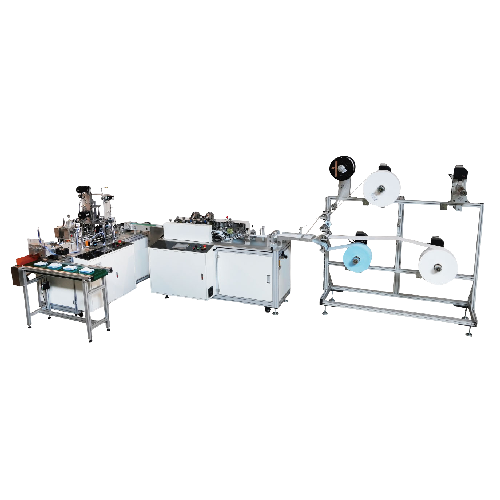

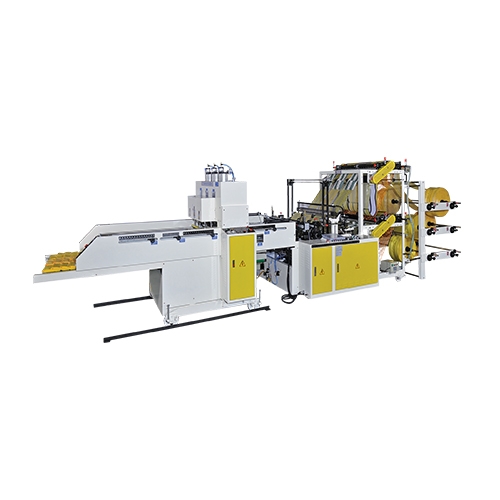

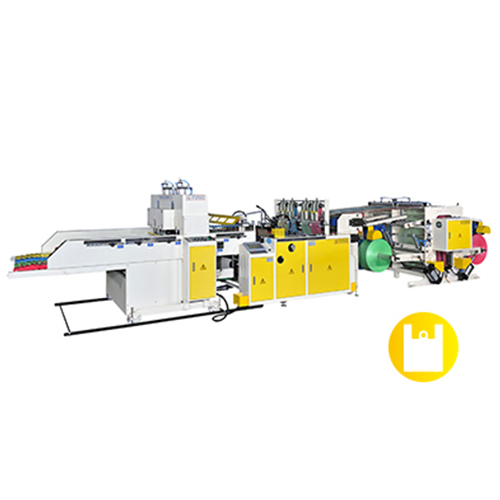

2 Lines Heat Cutting T-shirt Bag Making Machine with 2 Photocells & 2 Servo Motors Model: CW-800P-SV/CW-1000P-SV

Categories : Plastic Bag Making Machines

‧ Human touch screen, simple operation. ‧ Servo motor feeding control, high-speed production. ‧ Inverter-Motor tension control un-winder, regarding to production speed, brake to change feeding speed. Max, dia of plastic film is 800mm. ‧ Unwind Stand with pneumatic loading device. ‧ Air Shaft. ‧ Auto-punching bags folding device. ‧ The machine adopted pluging type IC circuit auto-controlled system for easy replacement. ‧ Punch-out scraps are collected by conveyor for easy disposal. ‧ Air blowing out feed system incorporating with bottom smoothing device. Ensure neat bags are stackedd fot accurate bags gripping and punching. ‧ Automatic punching machine use air pressure to push oil hydraulics. Easy to operate, without noise fault of hydraulic

Fully Automatic High Speed Disposable Plastic Gloves Making Machine / SSD-800-HGL(Calendar)

Categories : Bag Making Machine by Applications

-Computer control over the entire process -Jumbo film roll to final pruduct ( 2 line output ) , one process flow -Automatically stop when running out of film / film feeding blocks or jam -Automatically tear off the waste edge film -Melting cut-off ( no cutting knife ) system save time and manpower on adjusting knife -Capable to produce 3 types in same machine

