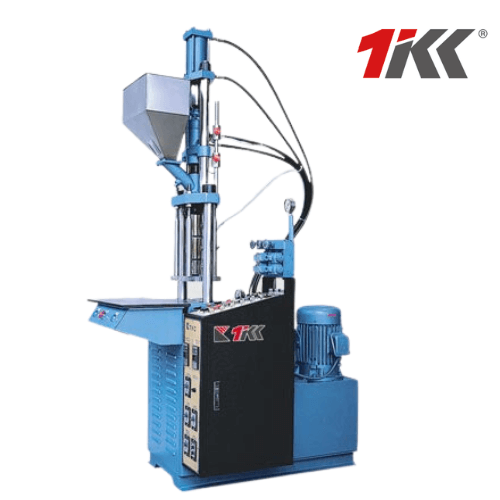

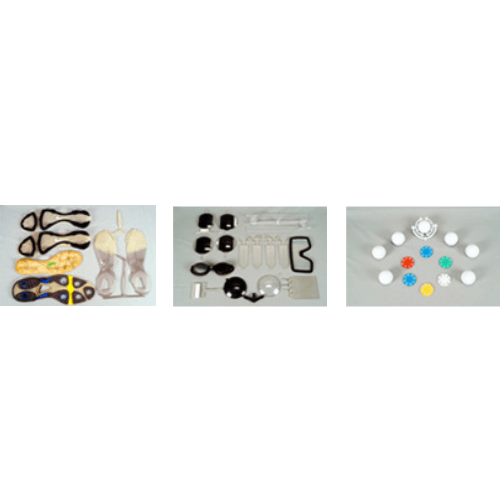

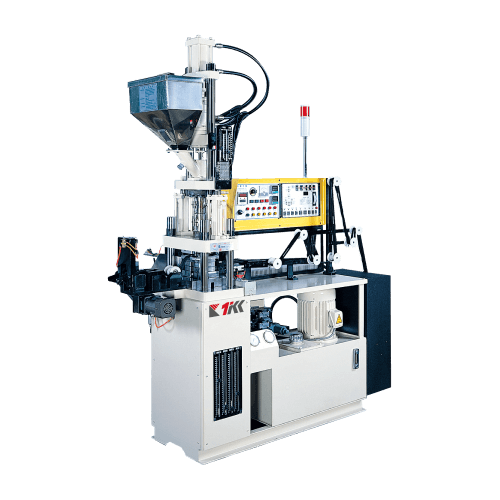

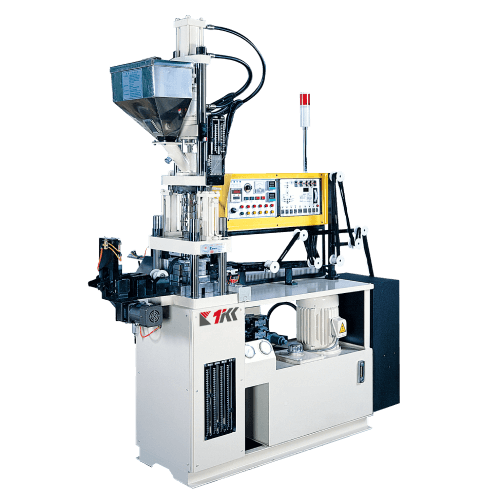

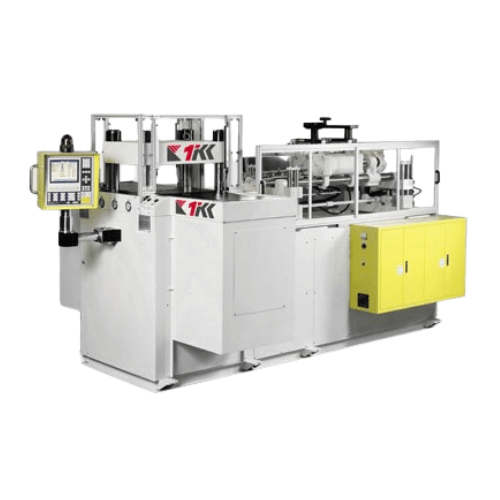

- Vertical mold clamping and injection machine, small footprint, and a high degree of precision. The injection molding machine is ideal for plastic and rubber injection of medium and small products with inclusions and inserts molding.

- Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items.

- Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation.

- Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.

- This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production.

