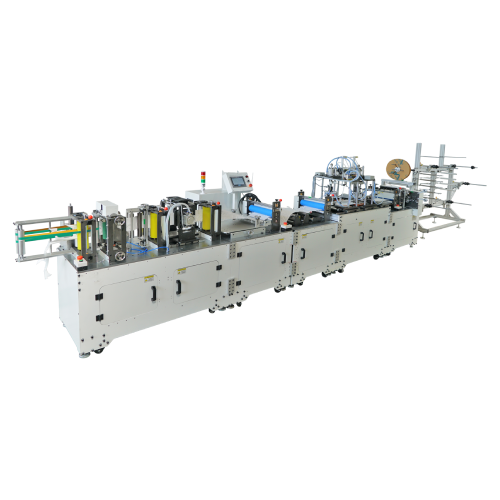

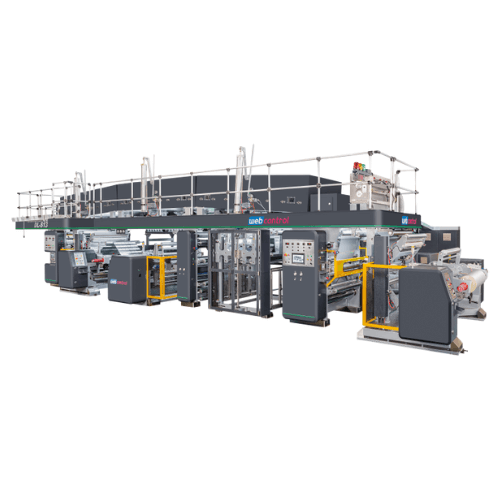

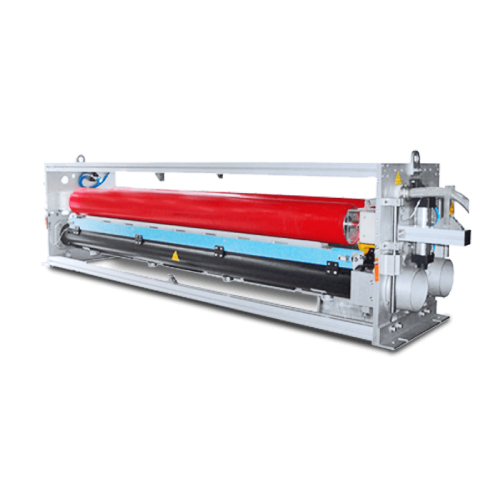

6 COLORS FLEXO PRINTING MACHINE (HIGH SPEED TYPE)

Categories : Flexographic Printing Machines

These flexographic printers are able to print in four colors with the following possibility: 0+6, 1+5, 2+4, 3 +3 Max. printing speed 70-80 mts/min Standard printing length is max. 800 mm, bigger printing length can be requested as your demand Equipped with Edge Position Controller (EPC) We didn’t show all our models, please don’t hesitate to contact us for bigger printing machines.

T.B Type Hydraulic Baling Press

Categories : Baling Press

The HY7-30TS is a 30 ton press for packing equipped with a carrier for feeding and delivering bags after manual packing.

