extruder are pulled through a water-filled cooling bath and blown dry by an air knife before entering the pelletizer. This simple pelletizing process is applicable to many different types of plastics and rubber. Our knives are made with tungsten carbide steel to ensure a long life and clean cuts. Puller and rotary knife can be synchronized to ensure uniform pellet size regardless of the extruder throughput. Designed with built in safety features, the moving parts are all enclosed within a protective cover.

Underwater Pelletizer - PSQ

Categories : Plastic Pelletizer Machines

The PSQ underwater pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and sticky materials. Hot melt is extruded through a die into a water-filled cutting chamber where it is die-face cut by a high-speed cutter. The resulting spherical pellets are conveyed via water slurry to a centrifugal dryer. Use in line with our PSL series centrifugal dryers to complete the underwater pelletizing system.

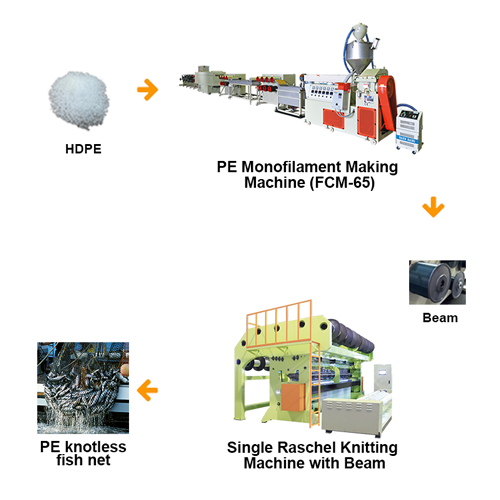

PE Knotless Fish Net

Categories : Industrial Knitting Machines

Raschel Knitting Net, PE Knotless Fish Net

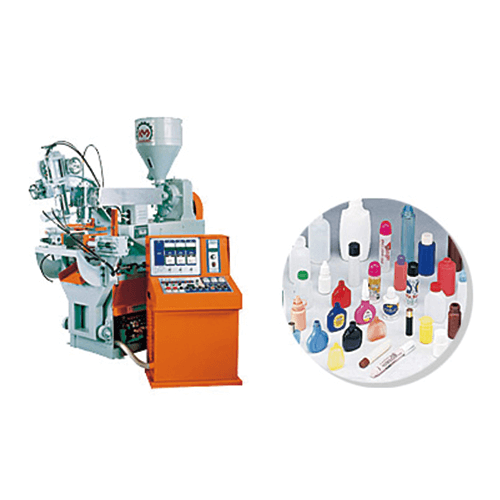

Blow Molding Machine PBS-605~705 Series

Categories : Horizontal Blow Molding Machines

Durable and horizontal traveling mold carriage combined with German linear motion guides for maximum stability. The series is excellent for producing medium and large sized containers. Available to equip with an auto deflashing device and take-out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

Blow Molding Machine PBS 905PC SERIERS

Categories : Automatic Blow Molding Machines

The PBS-905PC Special Purpose Blow Molding Machine is specially designed with an advance German type die head, featuring "first-in, first-out" performance. It is ideal for producing high quality, high clarity and high gloss PC water tanks. The machine is suitable for producing 2.5~5 gallon containers.

Blow Molding Machine PBS 905 Series

Categories : Electric Blow Molding Machines

Powerful, crank type mold clamping system combined with German linear guides for maximum stability. This series is ideal for producing medium and large sized containers.

Blow Molding Machine PBA Series

Categories : Horizontal Blow Molding Machines

These machines are high cycle pneumatic blow-molding machines, suitable for popsicles & wide variety small size bottles.

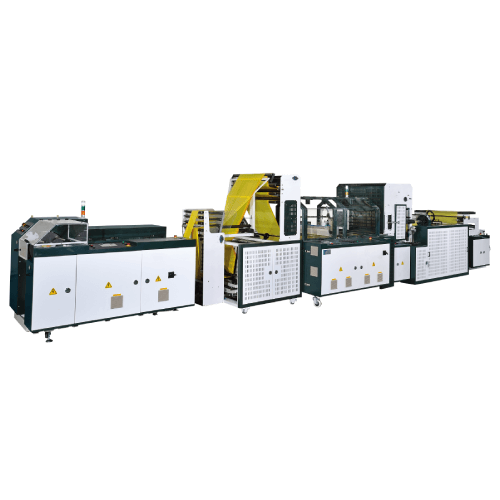

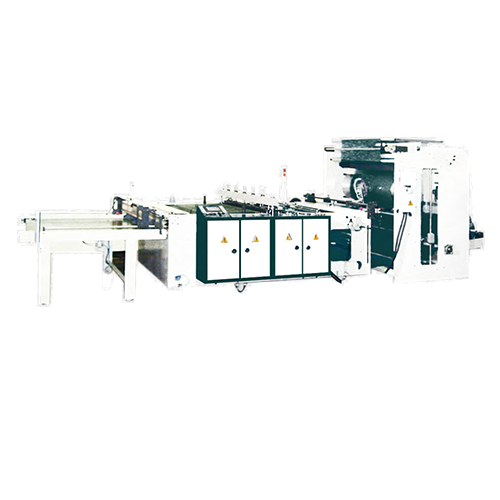

Draw Tape Bag Making Machine with Interleaved Winder

Categories : Plastic Bag Making Machines

Servo motor - Accuracy and highspeed @65M/min Malfunction alarm / stop - Abnormal temperature / No material feed / Photocell track miss / Bag jam Upgradeable to Swing-type sealing unit - Using servo-synchornized counter movement to the film flow, swing type sealing unit can seal without intervals on the film flow securing strong welding results and increase productivity. Optional Rotary type perforation device

Bag Making Machine for Bag on Roll

Categories : Plastic Bag Making Machines

Biodegradable bags making machine

Twin Servo T-shirt Bag Making Machine + Bag Folding System BFTDGFA-V

Categories : Bag Making Machine by Applications

Twin-servo system - 2 servo controlling 2 lines with printing register accurately. Up-down die cut - Synchornized up-down die cut & feeding ensures stable & high speed performance. Vacuum waste film removal system for T-shirt bag on rolls. Automatic Folding system - Servo-controlled 1st & 2nd fold individually (piece by piece), 3rd fold by pneumatic cyllinder every 1-15 pieces pile. 4th & 5th folds by optional.

