2-in-1 Conveying Dryer (CD)

Categories : Dryers and Dehumidifiers For Plastic Materials

Hopper dryer combine vacuum loader is perfect to move anywhere for your need. A stainless insulated hopper dryer with dual layer to help drying better and faster. Save more energy and increase higher efficiency. A vacuum loader automatically supplies dried resin to avoid the shortage of material during production. Installed pipe-clean device (Taiwan Pat:M299801) and closed-loop can prevent the moisture return, static electricity and resin pollution inside the pipe for better quality. Patented Heat-recycler (Taiwan Pat:226245;China Pat:01258213.1) can save your energy, increase drying and decrease the pollution of hot air and dust. Installed weekly timer and safety protectors can save your labor cost and protect operators in better working environment. Only one control unit is convenient for you to monitor all suction points. Able to extend suction points up to four as 1 to 4 small central conveying system to supply resin for raw material areas and numerous molding machines. Save your equipment cost and space without extra spend.

Solvent-less Laminating Machine (WSL Series)

Categories : Industrial Lamination

For the solvent-free lamination, WORLDLY launches solvent-less laminating machine WSL series. The manipulation is much easier and simple with the PLC digital control system and touchable human-machine interface. Solvent-less laminating machine WSL series is the leading popular machines for solvent-free. It has higher compound speed in order to increase productivity. And, there is no wasted costs caused by the solvent evaporation. Also, the coating thickness is very thin with 100% solid ingredient which can reduce a lot of cost. The production won't produce solvent evaporation and there is no solvent residue. It all conforms to food safety regulations. Meanwhile, there's no need for drying chamber which can save energy. The machine itself can be shorten to save space for additional use which can make a significantly cost reduction.

4 Shuttles Leno Loom

Categories : Industrial Knitting Machines

The HY7-m4SCLL four shuttles leno loom is designed for tubular net weaving with PP and HDPE yarns, this is the most new & unique weaving technology in the world, which featrues high production and energy-saving ...

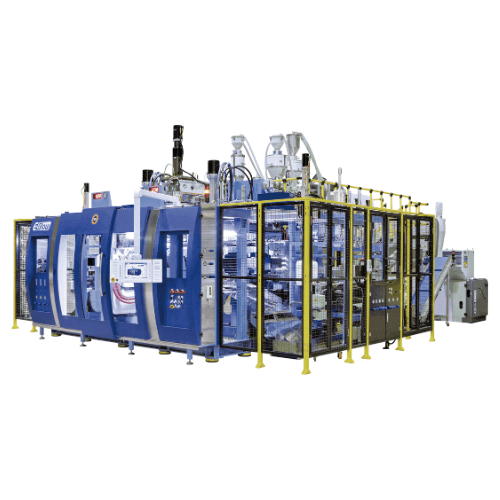

All Electric 3 Layer, Double Station Blow Moulding Machine for Plastic Bottle Making

Categories : Electric Blow Molding Machines

All Electric 3 Layer, Double Station Blow Moulding Machine for Plastic Bottle Making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system.

Force Hopper Feeding Plastic Recycling Machine (H Series)

Categories : Plastic Pelletizer Machines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost save up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Granulating System: Underwater Pelletizer

Categories : Plastic Pelletizer Machines

Underwater pelletizer with advanced water cooling technology. Energy saving, Easy Operation Underwater Pelletizing System. Mainly used for plastic materials such as PP、TPU、TPR、TPE etc.

PLASTIC WOOD COMPOSITE MATERIAL PELLETIZER

Categories : Plastic Pelletizer Machines

Our Plastic Wood Composite Material Pelletizer is a state-of-the-art WPC pelletizing machine designed to deliver consistent, high-quality pellet production for wood-plastic composites. This WPC pelletizing machine offers precise temperature control and an optimized extrusion process to ensure uniform pellet size and superior material characteristics. With a robust and efficient design, the pelletizer reduces energy consumption while maximizing output, making it an essential solution for manufacturers looking to enhance productivity and material quality in their WPC pelletizing operations.