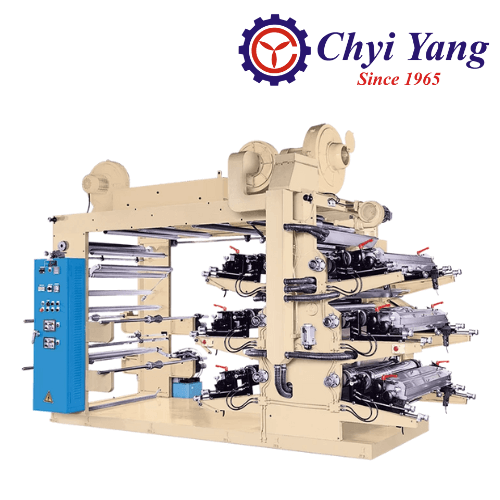

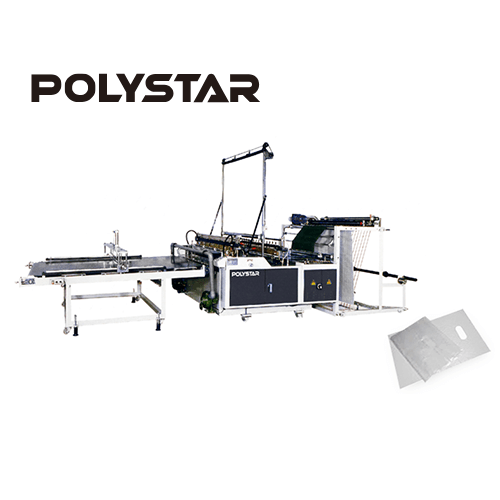

DHL Bag Making Machine

Categories : Sealing Machines

1. Servo Motor Driven, Efficient mechanical structure produce 180 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Universal Welding Device, easy operating and able to produce up to 15 kind of bag. 8. SHSS-T Twin Servo Motor Driven Model can produce two different size of printed plastic bag at same time. • The Conventional mechanical clutch / brake and rack & pinion system is also available.

Air Bubble Film Machine (YSW-T)

Categories : Air Bubble Film / Sheet Extruders

The air bubble film can be used as cushion envelope, heat-insulation cushion, packing cushion, anti-static air-bubble bag..etc

Hot Stamping Machine HSM-10-M

Categories : Hot Stamping Machines

Stamping dia: Ø19~50 mm Stamping length: 3~120 mm Stamping speed: 5~10 pcs/min Heater: 1.5 kwAir consumption: 50 L/min Power consumption: 1.6 kw Machine size: 1250 x 600 x 1500 mm Total net weight: approx. 190 kg

Thick Bag Making Machine

Categories : Plastic Bag Making Machines

● Tensionless sealing ● For making thick heavy duty bag ● Flying knife can be added ● Tension sealing as option

Single Shaft Shredder

Categories : Plastic Shredders

Single-shaft shredder system can be almost universally used to and are able to process a board range of different materials (woods, copper wire, plastic lump, tire paper, etc.)

Heavy Duty Model Dispersion Kneader

Categories : Dispersion Kneaders

Compounding For Rubber、Plastic & Chemical Industries

Turbo Washer - PET Flakes Friction Washer

Categories : Plastic Washing Line

Turbo Washer - PET Flakes Friction Washer

3-Folded Garbage Bag Making & Folding Machine - T-shirt Style & Flat Style

Categories : Plastic Bag Making Machines

1. Servo driven rolls prouder smooth consistent bag delivery and precise cut offs. 2. With this sealing & cutting machine, each sheet folds automatically. It saves time and labor. 3. Number of sheet to be processed can be set with Auto-Digital Counter. 4. Depending on width, bags can be folded in three or four to speed up packaging. 5. Easy to adjust using pneumatic controls with electromagnet. 6. Removable T-Shirt bag punch and power roller. 7. Waste collect conveyor.

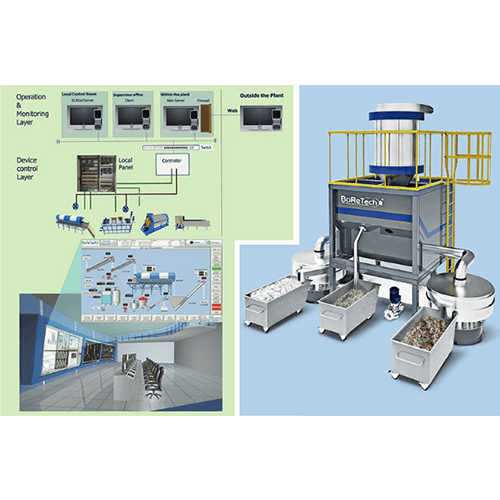

PET Bottle Recycling System

Categories : Plastic Waste Recycling Machines

PET Bottle Recycling System

Micro Dehumidifying Dryer (DHM-SL )

