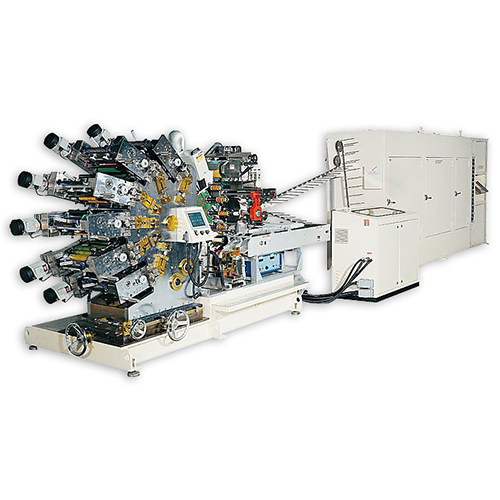

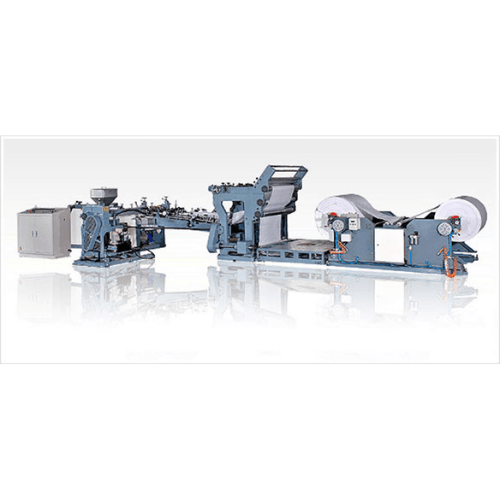

Computerized 6 Color Printing, Coating & Drying Machine PCD-80-06-UV

Categories : Extrusion Coating Machines

For UV lacquer, special UV oven is required, which is equipped with rapid drying mechanism to produce tubes with glossier surface. We also offer UV & heater oven, which can save electricity and without space-limit. Customers can choose either of them accordingly. Precise index ensures accuracy of every movement. Tube feeding system works with detector. Coating mechanism will not move without tubes on mandrels.

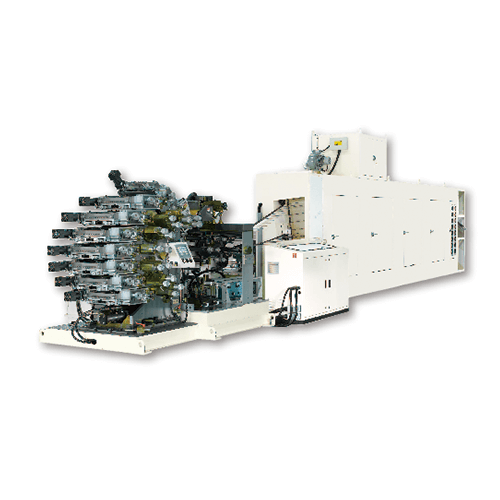

8 Color PE Tube Dry Offset Printing Coating Machine PCD-80-08H-RE(UV)

Categories : Extrusion Coating Machines

Double transferring rollers design. Stopless roller adjustment design. Plate wheel outer finetune mechanism Quick release ink rollers. Printing wheel clean system (200 mm dischargeable) Sleeve Printing Plate wheel pre-register mechanisim.

Door lock Related Part

This product is made of PP+GF (Glass Fiber Reinforced Polypropylene), offering high strength, impact resistance, heat resistance, and low deformation rate, ensuring the stability and durability of large panels and main boards in high-load environments. It is designed for applications in structural support, industrial equipment, and automotive interior and exterior components, delivering excellent mechanical performance and long-term stability. Manufactured using a 1600-ton large injection molding machine, this product enables the production of large-sized, high-precision plastic components, ensuring superior structural rigidity and consistency to meet various large-component requirements. Additionally, compared to metal parts, PP+GF provides both high strength and lightweight advantages, effectively reducing product weight.

