Repet Wood WPC Granule Pelletizer Plant

Categories : Plastic Pelletizer Machines

Indoor & outdoor building material Outdoor furniture

Floor Mounted Auto Vacuum Loader

Categories : Loading and Conveying Machines

The separated design of a blower and a suction hopper with mighty horsepower is suitable for long distance conveying. The flexible combination of one blower with one suction hopper up to four suction hoppers can help you to save space and equipment investment cost. That also keeps your resin away the pollution and extend suction points easily for future need. TA series Easy use by a quiet and powerful induction motor. The motor cabinet can be placed on the floor for convenient operation and the suction hopper on the hopper dryer for easy installation. TB series Use the same commutator motor as the BC series, and separate motor cabinet and suction hopper design as the TA and TC series. Combine the advantages of the hopper mounted and floor mounted loaders. TC series The blowers are belt-driven that are the best choice for silent operation. Patented Optional Parts Vortex Cyclone (VC): Works with any auto loaders to stop the regrinded resin from discharging to the surrounding area. Filter Set: s optional equipment from YANN BANG is perfect for dust-free of indoor working place. To do the filter routine maintenance is so easy without dirtying your hands and place. Unload the filter set without opening the cover until move to the please you want to clean. Auto Dust Cleaner: Saves your time and labor. No need to clean your filter anymore. The Auto Dust Cleaner is designed to install upon the filter of the loader. Set the timer and it cleans your filter routinely.

Tube Loader (AL)

Categories : Loading and Conveying Machines

Stainless unique design is dust-free and clean –free for optics users perfectly. Light weight and compact size can be directly mounted to any vessel and machine without purchasing another vacuum loader. Save your cost and space. By using compress air efficient venture draws resin from material tank. No motor and low noise is perfect for clean room, indoor work, and electronics and medical users. Good for small batch and various kinds of production, high stability, high efficient supply to prevent moisture return of resin. Glass sight window gives a clear view of loading and safety protectors to help operators working more efficiently.

Co-Extruder, Co Extrusion Machine

Categories : Extrusion Lines For Pipes and Profiles

Part for indoor and outdoor application: Door Frames, Furniture Components, Spacing Panels, etc.

Heavy Duty Crushing Machine - Silent Type C-300STC-560ST

Categories : Plastic Crushers

• Fully enclosed stainless steel casing. • Convenient access doors on five sides. • Dual layer insulation for substantial noise reduction.

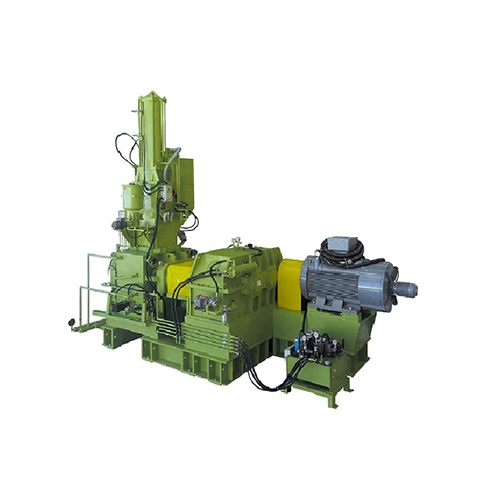

Intensive Mixer

Categories : Rubber Mixers

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber: Drill hole type jacket. Excellent cooling ability. Material contact surface: Hard chrome plating and fine polish. 3.Discharge door: Excellent sealing. No material leakage. 4.Ram: Drive by air cylinder. Good mixing and dispersion quality.

Rubber / Plastic Mixer Machine

Categories : Rubber Mixers

This Intensive Mixer is designed for mixing compounds and specific plastic. The structure of the machine consists of the main air cylinder, floating weight, feeding door, mixing chamber, rotors and discharge device. When performing mixing compound operations, the material and ingredients are fed together into the mixing chamber. The material in the mixing chamber is repeatedly sheared and squeezed by the rotors. This provides a series of chemical rotations between the material and the ingredients, which enables the material pieces to stick together into a paste mass shape. Mixing compound operations are performed according to the set temperature and conditions. This specially designed mixing machine provides efficient mixing and refining for a wide range of raw materials, such as raw rubber, resins, asphalt, cellulose, PVC ane EVA…etc.