- There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

- The differences between vertical and horizontal injection molding machines lie in their respective designs and functionalities. Vertical injection molding machines, renowned for their space-saving design, are especially well-suited for factories with limited space, making them an ideal choice for such environments. These machines employ a direct-pressure mold locking mechanism, ensuring consistent stress distribution and providing robust stability. Moreover, when equipped with features like a rotating work table or conveyor belt, they possess the capability to significantly boost production efficiency.

|

Machine Type |

Unit |

K2S(D) |

KT-200-D(DM) |

KT-300-D(DM) |

KT-400-D(DM) |

KT-500-D(DM) |

KT-600-D(DM) |

KT-700-D(DM) |

KT-800-D(DM) |

KT-900-D(DM) |

||||||||||||||||||||||

|

Screw Diameter |

mm |

20 |

25 |

20 |

25 |

30 |

25 |

30 |

35 |

30 |

35 |

40 |

35 |

40 |

45 |

50 |

35 |

40 |

45 |

50 |

40 |

45 |

50 |

55 |

45 |

50 |

55 |

60 |

60 |

65 |

70 |

|

|

Injection Pressure |

kg/cm2 |

1715 |

1098 |

2730 |

1747 |

1213 |

2509 |

1742 |

1280 |

2170 |

1594 |

1220 |

2171 |

1663 |

1314 |

1064 |

2577 |

1973 |

1559 |

1263 |

2695 |

2129 |

1724 |

1425 |

3318 |

2688 |

2221 |

1866 |

1866 |

1590 |

1371 |

|

|

Theoretical Shot Volume |

cm3 |

31 |

49 |

31 |

49 |

71 |

59 |

85 |

115 |

99 |

135 |

176 |

135 |

176 |

223 |

275 |

173 |

226 |

286 |

353 |

276 |

349 |

432 |

522 |

381 |

471 |

570 |

678 |

678 |

796 |

923 |

|

|

Max. Shot Weight(PS) |

g |

29 |

45 |

29 |

45 |

64 |

54 |

77 |

105 |

90 |

135 |

160 |

123 |

160 |

203 |

250 |

158 |

206 |

261 |

321 |

248 |

314 |

388 |

469 |

343 |

424 |

513 |

610 |

617 |

724 |

840 |

|

|

oz |

1 |

1.5 |

1 |

1.6 |

2.3 |

1.9 |

2.7 |

3.7 |

3.2 |

4.3 |

5.7 |

4.3 |

5.7 |

7.2 |

8.9 |

5.6 |

7.3 |

9.3 |

11.3 |

8.8 |

11.2 |

13.8 |

16.7 |

12.2 |

15.1 |

18.3 |

22 |

22 |

25 |

30 |

||

|

Injection Rate |

cm3/sec |

20 |

30 |

22 |

35 |

50 |

36 |

52 |

71 |

51 |

69 |

90 |

82 |

107 |

135 |

167 |

87 |

114 |

144 |

177 |

102 |

129.3 |

159.6 |

193 |

123.6 |

148.3 |

178 |

212.5 |

247 |

291 |

336 |

|

|

Screw Stroke |

mm |

100 |

100 |

120 |

140 |

140 |

180 |

220 |

240 |

240 |

||||||||||||||||||||||

|

Screw Speed Max. |

rpm |

0-215 |

0-205 |

0-190 |

0-175 |

0-200 |

0-180 |

0-220 |

0-160 |

0-140 |

||||||||||||||||||||||

|

Nozzle Contact Force |

tons |

- |

2.0 |

2.4 |

2.6 |

2.9 |

3.3 |

4.2 |

6 |

8.7 |

||||||||||||||||||||||

|

Nozzle Retraction Stroke |

mm |

- |

140 |

180 |

200 |

220 |

300 |

300 |

320 |

340 |

||||||||||||||||||||||

|

Number of Temperature Control |

- |

2 |

3 |

3 |

3 |

4 |

5 |

5 |

5 |

5 |

||||||||||||||||||||||

|

Material Hopper Capacity |

| |

15 |

20 |

20 |

30 |

30 |

30 |

30 |

30 |

30 |

||||||||||||||||||||||

|

Machine Type |

Unit |

K2S(D) |

KT-200-D(DM) |

KT-300-D(DM) |

KT-400-D(DM) |

KT-500-D(DM) |

KT-600-D(DM) |

KT-700-D(DM) |

KT-800-D(DM) |

KT-900-D(DM) |

|

Clamping Force |