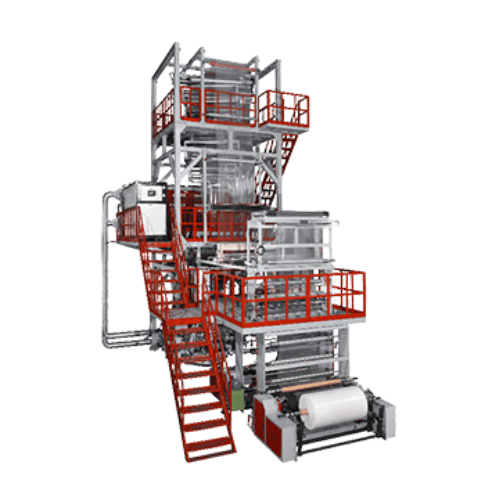

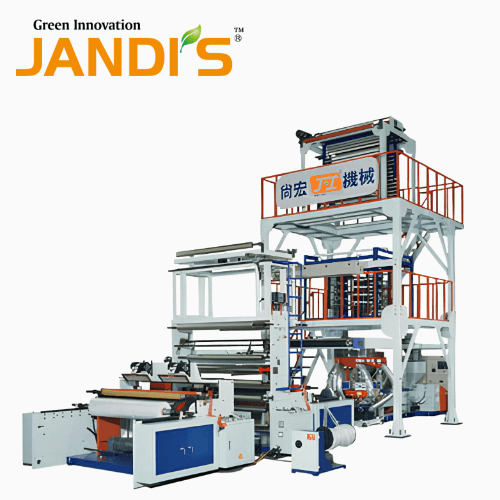

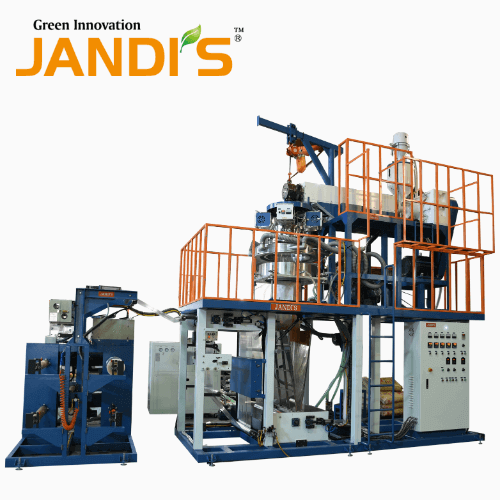

Multi-Layers Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Relying on the many years manufacturing experience of extrusion products, we understand the principle of each process of plastic blown film extrusion, we have the manufacturing capacity of blown film production line. Besides, Eterlong’s Plastic Film Blowing Machine is customized which depends on characteristics of raw materials and final applications. Before designing the products, HSIN LONG emphasizes on communications and discussion with customers in order to build the reliance with customers. Depending on the use of material, we offer from 3 layers up to 5 layers co-extrusion plastic film blowing machine. Also, the final products have all the desired properties at a significantly reduced cost.

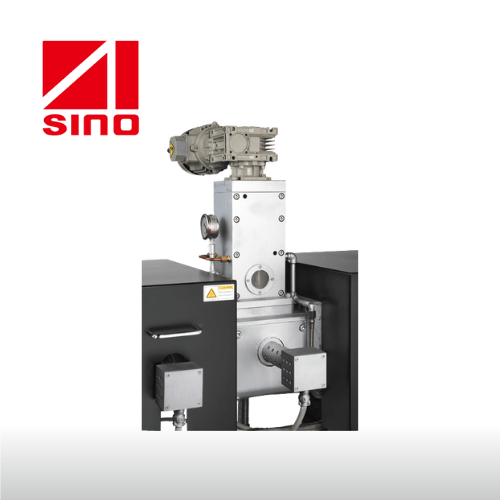

Anti-Leakage Vacuum-PSY

Categories : Valves

The PSY anti-overflow vacuum was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Developed to prevent extruded material overflow from the vacuum vent during degassing and subsequent vacuum failure. The PSY anti-overflow vacuum is driven by a pair of vertical intermeshed screws to move overflow material back to the material barrel while degassing with the vacuum. Can also be installed on side feeders to prevent overflow.

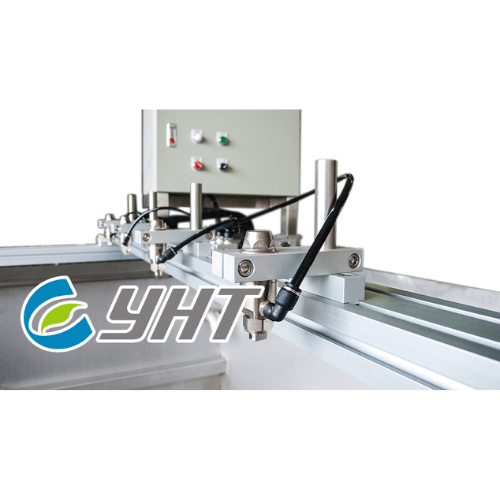

Auto Spray Activator System

Categories : Hydrographic / Water transfer Machines

To Maintain the Spraying Activator quantities, and average range. Saving the label and maintain the quality.

