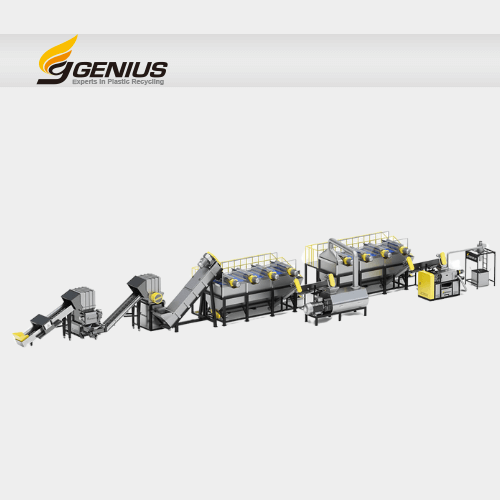

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Crushing, Washing And Drying Whole Plant Facility For Plastic Film

Categories : Plastic Crushers

Suitable for different kind of plastic materials, e.g. plastic scrap and plastic shampoo bottle. Suitable for different kind of plastic materials, are able to separate high density and dirty material. With high speed washing machine, enable plastic materials inside the machine to be twisted, separated high density and dirty material and washed it for further use. Whole set of electric facility are with automatic startup to protect wires in safe. Optional Equipment: GEORDING unique design Vertical dryer & Centrifugal dryer. With Centrifugal Dryer, single screw rubbing drying machine can separate mud/dust, and dry material efficitently, making the product 3% under moisture. You can opt to have 3 water tanks, depending on how dirty material is. Customize GEORDING could help customer build and modify according to individual specifications.

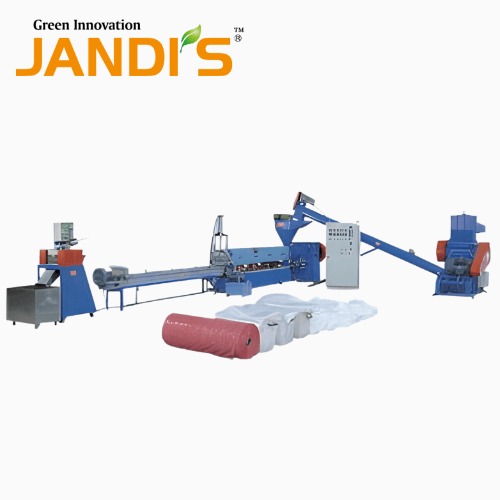

Water Cooling Type Plastic Film Recycling Machine (GSR-100)

Categories : Plastic Waste Recycling Machines

Water-cooled plastic film recycling machine GSR-100

Film Washing Line

Categories : Plastic Crushers

Solution for different level of plastic films The film washing line equipped crushing, washing and drying units. Which allowing to process different dirty levels of materials, from agriculture films, land-filled waste film to industrial stretch warp films. The washed films been feed into a squeeze dryer to remove the moisture. GENIUS

Plastic Squeeze Dryer (DW Series)

Categories : Plastic Washing Line

Lower moisture, higher capacity A plastic squeeze dryer is a vital part of the plastic film washing line. Washed films retain up to 30% wetness normally. High humidity will be affecting the efficiency and production of the following pelletizing process. Having a plastic squeeze dryer is a must to dehydrate the washed film, reduce the volume of recycled materials, and refine the final plastic pellets' essence. Final moisture less than 1% ↓ after processed. GENIUS

