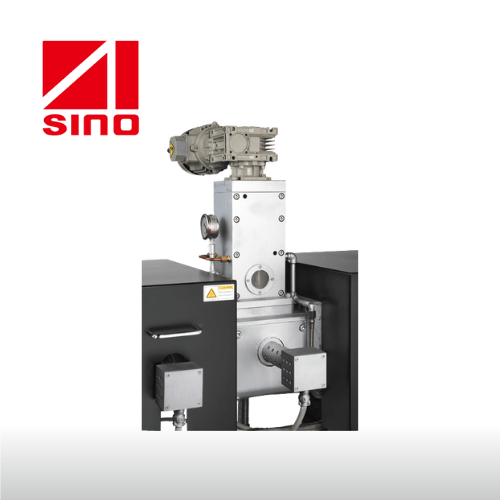

Anti-Leakage Vacuum-PSY

Categories : Valves

The PSY anti-overflow vacuum was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Developed to prevent extruded material overflow from the vacuum vent during degassing and subsequent vacuum failure. The PSY anti-overflow vacuum is driven by a pair of vertical intermeshed screws to move overflow material back to the material barrel while degassing with the vacuum. Can also be installed on side feeders to prevent overflow.

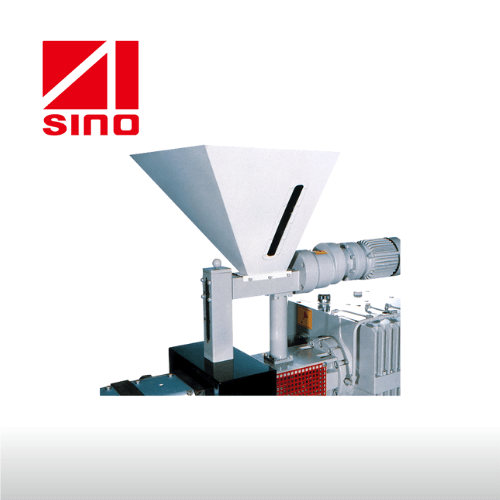

Twin Screw Feeder-PSB

Categories : Feeders

The PSB series twin-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSB twin-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Screw options include intermeshed, T-type, and single-flight screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. The deeper and wider groove from a single-flight conveyor, T-type, or non-intermeshed screw is more suited for particulate, flake, fiber, or powder feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

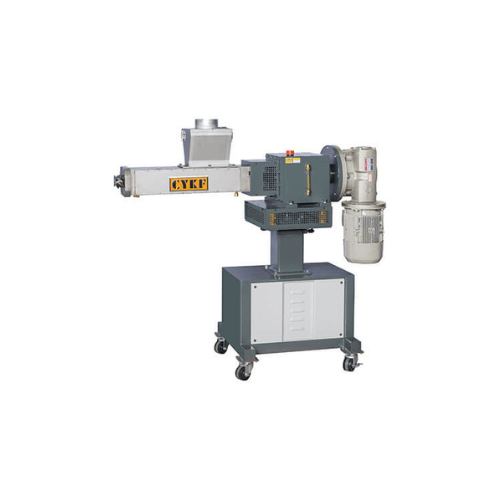

Side Feeder / Side Feeder Twin Screw

Categories : Feeders

CYKF developed its own twin screw side feeder to enable the feeding of additives and fillers, such as glass fiber, CaCO3, TiO2, Talc, fire retardant, etc. Materials in powder or pellet are all acceptable. Our rich experiences in plastic extrusion help us catch the critical design points to satisfy different production requirements.