Success Story - Cutter Compactor Plastic Recycling Machine

Categories : Plastic Waste Recycling Machines

KRIEGER-85 / Cutter Compactor Plastic Recycling Machine / LDPE Film / USA KRIEGER-125 / Cutter Compactor Plastic Recycling Machine / LDPE and HDPE Film / Indonesia KRIEGER-100 / Cutter Compactor Plastic Recycling Machine / PE Film / Vietnam KRIEGER-Z-125i / Cutter Compactor Plastic Recycling Machine / PE Foam / Korea Genius Achieves Exceptional Business Success in Cooperation with Taiwan’s PE Recycling Giant KRIEGER-150 / Cutter Compactor Plastic Recycling Machine / BOPP Film / Korea

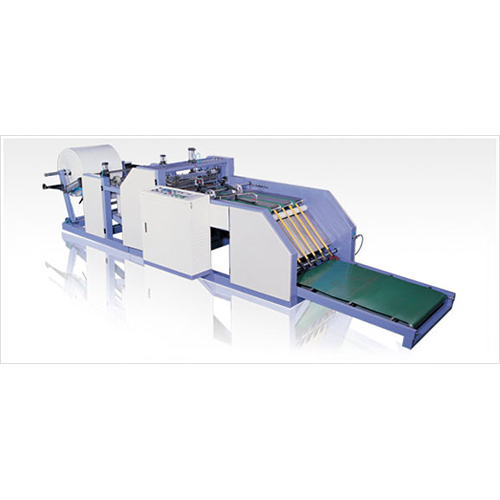

PP Woven Bag Automatic Cutting-Sewing Machine CS-2002/1-4 colors

Categories : Cutting Machines

● Zigzag Type High Quality Alloy Steel Cutter ● Double-Fold sewing Guide Device ● Cold Cutting System (for laminated bag) ● Mark reading sensor (for pre-printed fabric roll) ● In-Line Gusset Device ● Perforation Needle Roller

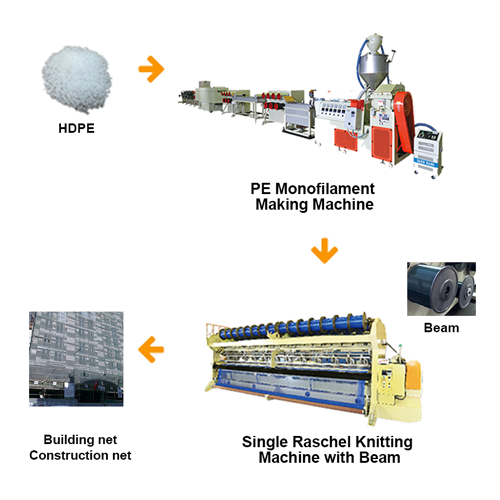

Building / Construction Net

Categories : Industrial Knitting Machines

This extrusion line is designed for making monofilament and suites for PE raw material. It can offer the round yarn (monofilament) to model SR-R & DR-R knitting machine. Model SR-R series is Single needle bed Raschel knitting machine which design for making the Round yarn (mono yarn) in all different kind of raw material, for example Nylon, PE, PP etc.

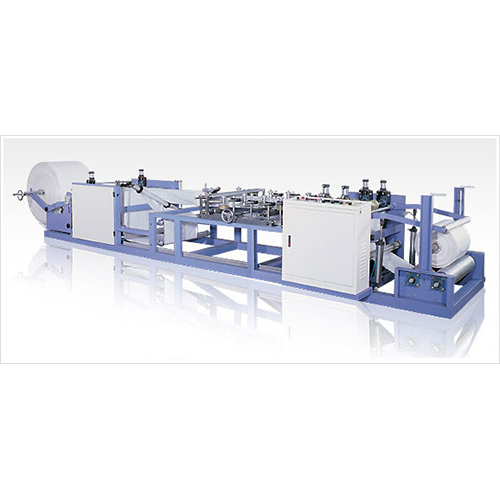

Automatic PP Woven Fabric Tubing Machine

Categories : Woven Bag Making Machines

General Performance: a. Diameter of Unwinding Cloth: 1000 mm Maximum b. Processing Flat Fabric Width: 640 - 1350 mm c. Production Output: Max. 100 Meter / Minute

Semi-Automatic Bag Sewing Machine

Categories : Cutting Machines

● Multi-purpose For Laminated PP Woven Bag, Un-laminated PP Woven Bag, Kraft Paper Bag ● Equipped Sewing Thread Broken Sensor ● Equipped Auto-scissor For Thread Cutting ● Finished Bad Auto-counting & Stack

Automatic PP Woven Bag Cutting Machine

Categories : Cutting Machines

● Equipped Servo Motor For Precise Cutting Lenght (+- 1 mm) ● Equipped High Quality Alloy Steel Cutter ● Equipped Bag Mouth Anti-Stick Device

Reel to Reel Gusset Line TRG-700

Categories : Plastic Bag Making Machines

● Reel to Reel line designed, easy for operation ● Equipped twist device for turn printing position to the central of gusset area

