Large Horizontal Rotary Table Two-Component Injection Molding Machine (HB-R Series)

Categories : Horizontal Injection Molding Machines

It is a large injection molding machine, which is suitable for large-scale home appliances and panels, automotive skylights, lights,

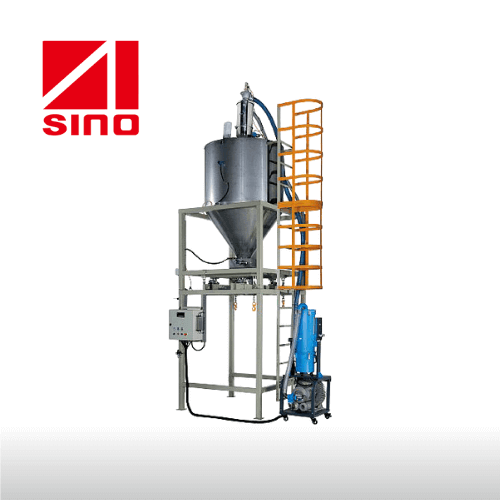

Automatic Batch Weighing and Mixing System

Categories : Dosing and Measuring Equipment

Automatically measuring equipment for efficient mix and material processing. Equip with auto conveying system, batching system, mixer, kneader, extruder and steel construction plant. Discharge feeder: scale screw feeder Automatically conveys material to extruder after mixing PC control monitoring system live network Complete installation of pulverizer series

Hopper Dryers - SHD-U

Categories : Dryers and Dehumidifiers For Plastic Materials

SHD-U hopper dryer can efficiently dry most of standard hygroscopic plastics as to ensure high quality molding products. The concise structure makes it easy to mount on the IMM, and the drying hopper can also be directly mounted on the floor with the floor stand. Besides, there are multiple optional accessories to meet different production demands, such as hot air recycler, magnetic base and maintenance ladder etc.

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

Two Platen Injection Molding Machine (LM Series)

Categories : Injection Molding Machines by Platen

It is medium and large scale injection molding machine. It is applicable to automotive industry such as bumper and

PET Stretch Blow Molding Machine for Wide Mouth / Large Containers

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Suitable for clean lotion, edible oil, detergent, pickle food, etc. Small & Medium Volume Bottles

PET Stretch Blow Molding Machine for up to 600ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

Storage Tank with Blowing-PSP

The PSP series storage tank with optional blower is Sino-Alloy’s solution for the temporary storage of the rubber or plastic pellets before packaging. The PSP series storage tank is made of stainless steel and can be customized to the customer’s specifications. The optional blower/dryer can help ensure there is no buildup of residual moisture. An optional vacuum loader can transport the rubber or plastic pellets from the PSN separator directly to the PSP storage tank. Also available with a packaging function includes air control valves to regulate the output quantity and an automatic weight scale.

Plastic Machine Controllers - AR Series

Categories : Industrial Software

The integrated innovative wise technology with reliable Distributed Control System contains higher performance. Software combined with State-of-art window screen to provide smart and instinct object-oriented editing style hybrid switching with simple and popular PLC ladder program editor. His high-speed Ethernet communication network link-up between Humanity Interface and remote devices to displaying the future one-stop control advantages! It can be broadly applied to automated machinery control, such as injection molding extruder machine controllers and equipment. Arico

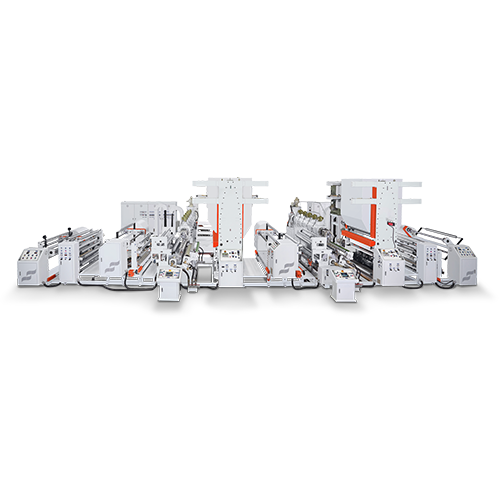

Extrusion Coating & Laminating Machine Tandem Type (WEL-DT Series)

Categories : Extrusion Coating Machines

The tandem type extrusion coating laminating machine has inline two extrusion units with three unwinders. It allows to produce five layers laminates in one go. It can save the semi-finished goods shifting time and optimize the ratio of utilization operating. It’s suitable for production on large scale and multi-layer jobs. Worldly tandem machine has very compact and user-friendly design.

