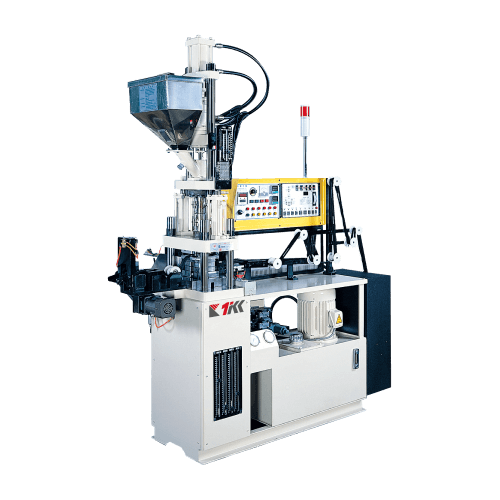

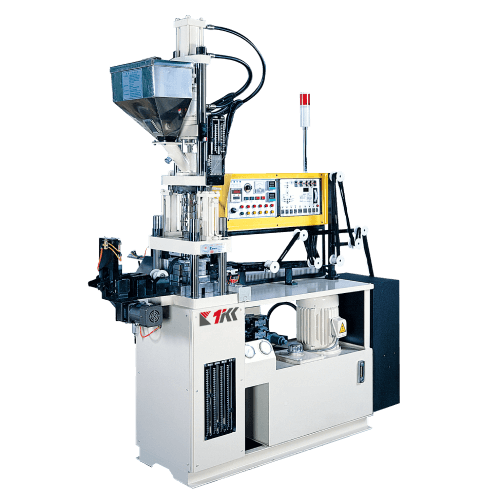

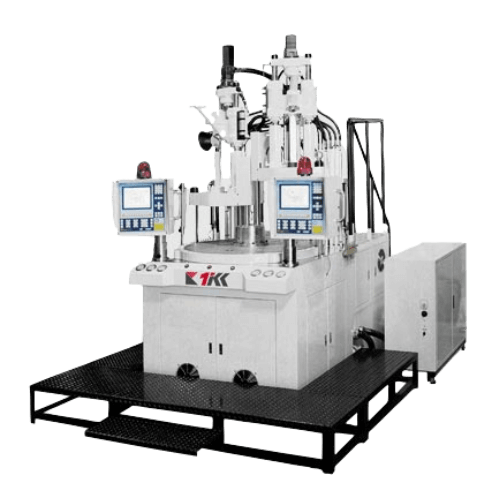

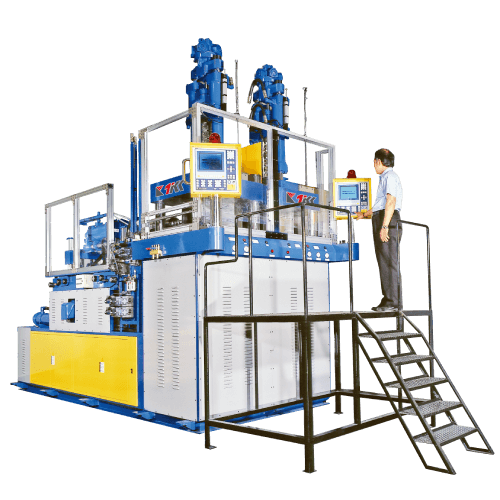

Classification : Vertical Clamping Horizontal Injection

Country: Taiwan

Phone: 886-2-26946450

Fax: 886-2-26946454

Contact Person: Nina Tsai

• Vertical clamping, without machine column design, the mechanical constitutive property is strong, Injection powerfully,

suit large-scale embedment to take shape the processing.

• Three-sides open space, easier operation for embedded parts and finished products, and able to combine automation

connecting planning.

• The height of operating surface is ergonomic, and the height of the machine is low. The operating environment can have

more additional space to use.

• Variety of logic design complies with the customer’s requirement.

| INJETCION UNIT | |||||||||

| V | 2S | R | |||||||

| Screw Diameter | mm |

|

|||||||

| Injection Pressure | kgf/cm2 |

|

|||||||

| Injection Capacity | cm3 |

|

|||||||

| Max. Injection Weight(P.S) | gr |

|

|||||||

| oz |

|

||||||||

| Injection Rate | cm3/sec |

|

|||||||

| Screw Rotation Speed | r.p.m | 0~170 | |||||||

| CLAMPING UNIT | |||||||||

| Clamping Force | tf | 40 | |||||||

| Clamping Stroke | mm | 215 | |||||||

| Max. Open Distance | mm | 395 | |||||||

| Min. Mould Height | mm | 180 | |||||||

| Mold Space | mm | 420x240 | |||||||

| Hydraulic Ejectior Force | tf | 1.7 | |||||||

| Ejector Stroke | mm | 40 | |||||||

| Height of Nozzle Center | mm |

140 ± 25 |

|||||||

| Distance From Mold Center to Nozzle | mm | min75 | |||||||

| SLIPFORM UNIT | |||||||||

| Slidable Journey | mm | 450 | |||||||

| Overall Size Slipform | mm | 870 x 240 | |||||||

| TABLE UNIT | |||||||||

| Table Diameter | mm | Φ750 | |||||||

| OTHER | |||||||||

| Drive Motor | kw (hp) | 5.5(7.5) | 5.5+2.2(7.5+3) | ||||||

| Heater | kw | 4.5 | |||||||

| Oil Tank Capacity | L | 200 | |||||||

|

Dimension of Machine (L x W x H) |

L(m) | 2.5 | 2.6 | 3.0 | |||||

| W(m) | 1.3 | 1.4 | 1.4 | ||||||

| H(m) | 2.5 | 2.6 | 2.7 | ||||||

| Weight of Machine | T | 3.5 | 4.0 | 4.8 | |||||

Hardware & Household Item

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Auto & Glass

Consumer Electronics

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

High-Speed Injection

.jpg)

Bakelite & LCP

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Medical

.jpg)

.jpg)

Other

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

IMD&IML

.jpg)

Hardware & Household Item

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

||||

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

||||

.jpg)

|

.jpg)

|

Auto & Glass

|

|

Consumer Electronics

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

||||

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

||||

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

High-Speed Injection

.jpg)

|

||||||||

Bakelite & LCP

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

||||

.jpg)

|

||||||||

Medical

.jpg)

|

.jpg)

|

|||||||

Other

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

.jpg)

|

||||

|

|

|

|

.jpg)

|

||||

IMD&IML

.jpg)

|

|

|

|

|||||