tons |

15 |

30 |

45 |

55 |

85 |

120 |

160 |

200 |

250 |

|

Opening Force |

tons |

7 |

6.5 |

8.3 |

13.5 |

10.5 |

15 |

20 |

26 |

28 |

|

Platen Size |

mm |

430x250 |

520x370 |

580x430 |

650x490 |

740x500 |

840x620 |

950x700 |

1070x810 |

1200x920 |

|

Distance Between Tie Bare |

mm |

250 |

355x205 |

400x250 |

500x340 |

560x320 |

620x400 |

750x500 |

870x610 |

920x640 |

|

Min. Mold Height |

mm |

100/40 |

160/100 |

210/150 |

260/200 |

250/200 |

250/200 |

250 |

300 |

300 |

|

Opening Stroke |

mm |

160 |

180 |

200 |

200 |

250 |

250 |

300 |

350 |

400 |

|

Max. Open Daylight |

mm |

260/200 |

340/280 |

410/350 |

460/400 |

500/450 |

500/450 |

550 |

650 |

700 |

|

Ejector Force |

tons |

1.3/1.3 |

1.3/1.3 |

1.3/1.3 |

1.3/2.1 |

3.3/3.5 |

3.3/3.5 |

4.8 |

4.8 |

4.8 |

|

Ejector Stroke |

mm |

45/95 |

45/95 |

45/95 |

45/145 |

75/145 |

75/145 |

75/145 |

75/145 |

75/145 |

|

Machine Type |

Unit |

K2S(D) |

KT-200-D(DM) |

KT-300-D(DM) |

KT-400-D(DM) |

KT-500-D(DM) |

KT-600-D(DM) |

KT-700-D(DM) |

KT-800-D(DM) |

KT-900-D(DM) |

|

Slide Stroke |

mm |

260 |

350 |

420 |

500 |

500 |

540 |

700 |

885 |

1000 |

|

Rotary Station |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

Max. Mold Weight |

kg |

60 |

90 |

120 |

150 |

200 |

300 |

380x2 |

450x2 |

500x2 |

|

Station Accuracy |

mm |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

|

Machine Type |

Unit |

K2S(D) |

KT-200-D(DM) |

KT-300-D(DM) |

KT-400-D(DM) |

KT-500-D(DM) |

KT-600-D(DM) |

KT-700-D(DM) |

KT-800-D(DM) |

KT-900-D(DM) |

|

Max. Hydraulic Pressure |

kg/cm2 |

140 |

140 |

140 |

140 |

140 |

140 |

140 |

175 |

175 |

|

Pump Output |

liters/min |

19 |

26 |

39 |

47 |

76 |

96 |

118 |

136 |

158 |

|

Oil Reservoir Capacity |

liters |

80 |

100 |

130 |

150 |

180 |

200 |

350 |

410 |

720 |

|

Cooling Water Consumption |

liters/hr |

400-600 |

400-600 |

600-800 |

800-1000 |

1200-1500 |

1500-1800 |

1400-1600 |

1800-2000 |

2000-2200 |

|

Pump Motor Power |

kw |

2.2 |

3.5 |

5.5 |

7.5 |

11 |

14.7 |

18.75 |

30 |

36.7 |

|

Barrel Heating Power |

kw |

2 |

2.7 |

3.5 |

4.5 |

5.6 |

7.5 |

10 |

14.3 |

18 |

|

Total Wattage |

kw |

4.2 |

6.2 |

9 |

12 |

16.6 |

22.2 |

28.75 |

44.3 |

54.7 |

|

Machine Type |

Unit |

K2S(D) |

KT-200-D(DM) |

KT-300-D(DM) |

KT-400-D(DM) |

KT-500-D(DM) |

KT-600-D(DM) |

KT-700-D(DM) |

KT-800-D(DM) |

KT-900-D(DM) |

|

Machine Weight |

tons |

0.5/0.55 |

1.1/1.2/1.3 |

1.4/1.5/1.6 |

2.1/2.3/2.5 |

4.5/4.8/5 |

4.9/5.2/5.4 |

5.2/5.6 |

5.5/5.9 |

6.5/7.2 |

|

Machine Dimensions(L x W x H) |

m |

1.4x0.8x2.1 |

1.6x1.24x1.9 |

1.7x1.35x2.15 |

1.8x1.45x2.65 |

2.0x1.7x3.2 |

2.4x1.6x3.1 |

2.1x1.5x4.3 |

2.1x1.7x4.5 |

2.5x2.2x5.2 |

|

Shipping Weight |

tons |

0.75/0.85 |

1.3/1.5/1.9 |

1.7/1.9/2.1 |

2.6/2.9/3.2 |

5.1/5.6/5.8 |

5.6/6/6.1 |

5.6/6.3 |

5.9/6.5 |

7.2/8.0 |

|

Shipping Measurements(L x W x H) |

m |

1.6x1.0x2.23 |

1.8x1.45x2.1 |

1.9x1.5x2.2 |

2.1x1.7x1.5 |

4.2x2.0x1.7 |

4.6x2.2x1.8 |

4.7x2.4x1.9 |

5.0x2.4x2.1 |

6.0x2.4x2.4 |