Door lock Related Part

This product is made of PP+GF (Glass Fiber Reinforced Polypropylene), offering high strength, impact resistance, heat resistance, and low deformation rate, ensuring the stability and durability of large panels and main boards in high-load environments. It is designed for applications in structural support, industrial equipment, and automotive interior and exterior components, delivering excellent mechanical performance and long-term stability. Manufactured using a 1600-ton large injection molding machine, this product enables the production of large-sized, high-precision plastic components, ensuring superior structural rigidity and consistency to meet various large-component requirements. Additionally, compared to metal parts, PP+GF provides both high strength and lightweight advantages, effectively reducing product weight.

Multi-function Dehumidifying Dryer (DHC-NA)

Categories : Dryers and Dehumidifiers For Plastic Materials

Multi-function Dehumidifying Dryer (DHC-NA) Three-in-one design can dry, dehumidify, and automatically convey resins, save money. 1. Low noise to promote the quality of environment. 2. Easy to move. The unit with wheels can move anywhere for your need. 3. Designed structure to save more space for use. 4. Combine drying and dehumidification system to save energy and lower carbon emission. 5. Air filter and pipe cleaning device are easy to take out without any tool to save your time. 6. Hopper Dryer made by stainless steel with clean door for easy maintenance.

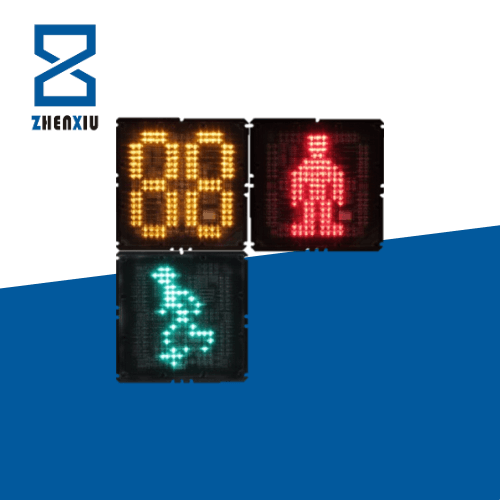

Pedestrian Signals

Categories : Injection Molded Products

This product is made of **ABS (Acrylonitrile Butadiene Styrene) plastic material**, offering **high impact resistance, weather resistance, waterproof, dustproof, and UV protection** properties. It ensures long-term stable operation of pedestrian signal lights in various outdoor environments. The housing design complies with **international traffic equipment standards**, providing **excellent durability and safety**. It is **highly resistant to breakage**, extending the product's lifespan and making it suitable for various pedestrian signal light systems.

LT67_Rectilinear Displacement Transducer With ip67 Protection

Categories : Indicators and Sensors

This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) The grooves on the profile provide an excellent alternative to the usual system of fastening with brackets Ideal for applications on plastic injection presses with installation at points that are highly exposed to lubricants Also indicated for processing machines on which the transducer cannot be protected by guards

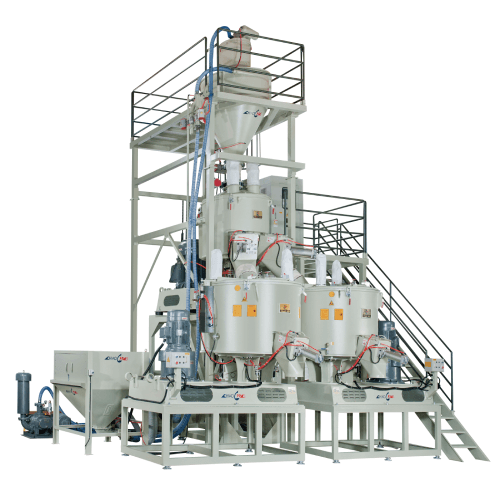

Complete Set of Mixing Metering & Conveying Equipment

Categories : Mixers and Blenders

A mixing system is a process of mixing raw plastic materials in particles or powders to manufacture piping and tubing structures. It is a part of the plastic extrusion process. It involves the pre-mixing of multiple additives, which is performed in an efficient manner. Mixing System is commonly used in manufacturing water pipes, plastic floors, wall panels, plastic floor tiles, wires, cables, plastic steel doors, windows, to name a few.

