Micro Dehumidifying Dryer (DHM-SL )

Categories : Dryers and Dehumidifiers For Plastic Materials

The latest micro dehumidifying dryer uses compressed air to dry the plastic resin. The air volume generated by the air compressor is suitable for the production of small parts, such as electronics parts. The perfect grade of dryness coupled with a moderate amount of drying air, the production efficiency greatly increased. Air compressor process the air via water filtration, and the air will be compressed between pressure 5~7kg/cm² . The compressed air will then go through the molecular sieve and supply the dry air with dew point up to -40 ~ -50 ℃. During the molding process, it will fully demonstrate the perfect plastic properties. In accordance with the different types of plastic, the drying time required is also slightly different, for 2 to 6 hours. The multi-function design can dry, dehumidify, and automatically convey resins. Comparing to the regular dehumidifying dryer, it can save space and directly connect to the inlet of molding machine. It can directly convey the drying resins to production to prevent resurgence and to ensure the production complete. 1. Display the dew point detection 2. Insufficient air pressure detection 3. Built-in positive pressure conveying system 4. Overheat preventer 5. Weekly timer 6. Install high-density filter 7. With Industry 4.0 features, Ethernet and RS485 can be used to connect with other brands. 8. The controller and main body can be separated or combined to facilitate for space arrangements.

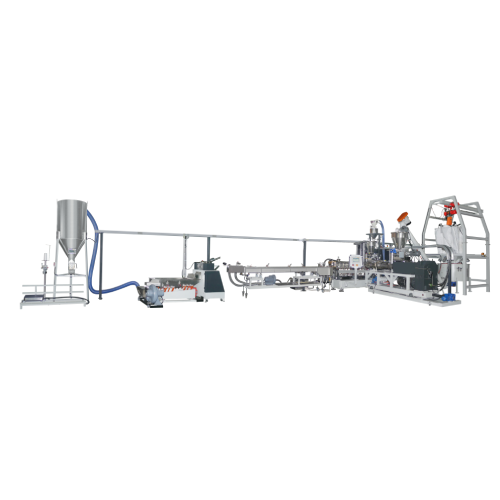

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

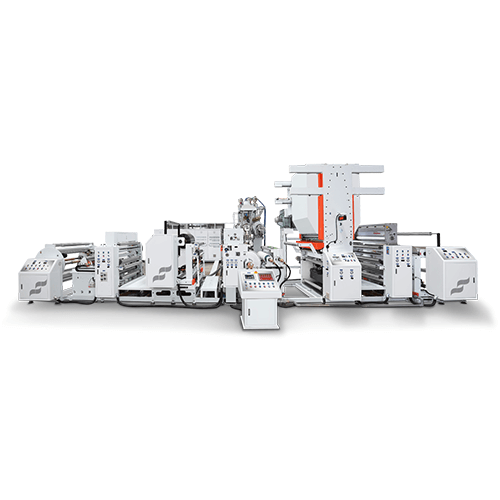

Fully Automatic High Speed Disposable Plastic Gloves Making Machine / SSD-800-HGL(Standard)

Categories : Bag Making Machine by Applications

-Computer control over the entire process -Jumbo film roll to final pruduct ( 2 line output ) , one process flow -Automatically stop when running out of film / film feeding blocks or jam -Automatically tear off the waste edge film -Melting cut-off ( no cutting knife ) system save time and manpower on adjusting knife -Capable to produce 3 types in same machine

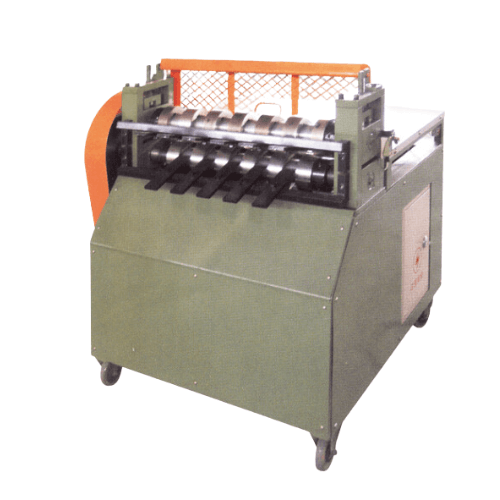

Rubber Slitting Machine - CR Series

Categories : Slitters and Rewinders

Rubber Slitting Machine - CR Series

Dynisco Burst Plugs BP520

Categories : Indicators and Sensors

The Dynisco Model BP520 burst plugs are custom assemblies with pop-top burst indication that are a design option on extruder barrel assemblies. Burst Plugs (also known as rupture disks) are designed for reliable, emergency relief of excess pressure in a system