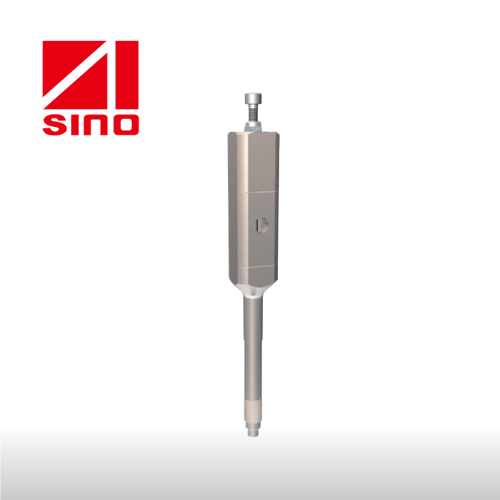

High Pressure Liquid Injector-PSX

The PSX high-pressure liquid injector was developed by Sino-Alloy Machinery as an important accessory to their extruder line. The PSX high-pressure liquid injector is made up of a storage tank, proprietary precision plunger pump, and one-way valve type fluid injector. It can generate pressures as high as 50 kg/cm. This feeder can be connected to any feeding port of the extruder. The PSX high-pressure liquid injector is also capable of injecting high pressure gases or super-fluid liquids. Not only is it suitable for the injection of liquid and gaseous additives in rubber or plastics materials, but also for may plastic and rubber reactive processes or the injection of liquid ingredients in food and pharmaceutical. The PSX high-pressure liquid injector can also be supplied with heating and insulation devices, loss-in-weight metering devices, or flow controllers for precise measurements of the input quantity.

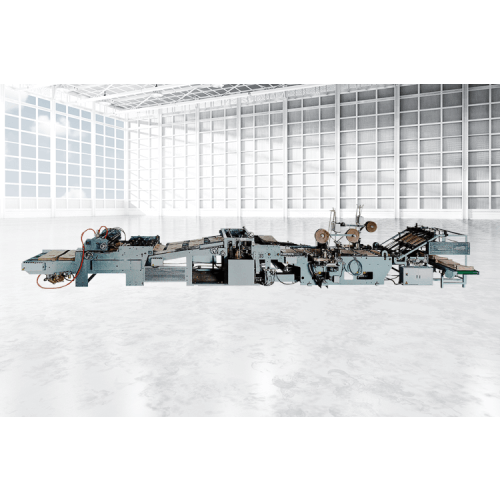

Automatic Valve Forming and Double Head Sewing Machine

Categories : Paper Bag Making Machines

The machine includes the bag feeder unit, valve former, double head sewing machine and counting conveyor for processing the tube made from multi-wall PP paper bag making machine to form a bottom sewn ready bag.

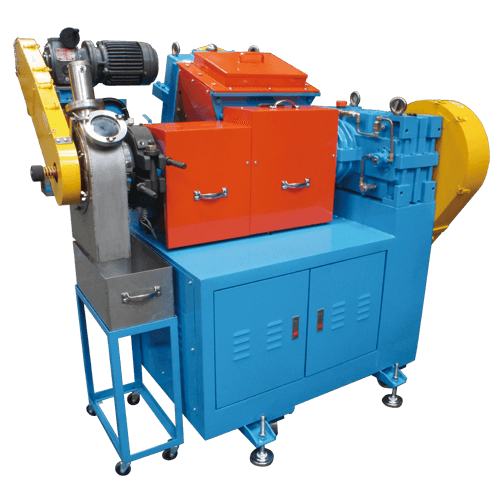

LAB EXTRUDER-Pelletizer (PR-50)

Categories : Plastic Pelletizer Machines

One of our main products, this can be attached to numerous different machinery lines, including pelletizing lines, master batch machines and compounding machines. Our machinery can process many different kinds of pellets including: (EVA, HDPE, PVC, PE, CaCo3 Sulfur etc) The PR-series is a combination of twin-screw feeder and extruder, which is able to process a round mass of raw materials produced by a banbury mixer. This twin-screw design feeds raw materials so stably that it’d decrease the risk of material supply shortage, and further, it’d increase both the yield rate and product quality. Besides, it would create a stable production line by reducing your labor cost and time with this unique design.

