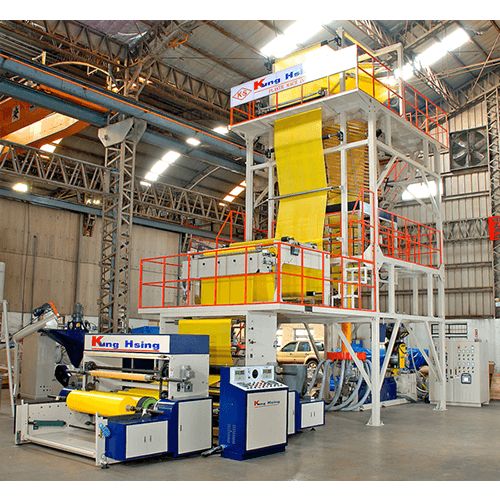

HDPE SINGLE HEAD TYPE HIGH SPEED BLOWN FILM LINE FOR JUMBO BAG

Categories : Blown Film Extruders

HDPE SUPER HIGH SPEED BLOWN FILM LINE, KS – FE80B EQUIP WITH GRAVIMETRIC DOSING UNIT BYDOTECO, ITALY. HORIZONTAL TYPE OSCILLATION TAKE – UP UNIT.

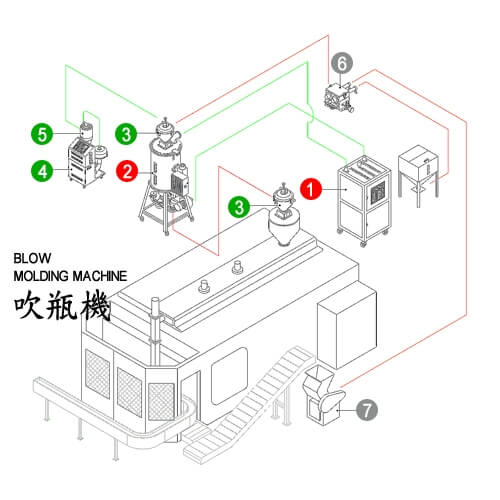

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Extrusion Blow Molding Machines

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

Knife-Cutting Bag Making Machine (GF-A812E-SV+C)

Categories : Cutting Machines

MODEL GF-24SE/SV GF-S600/SV GF-32SE/SV GF-S800/SV GF-40SE/SV GF-S1000/SV GF-50SE/SV GF-S1200/SV CUTTING WIDTH 600 mm 800 mm 1000 mm 1200 mm CUTTING LENGTH 800 mm FILM THICKNESS 0.01 - 0.1 mm PRODUCTION SE model : Max. 200 Cycles/Min ; S model : Max. 150 Cycles/Min REAR FEEDER 1 SET WITH GUSSET / FOLD / SLITTER / ADHESIVE TAPE APPLICATOR CONTROL PANEL 1 SET WITH HMI CONTROL SERVO DRIVE 1 SET, YASKAWA/JAPANL PRINTING SCANNE 1 SET, SICK/GERMANY CONVEYING BELT 1 SET COLLECTING TABLE 1 SET OPTIONS TENSION CONTROL, EPC, TRIANGLE FOLDING DEVICE, PUNCH HOLE DEVICE, MEXICAN HAT PUNCH DEVICE, ULTRASONIC SEALING DEVICE, PERFORATING SEALING KNIFE ENVELOP PUNCHING MOLD, AUTOMATIC STACKING TABLE glove making machine plastic gloves making machine

