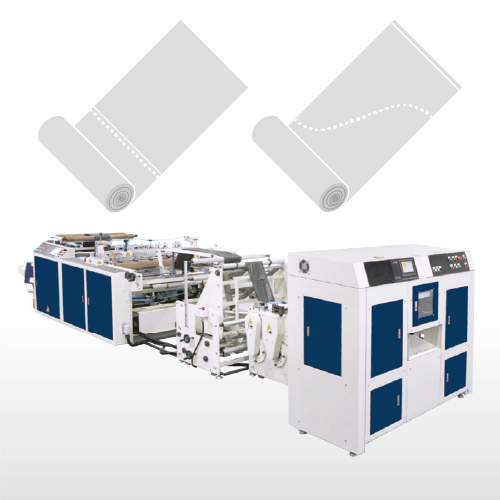

Fully Automatic High Speed Bottom Seal & Star Seal Bag on roll Making Machine (Perforation Bag & S Shape Bag)/ SOSR-1000-R

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatic film feeding, cordination free from tension adjustment Automatically stop when running out of film / color scanning error / film feeding blocks or jam Oscillation film feeding system for stability and high out put

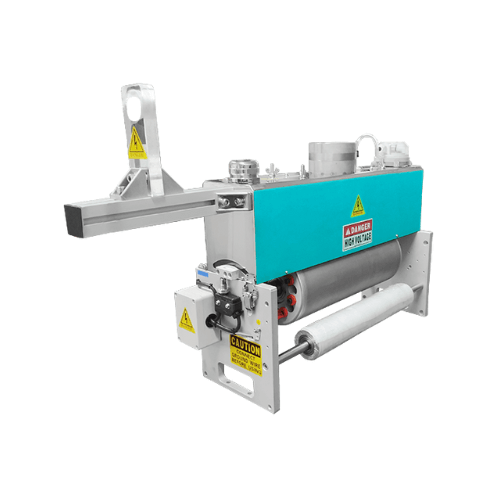

Corona Treater - Label Printing TRB Series

Categories : Surface Treatment Equipment

This corona treater is design for corona treatment laminating such as Laser film laminating, Label machine type, Copper aluminum foil other moralize foil label & sticker printing or other metallic film. Ceramic discharge bar, three step (Up to 9 step)

Aluminum Foil / Paper Embossing Machine-FEM-Series

Categories : Embossing Machines

-Designed for surface embossing on beer labels, aluminum foil for tobacco packaging, various beverage labels, book cover, envelops, invitation cards, congratulatory cards, packaging paper boxes. The Foil /Paper Embossing Machine will upgrade outlook effect and product quality level. aluminium

Aluminum Foil Coating Machine Tandem Type (WAC-DT Series)

Categories : Industrial Lamination

For its strong characters of odor free, lightproof, antioxidant, and flavor preservation, aluminum foil has become one of the most popular solutions for soft packing industries. Laminated aluminum foil has multiple advantages: antioxidant, moisture-proof, also avoiding from direct sun exposure and etc., and it not only does help extend the expiration period but also increase the product value by effective visual presentation through its metallic glossy texture. For years, aluminum foil has been widely used in many different industries, such as pharmaceutical and food sectors; to create satisfactory solution to the demand of those sectors, it requires specific machinery technologies in aluminum foil printing or coating. This model is specially designed for aluminum foil coating. The whole structure of machine is consisted of primer coating unit, HSL coating unit , So it allows same side or two side coating in one go. The coating process options are available options for different requirements of direct gravure coating & semi-flexo coating. The high efficient drying tunnel is set on top of the machine . For feeding operation, double shaft turret type automatic splicing devices both on unwinding/rewinding units. The whole machine is controlled by PLC digital control system and HMI touch screen interface, which makes coating production easier and more convenient.