Patented Housing Desiccant Rotor Dehumidifying Dryer (DHML)

Categories : Dryers and Dehumidifiers For Plastic Materials

Patented Housing Desiccant Rotor Dehumidifying Dryer (DHML) 1. Unique design of insulated desiccant rotor system. 2. Efficient and energy saving design of exclusive rotation mechanism for the rotor & desiccant chambers. 3. Easy-load design for desiccant replacement. 4. No pneumatic valves necessary to control the air flow between areas. 5. Accurate PID temperature controller. 6. Ideally design for PET preform systems. 7. Intelligent Microprocessor Control and premium overheat protector 8. Energy saving heater and unique design for saving electricity. 9. Well designed Solid State Relay (SSR) and protective devices. 10. Obtained numerous domestic and oversea patents of Japan, the United States, Germany, Taiwan and China.

Energy-efficient Hopper Dryer-SEHD

Categories : Dryers and Dehumidifiers For Plastic Materials

The SEHD energy-efficient hopper dryer can be used for drying most non-hygroscopic materials, such as PS, PP, ABS, etc. The maximum drying temperature can reach 160℃ and it also can choose the optional double-layer insulation model to obtain uniform hopper temperature with less heat losses. Besides, multiple components are available as options that can recycle the hot air and filter the iron impurities in the material, which also can be installed on the ground with the floor stand.

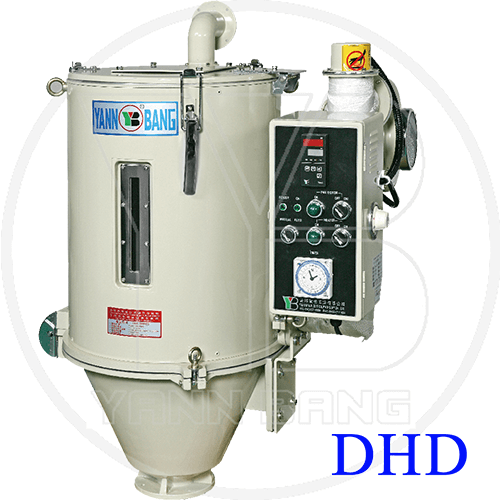

Hopper Dryer (HD/IHD/DHD)

Categories : Dryers and Dehumidifiers For Plastic Materials

‧ HD Series Rapid heating. Constant temperature control. ‧ IHD Series Special insulated design. Energy saving. Save against burns. ‧ DHD Series Insulated design. Dust-free, clean free. The standard DHD model is equipped with timer(T), EGO overheat protector(P),and patented magnetic stand (NSD)

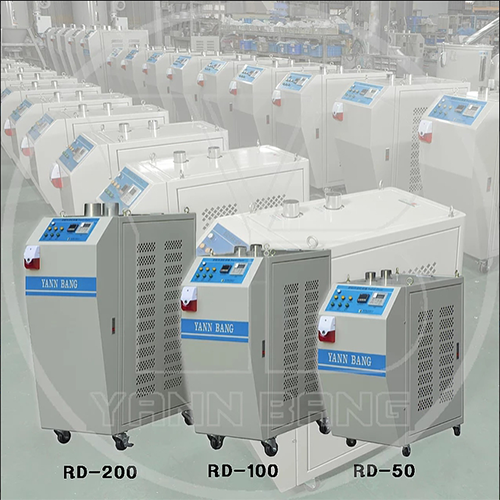

Rapid Dryer (RD)

Categories : Dryers and Dehumidifiers For Plastic Materials

Without replace your old hopper dryer, use this new dryer to dry faster with better quality and to upgrade production more efficiently. 1. Wide application. Suit to numerous material such as PC, PMMA, PA46, PPS, NYLON and some PET/PETG. 2. Save time and energy. Patented technology significantly shortens the drying time. Normally NYLON takes four hours to dry. Work with Yann Bang’s rapid dryer (RD), it only takes two hours to dry completely and ready to use. RD can decrease 50% of drying hours and save 50% of energy for you. 3. Upgrade energy save. Combine with Yann Bang’s Energy-efficient Hopper dryer can save more energy obviously. 4. Increase yield rate of output. Moisture content can be reduced to 0.02% (depend on the initial moisture content of resin), improve the drying quality of resin, and lower defective products. 5. Easy maintenance. Install with plug-in air filter and dust collector (oil collector) that you can unload easily to clean and replace parts.