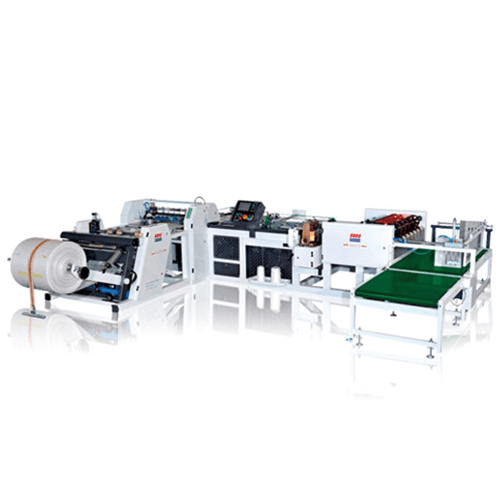

PP Woven Bag Automatic Cutting-Sewing Machine CS-2012

Categories : Cutting Machines

• Equipped Two Servo Motors • Equipped 90゚Bag Transfer Gripper • Display Screen Operation Interface • High Product Output (32-45 Bag / min) • Custom-made designs are available

Jumbo Bag Cutting Machine

Categories : Cutting Machines

● Equipped Servo Motor for precise cutting length (±1%). ● Equipped high quality alloy steel cutter. ● Equipped bag mouth open device. ● Punching Unit for "X" Hole and "O" hole Punch available. ● Custom-made designs are available.

Continuous Extrusion Blow Molding Machine with In Mold Labeling

Categories : Horizontal Blow Molding Machines

This series is a single station extrusion blow molding machine for containers from 50ml to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer requirements.

Pneumatic Extrusion Blow Molding Machine - Rotary Type

Categories : Automatic Blow Molding Machines

This machine is mainly suitable for plastic package with being blow up from side. Such as the plastic bottles for ice lolly, popsicle, or frozen bar. The main character of this machine is its simplicity & stabilization of operation. It has been famous for its excellent performance, low maintenance ratio, less consumption of electricity & low noise.

PET Semi-Auto Stretch Blow Molding Machine

Categories : Automatic Blow Molding Machines

This semi-auto stretch blow molding machine is the most cost effective solution for low level production of bottles, containers, and jars in small to large sizes.

Fully Electric Extrusion Blow Molding Machine - Dual Diehead & Single Station

Categories : Horizontal Blow Molding Machines

Full electric movement, energy saving 15%~40%. Fully Electric Extrusion Blow Molding Machine - Dual Diehead & Single Station

PET Stretch Blow Molding Machine for Wide Mouth / Large Containers

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Suitable for clean lotion, edible oil, detergent, pickle food, etc. Small & Medium Volume Bottles

Continuous Extrusion Blow Molding Machine-Single Station

Categories : Electric Blow Molding Machines

Energy Saving. Using one hybrid servo motor to control all machine actions. Power consumption is less than a general hydraulic machine by 20~45%, easy to reach energy saving and carbon reduction goals. Servo Hydraulic and Electric Power System: Accords actual operation condition to carry on the automatic velocity modulation, reduces the energy loss of auxiliary construction section greatly, and tallies with recent modern energy conserving and environmental protection. Reduces the system response time, and reaches the quality requirement of high accuracy products.

5 Gallon Bottles PET Fully Electric Stretch Blow Molding Machine

Categories : Automatic Blow Molding Machines

CMSQ1 PET all electric stretch blow molding machines are suited for 3 gallon to 5 gallon water bottles.

PET Stretch Blow Molding Machine for up to 600ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

Continuous Extrusion Blow Molding Machine for Small Bottles

Categories : Horizontal Blow Molding Machines

This model is a blow molding machine for high speed production of high quality small bottles. This machine offers PLC control, and linear guide in blowing unit for shorter cycle times and much higher efficiency.

Hybrid Type Extrusion Blow Molding Machine

Categories : Electric Blow Molding Machines

In order to satisfy the purchase demand for power-saving and durable blow molding machine, Chia Ming researches and develops energy saving and practical servo hydraulic electric series (hybrid blow molding machine). It has characteristics of speedy positioning, accuracy and energy saving of the fully electric type, and also keeps the characteristics of high thrust of hydraulic oil structure. Also, the cost is lower than fully electric types while keeping the same characteristics.

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

PET Fully Electric Stretch Blow Molding Machine

Categories : Electric Blow Molding Machines

A handle bottle makes it easier to carry and pour from a container to container. CMS series stretch blow molding machine equipped with a robot device is the choice of making bottle with handle. The container with a firmly fixed rigid polypropylene handle ensures the shape that does not been distorted, and it is currently used for new products, especially for family size packs.