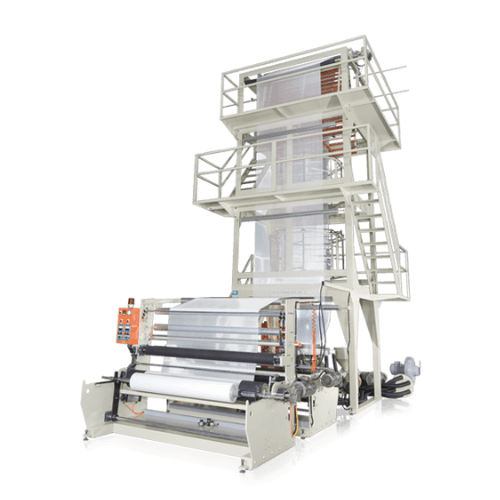

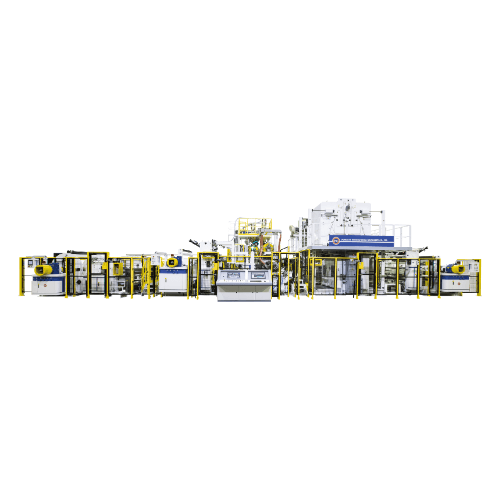

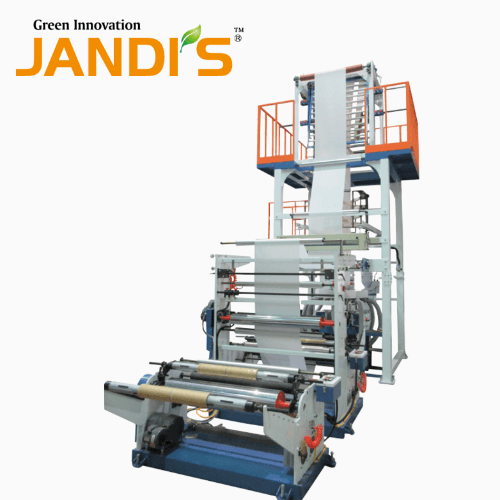

HDPE super high speed blown film line

Categories : Blown Film Extruders

HDPE super high speed blown film line

Water Chiller (YBW)

Categories : Cooling Equipment / Industrial Chillers

Water Chiller (YBW ) Use the latest European, American or Japanese compressor, available in single and double compressors. The compressors of the double-compressor model can either run alone or together. High-efficient shell-pipe condenser which has heat-transmission function can save energy. Well-designed safety protection. It is also equipped with a digital temperature display indicator and abnormal warning indicators for the long lasting. Applied Machinery: oil temperature, ultrasonic ,high frequency machine/injection /extrusion/blow molding machine

Pouch Making Machine For Three Side Seal Bag / Stand-Up Pouch / Zipper Pouch / Four Side Seal Bag-FTSC-V

Categories : Plastic Bag Making Machines

Suitable for sealable co-extrusion films, multi-layer films such as laminates of Polyester,BOPP and CPP... The FTSC-V Pouch Making Machine is ideal for the production of 3-side sealing bag, stand-up pouch, bottom gusseted stand-up pouch, zipper pouch, combined stand-up/zipper pouch, four side seal bag.

Signal Transmitter

Categories : Indicators and Sensors

Others ProductsARICO - The Best Solution Of Others Products ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision Others Products and related application equipment, but also provides high-quality Others Products with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with Others Products, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.