PRECISION HYDRAULIC AUTOMATIC DIE-CUTTING MACHINE/4COLUMU TYPE CSS-603

Categories : Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance. 4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders. The unit performs precisely, stably, quietly, nimble and powerful. lt'sconvenient even for the use at the upstairs of a factory. Cutting depth can be precisely set up to a tolerance of 0.008 mm. Through the use of the longwearing special designed steel plate to replace conventional cutting board, can prolong lift of cutter and obtain better cutting quality and efficiency Processed item may be full or half cut-off. ltems with adhesive may be used as well Products are free from rough edges. The machine is equipped with a protecting device to ensure safety of people and the machine. Automatic cooling system and full-auto cutting device are available for additionally purchase and fitting. Designed in high-precision construction, this machine can be used to perform full-cut and half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with linear rail designed for the feeding mechanism. Two-step pressure control to achieve flexible and lower noise operation. It is suitable for multi-level factory buildings. Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy (0.001mm optional). High-precision german steel plate is used to achieve higher durability and wear free operation. This machine uses advanced and durable hydraulic system and electronic control circuits. The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

HIGH-SPEED MONO-LAYER BLOWN FILM MACHINE

Categories : Blown Film Extruders

Advanced screw design and groove feeder to get excellent material mixing, high output, and reliable production quality. Unique die head and air ring to achieve stable bubble and better even thickness film and bag. Provides a good solution for T-shirt bag, shopping bag, agriculture, and many others. Adjustable tower height. FEATURES Raw material be used: HDPE / LDPE / LLDPE / EVA. High efficient machine with low energy consumption but high output. High class gear box with enforced lubrication system and oil cooler. Good mixing performance from screw and barrel. OPTIONAL DEVICES Auto-loader Single-layer dies & air rings A/A Two-layer dies & air rings Rotary die Manual screen changer I.B.C. (Internal Bubble Cooling) OBC Film thickness (gauge) control system. Corona treaterEmbossing roller Double winder Load cell In-line flexographic printer

Extrusion Blow Molding Machine PK-CS/CD/CS3/CS4/CS8/CS12

Categories : Extrusion Blow Molding Machines

Single Station Single/Double/Triple/Quadruple..12 Head Horizontal Operated Clamping System Production Volume:2ml~35L Multi layers: Co-Extrusion 1-6 Layers Multi cavities: 1~12 cavities Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material Special function:View Stripe Clamping system:Toggle/3 Tie Bar/4 Tie Bar Driven Model: Hybrid servo motor drive system/ High performace hydraluic power saving system/Close loop proportional valve Support Parison controller/Auto Deflasing/Auto Recycling/Auto material feeder/Remote trouble shooting funciton/IML

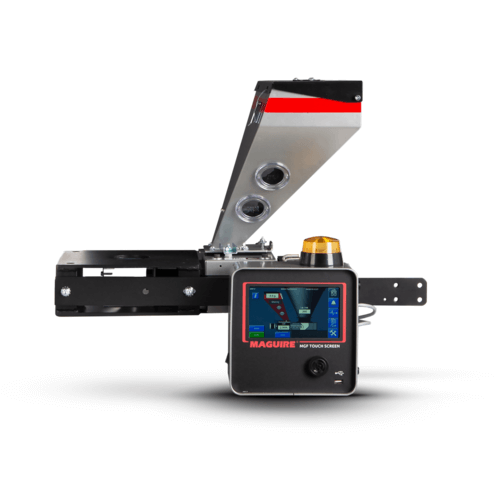

MGF Gravimetric Feeders

Categories : Dosing and Measuring Equipment

Robust hardware, integrated with industry-leading software control to achieve repeatable consistent dosing accuracy. Unique twin load cell technology Dosing accuracy ± 0.2% on 1% setting Feeder ideal for all molding and extrusion processes

SINGLE INJECTION MOLD

Categories : Injection Molds

Single Injection Molding is a standard process that YOMURA TECHNOLOGIES excels at. Our YangMei plant is equipped with a resin feeder system to increase yield rates for mass volume production. Material: TPR , PC, PC/ABS, ABS ADVANTAGES: Works with Complex Designs Has the Advantages of Both Plastic & Rubber Flexible & Soft Touch