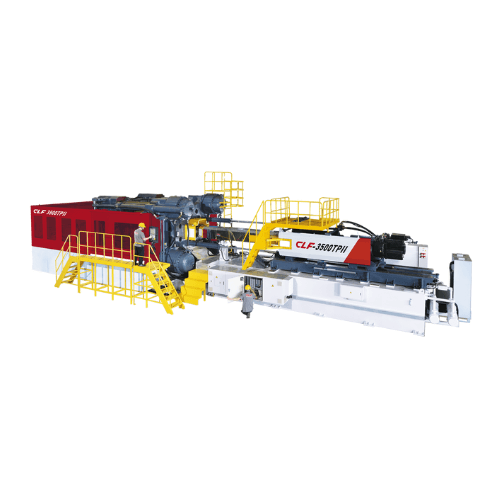

Two Platen Plastic Injection Molding Machine - TPII SERIES

Categories : Injection Molding Machines by Platen

Unique two platen design for clamping mechanism exhibits exceptionally high speed clamping feature.

Blow Molding Machine PBS 905PC SERIERS

Categories : Automatic Blow Molding Machines

The PBS-905PC Special Purpose Blow Molding Machine is specially designed with an advance German type die head, featuring "first-in, first-out" performance. It is ideal for producing high quality, high clarity and high gloss PC water tanks. The machine is suitable for producing 2.5~5 gallon containers.

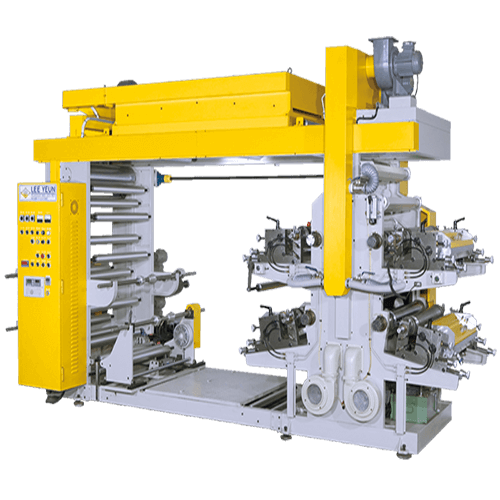

6 Color Stack Type Flexo Printing Machine for Woven Bags and Paper: HY-G5000 Model

Categories : Woven Bag Printing Machine

Special for the pp/pe woven sack roll, and craft paper printing, and various kinds of heavy duty packaging materials. machine body use big iron casted frame with varnish coating, unwinding with auto tension controller and epc system, roll to roll continue printing bring the most stable and rapid production volume, before fabric and paper go into the printing station with the banana roller to spread the film and paper more even, standard equipped with the crane chain type assist the change raw materials and unload the printed materials.

4 Color Reel-to-reel Offline Type Flexo Printing Machine: LL-5000 Model

Categories : Flexographic Printing Machines

Reel to reel type off-line flexographic printing machine, very good quality for printing the color flexible of 4+0, 3+1, 2+2, machine standard with the manual tension control, machine frame is iron casted and varnish coated, very strong and long duration. Upper side with 2 sets drying box, the films after printing will guide to the drying boxes for drying, ensure that the films can be dried accordance with the speed.

4 Color Stack Type Flexo Printing Machine for Woven Bags and Paper: HY-GP5000 Model

Categories : Woven Bag Printing Machine

Special for the pp/pe woven sack roll, and craft paper printing, and various kinds of heavy duty packaging materials. machine body use big iron casted frame with varnish coating, unwinding with auto tension controller and epc system, roll to roll continue printing bring the most stable and rapid production volume, before fabric and paper go into the printing station with the banana roller to spread the film and paper more even, standard equipped with the crane chain type assist the change raw materials and unload the printed materials.

Flexographic Printing Machine for PP Woven Bags

Categories : Flexographic Printing Machines

● The BOTHEVEN Flexographic Printing Press #MP Serial is design for fabric sheet printing, such as after cutting and bottom sewing of laminated or un-laminated bag, paper bag ....etc. ● Easy operation, easy change printing plate. ● Special design a Action Roller dispense device, the printing cylinder won't dirty conveyor when empty load.

4 Color Offline Type Flexo Printing Machine: FSP-5000 Model

Categories : Flexographic Printing Machines

This is a higher grade flexographic printing machine than ll model, standard equipped with the japan original imported unwinding auto tension controller, and the hydraulic type edge position control (epc) system, double unwind and rewind station, let the operation more efficiency. Films go to the printing station with the banana roller to spread the films much even, and printing station with individually drying pipe providing the printed films for the primary drying, machine with t5 working light keep the working place very bright, upper side with overhead big drying chamber enlarge heating capacities cooperate with the blower ensure the films can be dried accordance with high speed.