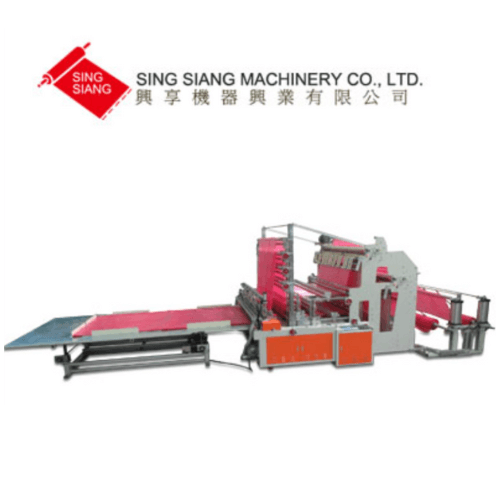

Reel to Reel Printing Line NRP-2012/8C (New Developed Model)

Categories : Flexographic Printing Machines

● Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to proide 12 colors(each side 6 colors) Reel to Reel Printing Line. ● Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

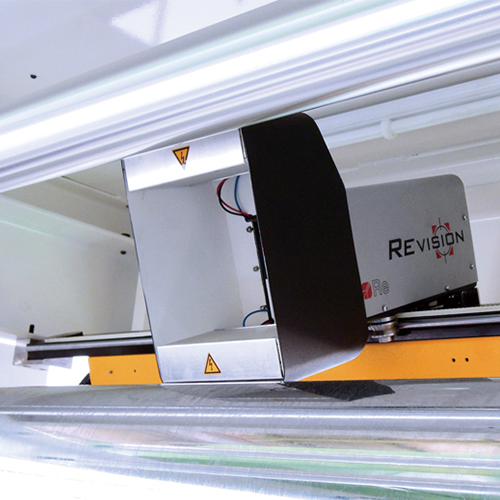

Tension Control Camera

Categories : Flexo Printing Parts

The auto tension control is from Italy, Europe, which is used for monitoring print position, resulting in easy monitoring.

Double Arm Open Type Kneader

Categories : Dispersion Kneaders

The KD double-arm kneader is available with a variety of blades in different shapes as well as with number of discharging methods and mixing conditions. This KD double arm kneader has already achieved considerable renown in a wide range of industries that deal with such high and medium-viscosity materials as adhesives, agglutinates magnetic materials and chemical material mixing. Applications: Banbury Type Lade Adhesives Hot-Melt materials Sealing Materials Ceramics Magnetic compounds Silicon Rubber Sigma Type Blade Printing inks Tapes Pigments Thermosetting Resins Chemicals

Sleeve Rewinding and Inspection Machine (Reversible) - FSP-250-2

Categories : Slitters and Rewinders

The FSP-250-2 is an ideal re-reeling machine for round roll material inspecting process such as printing, surface or the seaming quality of shrink sleeves. 2 motors driven system and memorized reverse function allowed the winding direction changed during operation.

Dispersion Kneader (Hydraulic ram)

Categories : Dispersion Kneaders

This machine most suitable kneading application for all kind Rubber, Plastic and Chemical materials. This machine with following features: High quality processed products/Easy for color changing /Easy for operating/increase production.

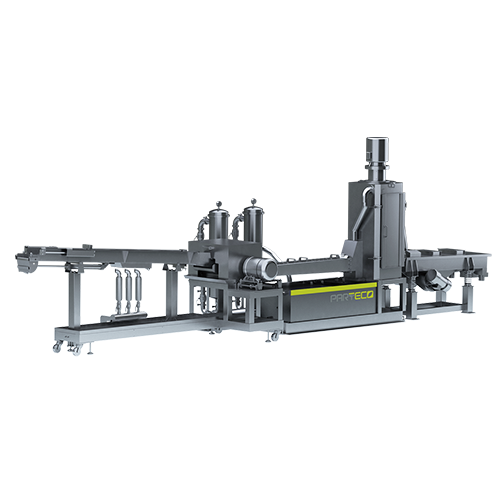

Granulating System: Flow Channel of Plastic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

The plastic strand pelletizing system consists of a die, water-cooling channel, pelletizer, centrifugal hydroextractor and a circulating water-cooling system. Mainly used for plastic materials such as PET、PA、PC etc

LD/LLDPE Super High Speed Inflation Machine (GF-L65ES-1)

Categories : Blown Film Extruders

LD/LDPE High Speed Film Blowing Machine-GF-L65ES-1

Crushing Machine For Immediate Recycling System - C-200 / 250 / 300 ST

Categories : Plastic Crushers

The plastic crusher is design for plastic manufacturing. Industrial recycling and granulation of plastic. • Suitable materials include plastics such as PP, PVC, PE, PET, ABS, etc. • Applicable fo...