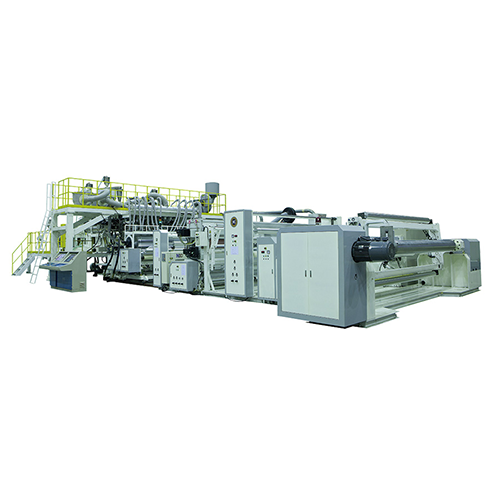

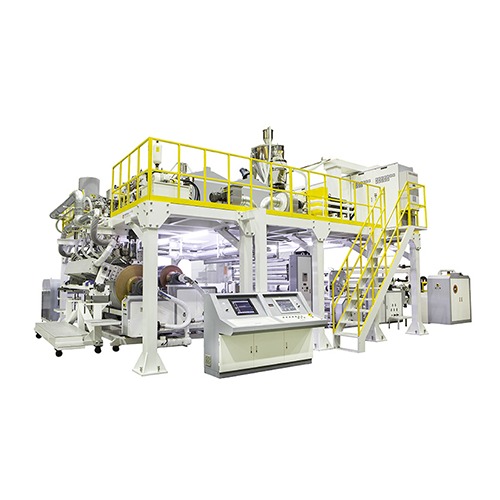

Automatic Cast PE Breathable Film Line

Categories : Film and Sheet Extrusion Lines

This machine is using 2.7M wide Automatic T-die from Cloeren, USA, with Automatic thickness Gauging System from NDC, USA. This machine has been designed to be a complete automatic machine and easy operation.

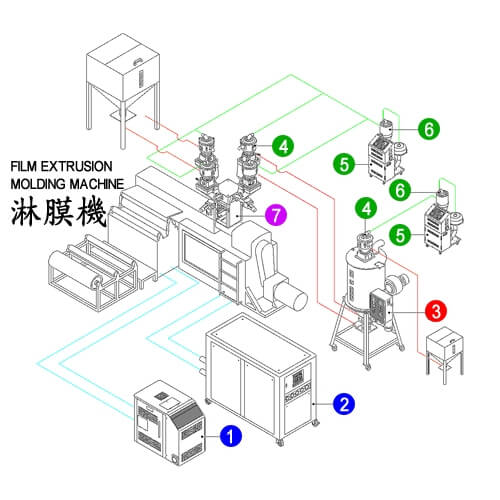

Film Extrusion Molding Machine Auxiliary Solutions

Categories : Assembly Systems

We have a wide range of auxiliary equipment for film extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

Taper Twin-Screw Sheet Preforming Machine

Categories : Film and Sheet Extrusion Lines

Sheet Pre-forming for Rubber, Plastic & Chemical Industries This new model TAPER TWIN-SCREW SHEETS PREFORMING MACHINE usage for the rubber compound mixing after DISPERSION KNEADER conveying to the hopper of this machine to go extruding and rolling for sheet. This machine not only simply to operate but also upgrading the work efficiency, and may go with the mixer to do the integrated production

Three Layer Co-Extrusion Cast Film Line

Categories : Film and Sheet Extrusion Lines

Three Layer Co-Extrusion Cast Film Line

3 Layer Co-Extrusion Cast Film Line

Categories : Film and Sheet Extrusion Lines

3 Layer Co-Extrusion Cast Film Line

Three Layer Co-Extrusion Cast Film Line

Categories : Film and Sheet Extrusion Lines

Three Layer Co-Extrusion Cast Film Line

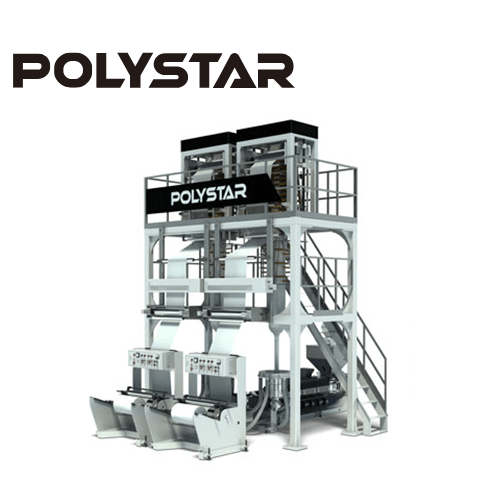

One Layer Twin Head Blown Film Machine

Categories : Blown Film Extruders

High speed for T-shirt bag conversion For film width 100~800mm Extruder dia. 45mm, 55mm or 75mm