4 Shuttles Leno Loom

Categories : Industrial Knitting Machines

The HY7-m4SCLL four shuttles leno loom is designed for tubular net weaving with PP and HDPE yarns, this is the most new & unique weaving technology in the world, which featrues high production and energy-saving ...

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Side feeding barrel is better for storage and steady material input at same time. Main Extruder can extrude the material whose moisture below 7%. Sub extruder conducts second time filtering and ventilating for dirtier materials. Die face cutting frame made in SUS304 to prevent the rust and corrosion. Knives adjustments automaticlly patent design.The knife and die plate always set at 90 degree. No need to adjust frequently. High speed dryer is soundproof with double layer sealing design. The underneath water tank can gather the waste water and filter the impurity. Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryer. The triple layers vibrating screener is easy to clean, disassemble and assemble. Can customize the diameter of the hole. Blower with noiseless design. Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

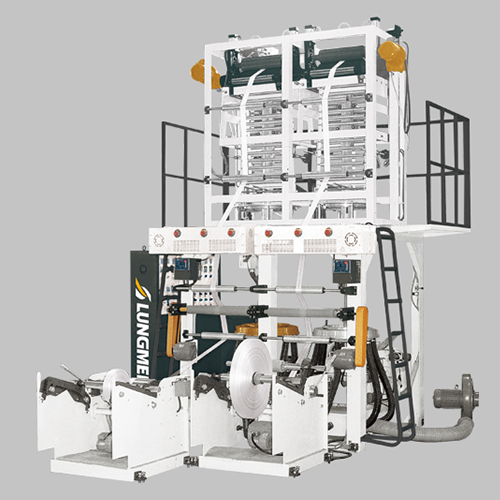

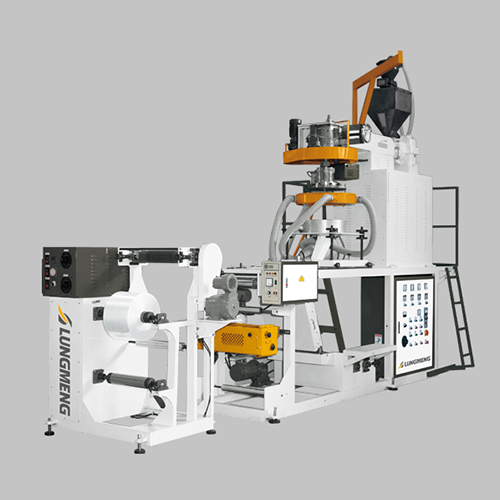

High Speed Twin Die Blown Film Machine

Categories : Blown Film Extruders

Extruder Mono-Layer HDPE/LDPE/mLDPE/PP High Speed Twin Die Blown Film Machine High performance main AC motor with inverter designed for saving energy and minimum maintenance Nip inverter designed for accuracy and reliability High torque gear box with enforced lubrication system to minimize machine down time High quality mixing in screw and barrel delivers excellent homogeneity and high output Designed for producing narrow and thin film

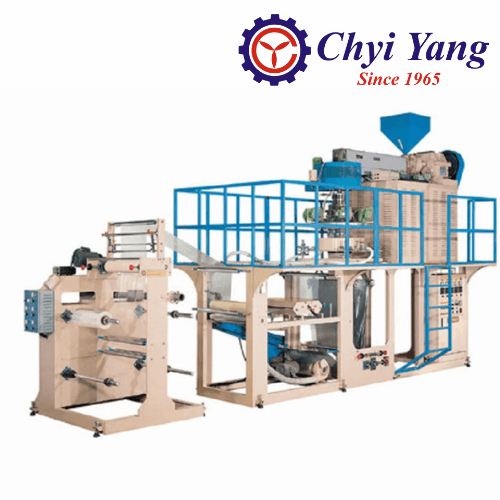

LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Double lip air ring & better cooling system to support the high speed capacity Can produce LDPE, LLDPE and shrinkable film Slitting device and double winder (up-and-down & back-to-back type) is offered to produce single layer film rolls. Optional Rotating die device is making uniform thickness film for printing & laminating purpose Optional Co-speed controller matches same speed for take-up unit and winder to avoid film to be stretched Purchasing HDPE die can produce HDPE film Fully automatic winder makes machine automatically & save time of operators We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