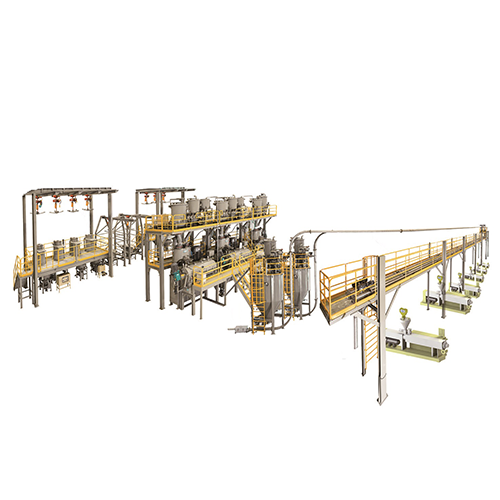

Automatic Metering, Mixing & Chain Conveying System

Categories : Loading and Conveying Machines

pvc pipe pvc window pvc door pvc corrugated sheet chain type conveyor

High Speed Mixer

Categories : Mixers and Blenders

The vertical mixer/vertical blender, also called the super mixer, rapid mixer, or high-speed mixer machine is driven by variable-frequency stepless motor. Which is can adjust the speed according to the materials with different characteristics. And also can save more than 20% of the electric power. Using special design of the mixing blade can makes the powder suspension flow due to high-speed running. Collocate of arc-shaped bottom design with zero dead corner. Even if material has big different proportions, it also can be well mixed quickly. This equipment is special for water pipes, plastic floors, wall panels, plastic floor tiles, wires and cables, plastic steel doors, windows, etc.

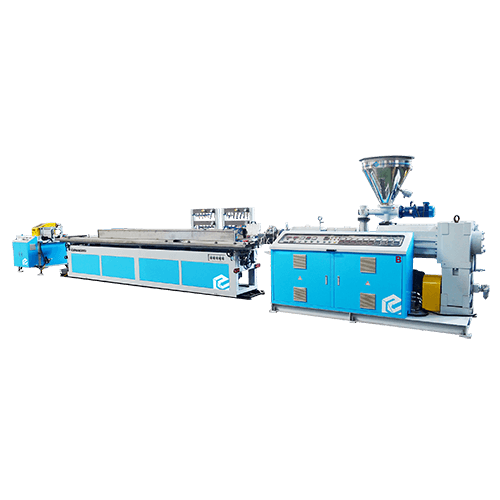

WPC extrusion machine line

Categories : Extrusion Lines For Pipes and Profiles

The circular economy is a topic of global concern, and Everplast has been committed to this. Among them, WPC can effectively use recycled PE/PP plastics and natural fibers to manufacture imitation wood products through the WPC extrusion production line. This WPC product is also widely used in outdoor building materials today. The new properties of Everplast plastic wood composites (WPC), such as PP/PE resin mixed with 40-80% natural fibers or PVC mixed with 40-70% natural fibers, produce different types of WPC profiles. According to the plastic base material, WPC is mainly divided into PVC, PE, PP, PS, and ABS plastic bases. Among them, PVC/PE/PP plastic wood could be more popular in the market, has a woody feel, and can standard high temperatures. The appearance and texture are very similar to real wood.

Auto Batch Vacuum Foaming System SA-1BVF

Categories : Vacuum Forming Machines

The SA-1BVF can be used with an existing auto batch foaming machine or with SUNKIST's own SA-1B, SA-1BS, SA-1BM and SA-1HA. After the mixture is loaded into mold box, the mold box is moved into this chamber via a carriage. After the mold box us placed inside the curing chamber, the door of the chamber automatically closes and shut tightly. An operator can then adjust the pressure inside the chamber with the control panel. The quality and physical properties of the foam that is formed will be affected when the pressure is changed, ie. the volume of the foam size will increase, foam tensile strength will also increase dramatically, and the hardness of the foam will change. This machine is environmental friendly, reduce the amount of chemicals used and reduce the fire risk.

Custom Vertical LIM LSR Injection Moulding Machine

Categories : Vertical Injection Molding Machines

Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. Increased productivity and efficiency with shuttle table or rotary table configuration. Pick and place products while another product finsihes molding. Energy savings of around 50-70% with servo pump power system. Safety cover, Light curtain, pneumatic door and dual palm safety button for personnel safeguard. Multi-Language PC Base industrial type Linux core system. 1000 sets of mold settings can be stored and export as backup. Complete record of history settings & warnings. Built in USB connect. On-line remote control and maintenance service.

