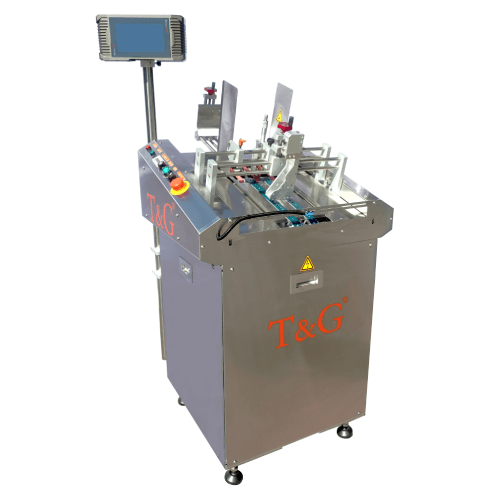

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS FLUSHING

Categories : Vacuum Packaging Machines

Automatic Tray Sealer with Vacuum and Gas Flushing from Jaw Feng Machinery Co., Ltd. is made of stainless steel. Outdoor security vacuum cover. When electrical box is opened, it will shut down immediately. Can use multiple die sets and easy to change over, Multi-lingual PLC touch screen with a movable arm. Operate 360°. Every functions on the screen are presented in narrative, simple to understand. Vacuum / nitrogen, vacuum / skin pack, and sealed packaging. Offering lots of models to meet different sizes of trays. Able to work with date injecting, date thermal printing, labeling, aligner feeder, etc.

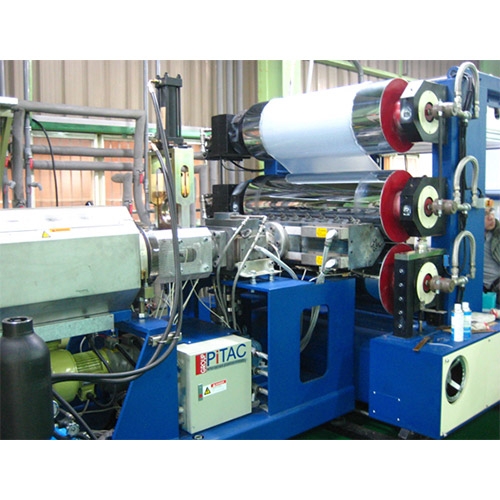

Rigid Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

1. Extruder is driven by AC Inverter duty motor, with excellent efficiency and lowest power consumption. 2. Extruder hopper with low-level sensor work with auto-feeder will keep material in stable supply. 3. Hydraulic driven screen changer avoid any particle goes to melting pump & flat-die. 4. Melting pump with accurate rotation control, keeps the material flow stable. 5. Extruder & melting pump speed is working on pressure synchronized controlling system.

Automatic Feeding And Partitioning Machine AFC-700

Categories : Cutting Machines

Special feeder mechanism will not cause scrape or daamge to materials, to ensure 100% productivity of stisfactory products. Feed length and feed speed can be programmed to suit different properties of materials, so it has high flexibility in production. Simple and easy operation interface with touch-control monitor to expedite personnel training. Automatic recoiling mechanism, with the design of electronic control, to enable one-man one-machine operation. Feeder with servo control to ensure accurate feeding dimensions, and take precise control of material costs.

All Electric / Hybrid Extrusion Blow Molding PK-e / Hybrid Series

Categories : Extrusion Blow Molding Machines

Single/Double Station Single/Double/Triple/Quadruple..8 Head Production volume:2ml~35L Multi layers: Co-Extrusion 1-6 layers Multi cavities: 1~8 cavities Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material Special function:View stripe Clamping system:Ultra locking system/Toggle/Tie bar Driven model: Precision servo gearmotor/Hybrid servo motor drive system/High performance hydraulic power saving system/ close loop proportional valve Support full electric/Full hydraulic parison controller/Auto deflashing/Atuo recycling/Auto material feeder/Remote trouble shooting function/IML

SINGLE INJECTION MOLD

Categories : Injection Molds

Single Injection Molding is a standard process that YOMURA TECHNOLOGIES excels at. Our YangMei plant is equipped with a resin feeder system to increase yield rates for mass volume production. Material: TPR , PC, PC/ABS, ABS ADVANTAGES: Works with Complex Designs Has the Advantages of Both Plastic & Rubber Flexible & Soft Touch