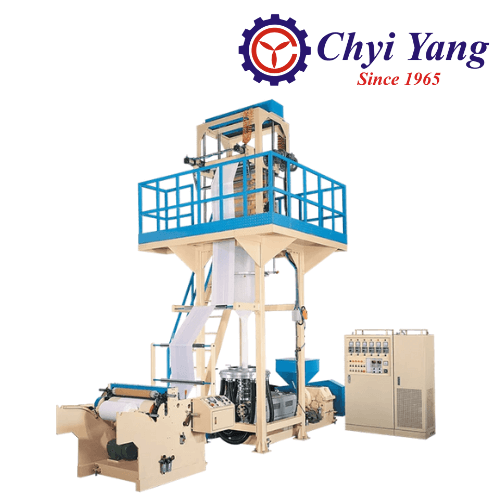

PP Blown Film Machine

Categories : Blown Film Extruders

Water cooling system makes glossier and more transparent PP film for food or garment packing. Unique screw provides high production for a long period life and holds film uniformly steady. Dry chamber provides a fast water removal, for food package purpose. Optional tension control for winder provides good tension film in rolls, used in food packaging & printing. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Super High Speed HDPE/LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Easy installation & operation Adjusting thickness easily by screws of die, high capacity & less plastic waste Automatic flying cutter & manual change reels winder, flying cutter to match the machine speed, won’t be re-winded on the nip roller Main Motor is driven by inverter for better performance & less electricity Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

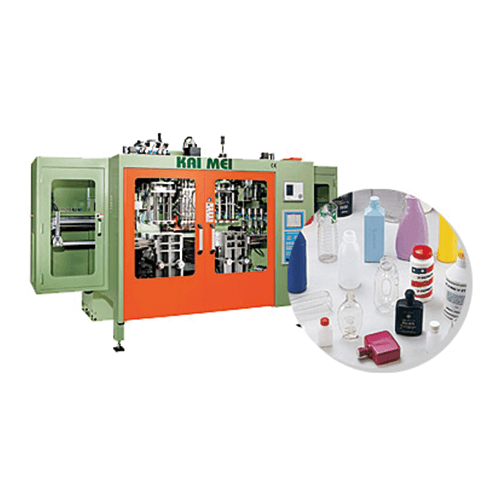

Blow Molding Machine PBSS SERIES 605 / 705 (S / D / T / Q)

Categories : Injection Blow Molding Machines

Double Stations Series Double station machine, full automatically, suitable for producing high-production runs of medium size bottles, ex. Cosmetic bottles detergents, etc. Mold-platen moves properly with high stability and high efficiency Three tie-bar horizontal traveling mold carriage combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production and small size container requirements. Available to equip with auto de-flashing device and take out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, convenient and user-friendly operation.

Fully Electric Co-Extrusion Blow Molding Machine (Dual Diehead & Double Station / Visi Strip)

Categories : Automatic Blow Molding Machines

Chia Ming has developed Fully Electric Blow Molding Machine for the packaging industry producing pharmaceutical, cosmetic and beverage bottles in clean-room. Fully Electric Blow Molding Machine is a total new innovative design with servo motors controls which significantly reduce energy consumption, give higher production rate, noise level much reduced, in long term total production cost being dramatically reduced.

High Speed PP Blown Film Machine

Categories : Blown Film Extruders

MONO-LAYER-HDPE-LDPE-MLDPE-PP HIGH SPEED PP BLOWN FILM MACHINE Special Screw Mixing design results ing good homogeneity and high output Greatly improved die& air ring, providing film uniformity smoothness, tension strength and stability. Gear box uses high torque and enforced lubrication system to minimize machine down time

Blow Molding Machine PBSS SERIES - 905 / 1005 (S / D / T / Q)

Categories : Horizontal Blow Molding Machines

Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production requirements. Available to equip with auto deflashing device and take-out robot to achieve fully automatic, highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

Blow Molding Machine PBSS - 905 O/1005 O

Categories : Electric Blow Molding Machines

It is designed for small containers Mouth-to-Mouth design. Mouth-to-Mouth design can improve two-time production for double-station machines. It creates a unique and new mold design and auto cutting device. It can increase machine stability and decrease defective rates. This is the latest high-producion machine technology.

HF-FTO 3 In 1 Series:3 in 1 Pelletizing Extrusion / Extruder Pelletizer

Categories : Plastic Pelletizer Machines

Produced by experienced plastic recycling extruder machine manufacturer. Suitable for handling differences of materials. Suitable for processing most of the thermoplastic materials. Applicable materials Film or Flakes : PE、LDPE、LLDPE、HDPE、PP、PET、PS、PA、BOPP、ABS