Tax Pneumatic Clamps

Categories : Mold Parts

The TAX system uses an automatic pneumatic pressure mechanism to individually clamp upper dies. This system is well suited for both smaller and larger hydraulic presses.

Mold Temperature Controller (YBMI/YBMD)

Categories : Control Equipment

Steady controlled temperature makes plastic molding accurate in size and consistent with quality. Accurate mold temperature solves the problem of plastic flow patterns, reducing flow and weld lines, gloss appearance, record grooves effect, silver streaking, stress-whitening, warping, and etc.... P.I.D temperature controllers are used for accurate control of temperature within±1℃. Two-step-heating selector makes rapid temperature increasing possible when require thus saving time and power specially start up in the morning. Patented “Heat-insulated” design improves your safety, extend the machine’s lifetime and make maintenance more efficiently. YBMI : By oil, suit for long-term continuous operation, keep the temperature steady, no flash on tiny and thin products, and no corrosion. However, the heater may be damaged if you do not use the thermo oil correctly or change oil routinely. Recommend to choose oil-type mold temperature controller when your required temperature is 150℃ or above. YBMD : By water, heating up faster, cooling better, harmless to your mold and more economic than oil type for maintenance and cost. However, the water boiling point is low and the element of different water may occur corrosion or limescale to affect the heat exchange and products quality. Recommend to choose water-type mold temperature controller when your required temperature is 150℃ or below.

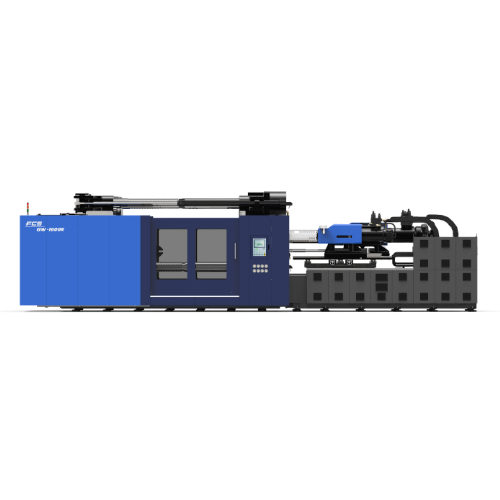

Two-Platen Multi-Component Injection Molding Machine (GW-R Series)

Categories : Injection Molding Machines by Platen

It is a newly launched large-scale two-plate multi-component injection molding machine, widely adopted in the automotive, home appliance, and furniture industries for manufacturing large two-color and multi-color products. It is particularly suitable for large household appliance casings, integrated headlamp cover, run-through connect taillamp covers, car windows, and automotive plasticized sheet. The clamping force ranges from 1,000 to 3,300 tons.

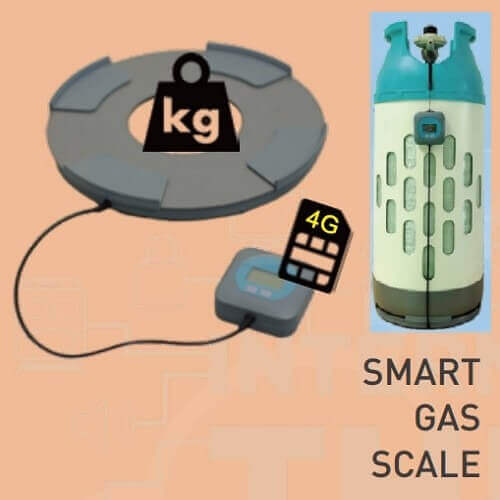

Electronic Analytical Balance Scale

Categories : Dosing and Measuring Equipment

The DT analytical balances accurately measures the weight(denier) of PP/HDPE flat yarn.