KF3B

Categories : Industrial Knitting Machines

Fabric technology: StayFleece Why it’s popular: Unlike other fleece fabrics, StayFleece is uniquly shrink-resistant. Gauge: 14G - 28G Diameter: 13" - 48" Feeders/inch: 3

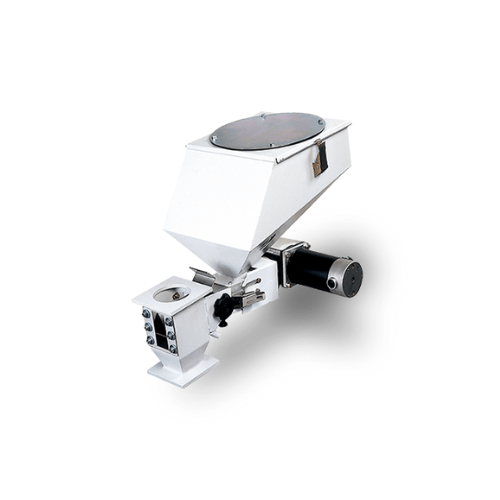

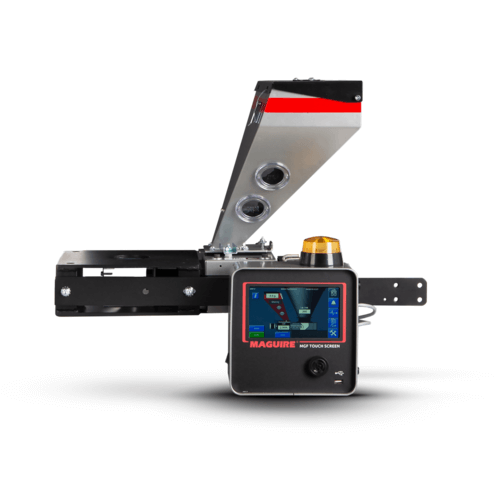

MGF Gravimetric Feeders

Categories : Dosing and Measuring Equipment

Robust hardware, integrated with industry-leading software control to achieve repeatable consistent dosing accuracy. Unique twin load cell technology Dosing accuracy ± 0.2% on 1% setting Feeder ideal for all molding and extrusion processes

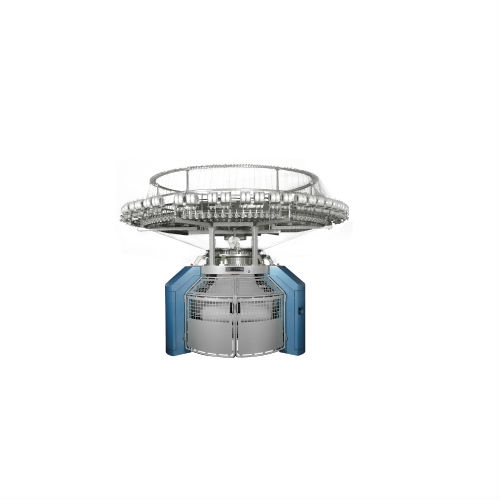

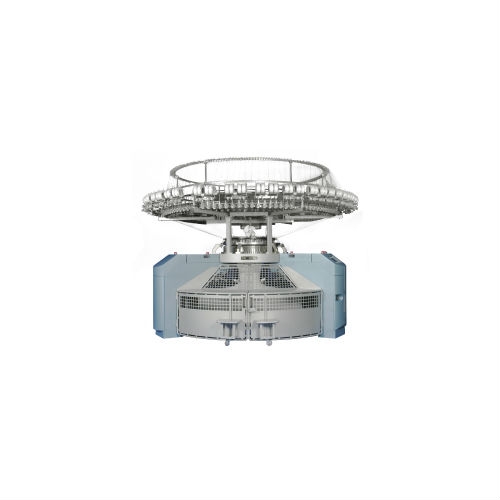

KS3B

Categories : Industrial Knitting Machines

Fabric Technology: single Jersey Why it’s popular: Our most versatile and productive single jersey. Gauge: 10G - 52G Diameter: 3" - 64" Feeders/inch: 3