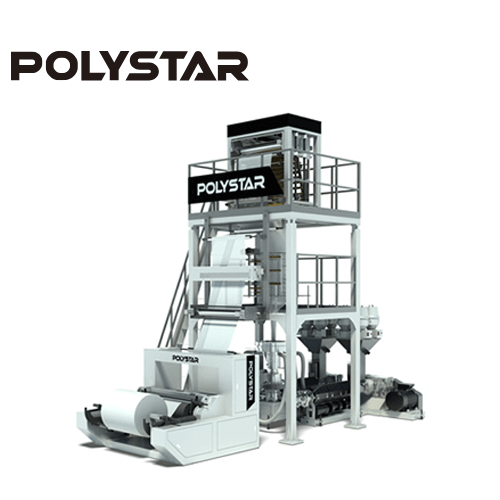

Three Layer ABA Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Film width up 500 to 1500mm(or more) 40mm or 45mm or 55mm or 65mm screw Industrial Packaging

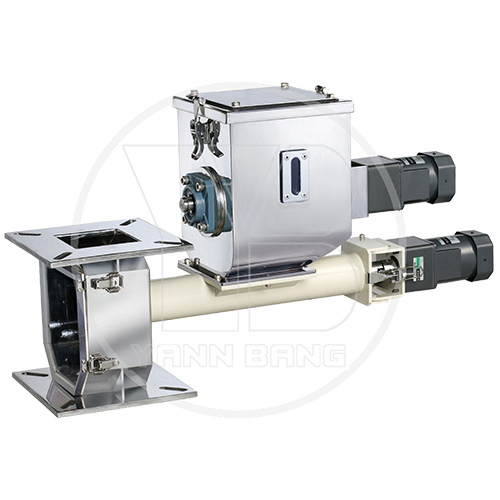

Master-batch Feeder for Powder (MFP)

Categories : Feeders

Easy operation: Enter the weight of the resins, screw back time, dosing capacity per turn and additional rate of the masterbatch, it will calculate proper R.P.M. rate automatically. The function is available to store up to 10 sets of R.P.M. Setting memory. Flexible extension: Each feeder controls and operates individually. It is easy to add extra a feeder or change the type of screw later. A dosing and mixing system of various resins is available for your early inquiry. Precise calculation: With the special process, the internal part of the unit has no dead corners and makes the dosing process more accurate.

Blown Film Machine With Oscillating Haul-Off Unit

Categories : Blown Film Extruders

MONO-LAYER HDPE/LDPE/MLDPE/PP BLOWN FILM MACHINE WITH OSCILLATING HAUL-OFF UNIT extruder 2-LAYER HDPE/LDPE/MLDPE/PP

Single Body Vacuum Oil Hydraulic Compression Molding Machine - FCV Series

Categories : Compression Molding Machines

Automobile & Motorcycle oil seal, valve steam seal, V seal, O-ring etc rubber seal products.. With high efficiency vacuum cover and vacuum system reduce products curing time and liminate inside air bubbles, increase products quality. Interface touch screen operation, every machine fanction can free adjustable, easy operation and understand fully at glance.

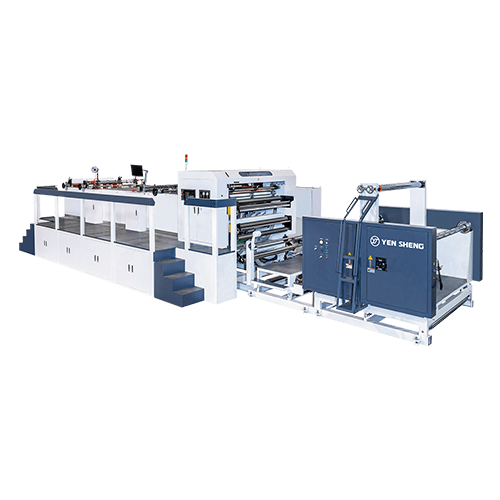

Paper Cutting Machine

Categories : Cutting Machines

● Cutting Tolerance: +-0.5 MM ● Machine Speed: 200 M/MIN

Electronic Vacuum Regulator (0~ -101kpa)