Energy-Efficient Hopper Dryer(G series)

Categories : Dryers and Dehumidifiers For Plastic Materials

Awarded patents in Germany, Taiwan and China, the advanced technology recycles internal heat and faster heating. That saves your energy over 30% and extend equipment life time. Work with a dehumidifier can save more! The temperature inside hopper increases quickly for better drying and shorten above 30% of drying hour. Simultaneously HEI can separate dust and oil for better quality. An energy-efficient device can save energy and improve working environment for you.

“Standard” Series SG-23E/30E/36E

Categories : Granulators

SG-23/30E series granulators have no significant differences with the standard model in construction and operability. The granulators feature quick blade change. They are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding and extrusion machines. Staggered blades can easily grab and granulate the materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.

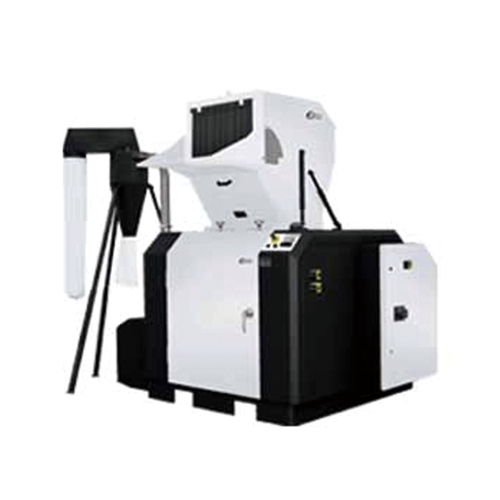

Sound-proof Central Granulators - SG-43

Categories : Granulators

SG-43 series are suitable for centralized recycling of waste and rejected parts form injection, blowing molding and extrusion lines. This series feature compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level ensures low energy consumption.

Sound-proof Central Granulators - SG-43-50-70

Categories : Granulators

SG-43 series are suitable for centralized recycling of waste and rejected parts form injection, blowing molding and extrusion lines. This series feature compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level ensures low energy consumption.

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

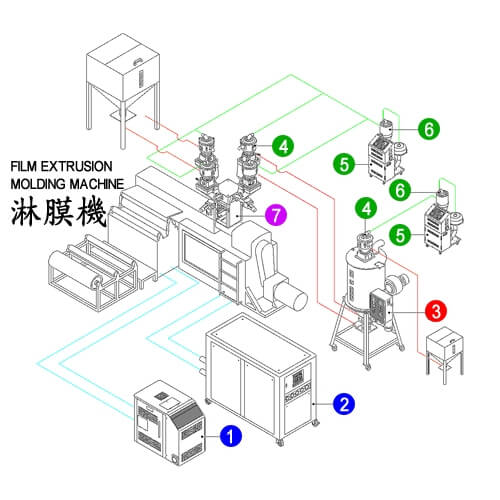

Film Extrusion Molding Machine Auxiliary Solutions

Categories : Assembly Systems

We have a wide range of auxiliary equipment for film extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

PET Fully Electricity Stretch Blow Molding Machine for Jar and Large Containers

Categories : Electric Blow Molding Machines

-Servo-motor technology (preform transfer system – preform stretching – press clamping). -Energy savings. -Quiet. -Faster cycle times. -Reduced downtime and labor. -Optional jar preform auto feed.

All Electric Blow Moulding Machine for 200ml, 500ml Shampoo Bottle

Categories : Electric Blow Molding Machines

All Electric Blow Moulding Machine for 800ml Bottle with view stripe High Efficiency and Eco-Friendly Design The FKI All-Electric HDPE Bottle Making Machine is specifically engineered for producing 200ml and 500ml shampoo bottles from HDPE (High-Density Polyethylene) material. This advanced machine integrates an energy-saving system, drastically reducing power consumption while maintaining high-speed, consistent output. With its fully electric operation, the machine eliminates the need for hydraulic oil, ensuring a cleaner, more sustainable manufacturing environment.