High Performance Pressure Transducers

Categories : Indicators and Sensors

ll Scale Pressure Range 0-100 thru 0-100K PSIS (0-6.89 thru 0-6894 bar) Accuracy (RSS) (BFSL Non-Linearity, Hysteresis, Non-Repeatability) 0-300 PSI thru 0-15K PSI Ranges±0.20% FSO ( ±0.15% FSO improved with "DN" option) < 0-300 PSI or > 0-15K PSI Ranges±0.25% FSO ( ±0.15% FSO improved with "DN" option) Linearity (Best Fit Straight Line) 0-300 PSI thru 0-15K PSI Ranges±0.10% FSO (BFSL), Typical < 0-300 PSI or > 0-15K PSI Ranges±0.15% FSO (BFSL), Typical Hysteresis < ± 0.05% FSO, Typical Repeatability < ± 0.05% FSO, Typical Full Scale Output (FSO) 16 mA Zero and Span Balance ±1% FSO Long Term Stability ≤±0.25% FSO per 6 months Response Time <2 mSec to reach 90% FSO Temperature Effect on Zero ≤±1% FSO per 100°F (37°C) Temperature Effect on Span ≤±1% FSO per 100°F (37°C) Compensated Temperature 70°F to 170°F (21°C to 76°C) Operating Temperature -40°F to 190°F (-40°C to 87°C) Storage Temperature Limit -65°F to 250°F (-53°C to 121°C)

Dual-Line Analog Input Process Meter - DL Series

Categories : Indicators and Sensors

Viatran's multi-purpose, easy-to-use DL Series analog input process meters are ideal for level, flow rate, temperature, or pressure transmitter applications. They accept current and voltage signals (e.g. 4-20 mA, 0-10 V). Three of the front panel buttons can be custom-programmed for a specific operation. The analog input can be scaled to display the process in two different scales; for example, the main display could indicate level in feet and the second display could indicate the volume in gallons.

VALVE GATE-AVMT

Categories : Hot Runner Systems

Suitable for large-scale parts or complex shape parts. There is a pin in the nozzle and drive by pneumatic or hydraulic to open or close the nozzle gate. When the valve pin open / close can control the melt filling. Especially for the big gate design, the valve pin will seal the gate after packing process to prevent the stringing and get the unapparent gate mark. For the multi-gate mold design, using the sequence control can eliminate the weld line problem.

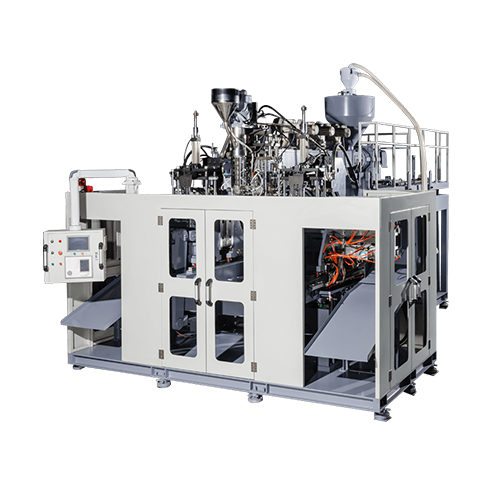

Medium Blow Molding Machine - Double Station

Categories : Electric Blow Molding Machines

Medium-Continuous Type Blow Molding Machine An all-rounder that is ideal for a variety of applications. Medium blow molding machines are used to produce medium-sized products but can also be adapted for small or large-scale productions. Products that are commonly manufactured by medium continuous blow molding machines include: 20/25L jerry cans 10/20L inner thread jerry cans Diamond-shaped jerry cans Round jerry cans Water tanks With applications for edible oil, lubrication oil, electronic, agriculture, and chemical liquids, this jerry can making machine is also available as a single or double station machine, for multi-layers, multi-cavities, or even multi-color productions.

