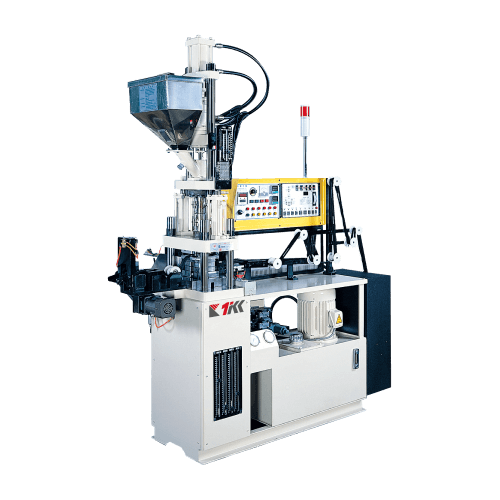

- Vertical mold clamp with horizontal injection with long closing and opening stroke, ideal for injection of large work pieces.

- Extra heavy structure and large mold capacity along with simple and easy-to-use layout.

- Horizontal injection can be raised or lowered using hydraulic screws for fast, accurate positioning.

- There are few restrictions on the dimensions of molds or mold lines, and the range of applications is very broad.

- The platen uses self-lubricated axles which require no further lubrication, for smooth, easy movement and super-long useful life.

- Special functions for certain products can also be programmed, including strong clamping force, small injection quantities, faster injection rates, multiple die-sets, mold ventilation, mold vacuum and other operations.

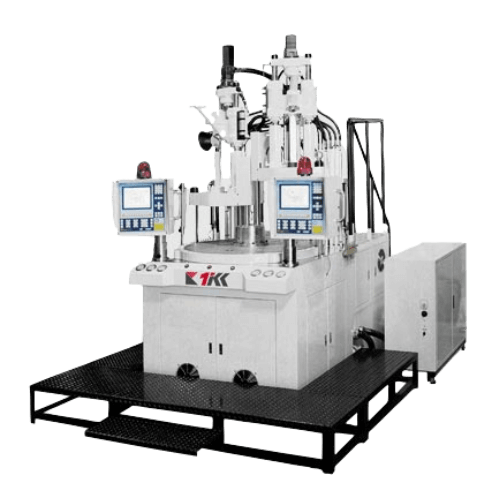

- Other functions include insertion and cyclic finishing with a slide platen or rotary plate as needed.

|

Machine Type |

Unit |

KR-85-D(R) |

KR-110-D(R) |

KR-150-D(R) |

KR-225D(DM) |

KR-300D(DM) |

|||||

|

Screw Diameter |

mm |

38 |

42 |

45 |

50 |

52 |

62 |

62 |

70 |

70 |

80 |

|

Injection Pressure |

kg/cm2 |

1750 |

1434 |

1560 |

1262 |

2486 |

1748 |

1748 |

1371 |

1600 |

1225 |

|

Theoretical Shot Volume |

cm3 |

190 |

231 |

286 |

353 |

509 |

724 |

724 |

923 |

1154 |

1507 |

|

Max. Shot Weight(PS) |

g |

173 |

210 |

260 |

321 |

463 |

658 |

658 |

840 |

1038 |

1356 |

|

oz |

6.1 |

7.4 |

9.1 |

11.3 |

16.3 |

23 |

23 |

29.5 |

37.3 |

48.8 |

|

|

Injection Rate |

cm3/sec |

86 |

105 |

118 |

145 |

127 |

181 |

220 |

280 |

244 |

319 |

|

Screw Stroke |

mm |

168 |

180 |

240 |

240 |

300 |

|||||

|

Screw Speed Max. |

rpm |

0-175 |

0-160 |

0-142 |

0-126 |

0-126 |

|||||

|

Nozzle Contact Force |

tons |

3.9 |

6 |

6.7 |

6.7 |

6.7 |

|||||

|

Nozzle Retraction Stroke |

mm |

250 |

250 |

250 |

250 |

300 |

|||||

|

Number of Temperature Control |

- |

4 |

5 |

5 |

5 |

5 |

|||||

|

Material Hopper Capacity |

| |

40 |

40 |

90 |

90 |

90 |

|||||

| Machine Type | Unit | KR-85-D(R) | KR-110-D(R) | KR-150-D(R) | KR-225D(DM) | KR-300D(DM) |

| Clamping Force | tons | 85 | 120 | 165 | 225 | 300 |

| Opening Force | tons | 14 | 18 | 29 | 14 | 34 |

| Platen Size | mm | 410x600 | 480x760 | 520x760 | 700x1030 | 900x1300 |

| Distance Between Tie Bare | mm | 1000x205 | 990x260 | 1180x260 | 720x390 | 1000x600 |

| Min. Mold Height | mm | 180 | 200 | 250 | 310 | 350 |

| Opening Stroke | mm | 250 | 250 | 350 | 350 | 400 |

| Max. Open Daylight | mm | 430 | 450 | 600 | 660 | 750 |

| Ejector Force | tons | 2.7 | 2.7 | 2.9 | 6 | 6 |

| Ejector Stroke | mm | 45/95 | 45/95 | 45/95 | 45/95 | 45/95 |

| Machine Type | Unit | KR-85-D(R) | KR-110-D(R) | KR-150-D(R) | KR-225D(DM) | KR-300D(DM) |

| Slide Stroke | mm | 300/Ø980 | 400/Ø980 | 420/Ø1170 | 505/700 | 800/1600 |

| Rotary Station | - | 2-4 | 2-4 | 2-4 | 2 | 2 |

| Max. Mold Weight | kg | 200x2/140x3 | 350x2/240x3 | 450x2/300x3 | 700x2 | 1000x2 |

| Station Accuracy | mm | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 |

| Machine Type | Unit | KR-85-D(R) | KR-110-D(R) | KR-150-D(R) | KR-225D(DM) | KR-300D(DM) |

| Max. Hydraulic Pressure | kg/cm2 | 140 | 175 | 175 | 175 | 175 |

| Pump Output | liters/min | 65-12 | 79-14 | 109-17 | 132-19 | 134-21 |

| Oil Reservoir Capacity | liters | 300 | 420 | 550 | 650 | 750 |

| Cooling Water Consumption | liters/hr | 800-1000 | 1000-1200 | 1400-1600 | 1800-2000 | 2200-2400 |

| Pump Motor Power | kw | 11 | 15 | 18.3 | 22 | 30 |

| Barrel Heating Power | kw | 7.5 | 10 | 14.3 | 14.3 | 18.6 |

| Total Wattage | kw | 18.5 | 25 | 32.6 | 36.3 | 48.6 |

| Machine Type | Unit | KR-85-D(R) | KR-110-D(R) | KR-150-D(R) | KR-225D(DM) | KR-300D(DM) |

| Machine Weight | tons | 4.9 | 7 | 10.4 | 12 | 14 |

| Machine Dimensions(L x W x H) | m | 3.75x1.35x2.4 | 3.9x1.5x2.7 | 4.3x2.1x3.1 | 4.7x3.0x3.6 | 5.0x3.3x4.0 |

| Shipping Weight | tons | 5.5 | 7.8 | 11.4 | 13.2 | 15.2 |

| Shipping Measurements(L x W x H) | m | 4.1x1.5x2.3 | 4.4x1.7x2.6 | 4.8x2.3x3.0 | 5.2x3.2x3.3 | 5.5x3.5x3.7 |