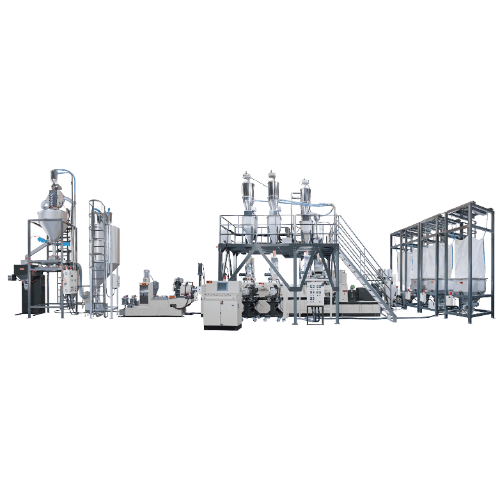

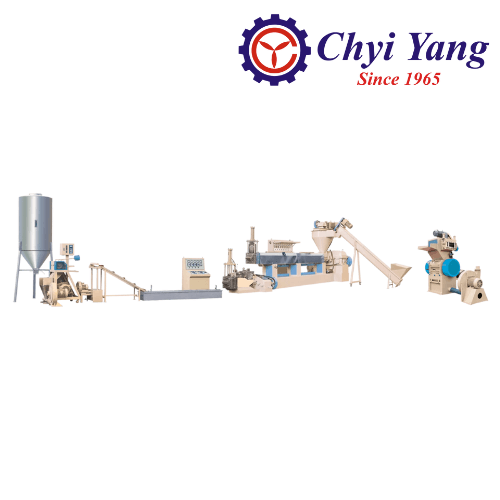

Co-rotating Twin Screw Automatic Metering / Weighing / Conveying Pelletizing Compounding Line | CK-HT

Categories : Twin Screw Extruders

CYKF is committed to the R&D and manufacturing of the automatic extrusion systems, and constantly strives for perfection. The CK-HT series Co-rotating Twin Screw Automatic Metering Weighing and Conveying Pelletizing Compounding Extrusion Line successfully overcomes the problem of customer limited site space and configures the optimal traffic line for customers. The high-efficiency system shows the advantages of safety, convenience, efficiency and quality, reflecting the greatest value of CYKF.

Hydrographic/Water Transfer Film- Wood Grain

Categories : Films

YHT have many different hydro dipping patterns of wood grain include Pine wood , curvy wood, ash burl wood, gold walnut, cherry wood, birdeye, burl wood patterns … different patters suitable for car interior design, aerospace project or any furniture designs.

Three Side Sealing Bag Making Machine(YSW-EM-3)

Categories : Plastic Bag Making Machines

• Servo motor control minimizes length tolerance ensure high efficiency and accuracy. • Using Plugging type IC circuit for easy replacement.

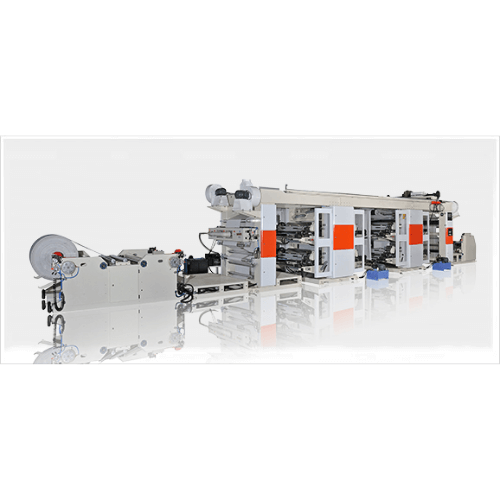

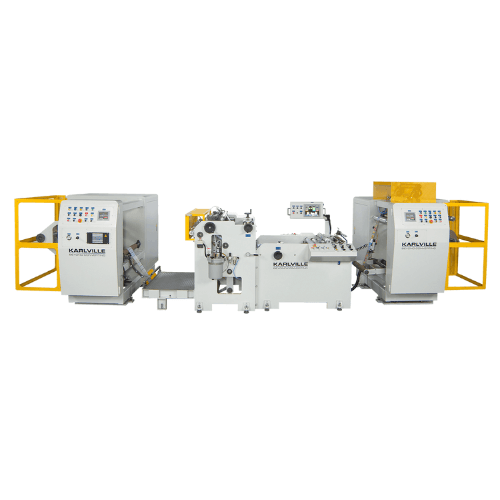

Reel to Reel Printing Line NRP-2012/8C (New Developed Model)

Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to proide 12 colors(each side 6 colors) Reel to Reel Printing Line. Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

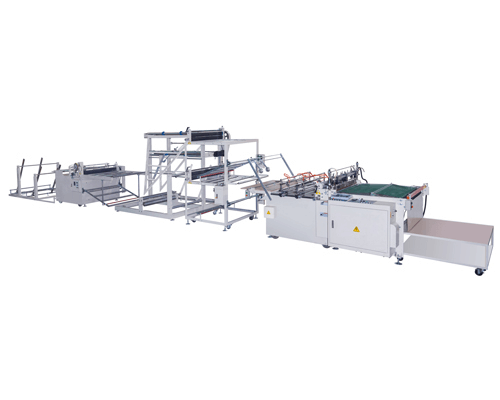

3 Layer Co-Extrusion PE/PP Lamination Machine for Flexible Packaging Film CE Certificate

Categories : Extrusion Lamination Machines

3 Layer Co-Extrusion PE/PP Lamination Machine for Flexible Packaging Film CE Certificate

Tube Filling & Sealing Machine (Heater Type)

Categories : Liquid Packaging Machines

Filling & Sealing Machine (Heater Type) Main motor: 1 HP with inverter. Hopper capacity: 60 L Filling speed: 20~40 pcs/mm Filling capacity: 3~200 gm Tube dia range: Ø19~60 mm Tube length: 50~200 mm Heater: 1.5 kw Power consumption: 2.7 kw Funnel capacity: 70 liters with agitator Rotation type, sealing, date & lot number one time marking. Machine size: 950 x 800 x 2200 mm Total net weight: approx. 1100 kg

Automatic Batch Weighing and Mixing System

Categories : Dosing and Measuring Equipment

Automatically measuring equipment for efficient mix and material processing. Equip with auto conveying system, batching system, mixer, kneader, extruder and steel construction plant. Discharge feeder: scale screw feeder Automatically conveys material to extruder after mixing PC control monitoring system live network Complete installation of pulverizer series

Intermesh Model Dispersion Kneader

Categories : Dispersion Kneaders

Machine application various kinds of glaze, plastics and chemistry industrial mixer mixing and kneading. Occlusal fitting low low temperature mixing material. Special machinery and manufacture due to this machine Machinery reached after designation: Easy dispersibility and uniformity. Easy operation simple operation Easy to change Color change shortening kneading time, super strong heat exchange capacity, achievable B kneading and primary kneading.

Plastic Machine Controllers - AR Series

Categories : Industrial Software

The integrated innovative wise technology with reliable Distributed Control System contains higher performance. Software combined with State-of-art window screen to provide smart and instinct object-oriented editing style hybrid switching with simple and popular PLC ladder program editor. His high-speed Ethernet communication network link-up between Humanity Interface and remote devices to displaying the future one-stop control advantages! It can be broadly applied to automated machinery control, such as injection molding extruder machine controllers and equipment. Arico

ABA Double Die Head

Categories : Extrusion Dies / Dies Heads

The Blown Film Die Head is the core component which is called the ‘‘heart’’ of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted polymer evenly so that the thickness measured around the circumference of the tube being produced is uniform. It is the key factor to ensure a quality film. A well-designed Blown Film Die make the molten polymer travel through the Die Head smoothly without any of the polymer staying inside. A good quality melt means it does not have flow die lines on the surface which could result in defects on the film. A good Blown Film Die Head design incorporates properly constructed flow channels to allow the molten film to flow with the average speed around the circumference. Co-Extrusion Dies are another type of design allowing for speedy production of multilayered films. Co-Extrusion Dies are often used to change the structure of the layers to match the characteristic of polymers. The difference polymers affect the design of Die Head, as well. This also requires Die Head to have a short residence time. Further, the purge or change-over times are not excessive when switching from one polymer to another. HSIN LONG