AT - 60, 80

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 14~20.9 KW

WT - 60, 90

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 14~26 KW

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS FLUSHING

Categories : Vacuum Packaging Machines

Automatic Tray Sealer with Vacuum and Gas Flushing from Jaw Feng Machinery Co., Ltd. is made of stainless steel. Outdoor security vacuum cover. When electrical box is opened, it will shut down immediately. Can use multiple die sets and easy to change over, Multi-lingual PLC touch screen with a movable arm. Operate 360°. Every functions on the screen are presented in narrative, simple to understand. Vacuum / nitrogen, vacuum / skin pack, and sealed packaging. Offering lots of models to meet different sizes of trays. Able to work with date injecting, date thermal printing, labeling, aligner feeder, etc.

Vertical Electric Injection Molding Machine-YE-50V

Categories : Vertical Injection Molding Machines

A number of patented electric injection device Precision electric injection function Precision electric metering function Electric pedestal does not slide function Energy-saving hydraulic servo mold clamping function Accurate low pressure off mode protection function Energy-saving hydraulic servo thimble function Template rust plating processing Template parallelism fine tuning function Template low-top design With 8 T-groove, easy to fix the mold Thick template with high tensile guide posts Configuration template guide column anti-drip bumper sleeve Configure mechanical closing safety bars Configure mechanical shut-off safety electrical protection Open all the safety gates to stop the design Configuration key type safety door safety switch Configuration rail horizontal operation safety gate design Injection device can be flipped to maintain the factory accuracy to reduce the height of the handling method Injection closed loop feedback function Holding pressure switching point accuracy of 0.01mm Packing pressure accuracy of up to 0.1% High-speed rigid filling, to eliminate floating phenomenon Prevent the drawing function A variety of peripheral equipment chain function Equipped with peripheral equipment power outlet With robot centralized terminal block Hopper holder moving function Equipped with resin feed tube holder Equipped with adjustable height white iron trough Equipped with a perspective control water divider Equipped with cooling water quick connector The machine is neat and without any pipe exposure Than the same level of oil-saving 25% to 60% Than the same level oil machine to save cooling water 70% Equipped with 10.4 "color touch screen PID automatic temperature adjustment function Japan's Mitsubishi control system Equipped with wear-resistant material pipe

PVC、PE、PA cover Iron wire extrusion equipment

Whole plant equipment includes rod for passing wire,Winding wire wheel,heating case,extruder,covering mold,cooling water tank,frozen wheel non-stop type winding wire driving motor,which are available for the wire cover such as cloth hanger,flower stand,outdoor iron-wire net,protective net for bank,and stone net.

AT-720

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 168~209 KW

VTOZ- Vertical Screw Type Injection Molding Machine

Categories : Automatic Injection Molding Machine

● Patented interchangeable 3-in-1 modular slide table design. ● Patented none-side-force injection unit design. ● Patented active bypass auxiliary plasticization system design. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Dual protection of safety door and safety light curtains. ● Intelligent program controller makes injection easier. ● The lowest table height injection molding machine. ● Precise energy-saving hydraulic system.

AT - 60,90

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C (Indoor) Humidity Range: 40~80% Cooling Capacity: 14~26 KW

AT - 90, 120

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 20.9~34.9 KW

AT - 480, 600

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 112~175 KW

VTOP- Vertical Plunger Type Injection Molding Machine

Categories : Automatic Injection Molding Machine

● Patented interchangeable 3-in-1 modular slide table design. ● Capable of producing precise micro products as 0.001-0.0001 gram products. ● Patented active bypass auxiliary plasticization system design. ● New design patent-IPIS (Interchangeable Plunger Injection System). ● Plunger Type Injection can highly save resin runner. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Dual protection of safety door and safety light curtains. ● Intelligent program controller makes injection easier. ● The lowest table height injection molding machine. ● Precise energy-saving hydraulic system.

AT - 240,300

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 56~87 KW

AT - 360

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 84~105 KW

AT - 24, 36

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 5.6~10.5 KW

AT - 120,180

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 28~47 KW