Categories : Indicators and Sensors

Product Serial: KaoLu's QKL-B3V electronic vacuum regulator is a type of inline vacuum regulator (Operating schematic diagram below). One port is connected to a vacuum source, and the other port is connected to a chamber. The precision vacuum regulator works electronically to regulate the highest level of uniform vacuum pressure despite various input conditions. The vacuum level is directly linearly proportional to the electronic command signal to the vacuum pressure controller. When 0-10V corresponds to 0 to (–)14 psig, a 5VDc command signal to the digital vacuum regulator will create a (-)7 psig vacuum pressure. The flow rate of QKL-B3V electronic vacuum regulator valve is 640 L/min. Should a higher flow rate is required, it is possible to couple a volume booster to the negative pressure regulator. QKL-B3V digital vacuum regulator allows user to regulate vacuum level via analog or digital control signal. The regulator is not self-relief, meaning that it does not exhaust excess air to reach target vacuum level. The monitor output is available either as analog output or switch output. QKL-B3V operates in dual solenoid valve principle with a closed loop electronic control. The internal negative pressure transducer monitors the vacuum level and controls the operation of the inlet and the outlet solenoid valve of the vacuum pressure regulator valve. With this special design, QKL-B3V electronic vacuum control regulator can be installed inline in any orientation, offering high flow rate, high accuracy, and high repeatability. Our vacuum pressure controller has the advantage of digital communication, which allows users to calibrate and monitor regulator status remotely. As for ingress protection, QKL-B3V digital vacuum regulator is compliant to IP65, and the M12 cable connection allows user to easily install and dismount from inline operation. QKL-B3V electronic vacuum regulator has been used in applications such as thermoforming, leak testing, tube extrusion, and tank blanketing. In order to control the both inlet and outlet pressure that allows massive air pressure into and out of the system, the user can utilize the vacuum flow regulator. Please consult our factory for further information. KaoLu also offers other types of vacuum regulator to control vacuum level in a chamber. Please refer to our FC series vacuum breaker applications. https://www.genndih.com/proportional-flow-control-valve.htm

Fully Automatic Tube Inspection Machine BIM 120-02

Categories : Inspection Machines

1. High-speed detection and defect removal; 2. Easy operation, fast learning modes, simple setup for defect monitoring system. 3. Accurate, real-time, and reliable data feedback: 4. Reduces labor costs: 5. Eliminates human detection errors:

Proportional Valve (PV)

Categories : Separators

The unique air valve structure design stops dust from entering the cylinder of the unit and thus reduces waste. Can mix or feed one kind of resin only if required. The controller is fitted with digital readout (PV-A-D Series) and setting for the mixing cycles which gives a high rate of accuracy. It is easy to set and be set in the range of 0-9.9 seconds. Transparent cleaning cover design for quick cleaning and easy changing materials. Individual controller for convenient operation.

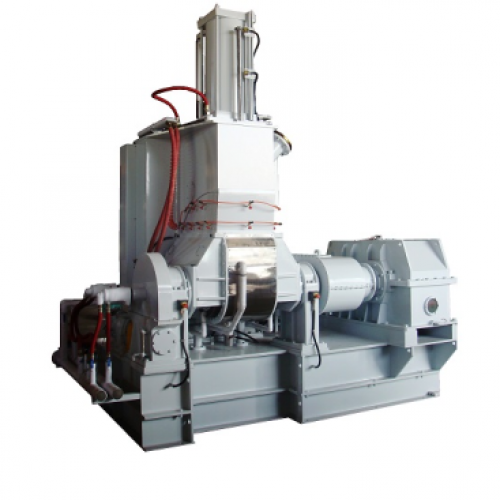

Super Cooling Dispersion Kneader

Categories : Dispersion Kneaders

This machine most suitable kneading application for all kind Rubber, Plastic and Chemical materials. This machine with following features: High quality processed products ╱ Easy for operating ╱ Easy for color changing╱Extra big rotor jacket for super Cooling ability╱Low temperature mixing╱One pass mixing.

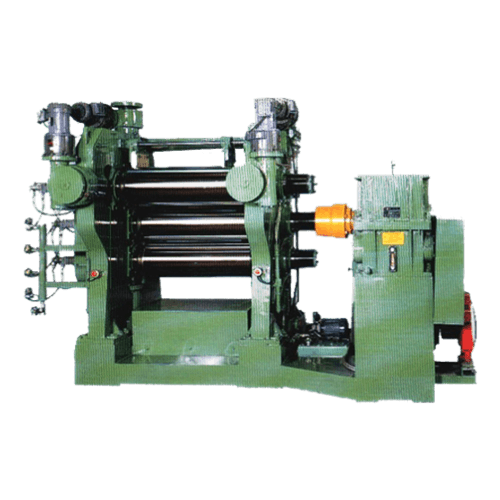

Calender for Rubber/Plastic

Categories : Calendering Machines / Mixing Mills

Sheeting for Rubber、Plastic & Chemical Industries This machine is used for sheeting produce for Rubber, E.V.A. or PVC and various kinds chemical material.