Car Cowl Cover Injection Molds

Categories : Injection Molds

Mold size: 1200W x 1030L x 950H mm Mold weight: 6600kg Injection machine: 950TON Car Cowl Cover Injection Molds

Plastic Squeeze Dryer (DW Series)

Categories : Plastic Washing Line

Lower moisture, higher capacity A plastic squeeze dryer is a vital part of the plastic film washing line. Washed films retain up to 30% wetness normally. High humidity will be affecting the efficiency and production of the following pelletizing process. Having a plastic squeeze dryer is a must to dehydrate the washed film, reduce the volume of recycled materials, and refine the final plastic pellets' essence. Final moisture less than 1% ↓ after processed. GENIUS

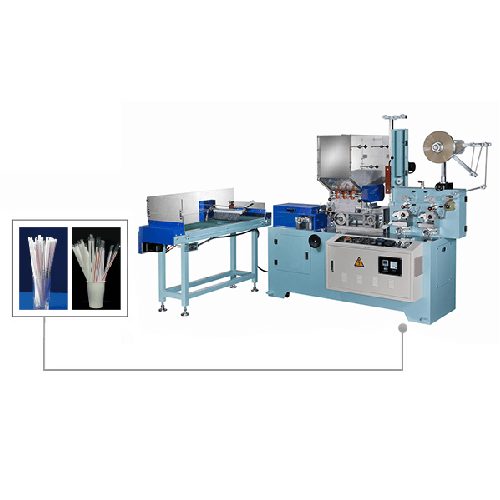

JS 605PW INDIVIDUAL STRAW PACKING MACHINE

Categories : Straw Packaging Machines

HIGH SPEED PRODUCTION : 1000 pcs/min. Ideal for packing a wide varlety of straws, the JUMBO STEEL JS 605PW Straw packing machine provides a high packing rate of 800-1000 pcs/min, and incorporates and automatic, two-color water base ink printing capability. The packing size is fully adjustable with a length range from 190 mm to 260 mm. JUMBO STEEL's Straw packing machine not only makes your straw packing operations easier and more efficlend, but provides you with highly rellable perfromance for year affer year operations. JS 605PW Packing material is OPP or paper, OPP film need to be pre-printed or keep transparent.

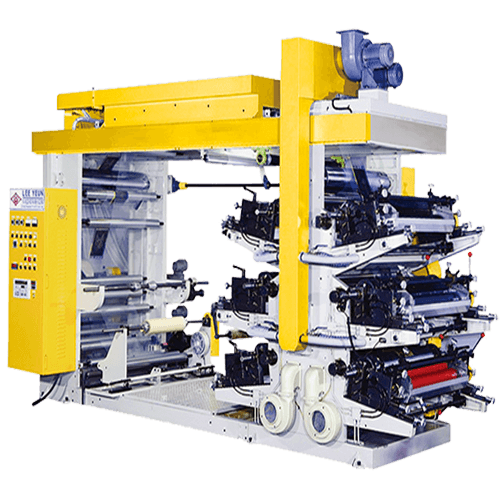

6 Color Offline Type Flexo Printing Machine: FSP-6000 Model

Categories : Flexographic Printing Machines

This is a higher grade flexographic printing machine than ll model, standard equipped with the japan original imported unwinding auto tension controller, and the hydraulic type edge position control (epc) system, double unwind and rewind station, let the operation more efficiency. Films go to the printing station with the banana roller to spread the films much even, and printing station with individually drying pipe providing the printed films for the primary drying, machine with t5 working light keep the working place very bright, upper side with overhead big drying chamber enlarge heating capacities cooperate with the blower ensure the films can be dried accordance with high speed.