Categories : Dryers and Dehumidifiers For Plastic Materials

The latest micro dehumidifying dryer uses compressed air to dry the plastic resin. The air volume generated by the air compressor is suitable for the production of small parts, such as electronics parts. The perfect grade of dryness coupled with a moderate amount of drying air, the production efficiency greatly increased. Air compressor process the air via water filtration, and the air will be compressed between pressure 5~7kg/cm² . The compressed air will then go through the molecular sieve and supply the dry air with dew point up to -40 ~ -50 ℃. During the molding process, it will fully demonstrate the perfect plastic properties. In accordance with the different types of plastic, the drying time required is also slightly different, for 2 to 6 hours. The multi-function design can dry, dehumidify, and automatically convey resins. Comparing to the regular dehumidifying dryer, it can save space and directly connect to the inlet of molding machine. It can directly convey the drying resins to production to prevent resurgence and to ensure the production complete. 1. Display the dew point detection 2. Insufficient air pressure detection 3. Built-in positive pressure conveying system 4. Overheat preventer 5. Weekly timer 6. Install high-density filter 7. With Industry 4.0 features, Ethernet and RS485 can be used to connect with other brands. 8. The controller and main body can be separated or combined to facilitate for space arrangements.

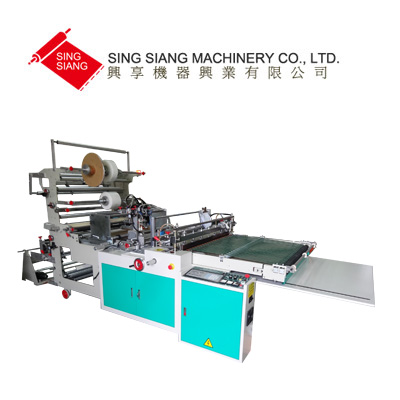

Servo Motor Driven Side Sealing Plastic Bag Making Machine

Categories : Plastic Bag Making Machines

Servo Motor Driven, Efficient mechanical structure produce 180 bags per minute. User-friendly Control Panel, easy to understand easy to operate. Digital control for production length adjusting, precise and less wastage.

Hydraulic Automatic Feed Die Cutting Machine (Four Column Press)

Categories : Cutting Machines

Application:Suitable for cutting one layer or several layer of such material as rubber sheet (bottom sole, medium sole), EVA, leather, plastic canvas, vacuum foaming products, nylons, carpet, mat, corks, soft tiles, paper boards and synthetic materials. yicheen The improved and upgraded traditional punching machines. Adopt four column of Hydraulic cylinder, average cutting force, high efficiency to raise the productivity. The upper die install by Magnetic platen, it is very convenient to change die. Microcomputer controller with touch sensing screen for maximum operation convenience and accuracy. Also, optional equipped with LCD screen computer control system is available, which it can memory operation program, provide the most convenient in operation and accurate cutting operation. Lubricated system design on Main shaft to avoid machine parts damage in movement and enhance machine lifetime. The Safety device (opening safe net for emergency stop motion) ensures the operator safety. Options: Air shaft unwind device, Air shaft rewind device

Belt Conveyors

Categories : Loading and Conveying Machines

Protection of Your Machine The belt conveyor allows to installing a metal detector on it. With the metal detector, it prevent any metal been feed into the pelletizing system. Protecting the pelletizing systems from damage which caused by metal. GENIUS