Stretch Blow Molding Machine MIB-SERIES

Categories : Injection Blow Molding Machines

This model of one-stage, three station in ection stretch blow molding machine is made by KAI MEI plastic machinery co. Itd. It has the possibility to economically produce high quality contain ers using various of many kinds of material in PET,PP,PC,TRITAN,PES,etc. and save energy. It lets our customers obtain the most profits with the fast cycle time from this injection stretch blow-molding machine. PROCESSING WITH 3 STATION ROTARY TABLE The process of this machine is by using a rotary disk to cycle three stations. At the first station,there is a high clamping force on the inection mould of this machine to ensure obtaining a good performace quality. At the second station, we assigned a controller to adjust the temperature so that our customers could obtain the best quality bottles. At the third station, it is in process of the stretching and high pressure blowing shape. At the last station,high quality bottles can be easily taken out.

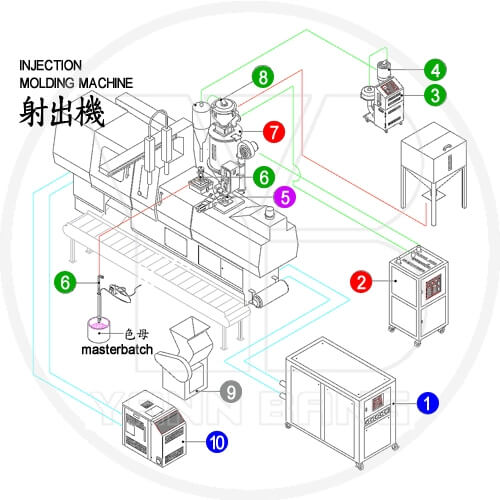

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Vertical Injection Molding Machines

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

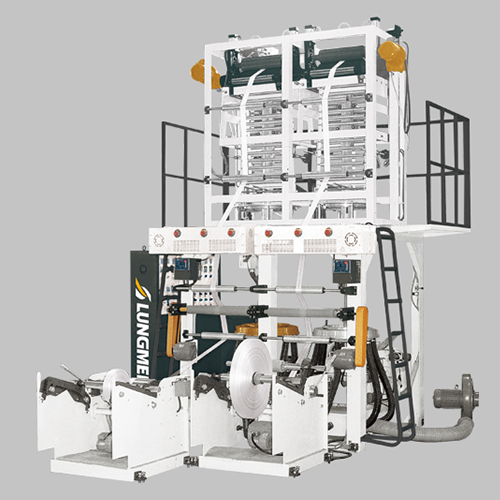

High Speed Twin Die Blown Film Machine

Categories : Blown Film Extruders

Extruder Mono-Layer HDPE/LDPE/mLDPE/PP High Speed Twin Die Blown Film Machine High performance main AC motor with inverter designed for saving energy and minimum maintenance Nip inverter designed for accuracy and reliability High torque gear box with enforced lubrication system to minimize machine down time High quality mixing in screw and barrel delivers excellent homogeneity and high output Designed for producing narrow and thin film

Corona Electrostatic Treater

Categories : Non Woven Production Line

This CORONA ELECTROSTATIC TREATER is used to turn materials such as melt-blown fabric (face mask sheet),non-woven fabric (non-woven sheet) and polymers into electrets. The equipment includes a high-frequency inverter power supply, special electrodes and rollers. Through the mutual control of these components, the electret material can deeply capture the charge energy, and maintaining the polarization for a long period. This equipment can be used for application such as turning melt-blown fabric, non-woven fabric (non-woven fabric) and air filter into electret. It greatly increases the filtration efficiency of the filter material by capturing tiny particle which is smaller than filter density. More importantly, this CORONA ELECTROSTATIC TREATER helps melt blown fabric increase 45~65% of filtration efficiency and turns it to the most important layer for medical face mask such as N95, KN95 etc. to reduce infected by corona virus COVID-19. Note: An electret is a material that almost remains electric polarization permanently and is able to generate an electric field in the surrounding area. The electret strength will last longer when corona electrostatic charges deeply by high voltage and frequency.

Mini Type Blown Film Machine

Categories : Blown Film Extruders

Designed for T-Shirt bag and flat bag production Small occupancy of space Simple, flexible and economic operation High output and saving energy Also can work with LDPE resin if changing air ring Film thickness HDPE 0.008~0.06 mm