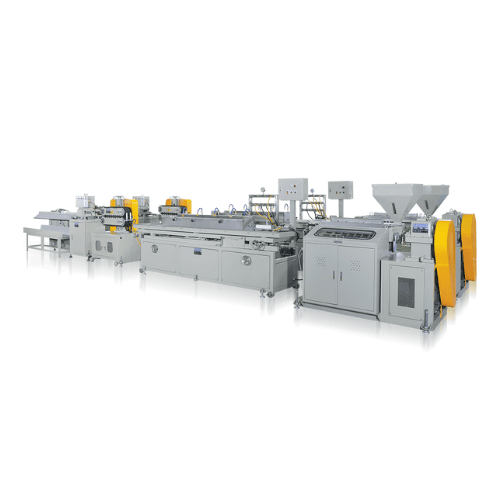

WPC PROFILE EXTRUSION LINE - PE/PP/PS/TPE/PVC

Categories : Extrusion Lines For Pipes and Profiles

The WPC profile extrusion line is a set of machines used in the production of WPC boards. Differences between WPC profile extrusion and general profile extrusion WPC profile extrusion machine is different from general profile extrusion machine, It has to maximize mixing while minimizing damage to the biomass furnish because the WPC material involves two different types of materials: wood and plastic. It is more accurate processing temperature, melt flow index, etc. are required. The same is that general profile extrusion is a process by which various plastic materials are used to develop quality plastic products that have a feature of continuous (ex: plastic board) but do not include sheet or film products. How does WPC profile extrusion line work? The process of WPC profile extrusion begins with the mixing of wood powder and plastic in the mixer. The ratio of wood powder to plastic varies depending on the desired strength and durability of the final product. Once the mixture is blended, it is fed into the conical twin-screw extruder. The extruder has two screws that rotate in opposite directions, pushing the mixture through a barrel and melting it. The molten mixture is then pushed through a die that determines the shape and size of the extruded profile. The extruded profile is then passed through the vacuum calibration table, which cools it and sets its shape. The haul-off machine pulls the profile through the calibration table, maintaining its shape and ensuring its dimensions are correct. The cutting machine cuts the profile to the desired length, and the stacker stacks the finished product. Advantages of WPC profile extrusion line Efficient and consistent production of high-quality WPC profile products. The extrusion process ensures that the final product has a uniform shape and size, with consistent mechanical properties. Highly automated, reducing the risk of human error and increasing efficiency. Cheng-Yu Plastic Machine is a professional WPC profile extrusion line manufacturer As demand for sustainable, eco-friendly products continues to grow, the wood-plastic composite (WPC) market is booming. We develop WPC profile extrusion lines for profile manufacturers who need a reliable, efficient, and high-quality production process. It is a versatile and flexible solution for profile manufacturers in various industries.

LT_Rectilinear Displacement Transducer

Categories : Indicators and Sensors

Reliability in measurement and control applications, even under harsh conditions. Brackets allow installation in most appropriate position. (Injection presses, hydraulic presses, sanders)

Batch-Off Machine

Categories : Dosing and Measuring Equipment

Sheeting For Rubber Industries We will following customer inquiry to add stripping device、collecting device or metal detector, or other special device.

Seaming Machines SEAM-350D-UHS-COMPACT (K5-C)

Categories : Shrink Sleeve Machinery

- Adjustable forming plate - Unwind turret cantilever - Rewind turret cantilever

Rectangular Box

Categories : Containers

Product Number: EG-96 Color: Natural Material: Fiber Shape: Rectangular

WASTE PLASTIC RECLAMATION & PELLET REGENERATING MACHINE (SPAGHETTI TYPE)

Categories : Plastic Pelletizer Machines

Available for dry and wet material, but you need to advise us in advance Simple operation & high capacity Application for PP, HDPE, LDPE, LLDPE, PS etc. Double extruder is used for better degasification Forced feeding for film We didn’t show all our models, please don’t hesitate to contact us for other size of recycling machines.