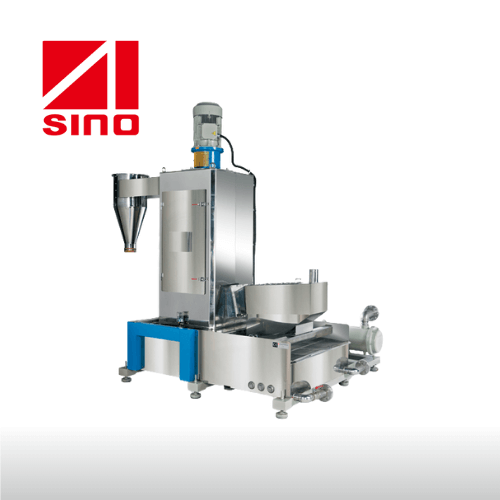

Centrifugal Dryer-PSL

The PSL series centrifugal dryer was developed by Sino-Alloy Machinery as an important and essential accessory for both the PSF series water-ring and PSQ series underwater pelletizers. The PSL series dryers utilize high-speed centrifugal force in combination with forced air flow and evaporation to dry the pellets. Superior performance over vibrating dryers in terms of drying efficiency, throughput, space-saving, and noise level. The PSL series centrifugal dryer can also be a great replacement for that old vibrating dryer.

Hot Air Filling & Sealing Machine

Categories : Liquid Packaging Machines

●Monitor screen for easy operation. ●Imported hot air patent can make sealing fast and blazonry. ●Tubes orientation automatically. ●Cutting tail automatically after sealing. ●No sealing if no tube. ●Tube tail is durable after being sealed.

Washing Machine JK-400T

Categories : Hydrographic / Water transfer Machines

Water Washing Machine Conveyor Type, 10 meters of length. This machine is perfect for those large size products and large volume of production/day. This washing machine is including a water heating system. The model of the same machine without water heating system is YH-400. With 360° water washing by high performance nozzle surrounded, all of residue of films and activator will completely washed away with perfect decoration remained. High daily working output with conveyor speed adjustment and 100% water circulation are all very efficient for your production.

Heating Side Sealing Slitter Rewinder - FSH

Categories : Slitters and Rewinders

For Side Sealing Slitter Operations: Suitable for producing various film rolls for extruded materials, such as HDPE, LDPE, LLDPE, PP, CPP, and etc.. Product thickness range from 0.006 to 0.1 mm. Production speed 20-40 meters per minute in 2-6 lines (Slit width over 40mm). For Regular Slitter Rewinder Operations: Suitable for slitting various materials, such as, cellophane, PET, OPP, CPP, PE, PS, PVC film rolls and printed films.

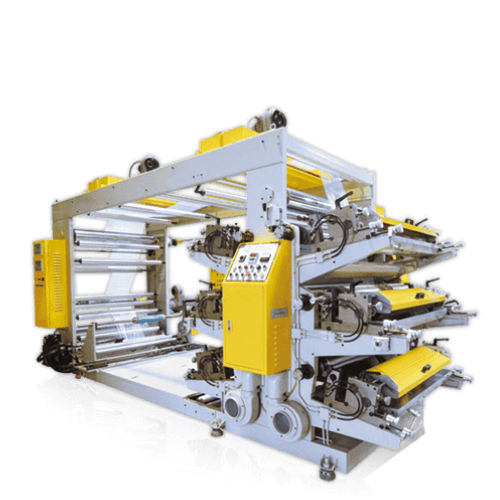

6 Color Reel-to-reel Offline Type Flexo Printing Machine: LL-6000 Model

Categories : Flexographic Printing Machines

The machine is suitable for printing: roller paper, packing paper, cellophane, fiber glass web, tubular films, PP woven sack and PP/LOPE/LLDPE/HDPE/BOPP poly bags. Require small space, easy operation and maintenance; man power and cost saving. Used with either solvent or water base flexo-printing ink only. The photo polymer plate or rubber plate with 2.50 mm in thickness is a first priority, other size is available by request. The printing plate cylinder is controlled by pneumatic system; easy operation and high accuracy, there will be no defect while starting or stopping the machine on the color fixing. Have a counter device to control production Q'TY, which is reached the presetting numerical then the machine will be stop working at the same time. When printing roller stop working, the rubber roller and screen anilox roller will be continuous running to avoid drying of printing ink on such rollers. The hot air fan and blower with respective heaters are mounted on the machine. For ink drying to increase production speed. The heater and fan will take off automatically when the blower stop working. Let this machine keep in safety position.