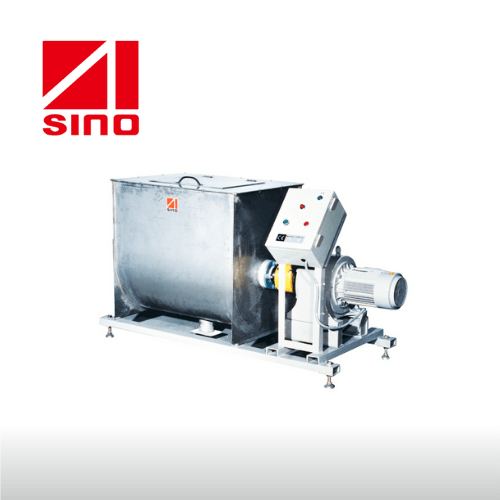

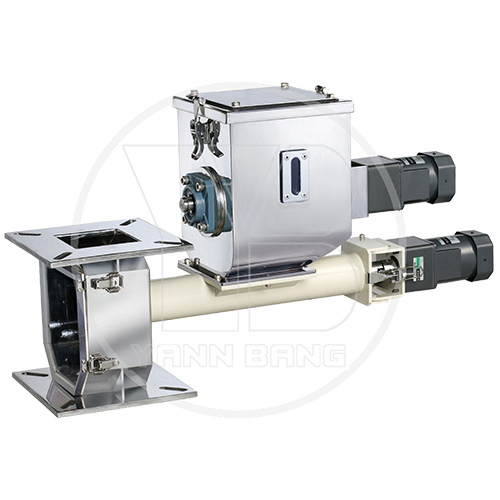

Low-Speed Mixer-PSE

Categories : Mixers and Blenders

The PSE low-speed mixer is a frequently used accessory for the PSM series co-rotating twin-screw extruder. Raw material does not heat up in the mixer which is beneficial to its stability. After the premix stage the material can be fed to the extruder via one of our PSA single-screw feeders, PSB twin-screw feeders, PSC twin-screw side feeders, or the PSD single-screw force feeder. Also compatible with feeders from other manufacturers or gravimetric loss-in-weight feeding systems.

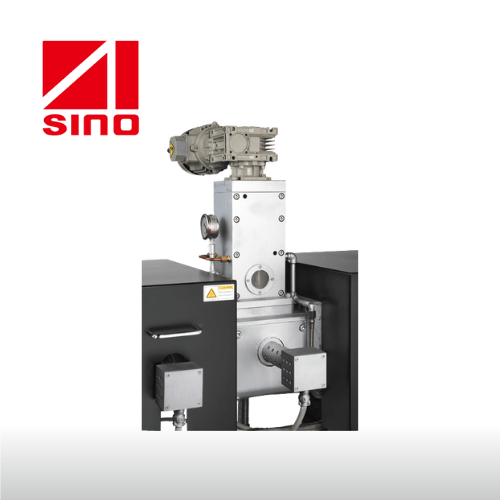

Anti-Leakage Vacuum-PSY

Categories : Valves

The PSY anti-overflow vacuum was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Developed to prevent extruded material overflow from the vacuum vent during degassing and subsequent vacuum failure. The PSY anti-overflow vacuum is driven by a pair of vertical intermeshed screws to move overflow material back to the material barrel while degassing with the vacuum. Can also be installed on side feeders to prevent overflow.

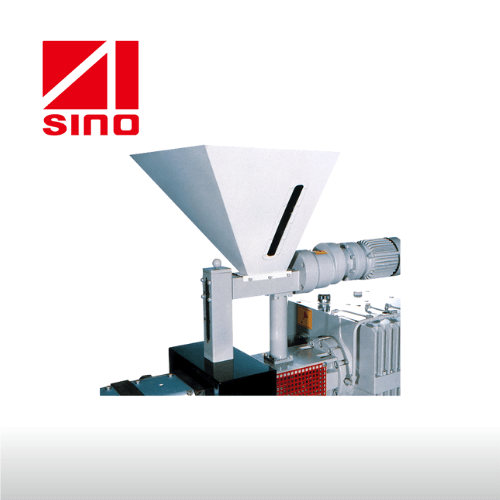

Twin Screw Side Feeder-PSC

Categories : Dosing and Measuring Equipment

The PSC series twin-screw side feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSC twin-screw side feeder has a large feeding screw chamber for a smooth flow of the feeding material. The intermeshed type twin-screw has a self-cleaning feature with powerful displacement force, high feed volume, stable feeding, and excellent aeration properties, making it suitable for moist, low coefficient of friction powders and mixed types of plastics which require forced side feeding. Sino-Alloy Machinery can also tailor the design of a PSC twin-screw side feeder to match extruders from other manufacturers. Customers can also specify options such as preheating or cooling to suit production needs.

Master-batch Feeder for Powder (MFP)

Categories : Feeders

Easy operation: Enter the weight of the resins, screw back time, dosing capacity per turn and additional rate of the masterbatch, it will calculate proper R.P.M. rate automatically. The function is available to store up to 10 sets of R.P.M. Setting memory. Flexible extension: Each feeder controls and operates individually. It is easy to add extra a feeder or change the type of screw later. A dosing and mixing system of various resins is available for your early inquiry. Precise calculation: With the special process, the internal part of the unit has no dead corners and makes the dosing process more accurate.