Solar Module Aluminum Foil Welder KUM-4088

Categories : Automatic Welding Machine

KING ULTRASONIC Solar Module Aluminum Foil Welder KUM-4088

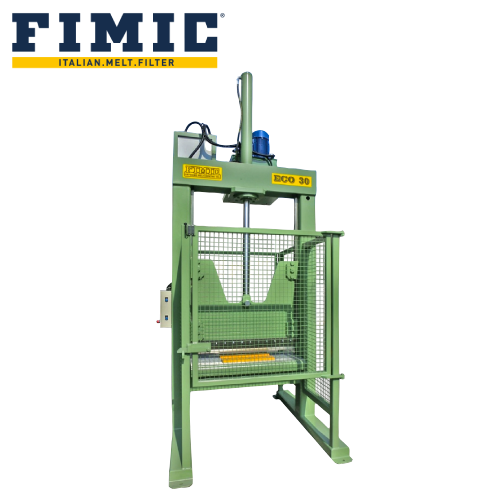

Hydraulic Plastic Cutter Machine

Categories : Plastic Crushers

When FIMIC was born, our main line of production was the manufacturing of guillotines for the cutting of bales and rolls of industrial waste, and they still retain their place as our flagship products thanks to our state-of-the-art production method, which sets them apart for the rest of the market. FIMIC guillotines can fit to each and any cutting scenario, covering every area of the recycling process of materials such as plastics, rubber and paper. FIMIC also offers the possibility of fully customizing its guillotines to fit every need concerning layout, safety and output.

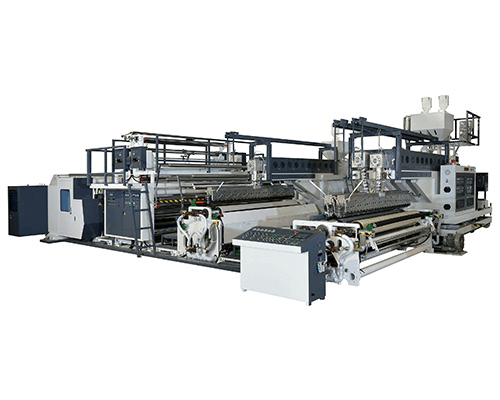

Dry Laminating Machine Shafted Type DL-1000/1300

Categories : Industrial Lamination

This machine is for the Laminating process that uses a solvent-based adhesive. Reliable tension control with a mature lamination process able to make high-end products such as retort, sterilize and medical pouches. The gravure coating station allows high precision and consistency in coating weight. An efficient drying tunnel has high performance in vaporizing solvent completely to keep the product safe. Various options of heating solutions for drying tunnels are available. The energy-saving system is an option to help decrease carbon footprint and the cost of production

TC5V Valve Gate Controller - 2 Zones

Categories : Control Equipment

Multiple Touch-off signal options ( AC220 / 110 / DC24 / Switch type ) Multiple output voltage options ( AC220 / 110 / DC24 / Relay / MOS Relay ) Time display is adjustable to the first digit after the decimal point Stopwatch can be either accumulative or countdown Three optional control modes Optional pressure retaining mode MOS Relay extension of working life Mechanical Relay ( up to 600 mA ) is optional Arico

Stepper-Controlled Proportional Valve 0-400L/min

Categories : Separators

Product Serial: FC-300+PM-300 Proportional Flow Control Valve consists of PM series driver and FC series proportional flow valve. With an input signal either through analogue or digital, the needle inside the proportional valve moves proportionally to the signal. This series is able to control the flow rate of air and liquid with high resolution, high accuracy, and high repeatability. It is developed for industries that require a high degree of adjustment in flow rate. Series PM driver provides series FC valve with the required power and control signal (step and direction). It controls the step of a bipolar stepper motor with an analogue signal (0-10 VDC/4-20mA/RS485 Modbus).

Pelletizing & Recycling System

Categories : Plastic Pelletizer Machines

MGB-RPW-65 For PP, HDPE and LLDPE recycling.

Corona Treater - TU Series

Categories : Surface Treatment Equipment

The corona treater is for High speed inflation machine, Corona Treatment Plastic such as:LDPE, HDPE, PP EVA NYLON