Bag Making Machine for Stationary Bags

Categories : Bag Making Machine by Applications

Inner Sleeves Making Machine Book Cover Prep Machine Automatic Inline Assembly Machine Option Automatic Inline Packaging Machine Twin Line File Sleeves & L-file making Machine FCV / FBV Photo & Name Card Sleeves Making Machine STV600

Twin Die LDPE Zipper Film Blown Machine

Categories : Blown Film Extruders

* Zipper film system - Zipper extruded at the same time of film extrusion. Can be in-lined by extuder - printer - bag making. * Double bag system - Small bags are extruded with 2 zippers and cold-slitted on bag making machine. * Double die systems - Single screw extrusion with 2 die heads for extrusions.

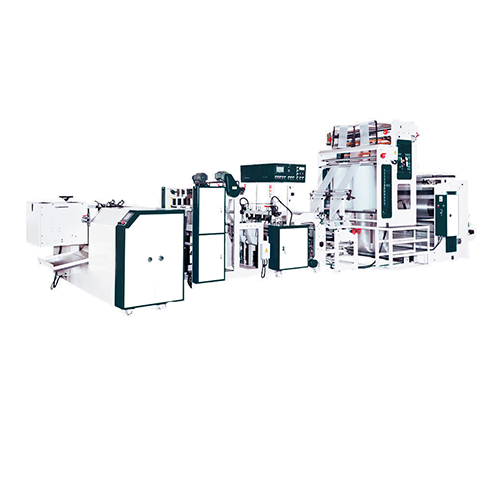

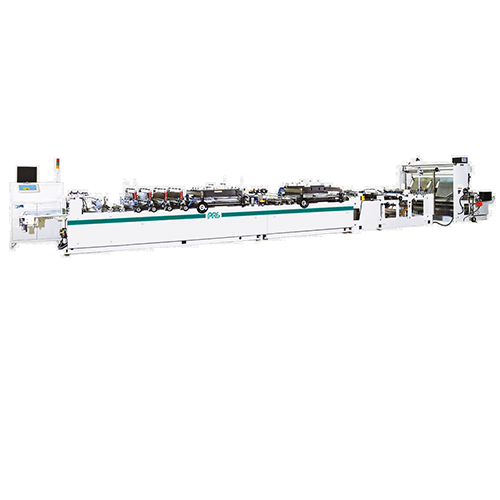

Fully Automatic Bottom Seal Bag on roll Making Machine + Heat-Slitting & Post-Gusset System

Categories : Plastic Bag Making Machines

Heat-slitting + post-gusset system - Adjustable heat-slitting knife slit and seal jumbo bobbin film in to multiple lines. Fully automatic rewinder Fully automatic non-stop system inserts paper core & change finished roll.

All Function Side Seal Shopping Bag Making Machine SWPFA-V

Categories : Plastic Bag Making Machines

Patch handle bag - Includes film feeding & cutting devices. Patch piece welded by heat press against the main body. Softloop handle bag - Includes film feeding & cutting devices, loop film pressed and turn toward the sealing position. Heated mould seals loop film against the main body.

High-Speed Zipper Profile Extruder INLL

Categories : Co-Extrusion Blown Film Machines

Zipper profile extrusion - Profile extruded by extruder directly into cooling water tank for formation. Profiles are closed and collected by carton or optional winder.

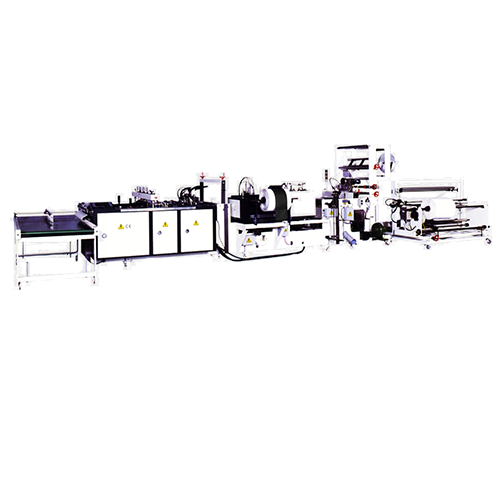

Side Seal Bag Making Machine + Heat-Slitting System

Categories : Plastic Bag Making Machines

-Standard side seal system - Sealing and cutting done simultaneously and pull by rocking take out belt conveyor. Finished bag collected on table or conveyor. -Multi-line heat-slitting system - adjustable heat-slitting knife and cold-slitting knives will slit single jumbo bobbin film into several lines.

Central Seal Pouch Bag Making Machine SCFA

Categories : Plastic Bag Making Machines

High-pressure sealing for laminated film - Low temperature, high pressure sealing bars are required for laminated film. For secure sealing requires multiple times of sealing and cooling to ensure good sealing quality. Central seal & closure device - Guiding rollers closes and seal the lap for central sealed bag.