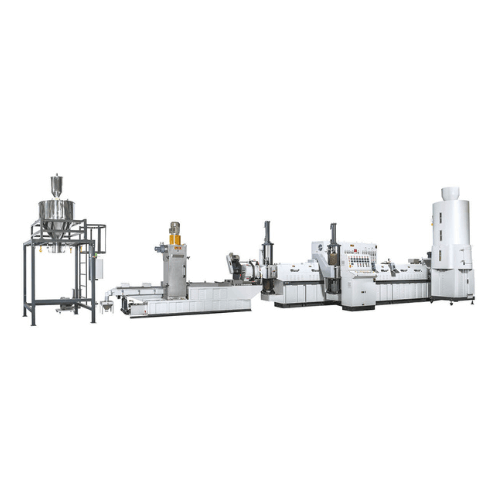

Side Force Feeder Type Double Section Recycling Pelletizing Extrusion Line | CK-SFD

Categories : Plastic Pelletizer Machines

CK-SFD series Side Force Feeder Type Plastic Recycling Pelletizing Line is ideal for recycling dirty plastic crushed films. Possible materials : EPE, EPP, EPS, PP, HDPE, LDPE, ABS, PS crushed films or flakes.

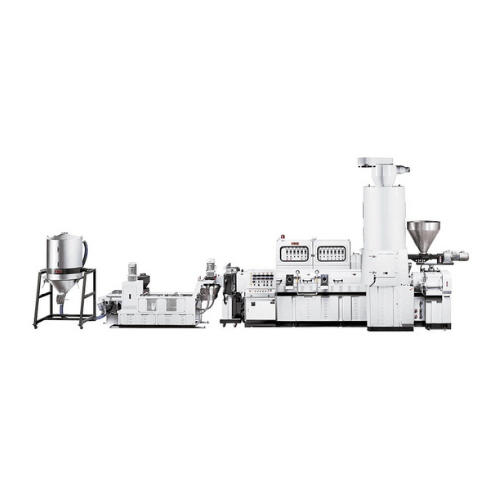

Side Force Feeder Type Recycling Pelletizing Extrusion Line | CK-SF

Categories : Plastic Pelletizer Machines

CK-SF series Side Force Feeder Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic crushed films. Possible materials : EPE, EPP, EPS, PP, HDPE, LDPE, ABS, PS crushed films.

Twin Screw Feeder-PSB

Categories : Feeders

The PSB series twin-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSB twin-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Screw options include intermeshed, T-type, and single-flight screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. The deeper and wider groove from a single-flight conveyor, T-type, or non-intermeshed screw is more suited for particulate, flake, fiber, or powder feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

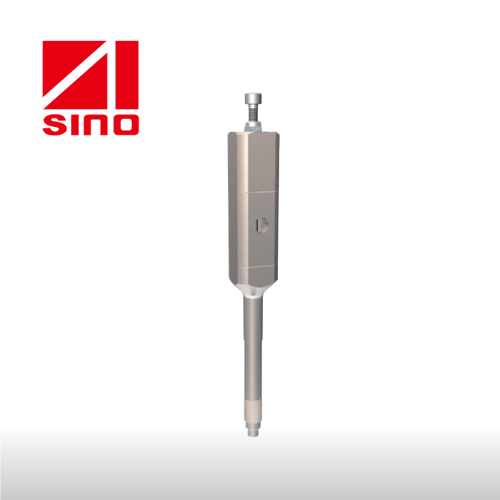

High Pressure Liquid Injector-PSX

The PSX high-pressure liquid injector was developed by Sino-Alloy Machinery as an important accessory to their extruder line. The PSX high-pressure liquid injector is made up of a storage tank, proprietary precision plunger pump, and one-way valve type fluid injector. It can generate pressures as high as 50 kg/cm. This feeder can be connected to any feeding port of the extruder. The PSX high-pressure liquid injector is also capable of injecting high pressure gases or super-fluid liquids. Not only is it suitable for the injection of liquid and gaseous additives in rubber or plastics materials, but also for may plastic and rubber reactive processes or the injection of liquid ingredients in food and pharmaceutical. The PSX high-pressure liquid injector can also be supplied with heating and insulation devices, loss-in-weight metering devices, or flow controllers for precise measurements of the input quantity.

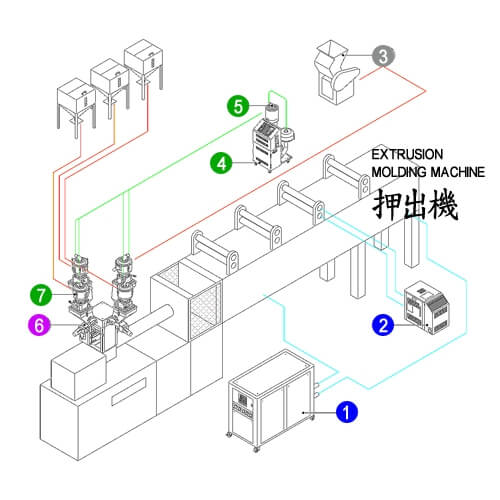

Extrusion Molding Machine Plastic Auxiliary Solutions

Categories : Assembly Systems

We are capable of offerring a wide range of auxiliary equipment specificaly for extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place