High Speed 2 Lines Bags on Roll Making Machine with Core Changing Device by Servo Motor Control Model: CW-800PR-SV

Categories : Plastic Bag Making Machines

High Speed 2 Lines Bags on Roll Making Machine with Core Changing Device by Servo Motor Control Model: CW-800PR-SV

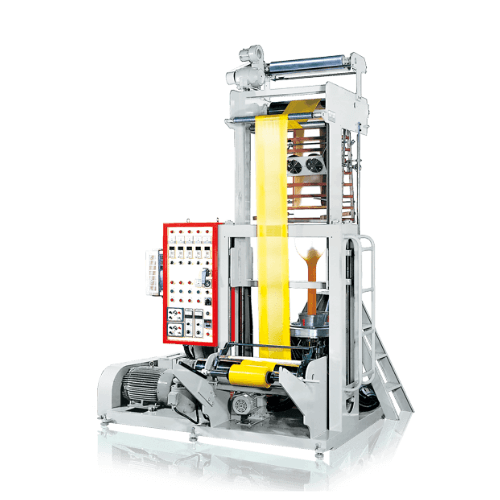

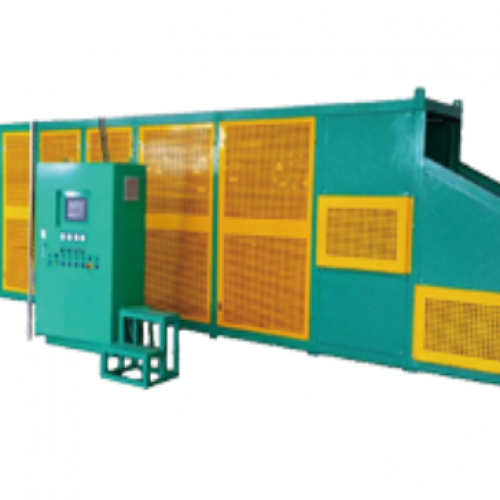

LD/LLDPE High Speed Inflation Machine (GF-L55)

Categories : Blown Film Extruders

LD/LLDPE High Speed Inflation Machine (GF-L55)

Crushing, Washing And Drying Whole Plant Facility For Plastic Scrap

Categories : Plastic Crushers

Suitable for washed plastic scraps Good at water removal. The residual moisture after drying could be around 1-3%. Whole set of electric facility are with automatic startup to protect wires in safe. You can opt to have 3 water tank, depending on how dirty material is.

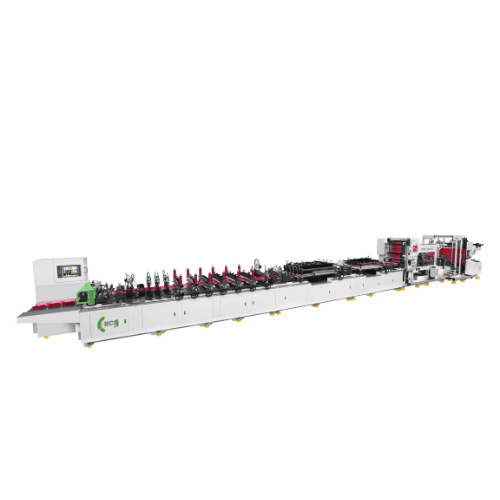

Quotation Business Folder Making Machine

Categories : Bag Making Machine by Applications

MGA-41C-600

Servo Motor Driven Bottom Sealing Bag Making Machine with Free Position Pouch Device

Categories : Plastic Bag Making Machines

Servo Motor Driven, Efficient mechanical structure produce 120 bags per minute. Equip with Front Thick Bags Sealing Device, will able to produce any long length of bags.