DR Die Lifter

Categories : Mold Parts

These Spring-Loaded Die Lifters easily slide into different sized T or U-slots on the bolster by adding spacers to the side walls of the Die Lifters. This allows for accurate and easy die positioning as well as quick and easy die removal. The DR Series Die Lifters are available in customizable lengths in increments of 100mm, and are available as either a ball type lifter or roller type lifter.

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot, 5 Set Post Cooling Units

Categories : Blow Molding Machines by Layers

3 Layer, Continuous Extrusion Blow Moulding Machine (Fixed Type Clamping Press) 220lt Tight Head Drum

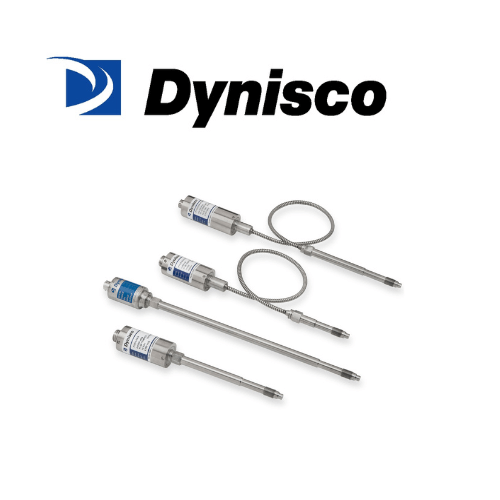

PT46X6 Series

The PT46X6 transmitters provide the industry standard 0 – 10 Vdc amplified signal designed to work with DCS and PLCs, 1 – 11 Vdc outputs are also available. The PT46X6 comes equipped with zero and span pots to adapt the transmitter to process conditions. Optional thermocouple or RTD configurations are available to provide melt temperature. The PT46X6 features a 1/2-20 UNF thread for installation in standard transducer mounting holes and can be supplied with a variety of electrical connections. The PT46X6 Series includes models PT4606, PT4626, PT4636, TPT4606, TPT4626, and TPT4636.

Garment / Laundry Bag Perforating On Roll Making Machine

Categories : Plastic Bag Making Machines

Garment bag perforating on roll making machine Laundry bag

2 Roll Rubber Calender Machine

Categories : Calendering Machines / Mixing Mills

Use for making the P.V.C. floor tile or automobile tyre, footwear etc.

Double Layer (6 Lines) T-Shirt Bag Cutting & Sealing Machine Model: CWA2+6+P-800-SV/CWA2+6+P-1000-SV

Categories : Bag Making Machine by Applications

‧ Automatic electronic control. Use pluging type IC easy replacing. ‧ Electromagnetic clutch and brake keep bags cutting and sealing accurately. ‧ The machine will stop automatically. When 1. The bags becomes super-imposed or overlapped. 2. Film finished. 3. The temperature not reaching setting. 4. Air pressure not enough. ‧ This machine use penumatic punching machine, low power consumption, low noise level, no hot air pollution, smooth & perfect punching.

P.P. Film Inflation Machine (GF-P65)

Categories : Blown Film Extruders

P.P. Film Inflation Machine (GF-P65)

Accumulator Head Blow Moulding Machine for Water Pressure Tank

Categories : Extrusion Blow Molding Machines

Accumulator Head Blow Moulding Machine for Water Pressure Tank For producing 20 liter to 1000 liter volume, all kinds of jerry can, containers, air duct and industrial blow moulding products.

Heat Cutting 2 or 4 Lines T-shirt Bag Making Machine with 2 Photo Cells & 2 Servo Motors Model: CW-1100P4-SV / CW-1200P4-SV

Categories : Bag Making Machine by Applications

This machine can produce 2 lines printed T-shirt bag or 4 lines non-printed T-shirt bag. In-line hydraulic punching machine with bag folding device and Japan made sensors for accurate bags punching and folding position.

Proportional Valve (PV)

Categories : Separators

The unique air valve structure design stops dust from entering the cylinder of the unit and thus reduces waste. Can mix or feed one kind of resin only if required. The controller is fitted with digital readout (PV-A-D Series) and setting for the mixing cycles which gives a high rate of accuracy. It is easy to set and be set in the range of 0-9.9 seconds. Transparent cleaning cover design for quick cleaning and easy changing materials. Individual controller for convenient operation.