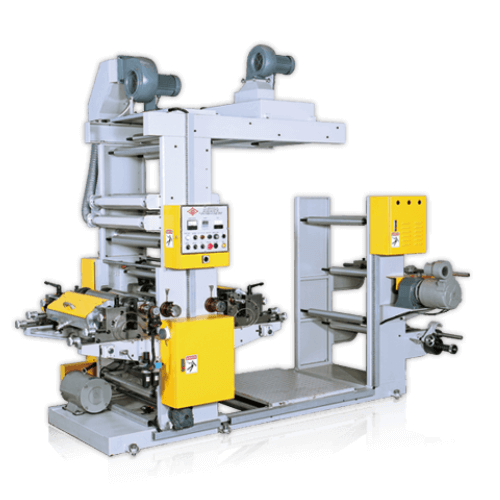

2 Color Inline Type Flexo Printing Machine: LS-2 Model

Categories : Flexographic Printing Machines

LS - 2 (2 Color) lager width available on demand. Dancing rollers equipped with 1 & 2 colors. in-line press for controlling control web-tension. Cooperate with the extruder to make the printing in-line continuously, machine can print one side 2 color combination, and both side with 1 color, in-put with the dancing roller to control the films goes into the printing station very even and smooth, machine equipped with the drying chamber ensure the printing pattern and color can be dried accordance with the speed, in-line printing can save the times and process for the operation.

2 Color Reel-to-reel Offline Type Flexo Printing Machine: LL-2000 Model

Categories : Flexographic Printing Machines

Off-line type printint the color 2+0, and 1+1 combination, single unwinding and rewinding station in the same way, convenience the operator to put on the raw materials and take out the printed films.

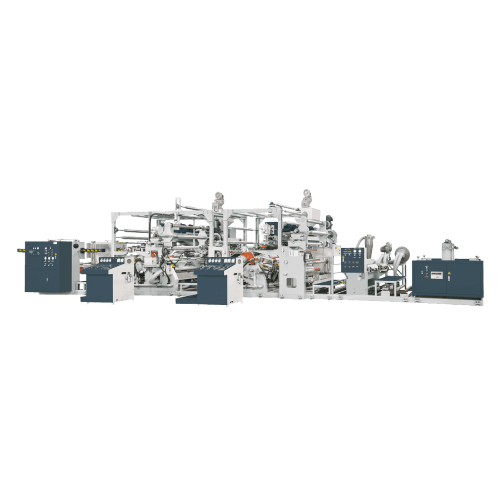

Tandem Extrusion Lamination Machine (YSL-T)

Categories : Industrial Lamination

This series of machines are available for tubular woven bag, other working materials to do double side lamination process.

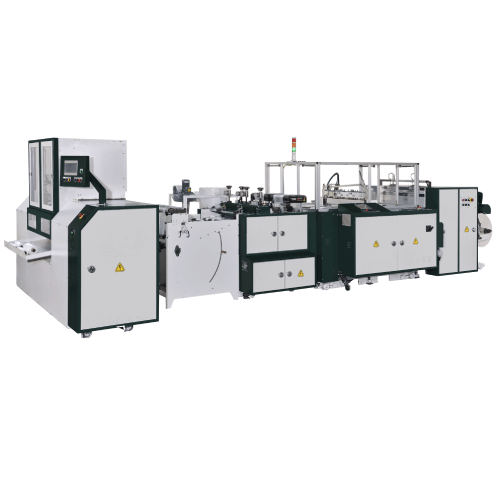

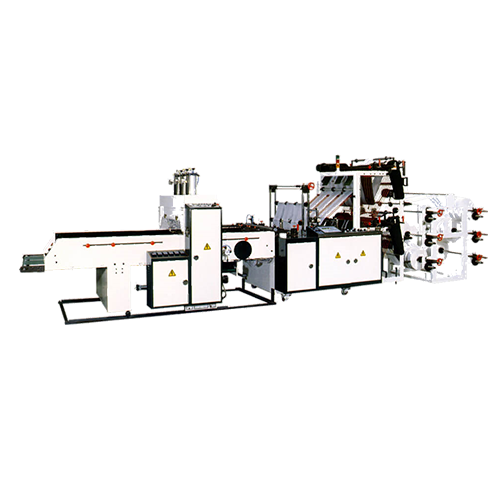

Double Deck T-shirt Bag Making Machine, Cold-Cut System (4/6/8 lines)

Categories : Bag Making Machine by Applications

* Cold-cut system - For thin film material. Machine uses upper heating knife and silicon roller base for sealing. Cutting knife before bag outfeeding. * Double-decks production - 2 sets of sealing blades & silicon roller sets are place vertically on top of each other to seal different lines, cutting done on the same knife. * Gripper + pneumatic punch - When counts reached, inline gripper collect and pneumatic punch cut out waste area and removed by conveyor.