Auto Batch Mixing Machine

Categories : Vacuum Forming Machines

Suitable for small to medium scaled foam factory. Block foaming machine consists of mixing system with moving forward and backward device. Metering system with re-circulation flow to control chemicals which are dosed from the chemical storage tanks through pipe work and pneumatic injection valve systems into the mixing barrel. As soon as the mixing time elapses, the hatch of mixing barrel will automatically open to load the mixture smoothly into the mold and close the hatch then can draw it backward to its original position automatically. No need to clean the mixing barrel between each shot.

Thermoforming molds for BM-C 4200

Categories : Vacuum Forming Machines

Thermoforming Molds for the BM-C 4200 thermoforming machine. Designed for large-scale operations, these molds enable precise and efficient forming of thermoformed products.

MICRO MOLDING

Categories : Injection Molds

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks. THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING : Micro means the size of the part. It is the most common definition when dealing with micro molding. Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features. Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding. SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS : Dimension Aspect ratios around 6:1 (material dependent) Wall thickness : 0.3 mm ( 0.012”) min. for plastic Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min. Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).

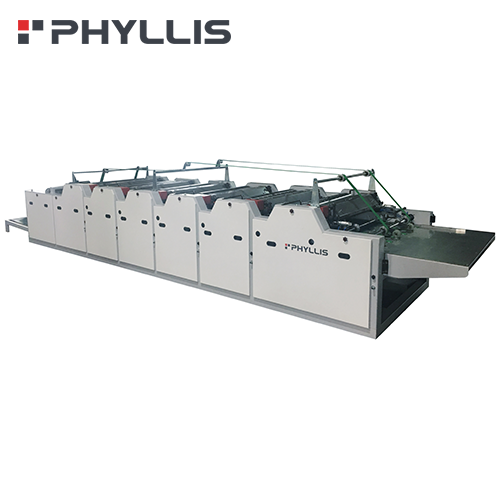

Flexographic Printing Machine (Manual feeding type)

Categories : Flexographic Printing Machines

Combination of simplicity and user-friendly design, the manual feeding type flexographic printing machine provides excellent price/performance ratio for small and medium scale purpose.

Water Conditioner / scale prevent and eliminate

Water Conditioners magnetically alter the natural characteristics of hard waterminerals, making it difficult for them to bond together and form a hard brittle scale. Instead,they remain in a suspended state and will either flow on through, or can be easily purged from, water-using equipment and plumbing systems. Superior technology also has zero environmental impact because it requires no energy or chemicals to operate.

DESIGN AND DEVELOPMENT PARTNER

Categories : Injection Molds

JDM / ODM SERVICES When bringing a new product to market or re-launching an existing product with new features, key success metrics are quality and timing t o market. Either or both may be negatively impacted if the design proves difficult to manufacture especially if there is a rapid demand for increased volume. A design partner who is well integrated with a full service manufacturing system knows how to minimize risk. Our design teams have executed numerous design-build projects for customers across a variety of industries on a global scale. We incorporate manufacturability, assembly and test principles into the EDI-early design stages involved of a product to assure seamless production. JDM/ODM services include : To use the PLM system to monitor the product life cycle management. Concept Development Mechanical Drawing Layout Documentation Verification Material Management & Sourcing Rapid Prototyping & Soft Tooling Initial Pilot Builds & DFM αTest /βTest/ Burn-in Tooling & molding in house Final Assembly Following the design phase of your product, we build prototypes to test the DFM manufacturablity and any industry compliances. Prototyping may occur multiple times at various points in the design and planning stages for a project. Once all the design and manufacturing issues are worked out, we can rapidly transition into full-scale production. Please visit our Contract Assembly page to learn more about our assembly facilities. OEM Our Original Equipment Manufacturer (OEM) service is responsible for designing and building a product according to a customer’s own specifications. Our service also includes & DFM,EDI,3D printer rapid prototype global distribution and returned product factory repair, which can greatly reduce customer’s overall production costs.

YC Vertical Clamping Horizontal Injection Tie-barless Series

Categories : Vertical Injection Molding Machines

Vertical clamping, without machine column design, the mechanical constitutive property is strong, Injection powerfully, suit large-scale embedment to take shape the processing.

Detergent for descale and oil

Detergent for limescale and industrial oil : DD-Descaler for prevnet scale build up, GC-S for industrial oil cleaning.