Power Unit

Categories : Mold Parts

The power unit powers the hydraulic pump which keeps the die clamps in place. This power unit is self-contained and it yields enough hydraulic power to suit the toughest clamping requirements. Furthermore it is very simple to adjust the hold-down force, stripping pressure and to select between a 0° or 180° stripping position. The power unit is also able to provide the different pressures needed for different circuits in the system.

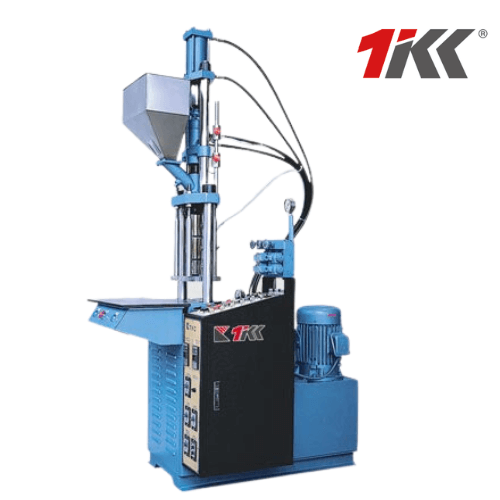

KT Series Injection Molding Machine (STANDARD)

Categories : Vertical Injection Molding Machines

Vertical Injection Molding Machine

Hot Air Tube Sealing Machine

Categories : Sealing Machines

-Monitor screen for easy operation. -Imported hot air equipment can make sealing fast and blazonry. -With automatic tube orientation.Cutting tail automatically after sealing. -Tube tail is durable after being sealed.

Dynisco Burst Plugs BP420

Categories : Indicators and Sensors

■ Welded one piece assembly – no degradation of joint strength at elevated temperatures ■ Iconel rupture disk – stable through a wide range of temperatures ■ Burst pressure ranges from 1,000 to 15,000 psig ■ Accuracy of ±10% of rated burst pressure at 300°C (750°F) ■ Leak rate exceeds 1x10-6 standard cc/sec

Portable Facial Massager KUP-300

KUP-300 is designed with 3 million times micro vibration per second, which makes no harm to the bond and muscles. It is safe to use on face especially the area around nose and eyelid.

Servo Motor Driven Double Layer Bag Making Machine

Categories : Plastic Bag Making Machines

1. Servo Motor Driven, Efficient mechanical structure produce 120 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Optional accessories: hot pin conveyor stack for T-Shirt bag making machine.

Trim Winding Machine-FDS

Categories : Slitters and Rewinders

-Designed to wind and collect the edge trim during bag making processes. -Especially suitable for rewinding high tensile strength material. -Allows for simultaneous operation at both ends. -The Trim Winding Machine is driven by a torque motor, providing synchronous motion with the main machine.

Single Side Extrusion Lamination Machine (YSL)

Categories : Extrusion Coating Machines

This series of machines are available for jumbo bag, geotextile, spunbond and paper …etc. To do single side lamination process.

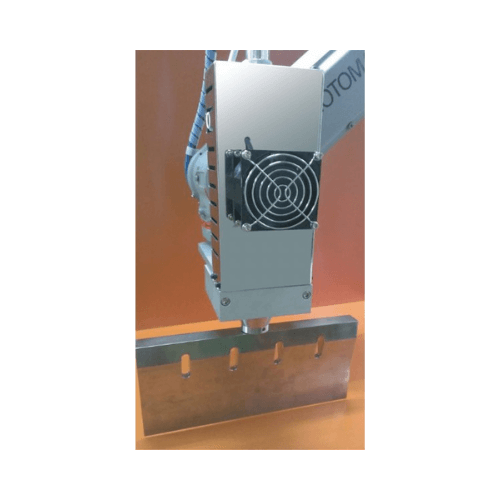

Ultrasonic Module for Food industry-Ultrasonic Food Cutting Module

Auto Frequency Tuning Ultrasonic System

Twin Servo Motor Driven Double Layer Flying Knife Bottom Sealing Bag Making Machine

Categories : Plastic Bag Making Machines

1. Twin servo motor driven, efficient mechanical structure. 2. Digital control for production length adjusting, precise and less wastage. 3. High production efficiency to save manpower and time. 4. Automatically stop when the temperature not reaching setting. 5. Automatically stop when running out of film or bag jams. 6. Flying knife device by servo motor control, unnecessary to adjust the cutting blade. 7. Using up and down heater for front sealing device, especially for heavy duty thickness up to 0.6mm. 8. With pneumatic unwind unit to lift up the film roll automatically.