Aluminum Foil Printing Machine(WAP Series)

Categories : Rotogravure Printing Machines

In order to meet the special requirement of aluminum foil printing, the quality and R&D oriented manufacturer-- Worldly Industrial Co., Ltd., has developed the best solution for this special printing accordingly-WAP series. Considering the diverse needs of product printing, Worldly has designed the six-color printing station in printing structure, and combined a coating machine in the terminal. This coating machine has the outstanding capacity to lacquer over aluminum foil after printing to Improve printing effect, and it is also equipped with spine glue function for many different printing requirements. Also, adopts special reverse structure for aluminum foil between each color printing station, and sets up doctor blade units on both sides to enable reverse printing in any color. Easily fulfills various requirements in printing. Besides of that, adopts "Sumimoto" sectional motor system in every printing station; therefore, saving operation time and improve effect/respond time of color register during printing cylinder replacement. This machine also equips a drying tunnel system on the top of it. It is a four-sectional drying tunnel which makes drying more efficiently. Unwinding and Rewinding units are splicing materials in double shaft automatically turret type. And it is non- stop the machine when changing materials, very simple and convenient. All machine is link-controlled by High-efficiency PLC logic controller and HMI touch interface, so the controlling effect is very precise and high efficient. In addition to that, this machine also equips with automatic color register function which makes printing quality beyond perfection. As for Q.C, Worldly selects VIDEO monitoring system to achieve real-time Q.C inspection. It effectively assists printing work and improves quality Even if in high speed printing operation.

Aluminum Foil Coating & Laminating Machine (WACL-1300)

Categories : Industrial Lamination

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension control, this machine has mainly designed for Alu-alu foil multi-layers lamination. The arch dryer roller has synchronized with line speed, it’s very low friction and steady when film pass through the dryer. The internal drying chamber has safety LEL detection, this system can automatically discharge when detected high VOC occur during the production. This machine also combined heat seal lacquering coating function. Additional primer coating unit before lacquering unit, so it allows to apply two side (primer+heat seal) coating in one pass. The coating unit has alternative function with direct gravure and semi-flexo coating systems. Coating trolley along with self-pump system and able for quick job change.

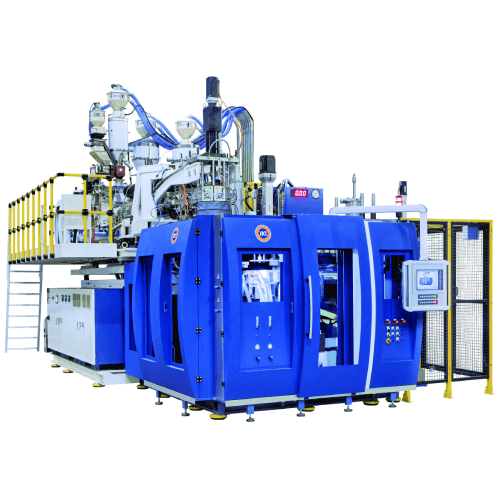

All Electric Single Station Blow Moulding Machine For 20lt Jerry Can, 3 Layer

Categories : Electric Blow Molding Machines

All Electric Blow Moulding Machine with a single head single station model was exhibited. In compliance to today’s global topic for a friendly environment, low energy consumption, less plastic in use, low carbon footprint.

Force Side Feeding Plastic Recycling Machine (RECO Series)

Categories : Plastic Pelletizer Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. More Labor-saving The feeding control system monitors the ampere and controls the feeding speed automatically. Only 1~2 operators are required for an entire plant. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Force Side Feeding Plastic Recycling Machine (RECOi Series)

Categories : Plastic Waste Recycling Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Cutter Compactor Plastic Recycling Machine (KRIEGER Series)

Categories : Plastic Crushers

Compacting & feeding The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

PP, ABS, PE PLASTIC WASTE RECYCLING EXTRUSION MACHINE

Categories : Plastic Waste Recycling Machines

ABS/PP/PE Waste Plastic Recycling Making Machine